ACO BASED METHOD COMPARATION APPLIED TO FLEET

MANAGEMENT PROBLEM

M. Antón-Rodríguez

1

, D. Boto-Giralda

2

, F. J. Díaz Pernas

3

, J. F. Díez Higuera

4

Signal Theory, Communications and Telematic Engineering Department, ETSIT,

University of Valladolid, Campus Miguel Delibes, 47011 Valladolid, Spain

Keywords: Route calculation, resource allocation, ACO meta-heuristic, optimization.

Abstract: Road Transport enterprises do have the need of fleet management applications in order to upgrade their

efficiency; the fulfilment of that need takes us in the search of optimization algorithms whose performance

better suits not only the optimal route search problem, but the resource allocation too. ACO (Ant Colony

Optimization) meta-heuristic has proven to be very useful when solving similar problems, but as ACO

comes in several different flavours, to make the right algorithm choice is the first step in the search for a

solution. This document presents a performance study made upon several ACO algorithms over the fleet

management problem, with the objective of determining which one is the best finding the optimal solution

in a reasonable amount of time.

1 INTRODUCTION

The heavy overburden suffered by the road networks

of almost all first world countries makes daily

mobility to be strongly restricted. Those restrictions

are quite stressed when other adverse conditions

concur. Conditions like bad weather, accidents or

road works add higher levels of inconvenience.

Those facts affect transport enterprises deeply,

downgrading their quality of service and increasing

costs. This is a reason why road transport fleet

management applications, capable of finding the

best possible route and assigning each freight to the

right vehicle of the fleet can be a key resource for

this kind of companies, helping them to minimize

costs and to upgrade the safety of their employees

and the quality of the services offered to their

clients.

Both the route calculation and the resource

assignment are very good NP-hard problem samples;

as such, the number of possible solutions grows

exponentially with the problem's dimensions. These

increasingly high numbers of solutions demand great

calculation resources. This is why the use of those

methods that give an exact solution to the problem is

not recommended. Instead heuristic and

metaheuristic methods are favoured, methods

capable of solving the problem in an almost exact

way in a reasonable amount of time.

ACO (Ant Colony Optimization) metaheuristic

(Asmar et al, 2005) has proven to be especially

useful when solving problems like TSP, QAP, SP…

ACO is directly inspired in the behaviour shown by

ant colonies when they are foraging (Corne et al,

1999). So we can accurately suppose that ACO is

also effective when applied to the complete road

transport fleet management problem. There are

several different ACO algorithms that can be used

when solving this problem, so our first objective will

be to find the one that better suits each one of the

two parts into which we have divided the fleet

management problem (route calculation and

resource assignment).

The study we performed and now feature in this

document is focused in the comparative analysis of

each one of the ACO algorithms and in their

practical implementation in order to solve the above

mentioned problems. Once they have been analysed

we will be able to pick the most efficient algorithm

for the given task, ready to face the challenge. In

those first steps of the investigation we will restrict

to the use of static parameters, in order to later

535

Antón-Rodríguez M., Boto-Giralda D., J. Díaz Pernas F. and F. Díez Higuera J. (2006).

ACO BASED METHOD COMPARATION APPLIED TO FLEET MANAGEMENT PROBLEM.

In Proceedings of the Third International Conference on Informatics in Control, Automation and Robotics, pages 535-539

DOI: 10.5220/0001216105350539

Copyright

c

SciTePress

introduce the dynamic features that better show the

always changing conditions of the road ways.

After briefly introducing this document’s

framework, some of the main characteristics of the

problem will be described (below in §2). Later, in

§3, we will see the efficiency trials taken, their

results and, finally, the conclusions derived from

them (in §4).

2 PROBLEM’S DESCRIPTION

The problem to solve can be described as the need

of, given a number of freights that have to be carried

from some places to others (e.g. from a warehouse to

clients, from one client to another, etc) and a fleet of

transport vehicles, perform the given task with the

minimal possible cost. In other words, it is intended

to find the best possible routes (in this first phase,

just distance will be used to consider), and then

assigning them in an efficient way to the transport

freighters (Perozo, 2002).

The route calculation problem, going over a non-

oriented weighted graph used to represent the

Spanish roadways (with 1.26 arcs per node and a

mean distance of 12 km per arc) consists of

searching the minimum cost routes from their

posting places to the final delivery points, from the

vehicles’ starting point to the freights posting places,

and from the delivery points of each freight to the

pick up places. This makes necessary the solving of

many problems. In particular, given n loads and m

transports, it is required the solving of n · (n + m)

different sub-problems, so finding an exact solution

would be a time and resources consuming task.

Once all possible routes are known, it will be

necessary to select the best combination of them, so

it would allow the optimal delivery of the freights

(minimum cost). This part can also be portrayed

using a graph, where the minimal distances are the

arcs’ weights and the nodes are either loads or

trucks. The described graph will have some nodes

representing trucks (one-way only and not reachable

from other nodes) that can get to any load, and from

those loads they can access to any other. It must be

taken into account that distances (costs) are

asymmetrical. For easing the problem, each truck

will only have capacity for a load at a time, so it will

have to complete a delivery in order to pick up the

next one.

The final solution to the problem must include the

resource allocation data (which freight and in which

order are they picked up by the transport), the

sequence of roadway points travelled, the distance

traversed by each truck and by the fleet as a whole

(being this last one the parameter to optimize).

The problem’s solution will be sought using a newly

developed meta-heuristic known as Ant Colony

Optimization (ACO). This is based on the imitation

of social insect’s behavioural patterns or Swarm

Intelligence (Bonabeau et al, 1999). Ant System (AS)

is an ACO algorithm proposed by Marco Dorigo

(Dorigo et al, 2004) as a useful way of finding a

heuristic solution to combinational problems. AS

can be adapted and optimized to face many

combinational problems, creating new versions of

the algorithm in the process: Elitist Ant System

(EAS) (Dorigo et al, 2004), Rank-Based Ant System

(AS

rank

) (Bullnheimer et al, 1997), MAX-MIN Ant

System (MMAS) (Stützle et al, 1999), Best-Worst

Ant System (BWAS) (Cordón et al, 2000), Ant

Colony System (ACS) (Dorigo et al, 1997). All those

algorithms share the inspirited use they make of the

stigmergy, which is the way ants communicate to

one another.

3 PERFORMANCE TESTS

The developed application is a software program

written in C language and is destined to implement

some ACO algorithms over a basic road network

(not considering, by now, dynamic conditions and

supposing some reasonable restrictions for the sake

of simplicity), with the objective in mind of

obtaining a systematic performance measure system

in the resolution of the cost-optimal route calculation

and resource allocation.

All testing has been conducted using a 1.5GHz

Pentium Mobile equipped computer, with 512Mb

DDR and running on MS Windows XP.

As the given objective was the performance measure

of the different ACO algorithms, some relatively

reduced size graphs have been used (smaller sections

of the general graph which depicts the Spanish road

network). Those graphs come in growing sizes, they

comprise from a small piece of a province up to a

size lager than several regions.

ICINCO 2006 - ROBOTICS AND AUTOMATION

536

The output data will provide the routes (a sequence

of nodes) found for each one of the sub-problems,

alongside the distance calculated for this route.

Because it is statistically interesting, some info

about the algorithm used is also given, execution

time, colony’s size, and values of some relevant

parameters, the total distance (sum of all routes) and

the total number of ants needed to give the proposed

solutions.

3.1 Route Calculation Module

The first step must be to find out the quality of the

found solution. This is the main determining

parameter, as our final objective is to minimize the

cost associated to that solution. By taking into

account the sum of distances of all best solutions

found at each sub-problem, we come by the graphic

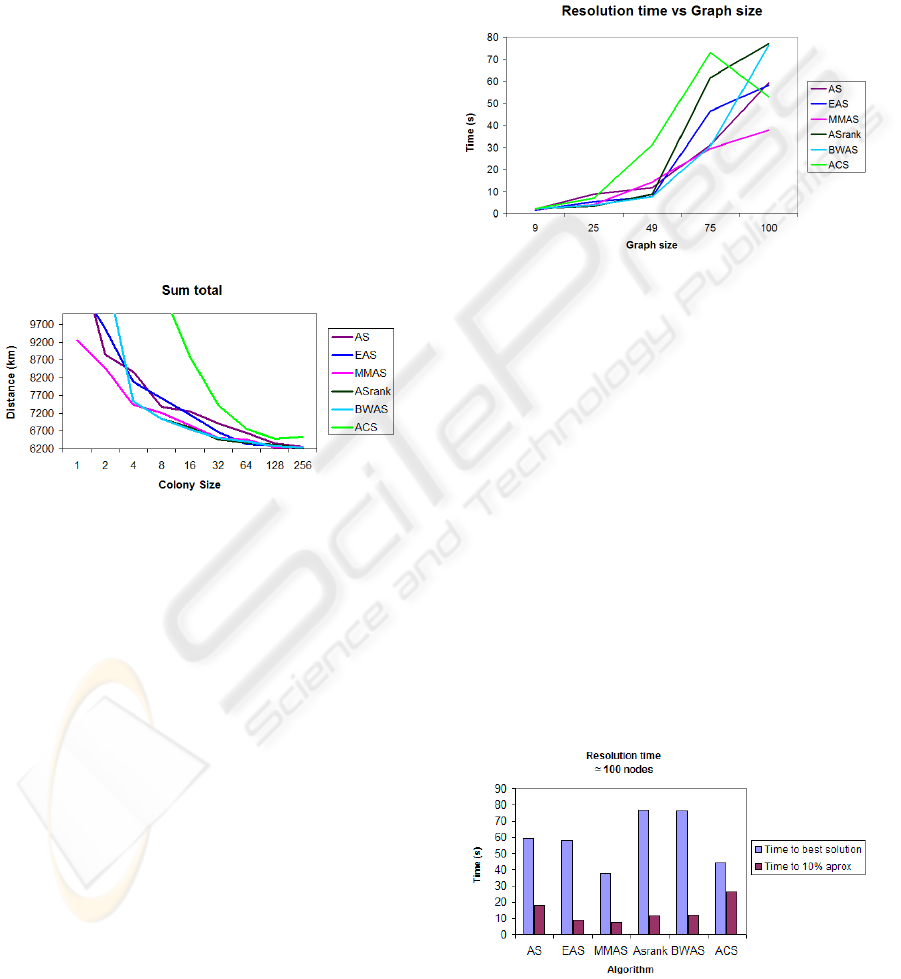

shown below:

Figure 1: Sum of all problems’ solutions.

As it can be seen in Figure 1, with a sufficiently high

number of ants per iteration the differences between

algorithms are scarce, but we see that AS

rank

and

EAS are the most effective because of the quality of

their solutions. On the other hand ACS seems to

have a worse global behaviour (the worst solution).

Moreover, there is also some irregular conduct

depending on the colony’s size: almost all the

algorithms (in the global) trace asymptotic curves

towards what is considered to be the ideal solution,

but there are some variations to that trend. This is

the case of ACS, finding a worse solution with 256

agents than the one found with just 128.

In both cases, ACS offers the worst behaviour. This

is due to how the algorithm works, diminishing the

pheromone quantity in an arc previously used by any

agent, choosing, generally, the one which provides

the most info. This is good if there are many

possible arcs, as the sooner some pheromone is

withdrawn from any of them, the quicker some of

the remaining others would become the one with a

maximum value of combined information. However,

in our problems, the number of neighbours is scarce;

so it would take many agents in order to have a

significant reduction in the trail. If this process is

repeated in many nodes, this algorithm can get to be

quite inefficient as it can be seen in our results.

Figure 2: Time taken to find the best solution.

Checking the time taken in each one of the graphs in

order to reach the best solution (Figure 2), it can be

seen that MMAS is the fastest in the last two graphs.

However, AS

rank

, is the algorithm obtaining the

highest quality solutions but takes too much time to

reach a solution due to the need of classifying the

colony’s ants depending on the quality of their

proposed solution; this has a great computational

cost if the colony is composed of many agents.

BWAS also suffers from the same problem.

As the graph which provides us with the most

information is the larger one, two graphics are

shown below with the results. The first one depicts

the resolution times over this graph (the time it takes

the algorithm to find the best solution it is capable

of, and then a solution which differs only in a 10%

from the original one) and in the second, some data

about time and the quality of the solution are shown.

Figure 3: Times for the 100 nodes problem.

ACO BASED METHOD COMPARATION APPLIED TO FLEET MANAGEMENT PROBLEM

537

Figure 4: Time-solution for the 100 nodes problem.

Watching both graphics (Figure 3 and Figure 4)

corroborates the already reached conclusions:

• The algorithm with the best performance

(quality of the solutions found) is AS

rank

even if

the resources and time expense are higher than

in the rest of the algorithms.

• ACS presents a far from ideal behaviour due to

the own nature of the problem: this algorithm

tends to show better performances in problems

with a higher number of arcs per node.

• EAS and MMAS perform well as they have the

shortest execution times, but their solutions, not

being too bad, are not the best found.

3.2 Resource Allocation Module

All data used in this module’s performance study

have been obtained from the 100 nodes graph (4

trucks and 10 loads), as it is the one which provides

us with the most information. The solutions

corresponding to the shortest distance route have

been obtained with AS

rank

(8 ants, rank 6, α=1, β=2,

ρ=0.1) and this very same solution space will be

used as the allocation module entry block.

Figure 5: Distances run in allocations performed with

different colony’s sizes.

For those big enough colonies, all of the algorithms

present reasonably good solutions. However, as can

be seen in Figure 5, the quality of the solutions

frequently shifts with the number of ants used in

each iteration. In some cases the lack of stability is

showy, as is the case of MMAS, AS

rank

and BWAS

algorithms which offer a very changing behaviour.

ACS instead does not only manage to get the best

solution (using a reasonable number of agents), but

it also maintains its stability, this is to say: a bigger

colony means a better solution.

The explanation to this behaviour is the same given

when the algorithm offered the worst performance in

the optimal route calculation module: it is the

relation among the number of nodes and arcs. In the

case of this road network, there is a mean value of

1.26 arcs per node, offering the agents relatively few

options when advancing to the next node.

Nevertheless, in the case of the 100 node graph with

4 trucks and 10 loads there are 130 arcs for a total of

14 nodes. Therefore, the exploration capabilities of

the ACS are ideal for this kind of graph, emphasized

by the random nature of the trucks’ selection: as

some pheromone is withdrawn from each arc as

soon as it is travelled, the possibility of the next

agent searching a new destination is highly powered.

This way, the exploration of a high number of

possibly optimal combinations is quite extensive.

Figure 6: Distance sum of the found solutions.

This good behaviour’s stability can be seen in Figure

6 where the sum of all solutions obtained for all the

different colonies’ sizes, in this ACS offers the best

performance, while all the rest of them offer a

slightly worse behaviour (up to a 1.5% in the case of

BWAS).

Generally, those algorithms that comprehensively

exploit the best solution found do have a more

irregular behaviour than those with wider search

options. This is partly due to the resource (vehicles)

allocation system used. This way, if in the first

iterations some not very good solutions are found,

the trend will be to look for better ones around those,

ICINCO 2006 - ROBOTICS AND AUTOMATION

538

this is why other solutions will not be quite

traversed, creating lock situations around not so

optimal solutions.

Figure 7: Solving time sum for every algorithm.

In Figure 7 it can be seen as all the algorithms show

similar resolution times, with the exception of

AS

rank

, but this is quite logical due to the nature of

the algorithm, as it ranks groups of ants, which of

course takes some calculation power in the ordering

and selection of the agents depending on the quality

of the solution found.

4 CONCLUSIONS

The many daily problems that appear in road

transport show the great need of applications

destined to help in the management of road fleets;

applications capable of finding the best possible

routes, and assigning them efficiently to the different

vehicles that form up the fleet. This is why it is

important to make the right choice of the algorithm

better suited for the problem to solve.

ACO meta-heuristic has some very beneficial

features for the resolution of this kind of situations:

it is capable of finding and optimal or quasi-optimal

solution in a reasonable time, it can optimize

multiple criteria simultaneously and it can be

adapted to work in a dynamic environment. But

these optimization techniques present themselves

under several different algorithms; this is why we

will have to choose what algorithm use in order to

solve each part of the problem.

Once all performance testing and the studies of those

algorithms over the solution of the transport fleet

management problem (both the optimal route

calculation and the resource allocation) were over

we were able to see that there are two algorithms

whose solutions’ quality stood out from the rest:

• The AS

rank

algorithm finds the best solution to

the route calculation problem, but its time and

resources consumption is something higher than

the rest of the algorithms (it can get better using

other ordering faster method). However when it

gets to the resource allocation module, it shows

a more irregular behaviour, spends more time

than the rest and does not easily find the optimal

solution.

• ACS is far from ideal in the route calculation

module; it is however the best in the allocation

part: it finds the higher quality solutions; it is

quite stable and offers a reasonable execution

time.

After analyzing the conclusions shown in this

document, the next step will be the incorporation of

dynamic parameters to the system (road network

status, weather conditions, etc.) when determining

the optimal route.

REFERENCES

Asmar, D. C., Elshamli, A., Areibi, S. A Comparative

Assessment of ACO Algorithms Within a TSP

Environment. DCDIS 2005, Guelph, Ontario, Canada.

July 2005.

Bonabeau, E., Dorigo, M. and Theraulaz, G. Swarm

Intelligence: From Natural to Artificial Systems,

Oxford University Press, 1999.

Bullnheimer, B., Hartl, R. F., Strauβ, C. A new Rank-

Based Version of the Ant System – A Computational

Study. Technical Report, Institute of Management

Science, University of Vienna, 1997.

Cordón, O., Fernández, I., Herrera, F. and Moreno, L. A

New ACO Model Integrating Evolutionary

Computation Concepts: The Best-Worst Ant System.

From Ant Colonies to Artificial Ants: Second

International Workshop on Ant Algorithms

(ANTS'2000), pp. 22-29. Brussels (Belgium), 2000.

Corne, D., Dorigo, M. and Glover, F. New Ideas in

Optimization, McGraw-Hill. 1999.

Dorigo, M. and Di Caro, G. and Gambardella, L. M. Ant

Algorithms for Discrete Optimization. Artificial Life,

5(2), 137-172. 1999.

Dorigo, M. and Gambardella, L.M. Ant colony system: a

cooperative learning approach to the travelling

salesman problem. IEEE Transactions on Evolutionary

Computation,1(1):53-66. 1997.

Dorigo, M. and Stützle, T. Ant Colony Optimization.

Massachussets Institute of Technology. 2004.

Perozo Rondón, F. J. Sistema de gestión dinámica de

flotas usando localización GPS/GSM y programación

evolutiva para la optimización de recursos. Tesis

doctoral. University of Valladolid, 2002.

Stützle, T. and Hoss, H. MAX-MIN Ant System. Preprint

submitted to Elsevier Science, 5. November 1999.

ACO BASED METHOD COMPARATION APPLIED TO FLEET MANAGEMENT PROBLEM

539