A HOLONIC FAULT TOLERANT MANUFACTURING

PLATFORM WITH MULTIPLE ROBOTS

Theodor Borangiu, Florin Daniel Anton, Silvia Tunaru, Anamaria Dogar

Dept. of Automation and Industrial Informatics, University Politehnica of Bucharest,

313, Spl. Independentei sector 6, RO-060032

Keywords: Remote control, Network reliability, Flexible manufacturing systems, Monitoring, Fault tolerant systems.

Abstract: To be competitive, manufacturing should adapt to changing conditions existing in the market.

Manufacturing firms also need to adapt to newly developed technologies and to rapidly changing

environmental protection regulations. Modern automated manufacturing systems need robotized material-

conditioning systems capable of moving materials efficiently throughout the entire production area. This

involves not only moving and storing materials, but also identifying, locating, qualifying, controlling and

measuring them during processing and transportation. The objective of the proposed project is the design,

implementing, testing and validation of a holonic, fault-tolerant manufacturing control platform integrating

multiple robots with visual guidance for on demand material conditioning and automated visual inspection.

1 INTRODUCTION

In general robotic systems are composed by a

multitude of software and hardware components

which are susceptible to faults, such component

faults can lead to an unexpected behaviour of those

systems and also to loosing the supplied services.

Some systems are designed to be fault tolerant

which means that in case of malfunction of a

component, the system will present a well known

behaviour or will “hide” from the user the

malfunction of those components.

The paper describes a system which can be used

to unify, control and observe the cell's devices (in

particular each robot-vision system) from a remote

location, e.g. the CAM/CAQC server linked to other

design and planning compartments.

1.1 Traditional Manufacturing

The literature to date in the area of manufacturing

and material-handling control considers four basic

types of control architectures (CAs).

(CA1) In the centralized system, there is a single

control unit that produces all decisions about the

flow of materials in the system.

(CA2) The hierarchical architecture is based on a

top-down, master-slave approach, where the flow of

commands comes strictly from the higher-level

controllers to the lower-level controllers assuming a

deterministic behaviour of the system.

(CA3) The hybrid architecture is mainly derived

from the hierarchical architecture, yet it allows

cooperation and sharing of information between

lower-level controllers.

(CA4) The heterarchical architecture is formed by

a group of independent entities called agents that bid

for orders based on their status and future workload.

1.2 The Manufacturing Holonic

Area

To compensate for the deficiencies of both

hierarchical and heterarchical control systems, in

recent years the research community introduced

several new concepts for the design of

manufacturing systems such as Fractal Factory,

Bionic Manufacturing, and Holonic Manufacturing

Systems (Van Brussel, 1998). Each concept attempts

to model a manufacturing system based on some

analogies with other existing theoretical, natural or

social organization systems.

The holonic concept describe a basic unit of

organization in biological and social systems

(Koestler, 1968). Two important properties of

holons make the holonic concept a suitable

557

Borangiu T., Anton F., Anton S. and Dogar A. (2006).

A HOLONIC FAULT TOLERANT MANUFACTURING PLATFORM WITH MULTIPLE ROBOTS.

In Proceedings of the Third International Conference on Informatics in Control, Automation and Robotics, pages 557-560

DOI: 10.5220/0001220305570560

Copyright

c

SciTePress

modelling tool for use in the design of both

manufacturing and material-handling systems. First,

autonomy

grants holons the right to make decisions

without consulting any supervising entity. Second,

cooperation

permits holons to communicate with

other peer holons to develop mutually acceptable

plans and execute them.

Research to date in the holonic manufacturing

systems has no focused specifically on the material-

handling function. Machine vision systems are more

often used to guide the motion of robots and to

inspect materials for geometry and surface status.

Consequently, vision systems may provide both the

function: Guidance Vision for Robots - GVR and

Automated Visual Inspection – AVI. The

taxonomy of guidance vision systems for robotic

GVR tasks has included in recent years two

important architectures: Look-and-Move and Visual

Servoing, each one being able to use position or

image feedback information (Hutchinson, 1996).

2 THE FAULT TOLERANT

SOFTWARE PARADIGM

Fault tolerance in any system implies a redundancy

form. There are two kinds of redundancy in time and

space. Redundancy in time means that the activity

(computation) of a defected server is launched again

on the same processor (after the malfunction cause

has been eliminated) or on another and repeated

after is completed with success. Redundancy in

space implies simultaneous execution of server

activities on several processors in parallel, then by

voting the final result is chosen.

The most important paradigms for the proposed

objectives are:

• Transactions: software structuring mechanism for

applications which access shared data (typically

for data bases).

• Check pointing: mechanism which, in case of

malfunction, the activity (computation) can be

restarted from a coherent state preceding the

malfunction.

• Replicated State Machine: the provided service is

executed in parallel on few processors (collection

of duplicated servers).

• Passive replication: a service is implemented on

few processors but only one is active (primary)

and treat the clients requests.

3 THE SYSTEM STRUCTURE

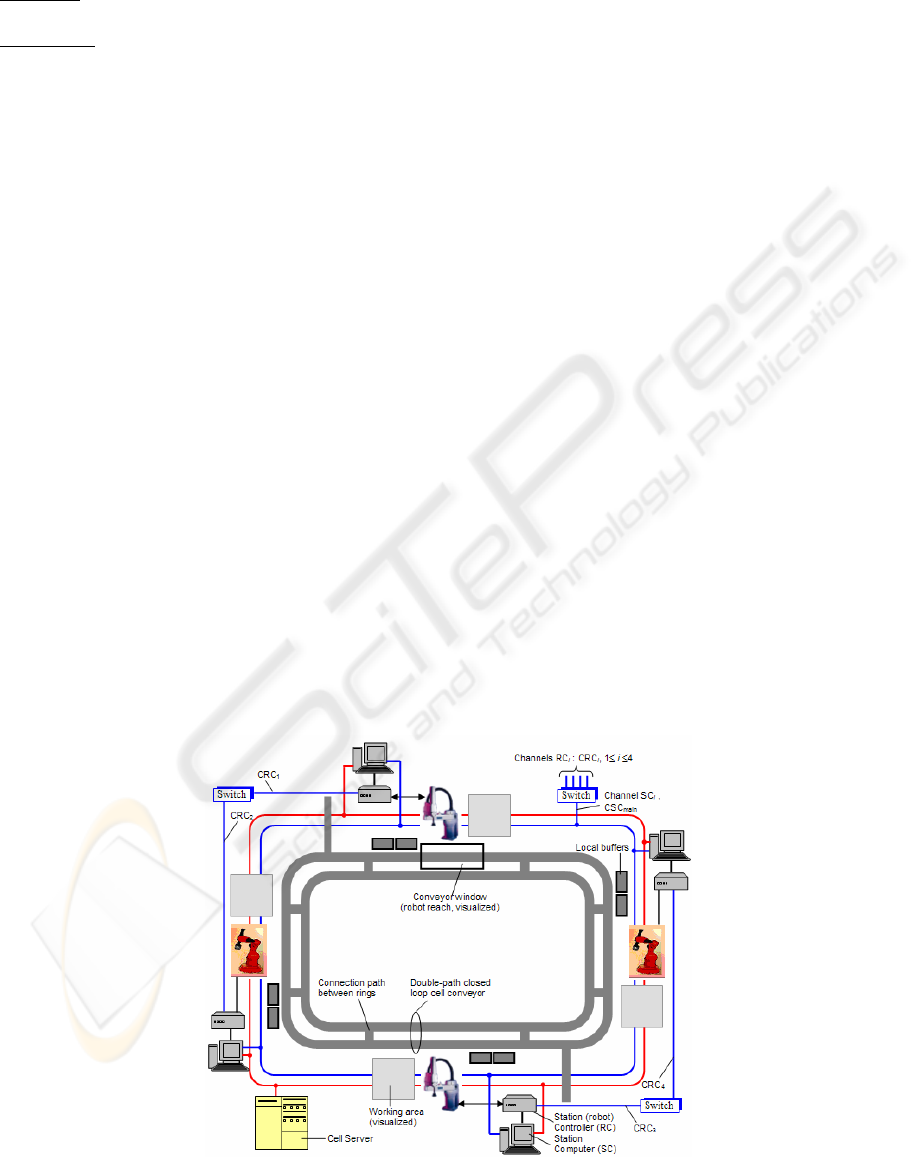

The physical layout of the multiple robot

development platform controlled according to the

holonic manufacturing concept is shown in Figure 1.

The platform contains four robots (of vertical-

and horizontal articulated type) accessing a double-

path, closed loop conveyor for part transportation.

Part diverting from the inner ring belt to the outer

ring belt of the conveyor is performed under the

control of a Programmable Logic Controller (PLC)

directly accessible for program editing and

Figure 1: The layout of the manufacturing platform with multiple robots, vision and holonic control.

ICINCO 2006 - ROBOTICS AND AUTOMATION

558

download from a IBM PC-type computer.

Robot controllers (RC) have master positions

over the four workstations, communicate between

them and are connected in a fault-tolerant multi-

network with Station Controllers of IBM PC-type.

The following issues are foreseen, deriving from

the objectives proposed above:

1. Process and system analysis, leading to the design

and configuring of a generic manufacturing cell

platform with four robot-vision stations, multiple

stationary and mobile matrix cameras covering

various fields of view including conveyor belt

windows; the backbone of the manufacturing is a

double-path, closed loop conveyor accessed by the

robots. The layout of the cell resources will allow

running different production scenarios under

holonic control at batch level.

2. Design and implementing of a fault-tolerant

communication system between station controllers

and computers (robot systems, conveyor control)

and the central cell server, both at controller level

and computer level.

3. Methodology, control solution and algorithms for

the material-conditioning problem in multi-agent

production structures, applying the holonic

manufacturing concept. There will be designed the

layered holonic control architecture (Global

Scheduler, Order Holon layer, Material-

Conditioning layer, System Monitoring and

Database) and implemented in a parallel

processing, multi tasking software architecture.

4. Design and implementing the Robot – Vision

cooperation mechanisms for merged tasks:

Guidance Vision of Robots (GVR) and Automated

Visual Inspection (AVI) of materials. The solution

5. is based on: (i) the description of material flows

by means of sets of specific features extracted

from images; (ii) configuring the operating

parameters of the vision environment by virtual

cameras; (iii) scene-, robot-, object-, and gripper's

fingerprint modelling; (iv) the utilization of a

powerful set of vision tools allowing user

definable measurements and evaluation of parts.

Related to the thematic area Integration of

technologies, advanced information technologies

(IT) will be integrated in the holonic production

control system: robot control with visual servoing,

intelligent image processing, feature-based material

description, object orientation, multi processing,

flexible manufacturing control.

The objectve of providing on demand qualities

for the production scheduling and manufacturing

control is representative for the thematic area ICT

supporting businesses and industry.

The holonic concept, transferred and tailored to

flexible manufacturing based on intelligent robots

guided by artificial vision, corresponds to the

thematic area Future and emerging technologies.

A significant scientific contribution will consist

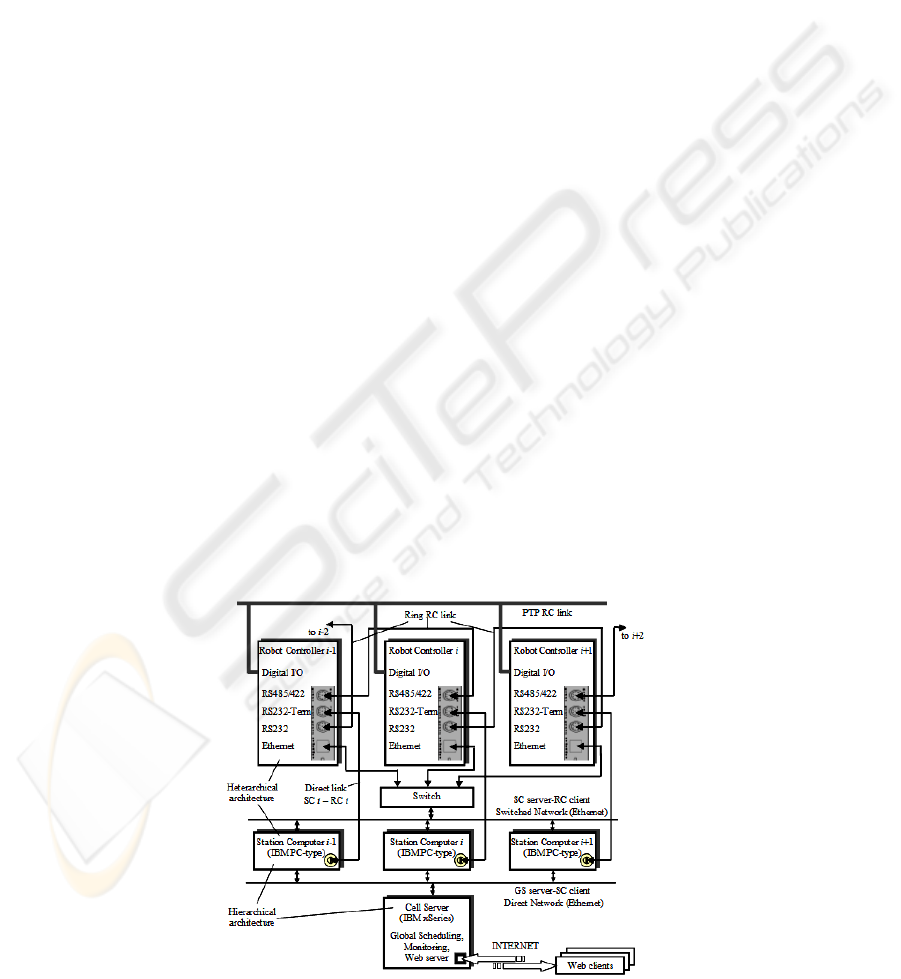

in adding fault-tolerance to the cell's communication

system. A fault-tolerant communication architecture

is proposed in Figure 2, providing redundancy at

both the Station Controller level, and at the Station

Computer level. The Global Scheduler (GS) will be

implemented by a IBM xSeries Server, which

transfers the recommendations of job scheduling to

the cluster of Order Holons implemented in the IBM

PC-type Station Computers (SCs) via a GS server-

SC client Direct Network (Ethernet). This holonic

control layer is hierarchical.

Figure 2: Fault-tolerant communication architecture for the multiple-robot platform with holonic production control.

A HOLONIC FAULT TOLERANT MANUFACTURING PLATFORM WITH MULTIPLE ROBOTS

559

The cluster of SCs implementing the Order

Holon (OH) and Material Handling Holon (MHH)

holonic control layers is interconnected to the

process devices (Robot Controllers) via a SC server

– RC client Switched Ethernet Network, creating a

heterarchical fault-tolerant architecture:

• the failure of a Station Controller is detected by

continuous monitoring via the direct serial links

SC

i

– RC

i

and determines in consequence the

rescheduling of jobs for the (n – 1) remaining

valid Robot Controllers j, 1 ≤ j ≤ n, j ≠ i.;

• if one of the Station Computers is down, its role

is taken over by the remaining (n – 1)

workstations, as each SC data base is replicated

and updated on line in all the other (n – 1) ones;

• if the switch is down, the heterachical

communication between the SC and the RC

clusters still operates via the direct links SC

i

–

RC

i

and the Ring RC link.

The vital inter-operational conditioning between

device tasks (mutual exclusion, synchronization) is

provided by a cross connection I/O network.

4 THE FAULT TOLERANT

COMMUNICATION LEVEL

The communication level represents the key element

of the management systems and command integrated

with robot controllers of FMC.

A critical aspect in designing a communication

level is the building, partitioning and the on-line/off-

line data bases transfer, fact that involve the

multiplication of the communication links insuring

the a global fault tolerant behaviour. So, it must deal

the interoperability on the dynamic aspect, allowing

the modules connected to the communication system

to cooperate between them. The features announced

above belong to a communication level which must

combine the reliability and the performance of an

industrial network with the building simplicity of a

communication system used for parallel applications

executed on multiprocessor machines.

In a normal way, each controller is connected to

the communication network. If in the setup stage of

the manufacturing or during the manufacturing, a

controller is malfunctioning, another controller will

take the tasks. To make this possible we need to

make available the data bases on each controller, and

also a commutation of the informational routes with

the help of the network. The availability is assured

by software redundancy which involve keeping at

least one replica of each data base.

4.1 Network Reconfiguration

Rebuilding the communication route in the network

represent the last step required to restart the normal

behave of the FMC control system.

In case of malfunction of the communication

network the following important cases can appear:

1. if the connection between Switch and the

Supervisor PC is down the remote control will be

lost, but the FMC will reconfigure: the RC will

use the ethernet network for communication, and

the RC with the first IP from the class will take the

functions of the Supervisor PC. If the connexion is

re-established the Supervisor PC makes a query

finds the replacing controller, transfer the

databases and restart the normal behave.

2. if the switch is not functioning, all the Ethernet

connexions are lost, but the controllers will use the

serial “network”. The behave is like in the first

case only that the web users can view the status

from the Supervisor PC, including the images

acquired by the observation cameras.

3. if a controller lose the Ethernet connexion he will

use one of the two serial lines to reach the

Supervisor PC depending on the cpu time of the

neighbours.

5 CONCLUSION

The project is under construction; most of the Server

Application's functions are already implemented and

tested on a pilot platform in the Laboratory of

‘Robotics and AI’ of the University Politehnica of

Bucharest. The research project will provide a portal

solution for linking the existing fault tolerant pilot

platform with multiple V+ industrial robot-vision

controllers from Adept Technology located in

University Labs from various countries. The SA

module is basically finished and successfully tested.

Currently, the eCAs are under construction.

REFERENCES

Hutchinson, S.A., Hager, G.D. and P. Corke, 1996. A

Tutorial on Visual Servo Control, IEEE Trans. on

Robotics and Automation, 12, 5, pp. 1245-1266.

Koestler, A., 1968. The Ghost in the Machine, New York,

Macmillan.

Van Brussel, H., Valckenaers, P., Bongaerts, L. and P.

Peeters, 1998, Reference architecture for holonic

manufacturing systems: PROSA, Computers in

Industry, 37, pp. 255-274.

ICINCO 2006 - ROBOTICS AND AUTOMATION

560