FAULT DETECTION OF THE ACTUATOR BLOCKING

Experimental Results in Robot Control Structures

Matei Vinatoru, Eugen Iancu

Faculty of Automation, Computers and Electronics, University of Craiova,

RO - 200396, Craiova, str. A. I. Cuza, nr.13, Romania

Keywords: Control system, robotic arm, fault detection and isolation.

Abstract: In this paper is presented an algorithm, which allows for a certain robotic structure, under the terms of an

actuator blocking occurrence during the operation, either a correct positioning (if it is possible) or a

positioning in an acceptable proximity of the desired coordinates by minimising an optimal criteria

(through the adequate commands to the functional elements). The paper is proposing the synthesis of the

commands for a poly-articulated robotic arm (3 segments). First, a workspace analysis is made, then is

presented the algorithm for the actuators, first in the terms of a normal operation (finding the optimal

motions) and second in the terms of the blocking of some robotic segments.

1 INTRODUCTION

The correct positioning of the robot control arm is

critical to the efficient operation in the applications

of poly-articulated robot arms. One of most impor-

tant problem in robot control is the detection and

isolation of faults occurring in the actuators. In this

case it is necessary to develop a control algorithm for

certain robotic structure, under the terms of actuator

blocking occurring during the operation. This

algorithm must provide a correct positioning of the

gripper or a positioning in an acceptable proximity of

the desired coordinates using an optimal criterion.

The fault detection and isolation (FDI) problem is an

inherently complex one. Good diagnostic performan-

ces without installing supplementary equipment,

force the diagnostic tools developers to use

techniques available to process all information that is

"hidden" in the technological process. Numerous

approaches have been developed to address the

problem of FDI in dynamically systems, including

the fault trees and parity space techniques

(Viswanadham, 1987, 1988), Kalman filters (Meril,

1984), and detection filters (Iserman, 1997), etc.

This paper describes the application of a fault de-

tection and isolation method based on linear or non-

linear parameter model of the robot arm. A new

closed loop control method achieves the actuator's

fault isolation and control in fault conditions.

2 FAULT DIAGNOSIS

A fault causes degradation in system behaviour but

does not necessarily cause complete failure of plant

operation. The system may continue functioning to a

lesser degree, though failure may occur if a fault is

not detected in time. The tasks of a fault detection

system are (Vinatoru, 1997), (Ivanescu , 2000):

- Fault detection - a binary indication if the fault is

present or the system is fault-free.

- Fault isolation - that means the knowledge of

which sensor or actuators have failed.

- Synthesis of commands in fault conditions which

must assure the viability of the system (possibly in a

slightly degraded manner).

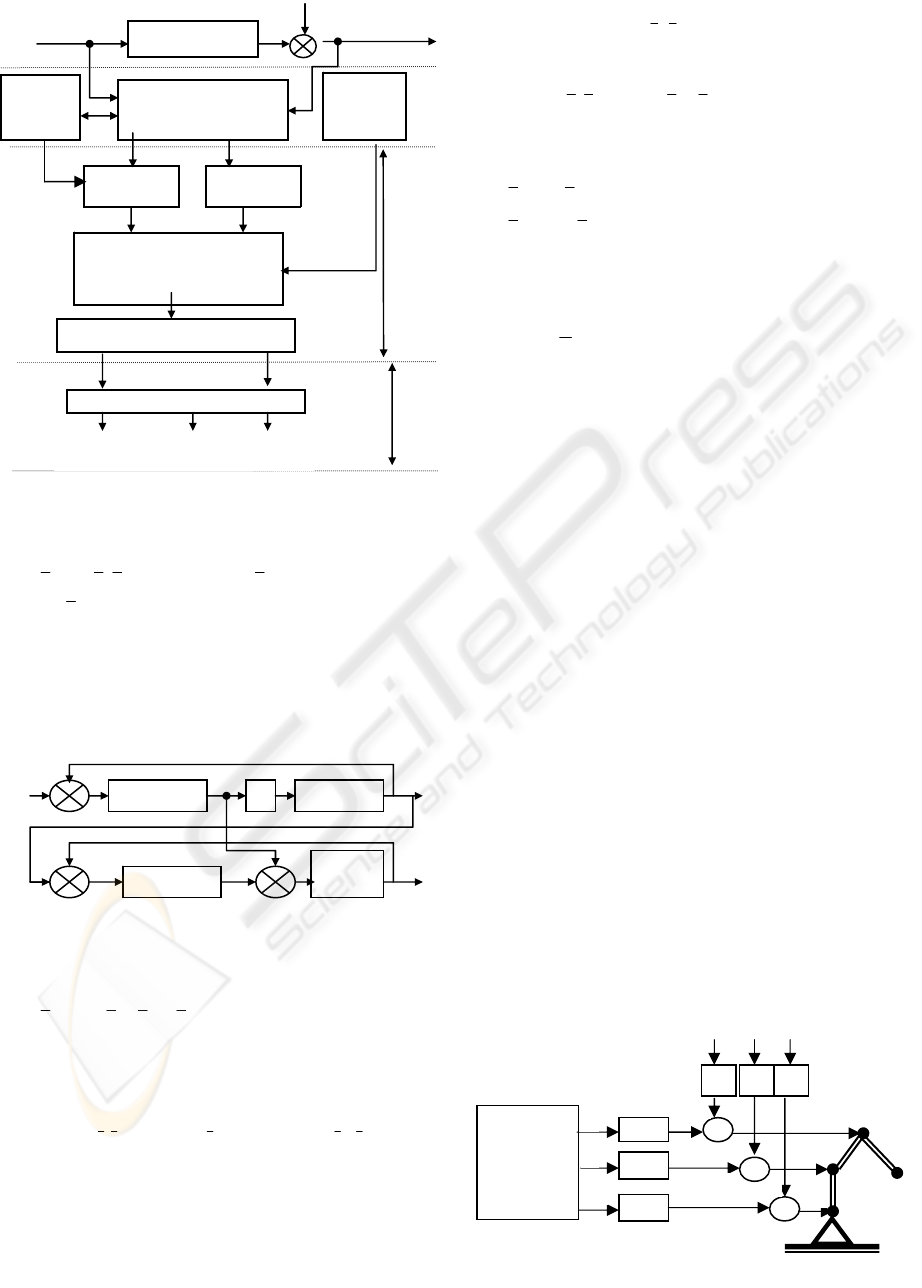

In figure 1 is presented a generalised structure of

the model based on fault detection and isolation.

In the design of automatic control systems, a

great emphasis is put on the structures capable to

detect and isolate fault conditions. The new solutions

can be classified in two different categories:

a) Fault detection and identification using dedicated

observers, detection and identification algorithms;

b) Fault management using FDIM architecture and

simulation results.

For the later category, in figure 2 we present a

structure for fault detection and isolation that assures

fast detection of a fault described thru a parameter in

the mathematical model.

548

Vinatoru M. and Iancu E. (2006).

FAULT DETECTION OF THE ACTUATOR BLOCKING - Experimental Results in Robot Control Structures.

In Proceedings of the Third International Conference on Informatics in Control, Automation and Robotics, pages 548-551

DOI: 10.5220/0001217505480551

Copyright

c

SciTePress

Let consider the plant described by the system:

),,(

α

c

xxfx = ; xCy

T

.= (1)

where

x is the state vector, y the measurable output,

α is a fault parameter and

c

x is the control command.

The real controller (PI type to ensure the steady state

errors equal with zero), is described by:

)()( yvKyvKx

IRc

−

+−=

(2)

where v is the set point of the control system.

The control structure for fault detection (fig. 2)

includes a plant model described by:

),,(

1 mccmm

xxxfx

α

+=

;

m

T

m

xCY ⋅= (3)

and the control signal:

)()(

1 mImRc

yyKyyKx −+−=

(4)

Replacing variables

m

yandy

in (6) we get:

)(),

1

,(),,(

1 m

xx

mc

x

m

xf

c

xxf

c

x

T

C

I

K

T

C

R

K

T

C

R

K −+−=

αα

(5)

The FDI control structure, if designed properly,

will modify the control signal x

c1

to obtain

0)(lim ==

∞→

tee

t

mms

. Therefore,

Y

s

=Y

m

s

0)( →−=−⇒

m

xx

T

C

m

YY

(6)

In this case, considering the steady state regime we

get:

[

]

0),,(),,(

1

0

=−

→

mcmc

t

xxfxxf

αα

lim

(7)

Using the linear model system (8) of the

equations (1) and (3):

mcicmm

c

dxbxbxAx

dxbxAx

α

α

⋅+⋅+⋅+⋅=

⋅+⋅+⋅=

(8)

after a few simple transformation in equations (7)

and (8) we get the diference between faulty

components real

α and modelled α

m

:

cs

x

d

b

m

⋅=−

αα

(9)

From the precedent analysis it results:

- the plant model shall reproduce the real plant ;

- the FDI control structure shall be asymptotically

stable, using the plant model controller;

- the response time of the FDI structure shall be

smaller than the response time of the real plant;

- the perturbations that appear in the real process

shall be included, as much as possible, in the model

structure.

3 SYSTEM ANALYSIS WITH

FAULT ACTUATORS

For analysis of the behaviour of the robot arm, when

one or many joints are blocked, we consider the

configuration presented in fig. 3. From this figure,

for the command

θ

ir

we can write the relations (10):

1,2,3i ,k)k1(

0iiiiir

=

θ

+

θ

−

=

θ

(10)

in which: k

i

= 0, for fault free actuator; k

i

= 1, in fault

conditions and the actuator blocked in θ

i0

position.

In figure 3,

θ

ir

has the significance of the real

command for the joint i. For the case when k

i

= 1, we

can simulate one actuator that don't work and remain

in blocked position

θ

i0

. In conclusion, the occurance

of one fault is equivalent with a jump modification

of the state equation structure for the actuators.

-

-

e

Controller 1 PLANT

EE

v

x

c

y

x

c1

e

m

Controller 1m

Plant

Model

y

y

m

Figure 2: FDI Structure.

+

Robot

arm

Figure 3: Synthesis of failed actuators.

Algorithm

for

commands

synthesis

1-

k

1

1-

k

2

1-

k

3

θ

1

θ

2

θ

3

θ

10

θ

20

θ

30

k

1

θ

1r

θ

2r

θ

3r

+

k

2

k

3

+

Modelling

Figure 1: Generalised structure of model based faul

t

detection and isolation methods.

State

estimation

Parameter

estimation

GENERATION OF:

Errors signals

Residuals

FAULT DECISION

FAULT DIAGNOSIS

PROCESS

MODEL OF

OBSERVED

PROCESS

Model

of normal

process

Model

of faulty

process

Fault detection

Fault diagnosis

Fault

diagnosis

Fault

diagnosis

Fault

diagnosis

Fault timeFault type

Fault

signature

U

N

Y

FAULT DETECTION OF THE ACTUATOR BLOCKING - Experimental Results in Robot Control Structures

549

The vector of commands has the expression:

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

+−==

30

20

10

3

2

1

)(

3

2

1

θ

θ

θ

θ

θ

θ

θ

θ

θ

D

K

D

KI

r

r

r

r

Θ

(11)

in which: K

D

=diag [k

1

k

2

k

3

] is called the fault

matrix. If

0K

D

≡ the system has no fault.

The vector:

[][ ]

3020100

θθθ

=Θ

T

(12)

represent the blocking position of the actuators.

Therefore, we can study the behaviour in fault

conditions, using a fixed fault matrix.

4 STRATEGY OF CONTROL IN

FAULT CONDITIONS

Using the equations of robotic arm joints and the arm

tip (Ivanescu 2000), we define the following fault

situations and the domains of the fault free joints.

Zone I – first joint blocked (J

1

):

)

π

,(θ)

π

,(θblockedθ

2

0

3

,

2

0

2

,

1

∈∈− (13)

Zone II – second joint blocked (J

2

):

)

π

,(θblockedθ)

π

,(θ

2

0

3

,

2

,

2

0

1

∈−∈ (14)

Zone III – third joint blocked (T):

blockedθ)

π

,(θ)

π

,(θ −∈∈

3

,

2

0

2

,

2

0

1

(15)

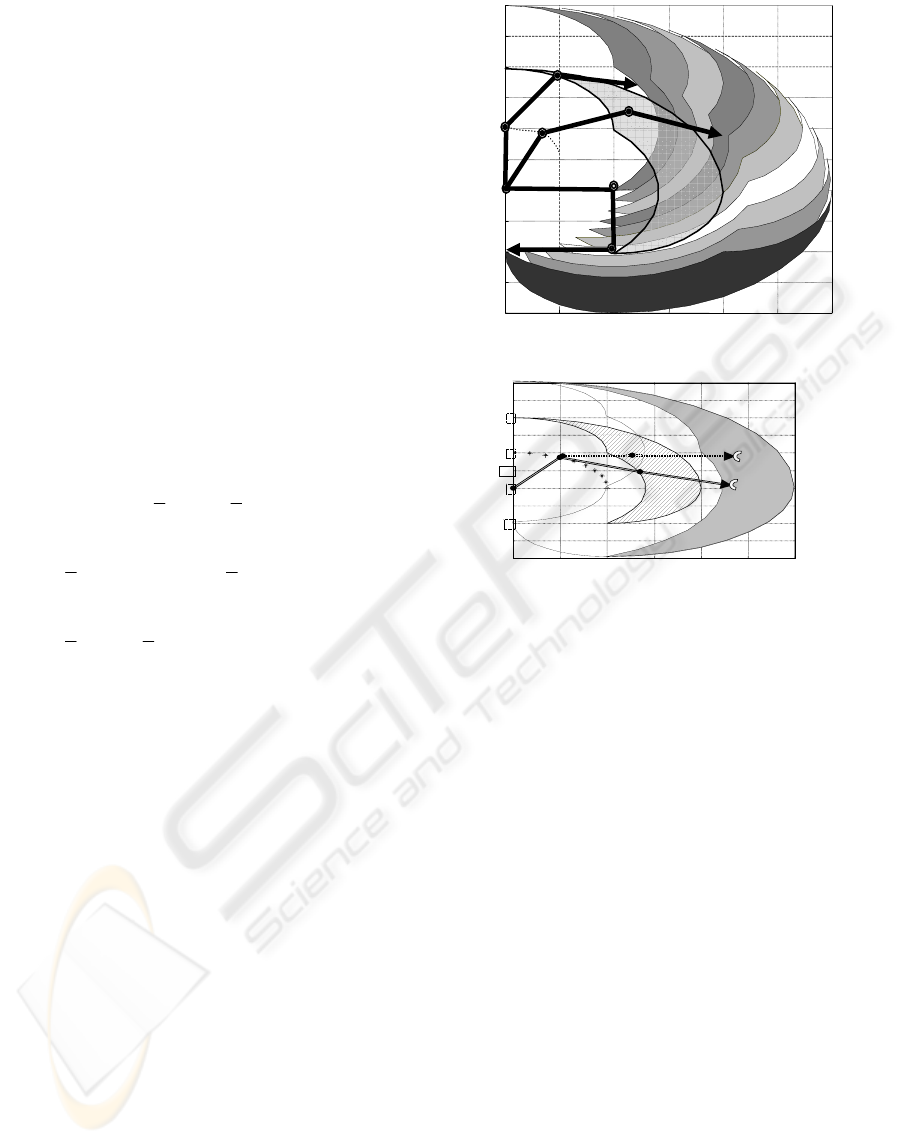

The equation of arm tip (T) defines the limits of

the work areas of the arm tip. For the case when

θ

i

=0

0

(suppose that i joints are blocked in this

positions, i=1, 2, 3), these areas are presented in

figure 4. There is a part of the fault free space of arm

tip (zone 0) that cannot be covered. In figure 4 it is

presented the movement of the zone I as function of

the

θ

1

parameter modifications. In the figure 5 it is

presented the work area for the joint 3 (J

3

) and the

arm tip (T) for the situation when

θ

3

is blocked at

90

0

. The border of each zone is a reunion of quarter

circle arcs with well known centre and radius. In this

case the strategy of control presented by the same

authors in (Ivanescu 2000) can be simplified. The

proposed algorithm is presented in following steps:

Step 1. Setting up a database in the memory of the

robot control computer with the border of the robot

fault zones, and the rotation centres.

Step 2. Setup the control structure presented in fig.3

of paper (Ivanescu, 2000).

Step 3. The residual vector

)t(r created by “Fault

detection and isolation block” offers the number

()

3,2,1k ∈ of blocked joint.

Step 4. Checking if the final position

(

)

3

k

3

k

y,x

of the

robot arm tip is inside of the border of the zone k.

If the result is “NOT” the computer generate an

alarm signal “Can’t touched the final position”. If

the result is “YES” the computer executes the control

algorithm, (Ivanescu, 2000), but only the step for

fault free joints. In figure 5 is presented the

movement of the robot arm tip for initial conditions I

to position 1 by

1

θ

and θ

2

control (θ

3

is blocked at 0

0

)

and the next step is the movement of the arm tip

from 1 to 2 only with control

Δθ

2

because the points

1 and 2 are situated in the intersection of zone III for

0

3

=

θ

and zone I for θ

1

=fixed in the position of last

command for point 1.

5 APPLICATION OF ROBOT

MODELS

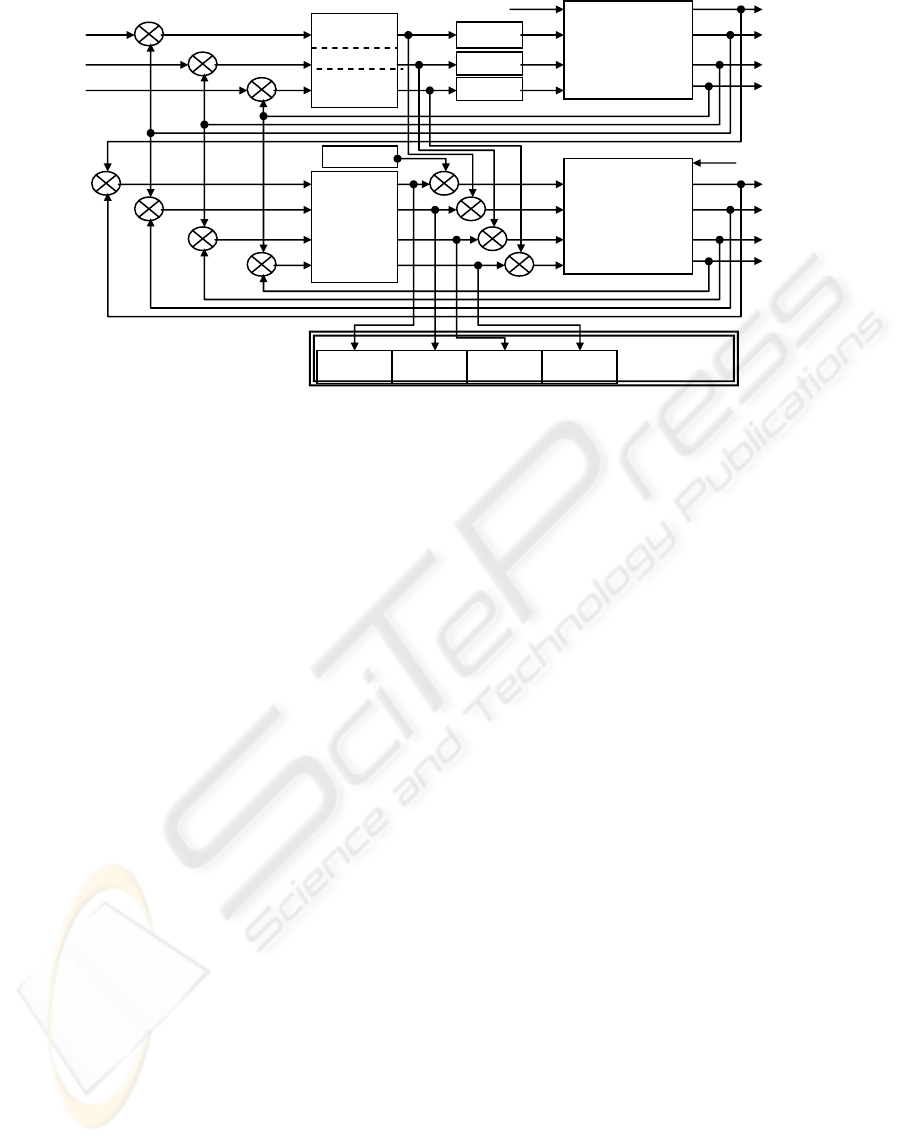

Our goal is to detect the faults by measuring the

accessible process variables in real time. For the

given process, these variables are the actuator's

positions θ

1r

, θ

2r

, θ

3r

and the griper position X

g

(figure 3). There is a strong interdependence between

these variables and the possible defects occouring in

0 0.5 1 1.5 2 2.5 3

-2

-1 .5

-1

-0 .5

0

0.5

1

1.5

2

2.5

3

80-90

70

-

80

50-60

0-10

Area J3

Area T

Figure 4: The movement of Zone I for θ

1

∈(0-90).

0 0.5 1 1.5 2 2.5 3

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

2.5

3

Figure 5: The robot control in fault condition (θ

3

=0).

ICINCO 2006 - ROBOTICS AND AUTOMATION

550

the control equipment, and this impose an adequate

method to choose the fault measurable outputs pairs.

In order to chose the corect perturbation-output

pairs, we use the sensitivity matrix method. For

experimental studies we implemented the fault

detection structure presented in figure 6, as extension

of the elements presented in the first part of the paper

(figure 2).

The structure can be easily implemented in the

robot supervising computers that collect information

about the robot arm. This structure does not require

supplimentary equipment, and it can be implemented

for the existing monitoring digital control system of

the robot.

6 CONCLUSIONS

In this paper it is presented an extension of the

algorithm developed in authors’ paper (Ivanescu,

2000). The results of this algorithm are:

- The resolute decision in fault conditions to continue

or not the movement of robot arms

- The diminution of the control times

- The diminution of memory space allocated for

database.

- The use of a simple algorithm for control imple-

mented on a small controller.

In the future it is possible to develop some control

algorithms in fault free conditions using the fault

zone definitions. As a result of this analyse it is

possible to develop the control of the robot arm only

with one or two joint command.

REFERENCES

Chow Y., A.Willsky, 1984. Analytical Redundancy and

Design of Robust Failure Detection Systems, IEEE

Trans. Aut. Contr., AC-29(7), pp. 603 – 614.

Isermann, R., 1997. Supervision, fault detection and fault

diagnosis methods - An introduction, Control

Engineering Practice, 5(5), pp. 639 – 652.

Ivanescu, M., M. Vinatoru, E. Iancu, 2000. Robotic Arm

Control in Fault Condition, Proceedings of the

IASTED International Conf. Artificial Intelligence and

Soft Computing, Banff, Canada, vol.I, pp. 361-365.

Merrill, W., B. Lehtinen, J. Zeller, 1984. The Role of the

Modern Control Theory in the Design of Control for

Aircraft Turbine Engines, AIAA Journal of Guidance

and Control, 7(6), pp. 652 – 661.

Vînătoru, M., E. Iancu, C. Vînătoru, R.J.Patton, J. Chen,

1998. Fault Isolation Using Inverse Sensitivity

Analysis, International Conference on Control'98,

Swansea, England, vol. 2, pp. 964-968.

Vinatoru, M., E. Iancu, C. Vinatoru, 1997. Robust control

for actuator failures, Proceedings of 2nd IFAC

Symposium ROCOND'97, Budapest, pp. 537 - 542.

Viswanadham, N., K. D. Minto, 1988. Robust Observer

Design with Application to Fault Detection,

Proceedings of American Control Conference, Atlanta

1988, 1393– 1399.

Viswanadham, N., J. H. Taylor, E. C. Luce, 1987. A

Frequency-Domain Approach to Failure Detection and

Isolation with Application to GE-21 Turbine Engine

Control Systems, Control Theory and Advanced

Technology, 3(1). pp. 603 - 609.

Willsky, A.S., A Survey of Design Methods for Failure

Detection in Dynamic Systems, Automatica, 12(6),

1976, 601-611.

Figure 6: Fault detection block diagram.

F

ti

AC1

AC2

θ

1

*

θ

2

*

AC3

θ

3

*

-

-

-

+

Controllers

Controllers

E

4

Real

Process

Robot

θ

2r

θ

1r

X

gr

θ

3r

E

3

E

2

Fault display

X

i

=

. . . . .

Actuator3Actuator2Actuator1

Fault

Detect

DE

Robot

Process

Simulator

θ

2m

θ

1m

X

gm

θ

3m

DE

DE

DE

-

-

-

-

X

g estimate

+

+

+

+

F

t

FAULT DETECTION OF THE ACTUATOR BLOCKING - Experimental Results in Robot Control Structures

551