MULTIPROCESSOR ROBOT CONTROLLER

An Experimental Robot Controller for Force-Torque Control Tasks

István Oláh, Gábor Tevesz

Department of Automation and Applied Informatics, Budapest University of Technology and Economics,

Goldmannn György tér 3. 4.em., Budapest, Hungary

Keywords: Robot controller, multiprocessor systems, PUMA 560, QNX, digital signal processor, hybrid position and

force control.

Abstract: There is ongoing research and development in the field of hybrid position and force control of the assembly

robots at the Department of Automation and Applied Informatics and the Department of Control

Engineering and Information Technology, Budapest University of Technology and Economics. As result, an

Experimental Robot Controller was built for the special needs of the project. Both the hardware and the

software system of the controller are under continuous development. The most recent achievement is, a built

in six-component force-torque sensor. The development of the software system is currently dealing with the

extension of the programming environment with force-torque control possibilities. There are numerous

industrial applications for force and torque control (i.e. screw driver, welder), but a flexible equipment can

provide much more than just the possibility of solving a single task. This paper presents an overview of the

robot controller hardware, separately detailing the force-torque sensor interface. The second part of this

paper overviews the software system of the controller and the possibilities of its extensions for force control

tasks.

1 INTRODUCTION

A few years ago an extended research and

development project started in the field of robot

control. In the project the Department of Automation

and Applied Informatics and the Department of

Control Engineering and Information Technologies

are taking part at the Budapest University and

Economics. The hardware development is

continuously focusing on the Experimental Robot

Controller. This is a multiprocessor control system

for a NOKIA PUMA 560 manipulator. The

connected power electronics and some extension

cards to the central PC-based control computer were

developed, supporting the research of the modern

robot control algorithms. The paper first introduces

the hardware architecture of the control computer In

the later part the software system of the

Experimental Robot Controller is shown. The

distributed software system and the possibilities of

the communication are introduced in the complex

robot controller plant. Finally the directions of

further research and development are overviewed.

2 THE EXPERIMENTAL ROBOT

CONTROLLER PLANT

The research and development project was started

from a quite old robot system. The manipulator was

the PUMA 560 type, made by the former Nokia

Robotics, the controller was made in Russia, called

SZFERA-36. Its manipulator was kept, an

approximately 30 year old system, and all other parts

were changed. The aim was to build a low-cost

control system that must agree with the following

requirements: modular architecture, extensibility,

easy system development possibilities, and

interfacing capabilities with different sensor

subsystems. The software side of the development

required much of the same: open system

architecture, the usability of standard development

tools and techniques, and the possibility of building

a configurable, modular system.

The PUMA 560 manipulator is a six-joint human

arm like device. This robot arm has a widely spread,

general configuration, additionally it is a very well

constructed manipulator and, since the project does

540

Oláh I. and Tevesz G. (2006).

MULTIPROCESSOR ROBOT CONTROLLER - An Experimental Robot Controller for Force-Torque Control Tasks.

In Proceedings of the Third International Conference on Informatics in Control, Automation and Robotics, pages 540-543

DOI: 10.5220/0001217405400543

Copyright

c

SciTePress

not deal with the mechanical aspects of the robot

manipulators, this device was chosen.

The first task was to develop the power

electronics that can connect the manipulator and the

controller system. A six channel servo amplifier was

build, especially optimized for precise DC drives.

This part receives the ±5V reference signals from

the central controller and provides the ±30V control

signals for every joint. These hardware controllers

are very fast, no time gap between the signals from

the central controller and to the drives of the

manipulator is assumed.

2.1 The Advanced Robot Controller

Cards

In parallel with the power electronics, another

hardware development has started. The architecture

of the IBM PC was chosen for the central control

computer and Gabor Tevesz has started to build a

general purpose robot (DC servo) controller card.

This PC extension card is called Advanced Robot

Controller card. The block scheme of this card is

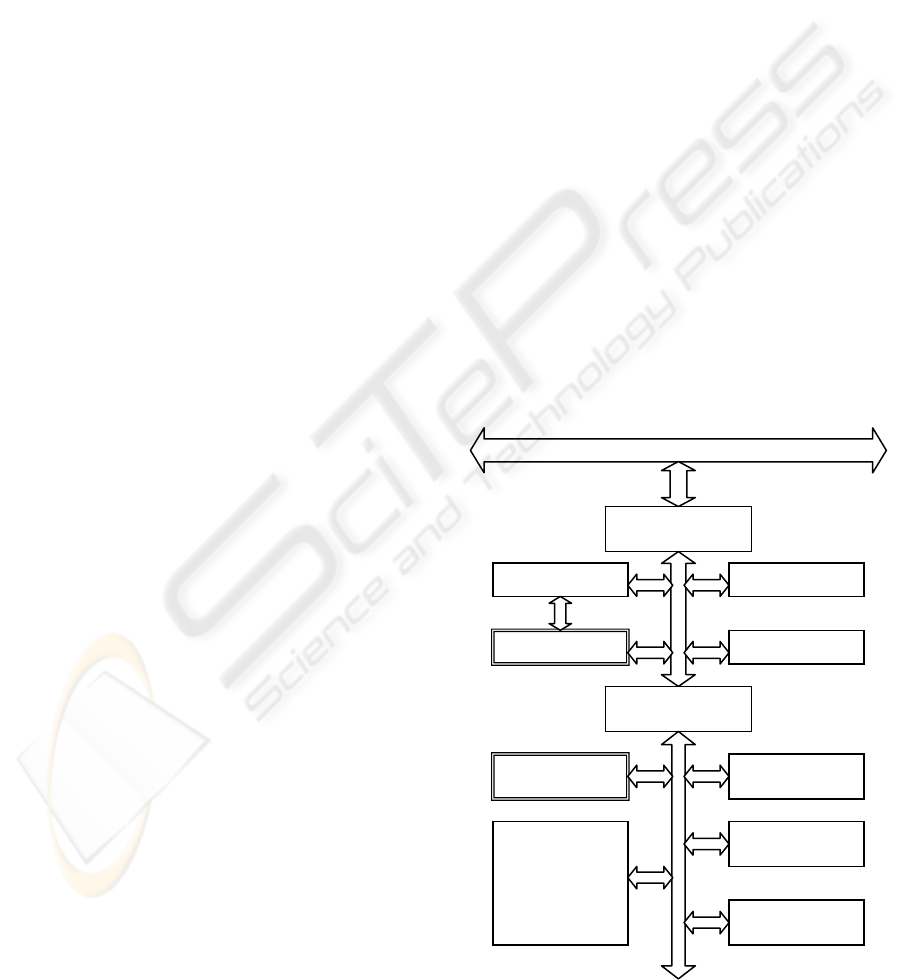

shown in Figure 1.

One ARC card is capable of controlling four

joints. In the Experimental Robot Controller there

are two ARCs, each responsible only for three joints.

Since the hardware build up of the manipulator

provides an Euler configuration wrist, the

partitioning of the first and second three joint

provides further possibility of creating a simpler

control software system.

Starting from the power electronics side, every

ARC cards contains a Texas Instruments

TMS320C31 digital signal processor with four

whole featured interfaces controlling electronic

drives. Together with its interfaces, the high speed

CMOS 32-bit floating point processor has the

following capabilities: taking the position signals

and calculating the speed and acceleration of the

corresponding joints; performing calibration and

credibility checks using null impulses; supervising

the position, speed and acceleration limits;

producing the set point values for the servo

amplifiers; providing synchronous movement

between the joints controlled by a stand alone or by

more ARC cards. The 16 MIPS and 32 MFLOPS

processor has high speed static RAM for the best

possible performance. This processor, using the pre-

programmed boot loader, can boot from the FLASH

memory or from the dual port RAM. The second

method can be well used for development and test.

Additionally to the drive interfaces, there is a three-

wire synchronization channel built in. With the help

of this feature more ARC cards are capable of acting

together and coordinating multi drive systems.

The next part of the ARC card is the so called

pre-processing unit. It is based on an Intel 80386EX

microprocessor. This embedded processor is fully

compatible with the PC environment and has a lot of

integrated peripherals supporting the rich

functionality. This unit can boot from the attached

FLASH memory and connected to the signal

processor via dual port RAM. On the other side, the

communication between the host computer and the

pre-processing unit goes through the ISA bus and

the dual port RAM. In both directions the handling

of the RAM is fully interrupt driven, in order to

reach the highest possible performance. The

interface could be converted into PCI for even

higher speed, but it would require the complete

redesign of this extension card. However, the ISA

bus interface is the slowest connection in the chain,

it provides enough communication bandwidth for

very complex control tasks.

The central part of the robot controller is the full

featured personal computer. Since the ISA bus

interface is required by the ARC cards, the host CPU

is an Intel Celeron 633MHz processor.

ISA

b

us

Dual Port RAM

4kword

DRAM memory

i80386EX

Flash memory

CAN interface

Dual Port RAM

4kword

SRAM memory

TMS320C31

Incremental

encoders

interface unit

Analog outputs

Digital IOs

Figure 1: The block scheme of the ARC cards.

MULTIPROCESSOR ROBOT CONTROLLER - An Experimental Robot Controller for Force-Torque Control Tasks

541

2.2 The Force Torque Sensor

Interface Card

The most recent hardware addition to the

Experimental Robot Controller is the six-component

force torque sensor. The sensor head is built between

the last joint of the robot and the end effecter. The

sensor is directly connected to its electronics, the so

called MiniForce unit. The tasks of this unit are to

receive the signals from the strain gages, perform

decomposition and produce the results of the

measurement. There is a metal cage in the sensor

head and the voltage of multiple gages is measured

in order to provide the three components force and

torque. The MiniForce unit is attached to the base of

the manipulator. It contains the controlling

electronics of the sensor head and it performs the

analogue-digital conversion, digital signal filtering

and matrix compensation, eliminating the crosstalk

effects. In this configuration the effects of the

electrical noises are the minimal, in the

measurement system as well.

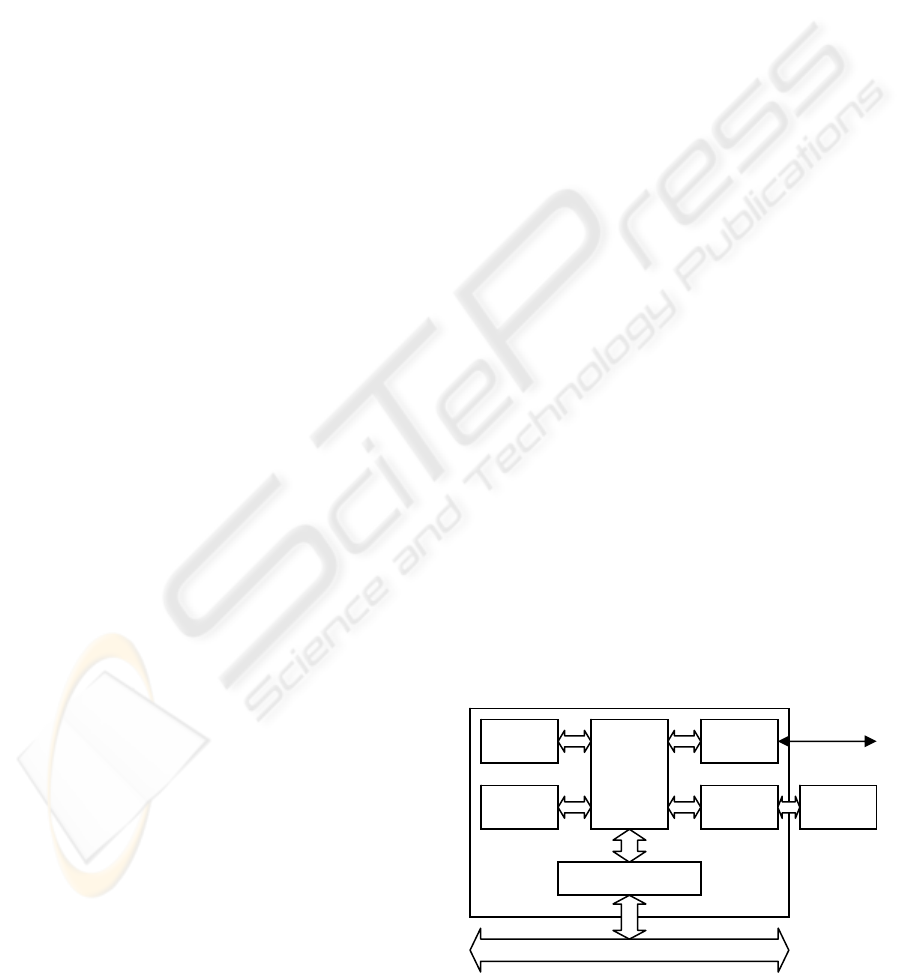

The MiniForce unit is connected through an

RS422 differential line to the force torque sensor

interface card. This is a PCI bus extension card

directly built in the central control computer (Hankó,

2004). This unit contains one additional (to the ARC

cards) Texas Instruments TMS320C32 digital signal

processor. The block scheme of this extension card

is shown in Figure 2. An additional CAN interface is

implemented on the sensor interface card in order to

provide fast and direct communication with the ARC

cards. This channel provides fast and direct

connection, avoiding the additional load on the host

processor (the Intel Celeron processor working on

the motherboard). This communication has limited

bandwidth, but it is enough for exchanging the most

important data.

3 THE SOFTWARE SYSTEM

In this section the whole software system of this

multiprocessor control system is presented. Starting

from the manipulator side, in the first line there are

the digital signal processors (DSPs).

3.1 The Software of the Extension

Cards

The manufacturer of this processor provides

assembler, optimizing ANSI C compiler and linker

for these devices. Every DSP environment is capable

to start automatically from the provided FLASH

memory. During the software development and test

phase the DSPs can be started from the connected

dual port RAMs by the host processor in the case of

the sensor interface card or by the communication

processor in the case of the ARC cards. This dual

boot functionality is supported by the boot loader

integrated in the processor and can be configured by

jumpers on the corresponding extension card.

The next operational unit is the communication

processor with its environment on the ARC cards. In

the current version the i80386EX processors

perform only data relay between the host processor

and the joint processors (the DSPs on the ARC

cards). The necessary computational power is

provided by the other parts of the system. As

mentioned above, the host system runs QNX

operating system and there is ongoing development

for embedding the QNX into the communication

processors. In order to embed the QNX operating

system, some additional BIOS functionality must be

implemented. These are required for initializing the

environment and starting the Initial Program Loader

(IPL). The duty of IPL is to load the compressed

operating system image, decompressing it in the

memory, switching into protected mode and starting

the QNX. With the help of this environment there

will be hopefully more resources available, while the

efficiency of the communication can be maintained.

3.2 The Software of the Central

Control Computer

The host computer is a full featured workstation.

Since the early times of this research and

development project the QNX operating system is

used on the central computer. This operating system

is a real-time Unix-like one, developed especially

PCI

b

us

SRAM

Flash

DSP

CAN

interface

RS422

interface

Dual Port RAM

Miniforce

Sensor

interface

card

Figure 2: The force-torque sensor interface card.

ICINCO 2006 - ROBOTICS AND AUTOMATION

542

for time critical process control task. The previous

version (QNX v4) contained a lot of special features

focusing on the primary aim, the very good real-time

performance. In those times the robot control

software system was very complex, containing more

than ten separate, but heavily communicating

processes.

Recently the whole software system was ported

under the new version of the operating system, the

so called QNX Neutrino. This is the 6

th

version (the

5

th

was omitted by the developer) and the whole

software suite is called QNX Momentics. It contains

not only the core operating system and numerous

supporting utilities, but a graphical user interface

(GUI) called Photon and a full featured development

environment as well.

Both versions of the operating system have

microkernel based architecture. The small central

kernel provides only the most important services

such as pre-emptive scheduling, status handling and

the basic communication services. A whole desktop

environment is slower in a microkernel architecture

system, but the system builders and software

developers have the ability to build a reduced,

efficient, very fast environment. This aim is

supported by the modularity and the fine tuneable

scheduling mechanism. The most important change

between the mentioned versions is that the process

based scheduling changed to a thread based one.

Another significant change is made in the

philosophy, and instead of using vendor specific

methods, the solutions according to the POSIX

standard are implemented.

Following the evolution, the whole robot control

software was rewritten last year according to the

new operating system version. The process structure

of the new robot control software is shown in Figure

3. The original robot plant used the Advanced Robot

Programming System (ARPS) as the robot

programming language. This environment was

implemented using the own developed robot

controller as well. Since the scheduling is now based

on the threads instead of processes, the structure is

quite simple. The last process, the one responsible

for MiniForce communication, is the most recent

software development. It was written and fitted in a

few months later than the software relocation took

place.

The participants of this research and

development project at the Department of

Automation and Applied Informatics have important

achievements. The most important outcome is the

integration of the sensor system and the start of the

software implementation of various methods based

on the capabilities of the hardware. However, there

is a lot of work to be done in the field of modern

robot control systems.

ACKNOWLEDGEMENTS

The project of studying modern robot control

algorithms and their realization in a real

environment is supported by Hungarian Research

Found (OTKA, grant No. T029072, grant No.

T042634).

REFERENCES

Tevesz, G., Bézi, I. And Oláh, I., 1997. A Low-cost Robot

Controller and its Software Problems. In Periodica

Polytechnica Ser. El. Eng. Vol. 41, No. 3., pp. 239-

249

Hankó, T., 2004. Hatkomponensű erő-nyomatékérzékelő

illesztése PCI buszra. (A PCI bus interface for six

component force torque sensor.) Diploma work, in

Hungarian, Department of Automation and Applied

Informatics, Budapest University of Technology and

Economics

Oláh, I., Tevesz, G., 2002. Software Problems of an

Experimental Robot Controller Based on QNX Real-

Time Operating System. In Periodica Polytechnica

Ser. El. Eng. Vol. 46, No. 3-4., pp. 151-161

Oláh, I., Tevesz, G., 2005. An Experimental Robot

Controller for Force-Torque Control Tasks. The

International Journal of INGENIUM 2005 (4) –

Engineering Achievements Across the Global Village,

edited by Janusz SZPYTKO, Cracow-Glasgow-

Radom, pp. 477-484

Figure 3: The process structure.

Kernel Init

Pendant

Interprete

r

Pathgen

Control

MFCom

m

MULTIPROCESSOR ROBOT CONTROLLER - An Experimental Robot Controller for Force-Torque Control Tasks

543