EMBEDDED FPGA SOLUTION FOR WATER QUALITY

MONITORING SYSTEM

Calibration and Measurement

1,2

Octavian Postolache,

1,2

Miguel Dias Pereira,

1

Pedro Girão

1

Instituto de Telecomunicações, Av. Rovisco Pais, 1049-001, Lisboa, Portugal

2

EST Setúbal LabIM/IPS, Rua do Vale de Chaves, Estefanilha, 2914-508, Setúbal, Portugal

Keywords: Reconfigurable measuring system, calibration control, real-time processing.

Abstract: This paper presents a field operating water quality monitoring system based on real time controller and

FPGA module. The system features functioning includes in-situ automatic cleaning and calibration of stand

alone sensors such as turbidity, pH or conductivity, on-line measurement of water quality parameters using

the calibrated sensors. In order to perform the above mentioned calibration and measurement tasks the

system uses a set of centrifugal pumps and electrovalves and associated embedded control materialized by

the LabVIEW programmed FPGA module. The voltages associated with water quality measurement

channels are acquired using a four channels analog input module that work also under FPGA control. The

data processing tasks are distributed between the FPGA module and the real-time controller included in the

system. A practical approach concerning the sensor model implementation capabilities using the real-time

controller (NI cRIO-9002) or FPGA (NI cRIO-9003) is also included. In order to provide the wireless

remote control of the system an Ethernet – wireless bridge (IEEE802.11g) and client-server TCP software

developed in LabVIEW were included in the system. A PDA based remote control solution was also

implemented to evaluate system performance.

1 INTRODUCTION

Real time monitoring and water quality assessment

of surface waters represents nowadays an important

challenge associated with water quality assurance

and requires measuring systems with multiple

measuring nodes with calibration facilities.

The systems architectures generally includes

different measuring nodes, installed at different

points of the monitored area, that includes sensors

able to output information related with the quantities

elected to characterize water quality and the

hardware required to power the sensors and to

process their outputs. Data collected at the different

nodes is preferably transmitted to a central land-

based station where it is further processed to yield

the desired information. The nodes must then also

include hardware for data transmission and usually

some kind of processing unit (e.g. microcontroller)

able not only to format data for transmission but also

to transform sensors’ output voltages into values of

the measured quantities. In previous papers, the

authors have presented solutions of distributed

measuring systems for water quality monitoring and

assessment (Postolache, 2002, Postolache 2003,

Girao, 2003, Postolache, 2005).

The quantities commonly used in the assessment of

water quality are: temperature, pH, conductivity,

turbidity, dissolved oxygen, and heavy metals

concentration. With the exception of temperature,

the performance of the sensors for these quantities is

highly dependent on periodic cleaning and

calibration.

Considering the calibration and measurement

requirements associated with water quality

measurement nodes the present work propose a

novel architecture based on a reconfigurable control

and acquisition system (NI CompactRIO). The

system permits accurate timing and the control of

several pumps and electrovalves associated with

water quality sensor (e.g. conductivity) test or

calibration for different standard solutions. Data

acquisition, data processing and data communication

are additional capabilities of the presented system.

Considering the field operation conditions and the

Wi-Fi compatibility of the presented system a

mobile solution based on a PDA is developed in

154

Postolache O., Dias Pereira M. and Girão P. (2006).

EMBEDDED FPGA SOLUTION FOR WATER QUALITY MONITORING SYSTEM - Calibration and Measurement.

In Proceedings of the Third International Conference on Informatics in Control, Automation and Robotics, pages 154-160

DOI: 10.5220/0001221301540160

Copyright

c

SciTePress

order to perform tasks such as water quality data

reading, start/stop calibration or measuring, fault or

pollution events checking, calibration or measuring

control, fault or pollution events detection and

diagnosis.

2 SYSTEM HARDWARE

The water quality field measurement system

includes as the main parts: a set of water quality

measurement channels (temperature, pH,

conductivity and turbidity) connected to high

accuracy analog input module plug in NI cRIO-9103

FPGA reconfigurable chassis that communicate

through the PC bus with NI CompactRIO 9002 real

time controller (National Instruments, 2005).

Additional digital output modules assure the control

of the system pumps and electrovalves, devices that

are actuated when the system works in calibration or

measuring mode. In order to distribute the data and

to receive the control commands an Ethernet to

wireless bridge is connected to the cRIO Ethernet

port. Data access, calibration and measurement

commands can be sent using a PDA Pocket PC (HP

iPaq 2700) included in the water quality wireless

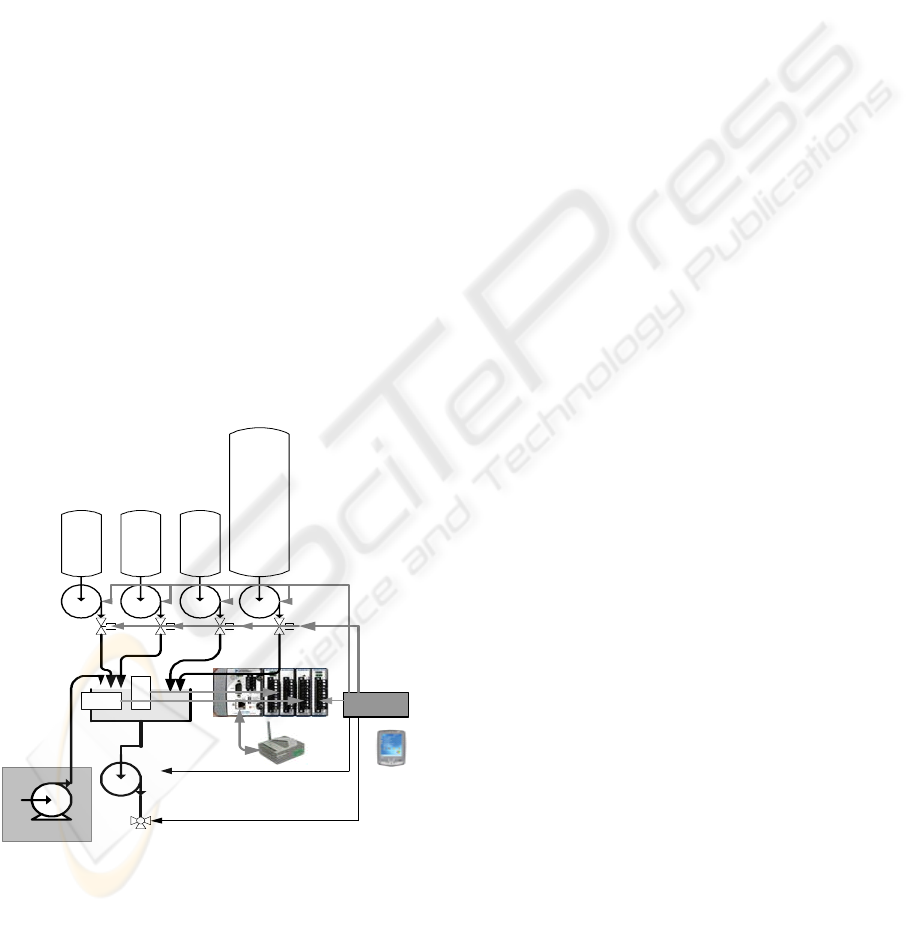

network (Figure 1).

Figure 1 shows the block diagram of the field

operating WQ monitoring system hardware that

includes the main sensing, control and processing

blocks associated with WQ parameters measurement

and the calibration of corresponding sensors such as

turbidity, conductivity and pH. Thus the control is

based on the FPGA reconfigurable I/O hardware (NI

cRIO 9103) which control the system actuators

(pumps and electro-valves) through a NI- cRIO 9472

digital output block, acquires the level information

(on/off) of the liquid (standard calibration solution,

water under test) in the test cuvette using the optical

level sensor connected to one of the digital input of

the NI cRIO 9423 module. In the calibration or

measurement mode the system acquires the voltage

from the WQ measurement channels using four

analog input of the NI cRIO 9215 module.

In Figure 1 the following notations were used: CSi –

calibration solution vessels l, P

1

, P

2

, P

3

, P

4

-

calibration pumps, LS-level sensor, WQ-S water

quality sensor under calibration, CP-cleaning pump,

WP –waste pump, ACTcc- actuator conditioning

circuit block, EVi-calibration electrovalves, CEV-

cleaning electrovalve and M_WEV-measurement

and waste electro-valve. The FPGA module

communicates using the PCI bus with a NI cRIO-

9002 real-time embedded controller characterized by

32 MB DRAM memory and 64 MB of non-volatile

flash storage. The real-time controller permits to

implement advanced processing algorithms (fault

detection, data forecasting, data fusion), WQ file

storage and wireless communication using an

Ethernet to wireless bridge (D-LINK DWL 810)

connected to the Ethernet port.

Considering the communication capabilities the

designed WQ calibration and measurement unit can

be considered as a smart node of WQ monitoring

distributed network that can deliver and receive the

data from different devices such as laptop, desktop

PC or a PDA included in the network. In the present

application special attention was dedicated to the

utilization of the PDA to read current values of the

measurement data delivered by the WQ

measurement system based on cRIO 9002.

As it was presented in Figure.1 the WQ sensor

calibration is performed using a set of standard

calibration solution (e.g. OAKTON pH 4.01, 7 and

10 standard buffer solutions for pH) stored in the

CS

i

calibration vessels and injected in the testing

cuvette using a set of pumps (pumps - Jabsco Pumps

42510-000, 12 VDC, 1.5A, 7.5 l/min) and

electrovalves (Bergamo 0-15 bar, 12 VDC, ¼”) that

work under control of embedded FPGA calibration

program. Additional pumps included in the system

are: the CP pump that is used to pass the cleaning

solution from the cleaning vessel to the test cuvette,

the WP pump is used to empty the test cuvette either

\

L

P

cRIO system

ACTcc

CS1 CS2 CS3

CS

PDA

Pocket

PC

WBridge

EV1 EV2 EV3 CEV

M_WEV

LS

WQ

S

P1 P2 P3 CP

WP

Water

MP

Figure 1: cRIO based embedded system for water

quality measuring and W Q sensor calibration tasks

Figure 1: CRIO based embedded system for water quality

measuring and WQ sensor calibration tasks

EMBEDDED FPGA SOLUTION FOR WATER QUALITY MONITORING SYSTEM - Calibration and Measurement

155

to the waste vessel (calibration phase) or to water

under test (measurement session), and the MP

(measuring pump) that is a submersible pump (1

submersible 12 VDC, 2.5A, 49 l/min Johnson pump)

and used to assure the circulation of the water

between the monitored area (river, estuary) and the

test cuvette

.

3 SYSTEM SOFTWARE

The system software includes two parts, one related

with

the smart calibration and measurement system based

on cRIO real-time controller and FPGA

reconfigurable module and another represented by

the software of the PDA Pocket PC.

The FPGA reconfigurable module software was

developed using LabVIEW for FPGA toolset and is

associated with the pump and electrovalves control

through digital output lines, the level on/off sensor

reading, the acquisition of the water quality sensors

voltage values when the system works in the

measurement mode and the sensor under test voltage

acquisition when the system works in calibration

mode. Using the FPGA onboard memory and the

memory read/write functions the FPGA embedded

algorithms for digital-code voltage to water quality

parameter (e.g. temperature) is carried out.

Taking into account the limitation of the FPGA

related the numerical values calculation (only

integers operation) the main part of processing of the

acquired data is developed on the real-time

controller level using the LabVIEW real-time. Thus

a multichannel voltage-to-WQ conversion block was

implemented. Taking into account temperature

variation influence on the measurement channel

accuracy, the temperature compensation based on

IEEE1451.2 correction engine algorithm was also

implemented.

Data logging software block was implemented on

the cRIO controller in order to store the information

about measured water samples.

Regarding data distribution in the water quality

network that includes the PDA and other PCs

(laptop or desktop PC) the cRIO real-time controller

includes a TCP server-multiple client component.

Implementing client software on the PDA level

using (LabVIEW for PDA) the PDA operator can

obtain the current values of the Water Quality

parameters and the calibration coefficients of the

water quality measurement channels. Calibration

and measurement start-up actions or measurement

channel tests when anomalous functioning is

reported (fault events) can be ordered using the PDA

software component.

3.1 Embedded FPGA Software

The embedded FPGA software is developed using

the LabVIEW FPGA toolset and is associated with:

electro-valves and centrifugal pumps control, WQ

sensor calibration, water quality measurement, fault

or pollution event detection multi-channel analog-

input and digital input control, digital filtering of

the acquired samples from the WQ measuring

channels associated with NI cRIO-9215 module.

For the particular case of WQ sensor calibration the

flowchart of the calibration session is presented in

Figure 2.

Referring the measuring mode an additional

submersible pump is used to bring the water under

test into the test cuvette and the voltages obtained on

the sensor channels are acquired. The water under

test level on the testing cuvettte is imposed constant

thus a simple on/off control of the WP and M_VEW

is implemented on the system while the level

information is obtained from the LS sensor.

When the system works in the measuring mode and

a strong variation of WQ parameter from one of the

measuring channel is detected (using the derivative

information) the pollution event detection mode is

start-up. In order to make an accurate discrimination

between the pollution and measuring channel

anomalous functioning a “one point test procedure”

is designed and implemented.

The action associated with this procedure is similar

to the calibration of the considered measuring

channel for one standard solution.

A comparison between the current acquired voltage

)(tU

CS

WQ

from the tested channel and reference

voltage value

)(

ref

CS

WQ

tU considered for the same

calibration solution (CS) is carried out.

The fault detection is expressed by the following

relation:

faultWQrefWQWQ

tUtU

ξ

≤− )()( (1)

Thus if the difference between the considered values

is greater than an imposed limit

faultWQ

ξ

(5% of

)(

ref

CS

WQ

tU in the present case) the anomalous

functioning message is delivered in the WQ

monitoring network. In opposite case the pollution

event signal is generated.

In order to increase the SNR (signal to noise ratio)

the acquired samples from the WQ measuring

channels are filtered using a FPGA embedded

ICINCO 2006 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

156

moving average digital filter algorithm. that is

implemented for each analog input channel of NI

cRIO-9215 module (Figure 3)

∑

−

=

+⋅=

1

0

)(

1

)(

M

j

jTiTx

M

iTy (2)

The effectiveness of the implemented filter is

controlled by selecting the appropriate number of

samples M for the averaged group. For the present

case a M=4 “smoothing factor” was used. Other

filter technique was also implemented in order to

achieve a shorter measurement time and less noise

sensitivity:

()

))1((1)()( TiyFiTxFiTy −⋅

−

+⋅= (3)

where F represents the filtering coefficient varying

between [0,1].

The acquired and smoothed voltages during the t

m

period are sent through PCI communication to the

cRIO-9002 controller where a LabVIEW Real-Time

developed software performs data processing, data

storage and data communication tasks

.

3.2 Real-time Controller Software

The software component associated with the cRIO

real time controller includes the GUI of the system,

the data processing, the data storage and data

communication blocks.

Referring to the data processing block it provides the

digital-code to voltage conversion:

VFS

FS

codeWQV

n

WQ

10,

2

_ =⋅= (4)

Figure 2: Calibration flowchart: U

WQ

j

–voltage associated with the sensor under calibration for the calibration point j,

U

T

– voltage associated with the temperature measuring channel, m – number of calibration points, Δt – time interval

associated with filling and disposal of test cuvette contents, LS –level sensor

level

measuring

next

calibration

LS=0?

standard solution

selection j=1..m

j=1

yes

j

≥

m?

n

o

j=j+1

WP, M_WEV

–

off,

EV

j

-off P

j

-on

mixing of

standard sol.

Δt>Δt

mix

mixing time

measuring

WP, M_WEV

–

off,

EV

j

-on P

j

-on

pumping standard

solution and

measurin

g

the

Δ

t

f

measuring

& primary

p

rocessing

Δt>Δt

m

?

no

y

es

n

o

δ

disposal of

test cuvette

contents

WP, M_WEV

–

off,

EV

j

-off P

j

-off

U

WQij

, U

T

acq. Δt -meas

Data

p

rocessin

g

Δt

meas

LS

meas

yes

Δ

t>

Δ

t

p

?

n

o

WP, M_WEV

–

on,

EV

ij

-on P

ij

-off

Δ

t meas

WP, M_WEV

–

off

CEV-on CP-on

yes

pumping

cleaning

LS=0?

LS meas

level

measuring

n

o

y

es

WP-on, M_WEV

–

off

CEV-on CP-on,

cleaning the

test cuvette

Δ

t>

Δ

t

c

l

?

Δ

t

meas

cleaning time

measuring

n

o

y

es

time

measuring

Start Cal

Stop calib

δ

yes

Figure 2: Calibration flowchart: U

WQ

j-voltage associated with the sensor under calibration for the calibration point j, U

T

-

voltage associated with the temperature measuring channel, m – number of calibration points, ∆t – time interval associate

d

with the filling and disposal of the test cuvette contents, LS – level sensor.

EMBEDDED FPGA SOLUTION FOR WATER QUALITY MONITORING SYSTEM - Calibration and Measurement

157

and voltage to WQ parameter value conversion that

uses the IEEE1451.2 for Smart Transducers

(correction engine) standard (Eidson,1998) given by:

[][ ][ ]

∑∑ ∑

== =

−−−⋅=

)1(

0

)2(

0

)(

0

2211,,

D

i

D

j

nD

p

p

nn

ji

pji

HXHXHXCWQ ……

…

(5)

where X

n

represent the input variable expressed by

acquired voltages from the sensor measurement

channel (U

T

, U

pH

, U

σ,

, U

TU

) in the present case, H

n

the offsets of the input variables, D(k) the degree of

the input X

k

, and C

i,j,..p

the POL

m

coefficients. The

C

i,j, p

coefficients are obtained using the multiple

regression method [11] associated with the latest

calibration of the measurement channel. Thus on the

particular case of considered water quality sensors:

temperature, pH, conductivity and turbidity sensors,

the multivariate relations are used to extract the

following quantities:

;

010

010

1110010

1110010

T

TT

TU

TUTU

TT

TpH

pH

T

pH

pH

pHpH

UCCT

UCCTU

UUCUCUCC

UUCUCUCCpH

+=

+=

+++=

+++=

σ

σσ

σ

σσ

σ

(6)

where U

pH

, U

σ

, U

TU

, U

T

represents the primary

variable associated with pH,

σ, TU, T quantities. At

the same time U

T

represents the perturbing effect

variable for pH and conductivity (

σ) calculation.

The calibration solution for the particular case of

conductivity, assumes the following conductivity

values

σ={80 uS/cm, 447uS/cm, 1413 uS/cm and

2070 uS/cm} and the temperature variation was

included in the [5;30]

°C interval.

Referring the implemented software it permits to

perform the WQ data logging during the

measurement mode. For example the operator can

specify a fixed data logging rate (DTR=

WQ/15min)

where the

WQ represents the water quality vector.

The data file can be accessed through the cRIO-9002

ftp server capabilities from other PCs of the water

quality wireless network. At the same the current

Figure 3: The LabVIEW sequence of FPGA based WQ channel acquisition software including the acquisition rate

control(acq_rate(uS)), the acquisition time period and the moving average filtering block for average factor M=5.

Figure 3: The LabVIEW sequence of FPGA based WQ channel acquisition software including the acquisition rate

control(acq_rate(uS)), the acquisition time period and the moving average filtering block for average factor M=5.

ICINCO 2006 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

158

values of the WQ can be shared with a PDA pocket

PC using the TCP client-server architecture

implemented in LabVIEW.

3.3 PDA Software

The mobile software component of the water quality

calibration and measuring system were developed in

order to permit an easy access of the WQ measured

data and send commands associated with measuring

and calibration procedures. The software that

implements the TCP/IP communication between the

PDA and cRIO real time controller was developed

using the LabVIEW PDA for PocketPC toolkit

(National Instruments, 2006). Based on the TCP

client components the operator can check the normal

functioning of the field water quality measurement

system by a direct access of the data acquired from

one of the measuring channels. The Figure.4 present

the PDA user interface associated with WQ

parameters values.

Figure 4: PDA interface for data visualization and

remote calibration control

In the figure can be observed the current values

measured by the field node based on the cRIO

system during a measurement cycle. Changing the

WQ data to Calib CTRL tab the user can verify the

date of the latest calibration and also can start-up a

new calibration. Additional functionalities related

with the fault detection and diagnosis are also

included.

4 RESULTS AND DISCUSSIONS

In order to underline the proposed solution

capabilities, in terms of the water quality

measurement, auto-calibration, data processing and

data communication capabilities, different testing

procedure were carried out.

4.1 Calibration and Measurement

Using the above mentioned calibration and

measurement system and the associated software

components several laboratorial and field tests were

carried out. In Figure 5 and Figure 6 present several

calibration curves associated with conductivity and

turbidity measurement channel calibration.

5

1

1.5

2

2.5

3

3.5

4

4.5

C(uS/cm)

5000

0 1000 2000 3000 4000

UC(V)

Figure 5 Conductivity calibration curve.

3.75

0.75

1

1.25

1.5

1.75

2

2.25

2.5

2.75

3

3.25

3.5

TU

50

0 5 10 15 20 25 30 35 40 45

UTU (V)

Figure 6: Turbidity calibration curve.

Figure 4: PDA interface for data visualization and remote

calibration control.

EMBEDDED FPGA SOLUTION FOR WATER QUALITY MONITORING SYSTEM - Calibration and Measurement

159

Referring to the above mentioned figure it can be

underlined that the turbidity curve non-linearity is

about

ε

TU

= 4% that justify the implementation of

voltage-to-turbidity conversion algorithm based on

piecewise linear approximation of sensor channel

inverse model.

4.2 Power Consumption Tests

Considering the measurement requirements the field

operation water monitoring system must have an

autonomy, power consumption is a very important

issue. The system is powered by a 12 VDC battery

and tests were conducted to obtain the evolution of

current and power consumption during both

calibration and measurement sessions.

The calibration session includes a maximum 3

cycles (1 cycle flowchart being presented in Fig.2)

according to the number of calibration points. Figure

6 shows the current and power evolution during the

calibration of one point for the TU sensor. The total

time (

Δt

i

sum) is 178 s, for an average current of

1.67 A and an average power consumption of 20.19

W.In the measurement phase, which takes about 200

s, the current consumption is 1.25 A.

5 CONCLUSIONS

The hardware and software proposed solution makes

not only viable stand-alone smart sensing nodes for

distributed water quality monitoring and assessment

but also increases the accuracy of the measured

quantities and assures equipment autonomy and life

time, reducing, in particular, maintenance costs. The

reconfigurable system based on FPGA assures

accurate timings and voltage acquisition that

guarantees accurate results on measuring or

calibration procedures. The system interface with the

operator is strongly improved by using the mobile

component expressed by a PDA and the

corresponding software is included in the system.

This feature is especially important when the WQ

measuring node is installed in inaccessible points.

Another important feature of the proposed system,

now presented, are the fault detection and diagnosis

capabilities at WQ node level and the advantage of

mobile component implementation in order to

receive signalling messages associated with

anomalous functioning, of one or multiple

measurement channels, pollution events that

occurred in the monitored area.

REFERENCES

O. Postolache, P.M. Girão, J. M. Dias Pereira, H.G.

Ramos; "An Internet and Microcontroller Based

Remote Operation Multisensor System for Water

Quality Monitoring", Proc. IEEE Sensors, Orlando,

USA, Vol. 1, pp. 254 - 259, June, 2002.

O. Postolache, P.M. Girão, J. M. Dias Pereira, H.G.

Ramos; "Wireless Water Quality Monitoring System

Based on Field Point Technology and Kohonen

Maps", Proc. IEEE Canadian Conf. on Electrical &

Computer , Montreal, Canada, Vol. 3, pp. 1873 - 1876,

May , 2003.

P. M. Girão, O. Postolache, J.M. Dias Pereira; H.G.

Ramos; "Distributed Measurement Systems and

Intelligent Processing for Water Quality Assessment",

Sensors & Transducers Magazine, Vol. 38, No. 12, pp.

74 - 85, December, 2003.

O. Postolache, P.M.B.S. Girão, J.M.D. Pereira, H.M.G.

Ramos, “Self Organizing Maps Application in a

Remote Water Quality Monitoring System”, IEEE

Trans. on Inst. and Meas., Vol. 54, n. 1, pp. 322-329,

February 2005.

National Instrument “CompactRIO Reconfigurable

Embedded System” on-line at http://www.ni.com,

2005

J. Eidson “IEEE1451.2 Correction Engine Applications”,

Hewlett-Packard Press, August 1998

National Instruments, “What is the LabVIEW PDA

module”, on-line at www.ni.com, 2006

ICINCO 2006 - SIGNAL PROCESSING, SYSTEMS MODELING AND CONTROL

160