INFLUENCE OF NBMAX AND TABU LIST IN THE SCHEDULING

PROBLEM

Antonio Gabriel Rodrigues

Universidade do Vale do Rio dos Sinos

Av. Unisinos 950, S

˜

ao Leopoldo, RS, Brazil

Arthur T

´

orgo G

´

omez

Universidade do Vale do Rio dos Sinos

Av. Unisinos 950, S

˜

ao Leopoldo, RS, Brazil

Keywords:

Scheduling Problem, Part Selection Problem, Part Family, Tabu Search, Flexible Manufacturing Systems,

Cluster Identification, Keep Tool Needed Soonest approach.

Abstract:

Considering a Job Shop Scheduling Problems with tooling and due date constraints, experiments were made

with a computational model based in Cluster Analysis and Tabu Search. Two minimization policies can be

done in this model: swtiching instants and tardiness time. Previous experiments identify the conflict between

these policies, as the positive influence of variation of TS parameters. This paper presents experiments consid-

ering the influence of the variation of TS paramenters nbmax (number of non-improving iterations performed

by TS) and tabu list size.

1 INTRODUCTION

The Job Shop Scheduling Problem with tooling con-

straints (JST) can be defined as follows: there is a set

of machines and a collection of parts to be processed

on these machines. With each part type is associated a

specific process plan, which consists in a sequence of

operations. Each operation is defined by a machine

type on which it must be processed, its processing

time and the tools which are needed. A machine can

process only one part at a time and they are contin-

uosly avaliable. Each machine has a tool magazine

with limited capacity. All parts to be processed are

avaliable at processing time zero and each part can be

processed by only one machine at a time. No indi-

vidual operation can be pre-empted. Each operation

needs a number of tools, which never exceeds the ca-

pacity of tool magazine. The classical objective is to

minimize the makespan, the maximum of the comple-

tion times of all operations. Since the tool magazine

have limited capacity, tool changes are needed. When

a tool change occurs on a machine, some tools are

replaced by others required for the next parts of the

sequence on this machine. This time spent exchange

tools is called switching instant(Hertz and Widmer,

1996).

In this paper we refer a Job Shop Scheduling Prob-

lem applied to a Flexible Manufacturing Cell (FMC),

considering due dates and tooling constraints (refered

here as JSTD). A FMC is composed by one workas-

tation (CNC/DNC machine whith possesses a device

for tool storage with restricted capacity), a mater-

ial handling system and a computer center (Groover,

2001). We define a objective function z which per-

mits the managing of the importance of due dates

and switching instants in the Scheduling. A com-

putational model based on simple Tabu Search and

Cluster Analysis is used to generate a scheduling

which minimizes z. Experiments performed with

this model in previous works (Rodrigues and G

´

omez,

2005) showed the conflict between due dates and

switching instants minimization. In the present pa-

per, another experiments are made, in which the vari-

ation of TS parameters nbmax and tabu list size are

analyzed.

2 COMPUTATIONAL MODEL

Are considered, additionally to the JSTD constraints

(described in the previous item), the two assumptions:

(i) once processed, any part can return to the system;

(ii) the production turn is considered, so any part can

be processed after the finish of the turn; A batch is

considered a set of parts which can be processed in

the workstation with the same set of tools. Between

the processing of two batches, a switching instant is

required. A switching instant lasts α + βr time units,

217

Gabriel Rodrigues A. and Tórgo Gómez A. (2006).

INFLUENCE OF NBMAX AND TABU LIST IN THE SCHEDULING PROBLEM.

In Proceedings of the Third International Conference on Informatics in Control, Automation and Robotics, pages 217-220

DOI: 10.5220/0001216702170220

Copyright

c

SciTePress

where α is a fixed time due to removal of the tool

magazine for the machine and clean the workspace

area, β is a fixed time for each tool replacement and

r is the total number of tools which must be replaced.

In the presented model, it was used an approach sug-

gested by G

´

omez (G

´

omez, 1996) where α and βr are

considered two different decision variables in the ob-

jective function.

2.1 Techniques

To group parts into batches, Part Selection Problem

(PSP) is studied. In this problem a set of parts must

be grouped into subsets,called Part Families (PFs), ac-

cording to some similarity. The PSP is represented us-

ing matrix formulation, a classical approach of Group

Technology (TG). To solve this problem is used the

Cluster Identification Algorithm (CIA) modified by

G

´

omez (G

´

omez, 1996). Originally developed by Ku-

siak and Chow (Kusiak and Chow, 1987), the modi-

fied CIA organizes the rows and columns of the ma-

trix A, generating a matrix B with part-tools clusters,

where each cluster is a FP.

To solve the Job Shop Scheduling Problem, a Tabu

Search (TS) approach was proposed (Glover and La-

guna, 1997). TS is a meta-heuristic composed by a lo-

cal search procedure associated with a memory struc-

ture which constraints the search to visit regions in the

solution space already visited. This memory structure

intents to make the search avoid the local optimals,

performing a better exploration of the space.

2.2 Architecture

The computational model uses TS e modified CIA to

find the schedule such the objective function z is min-

imized. The z function has the following decision

varaiables:

• tardiness time (At): diference between due date

and date of the completion of the part, expressed

in minutes.

• tool replacement time (St): representing the

βr time in the switching instants, expressed in

minutes.

• tool removal time (Sp): representing the α time in

the switching instant, expressed in minutes.

The importance of these decision variables in the fi-

nal schedule can be managed through the assignment

of weights to them. The objective function was devel-

oped considering two dimensions: physical dimen-

sion (Part Families) and time dimension (scheduling).

Considering: N the total amount of parts; L the num-

ber of setups in s; U the number of switching tools in

s; Dv

i

the due date of part i; Ds

i

the completion date

of part i; T r the time to removal the tools e prepare

the workstation for new parts, in minutes; T e the time

to replace one tool in minutes.

Minimize

z(p, f ) = P

1

· At(p, f) + P

2

· Sp(p, f)

+ P

3

· St(p, f)

(1)

Where

At(p, f ) =

N

X

i=1

(Dv

i

− Ds

i

)

such (Dv

i

− Ds

i

) ≥ 0,

i ∈ {1, . . . , N}

(2)

Sp(p, f) = T r ·

L

X

i=1

Sp

i

such Sp

i

≥ 0, T r ≥ 0,

i ∈ {1, . . . , L}

(3)

St(p, f) = T e ·

U

X

i=1

St

i

such St

i

≥ 0, T e ≥ 0,

i ∈ {1, . . . , U}

(4)

P

1

≥ 0, P

2

≥ 0, P

3

≥ 0 (5)

The computational model was developed in four

modules: (i)Part generator, (ii) PF generator, (iii)

Initial Solution generator and (iv) TS-based mod-

ule. More datails about the computational model can

be seen in previous works (Rodrigues and G

´

omez,

2005).

3 EXPERIMENTS

The variation of weights of the objective function was

analyzed in previous papers (Rodrigues and G

´

omez,

2005). A summary of the results are replicated here.

Based on these results, new experiments were made,

considering the influence of nbmax and tabu list size

in the objective function.

3.1 Summary of Previous

Experiments

The previously performed experiments were made

with objective of the managing of the three decision

variables of the z function, presented in the item 2.

The parameters of the experiments performed were:

ICINCO 2006 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

218

(i) a set of 10 parts and 9 tools; (ii) the magazine ca-

pacity is 4 tools; (iii) the time spend for each tool

replacement is 4 minutes; (iv) the time for tool re-

moval is 5 minutes; (v) the production period (turn)

is defined as 480 minutes; (vi) the tabu list initially

stores 10 forbidden moves; (vii) and nbmax number

is defined as 100 iterations. Initially was defined

a non-tendentious solution (NTS), in which all the

decision variables have the same contribution in z.

The values of the weights of decision variables are:

At = 17.27 · Sp and At = 9.89 · St.

Once defined the NTS solution, experiments with

variation of the weights of z were made. The

methodology used was: one of the three weights of

z were increased and the other two were made con-

stant with the values of the NTS solution. There

were made experiments which represents three dif-

ferent minimization policies (minimizing Sp, St and

At). The same behavior (reducing of St and increas-

ing of At) occurs when Sp is minimized. Using the

above TS parameters, the increasing of this weight did

not contribute to generating a schedule with less tar-

diness. Thus, other experiments were performed, in

which nbmax and tabu list size are varied. The results

of this lasts experiments are showed in table 1.

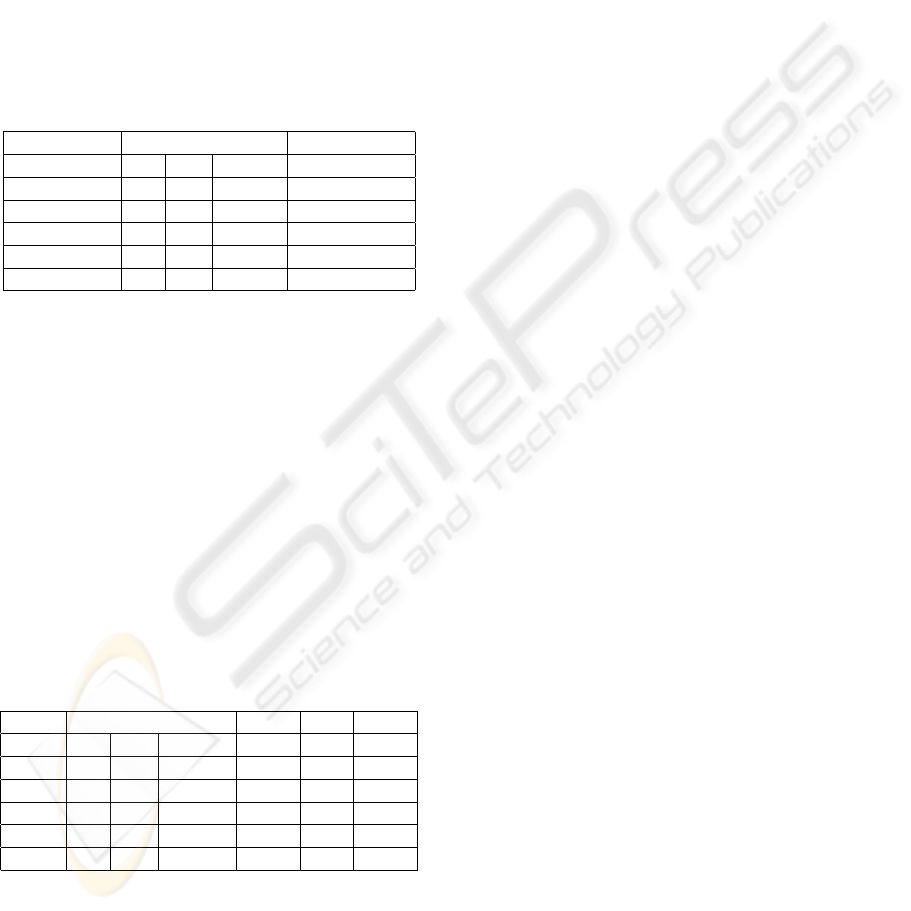

Table 1: Tabu list size and nbmax variation for solution that

At = 10.

nbmax tabu list At St Sp

200 100 355 30 56

300 150 397 25 44

400 200 355 30 56

500 250 397 25 44

600 300 355 30 56

700 350 344 30 56

800 400 361 30 56

900 450 397 25 44

1000 500 397 25 44

As the values of At become smaller with the in-

creasing of TS parameters, the values of St and Sp

became high, confirming the conflict between switch-

ing instants and tardiness. New experiments are made

in a manner to determine better the influence of the

variation of these parameters in At minimization.

3.2 Experiments with Nbmax and

Tabu List Size

In the new experiments, the tabu list size and nbmax

size are varied one at each time. The initial solu-

tion was generated using Part Family rule (FAM) dis-

pacthing rule. The initial sequence of parts for these

experiments is {3, 4, 5, 1, 7, 9, 2, 6, 8, 10}. Other pa-

rameters are the same of the previous experiments.

The value (in minutes) of each decision variable using

the FAM rule is: St = 40, Sp = 20 and At = 1026.

The values of the weights used in the new exper-

iments are: At · 100, St · 10, Sp · 18. In the first

type of experiments, tabu list size was varied, while

nbmax = 1000. The best result was found at TS in-

teraction 1712, with At = 311, St = 56, Sp = 30

and tabu list with size = 500. In the figure 1 shows

the behavior of At in the experiment and the iteration

where it was found the better result.

Figure 1: Values of At considering variation of tabu list size

and iteration when it was found the best result.

A second type of experiment was performed, Using

the best value of tabu list size in the experiment pre-

sented above. In this experiment NBMAx was varied

and the same better solution was found in the TS iter-

ation 1712, with nbmax ≥ 900. Figure 2 shows At

and the best iteration behavior.

Figure 2: Values of At considering variation of nbmax and

iteration when it was found the best result.

Comparing the variation of two graphs, it can be

noticed that tabu list size determines the search reach

to the better results for At, considering a high nbmax

number. The increasing of these parameters reduces

de At value significantly, but increases the amount of

memory used by the model and the running time. In

INFLUENCE OF NBMAX AND TABU LIST IN THE SCHEDULING PROBLEM

219

the next item, comparsion is made between TS pa-

rameters of previous works and new TS parameters

used in the presented experiments.

3.3 Comparing Results

Table 2 shows a comparsion among initial FAM solu-

tion, NTS solution (At · 1, St · 10 and Sp · 18) and

the solutions obtained with 3 minimization policies

weights in previous works (Rodrigues and G

´

omez,

2005).

Table 2: Comparsion among initial solution and policies of

minimization considering nbmax = 100 and tabu list size

= 10.

Minimizing decision variables best iteration

St Sp At

St 28 20 891 7

Sp 32 20 709 7

At 56 30 451 16

NTS 32 20 709 7

FAM 40 20 1026 -

The initial solution (FAM) groups parts with same

PF, forming a sequence with minimum switching in-

stants time (20 minutes). The increasing of Sp can-

not improve z and the tool replacement time remains

the same. The St minimization results in less tool re-

placement time and a higher tardiness value, accord-

ing to the previous experiments. The At minimization

reduces 575 minutes the tardiness time (

∼

=

56%), in-

creasing the tool removal and tool replacement time.

Table 3 shows the impact of the variation of TS pa-

rameters in the decision variables of z, considering

the initial, solution, NTS solution and minimization

policies.

Table 3: Comparsion among initial solution and policies of

minimization. BI = best iteration; TL = tabu list size; NB =

nbmax.

Min Desision variables BI TL NB

St Sp At

St 28 20 891 7 50 500

Sp 32 20 624 70 50 100

At 56 30 311 1712 500 1000

NTS 32 20 397 43 50 100

FAM 40 20 1026 - - -

The increasing of tabu list size doesn’t contribute

for improvement of any decision variable in St min-

imization. Its influence is low in Sp minimization,

reducing the tardiness time in 85 minutes. With the

NTS solution, the variation results in a better At time,

while St and Sp remain the same value. It was needed

a higher variation of TS parameters to find a better re-

sult of At, when its minimization is considered.

4 CONCLUSIONS

The experiments presented in this paper has the ob-

jective of investigate the influence of TS paramenters

in a computational model developed to deal with Job

Shop Scheduling Problem with tooling and due date

constraints. This model allows to manage three deci-

sion variables of an objective function: tardiness, tool

replacement and tool removal. Previous experiments

shows a conflict between minimizing tool replace-

ment and tool removal versus tardiness. Those expri-

ments shows the positive influence of the increasing

of the tabu list size and nbmax number in minimiza-

tion of tardiness.

Experiments were made, where these TS parame-

ters were variated. In the initial experiments, tabu

list size was variated, and the increasing of this pa-

rameter results in better At time. It noticed that some

values assigned to tabu list size minimizes At more

than other values. In the second type of experiments,

nbmax was increased, considering the best value of

tabu list size. The reduction of At value obtained was

the same of the initial experiments. The tabu list size

parameter is the main factor in the diversification of

the search, determining the variation of At compo-

nent.

REFERENCES

Glover, F. and Laguna, M. (1997). Tabu Search. Kluwer

Academic Publishers.

G

´

omez, A. T. (1996). Modelo para o seq

¨

uenciamento de

partes e ferramentas em um sistema de manufatura

flex

´

ıvel com restric¸

˜

oes

`

as datas de vencimento e

`

a ca-

pacidade do magazine. PhD thesis, Instituto Nacional

de Pesquisas Espaciais, S

˜

ao Jos

´

e dos Campos, S

˜

ao

Paulo, Brasil.

Groover, M. P. (2001). Automation, production systems and

computer-integrated manufacturing. Prentice-Hall,

second edition.

Hertz, A. and Widmer, M. (1996). An improved tabu search

approach for solving the job shop scheduling problem

with tooling constraints. Discrete Applied Mathemat-

ics, 65:319–345.

Kusiak, A. and Chow, W. S. (1987). Efficient Solving of the

Group Techonology Problem.

Rodrigues, A. G. and G

´

omez, A. T. (2005). Production time

minimization strategies: a Tabu Search approach. In

Annals of the 2nd ICINCO - International Conference

on Informatics in Control, Automation and Robotics.

ICINCO 2006 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

220