A COMPARISON OF CYLINDRICAL PASTING METHODS

Shalini Aggarwal

Computer Graphics Laboratory

University of Waterloo

Stephen Mann

Computer Graphics Laboratory

University of Waterloo

Keywords:

Tensor product B-splines, hierarchical modeling, surface pasting.

Abstract:

In this paper, we study six different boundary control point mappings for cylindrical surface pasting and

compare the resulting pasted surfaces for C

0

join continuity. All six methods are algorithmically simple

with low computational costs, requiring minimal computation aside from surface evaluation. The results

demonstrate an order of magnitude quality improvement for some of our methods on a convex-only curved

base, however, as the complexity of the base surface increases all methods show similar performance.

1 INTRODUCTION

The ability to construct smooth composite surfaces

with multiple levels of control and adjustability, that

can be modified or animated at interactive rates, is

important to the modeling industry and to computer

aided geometric design research. Hierarchical model-

ing offers a conceptual basis for generating surfaces

with varying levels of detail. The surface building

blocks are typically tensor product B-spline surfaces,

preferred for their flexibility, compact representation

and adjustable levels of internal continuity. Tradi-

tional methods for adding local detail to tensor prod-

uct B-spline surfaces are knot insertion or degree rais-

ing, which increase complexity of the entire surface.

Instead, hierarchical modeling techniques such as hi-

erarchical B-splines (Forsey and Bartels, 1988), cer-

tain wavelet methods (Stollnitz et al., 1996), displace-

ment mapping (Foley et al., 1990) and surface pasting

(Bartels and Forsey, 1991; Barghiel et al., 1995) op-

erate locally.

Surface pasting was introduced by Bartels and

Forsey (Bartels and Forsey, 1991) to mimic the phys-

ical process of modeling with clay. It places a tensor

product B-spline surface called the feature, on top of

a tensor product B-spline surface hierarchy known as

the base, via a smart mapping of feature control points

onto the base. Surface pasting has a couple advan-

tages over other known hierarchical modeling tech-

niques — it offers lower computational costs, lower

storage requirements, easy repositioning, and flexibil-

ity of non-parametric alignments. At the same time,

because of the approximations involved in mapping a

feature onto its base, a pasted feature is not guaran-

teed to meet its base surface with any order of conti-

nuity at the join boundary.

Original surface pasting focused upon constructing

hierarchical surfaces comprised only of tensor prod-

uct patches. The standard algorithm then utilized the

linearity of patch boundary control points to minimize

join discontinuities.

Cylindrical surface pasting was introduced by

Mann and Yeung (Mann and Yeung, 2001) to extend

the scope of pasting to model surfaces that include

tensor product cylinders. In their work, the process

of pasting a cylindrical feature’s boundary onto a

base surface was accomplished using the same ap-

proximations used by standard surface pasting. How-

ever, a fundamental construction difference between

the closed curve boundary of a tensor product cylin-

der and the linear boundary of a tensor product patch

leads us to believe that we can do better than this di-

rect application.

In this paper, we propose and examine five alter-

native cylindrical pasting techniques that attempt to

account for the cylindrical feature’s structural dif-

ference. Previous work has been done to improve

pasted surface quality by incorporating approxima-

tion schemes such as quasi-interpolation (Conrad and

Mann, 2000), least-squares fittings (Leung and Mann,

2003) and Greville point interpolation (Siu and Mann,

2003); the first two of these extensions having only

108

Aggarwal S. and Mann S. (2006).

A COMPARISON OF CYLINDRICAL PASTING METHODS.

In Proceedings of the First International Conference on Computer Graphics Theory and Applications, pages 108-115

DOI: 10.5220/0001353901080115

Copyright

c

SciTePress

been examined in the context of patch pasting. In

the context of cylindrical pasting these implementa-

tions are expected to suffer from high evaluation costs

and/or significant algorithmic complexities. Our work

focuses upon determining a cylindrical pasting tech-

nique that is computationally inexpensive, simple to

implement, and that consistently gives the best com-

parative approximation of boundary continuity (i.e.,

C

0

continuity) between a pasted feature cylinder and

its underlying base surface. In a more general sense,

our work attempts to find a low-cost method of using

a given closed B-spline curve to approximate a dif-

ferent given closed curve, with minimal reproduction

error.

2 PASTING BASICS

We begin with an overview of surface pasting theory

since it forms the foundation for the work done in this

paper. Surface pasting combines a base surface and a

feature surface, each of which is in tensor product B-

spline form and defined over its own two-dimensional

domain. The basic idea is to adjust the feature’s con-

trol points in a manner that results in the boundary of

the pasted feature lying on or near the base surface,

while simultaneously ensuring that the shape of the

pasted feature reflects characteristics of both its orig-

inal form as well as of its base. To achieve this, the

pasting process involves the following steps:

1. The feature’s domain is embedded into its range

space. Tensor product construction ensures that

each feature control point P

i,j

has an associated

domain point at which it maximally influences the

feature surface. This domain point is referred to

as the Greville point (γ

i

,γ

j

)=γ

i,j

, where γ

i

is

the i

th

Greville abscissa in the u parametric di-

rection and γ

j

is the j

th

Greville abscissa in the

v direction. Taking the embedded Greville point

(γ

i,j

, 0) = Γ

i,j

in feature range space as a point of

origin, and using the feature’s corresponding para-

metric domain directions to define a set of basis

vectors, a local coordinate frame associated with

each P

i,j

is constructed. Now, each feature control

point can be expressed relative its local coordinate

frame in terms of a displacement from its origin

called the Greville displacement

d

i,j

.

2. The feature domain is mapped into the base domain

using an invertible transformation T . T determines

the relative size and placement of the feature sur-

face with respect to its base.

3. A base domain displacement representation of each

feature control point is created by expressing each

displacement

d

i,j

in terms of a local base coordi-

nate frame.

4. The feature control points are positioned relative

to the base surface using the local base coordinate

frame and the mapped displacement vector recom-

puted relative to this frame.

Note that surface pasting is only an approximation

technique. Rather than mapping every point of the

feature surface, it maps a small number of sample

sites, the feature Greville points. If the feature sur-

face is described by too few control points or a coarse

knot structure relative to its base, noticeable gaps at

the join boundary may appear in the composite sur-

face. In general, there is no guaranteed continuity be-

tween feature and base surfaces.

In the case of standard surface pasting, C

0

continu-

ity is approximated by defining the embedded feature

domain such that all boundary control points of the

feature coincide with their respective Greville points.

This ensures that the feature’s boundary control points

lie in the feature’s domain plane and that upon being

pasted they will lie directly on the base surface. Pro-

vided the base has low curvature relative to the spac-

ing between these points, a near C

0

join is achieved.

For further details on standard surface pasting, refer

to earlier works on the subject (Bartels and Forsey,

1991; Barghiel et al., 1995).

Cylindrical surface pasting integrates concepts

from parametric trimline-based blending to extend

surface pasting to handle a wider variety of modeling

situations. While standard pasting was designed only

to handle the pasting of one open surface atop another,

cylindrical pasting offers a method for connecting two

base surfaces smoothly using a tensor product cylin-

der as the feature surface. In this paper, we are only

concerned with pasting one end of a cylinder onto a

base tensor product surface.

To paste one end of a cylindrical feature onto

its base surface, the corresponding edge of the fea-

ture domain is mapped onto a paste curve in the

base domain. Determining the placement of con-

trol points such that the pasted cylinder’s boundary

closely matches the image of a user-defined paste

curve on the base surface is our challenge. The orig-

inal cylindrical pasting technique directly applied the

C

0

continuity approximation of standard surface past-

ing to the C

0

layer of a feature cylinder, i.e., each

boundary control point was located at its correspond-

ing Greville point. However, while zero displacement

control points reproduce the linear boundary of a ten-

sor product patch, placing the control points on the

closed curve boundary of a tensor product cylinder

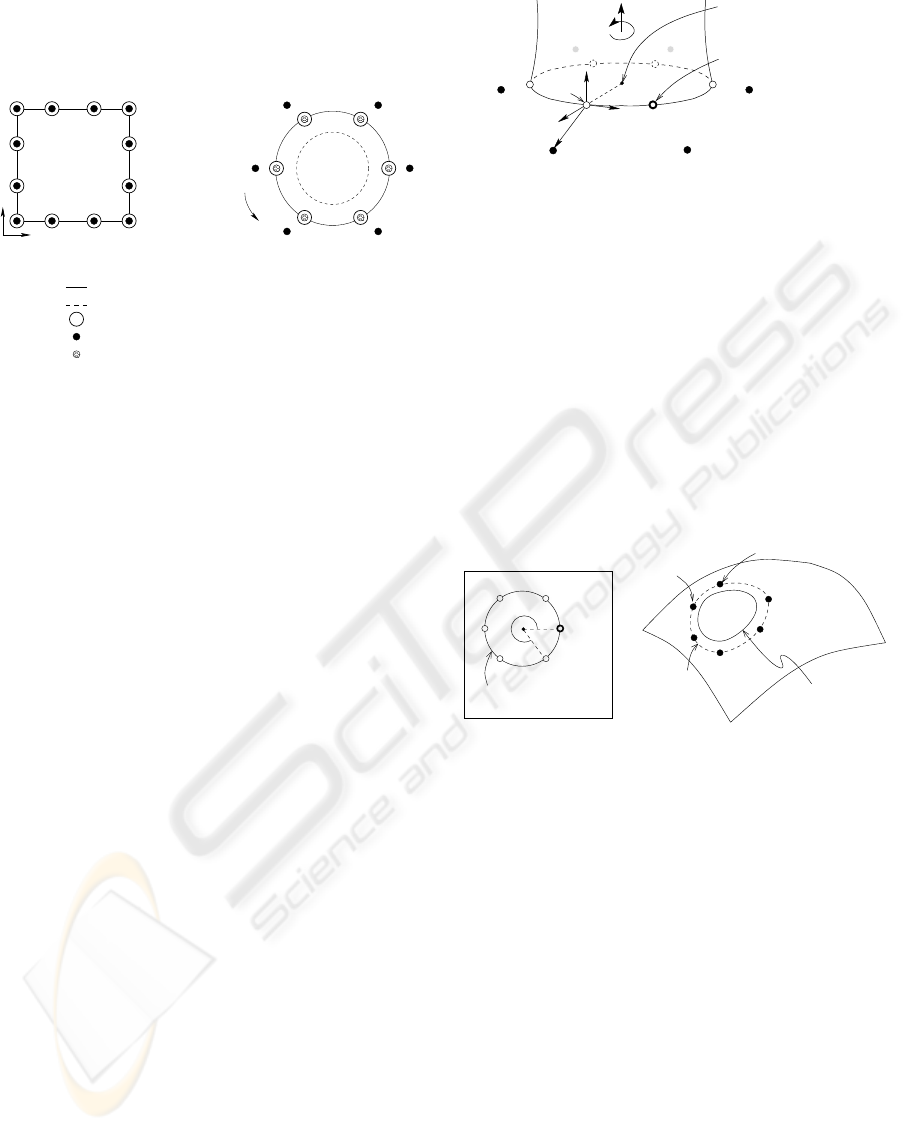

does not reproduce its boundary (Figure 1). Our work

explores alternate methods that have the potential of

producing better C

0

continuity between the pasted

cylinder and its underlying base. To maintain the

prototyping nature of pasting, the methods we have

designed have low computational costs, with a paste

not costing much more than one base surface evalua-

A COMPARISON OF CYLINDRICAL PASTING METHODS

109

tion per boundary control point. We have limited our

study to algorithmically simple techniques, as our in-

tent was also to establish a standard for pasting the

boundary of a cylindrical feature.

control points placed at a zero greville displacement

v

Cylindrical Pasting

v

u

shifted curve given by hashed control points

control points describing the original curve

image of original curve greville points

Patch Pasting

original curve given by filled control points

Figure 1: Greville displacement of boundary control points

set to zero.

3 BOUNDARY CONTINUITY IN

CYLINDRICAL PASTING

The results of pasting the boundary of a feature cylin-

der onto a base surface depend upon the feature-to-

base space mappings used. We have examined four

types of mappings (with minor variations on two of

them), which we present here. Our method discus-

sions assume that a given m × n tensor product fea-

ture cylinder C(u, v)=

M

i=0

N

j=0

P

i,j

N

i,j

(u, v),

as shown in Figure 2, is being pasted onto the sur-

face of a tensor product base B(u, v) along the cylin-

der’s L

0

: u = u

0

edge. The pasted feature boundary

is to be constructed as an approximation to a curve

on the base surface called the trim curve. The trim

curve is a mapping into base range space of a user-

defined circular paste curve given in the base domain.

Although a polynomial paste curve could have been

used, working with a circular representation allows

for simpler implementations while still providing use-

ful paste-quality comparisons (Aggarwal, 2004).

3.1 Greville Paste

The Greville Paste method is similar in concept to

the technique described in the original work on cylin-

drical pasting. It assumes that the feature cylinder’s

boundary control points and its corresponding sur-

face Greville points coincide, i.e., the boundary con-

trol points lie on the cylinder’s edge. As discussed in

§2, this assumption will inevitably result in a gap be-

tween the pasted cylinder boundary and the base sur-

face trim curve. Although this cylindrical pasting C

0

v

u

ˆ

F

y

j

C(γ

0,j

)

barycentre of

surface Greville points,

C(γ

0,0

)=C(γ

0,N −2

)

d

j

= a

ˆ

F

x

j

+ b

ˆ

F

y

j

+0

ˆ

F

z

j

surface Greville point,

C

c

P

0,j

L

0

control point, P

0,0

= P

0,N −2

ˆ

F

z

j

ˆ

F

x

j

Figure 2: Feature Cylinder C(u, v).

continuity approximation seems less than acceptable,

the Greville Paste method is useful as a comparative

base case method. In particular, one can expect its

application to yield three things:

1. a minimum cost metric: it requires only one surface

evaluation per boundary control point

2. a maximum acceptable error bound

3. a well-defined convergence: upon infinite refine-

ment the pasted control points will define the trim

curve exactly.

pasted feature boundary

paste curve

pasted L

0

control points

t

0

θ

j

γ

0,j

= t

j

Base Domain

trim curve

P

0,j

= B(γ

0,j

)

Base Surface B(u, v)

user-defined

Figure 3: Greville Paste.

To describe the Greville Paste process we use Fig-

ure 3. We start by embedding the feature cylinder’s

L

0

surface Greville points {C(γ

0,j

)}

N−3

j=0

into the

base domain. The embedded Greville points γ

0,j

are

obtained by a simple placement of each γ

0,j

onto a

corresponding paste point t

j

given on the paste curve

in the base domain’s uv-plane. The paste point t

0

is

chosen relative to the centre of the paste curve circle

at an angle of zero degrees to the u-parametric direc-

tion of the base domain, and the remaining t

j

s are

then determined in proportion to the v-interval of the

cylinder’s domain. Now, each C(γ

0,j

) can be mapped

onto the base surface by performing a de Boor surface

evaluation of the base at its embedded Greville point,

giving the pasted Greville point B(γ

0,j

). Placing the

feature cylinder’s L

0

control points at the pasted Gre-

ville points with zero displacement results in a set of

pasted control points P

0,j

= B(γ

0,j

), which are used

to describe the cylinder’s pasted boundary.

GRAPP 2006 - COMPUTER GRAPHICS THEORY AND APPLICATIONS

110

3.2 Control Point Paste

Control Point Paste is the first of three new cylin-

drical pasting techniques we devised, that attempt

to better account for the non-zero Greville displace-

ments of cylinder control points. Under Control Point

Paste, the embedded location of each cylinder control

point within the base domain is determined as the sum

of its associated embedded Greville point and trans-

formed Greville displacement vector. Implementation

specifics are illustrated in Figure 4.

points

s

j

x

pasted feature boundary

Base Surface B(u, v)

P

0,j

= B(p

j

)

trim curve

t

j

initial paste points

paste curve

s

j

y

Base Domain

p

j

= t

j

+ α(aˆs

x

j

+ bˆs

y

j

)

pasted L

0

control

Figure 4: Control Point Paste.

The first step is to determine the L

0

Greville dis-

placement vectors

d

j

(Figure 2). For each control

point P

0,j

,

d

j

is computed with respect to a unique

local coordinate frame F

j

, constructed such that

• F

O

j

, the origin of F

j

, is at its corresponding surface

Greville point: F

O

j

= C(γ

0,j

)

•

ˆ

F

x

j

is given by a unit normal along the differ-

ence vector between the surface Greville point and

the centre of the cylinder’s L

0

edge (C

c

, deter-

mined using Ceva’s Theorem (Wells, 1991)) as:

ˆ

F

x

j

=

F

O

j

−C

c

|F

O

j

−C

c

|

•

ˆ

F

y

j

is given by the normalized tangent to the cylin-

der’s boundary curve at the chosen origin, and is

along the v-parametric direction; this is also the di-

rectional derivative obtained by a de Boor evalua-

tion of the L

0

curve

•

ˆ

F

z

j

is given by a unit vector perpendicular to both

ˆ

F

x

j

and

ˆ

F

y

j

.

The coordinates of each control point in relation to

this local frame give the xyz components of the Gre-

ville displacements. By construction, the tensor prod-

uct cylinders we use are such that the control points

within each u-layer are coplanar, therefore, the z-

component is always zero.

The initial paste points t

j

on the base domain paste

curve are determined as they were for the Greville

Paste method. These are the locations at which we

would like our mapped L

0

surface Greville points to

lie. So, using our

d

j

s we compute a relative place-

ment of feature control points within the base domain

space. In particular,

ˆ

F

x

j

is mapped to ˆs

x

j

, the out direc-

tion at t

j

given by the 2D difference vector between t

j

and the circular paste curve’s centre point.

ˆ

F

y

j

maps

to ˆs

y

j

along the tangent to the paste curve at t

j

.To

account for the space change, a scale factor α, equal

to the ratio of paste curve to cylinder curve radii is

used. Applying the proportional displacement gives

the paste points p

j

within the base domain. De Boor

evaluations at the p

j

s produce the set of pasted control

points P

0,j

= B(p

j

) describing the pasted cylinder

boundary using Control Point Paste.

Applying a 3D displacement within a 2D domain

space results in pasted control points that lie on the

base surface; however, the resulting pasted cylinder

edge is unlikely to lie on the base unless the paste

region is planar. A potential way to avoid errors in-

troduced by 3D-in-2D computations is to account for

the feature’s L

0

Greville displacements in the 3D base

range space instead. This alternative is explored using

the next method.

3.3 Directional Displacement Paste

Directional Displacement Paste attempts to reduce C

0

gaps by computing the pasted control point locations

relative to points on the trim curve in the base range

space. The details, in context of Figure 5, follow.

s

j

= α(aˆs

x

j

+ bˆs

y

j

)

= ku + lv

P

0,j

= B(t

j

)+k∂u + l∂v

= B(t

j

)+αa∂ˆs

x

j

+ αb∂ˆs

y

j

points

pasted L

0

control

s

j

x

v

t

j

s

j

y

paste curve

u

initial paste points

trim curve

∂u

j

t

j

= B(t

j

)

∂v

j

pasted feature boundary

Base Domain Base Surface B(u, v)

Figure 5: Directional Displacement Paste (Local).

Evaluating the base surface at points t

j

generates a

set of points t

j

lying on the trim curve. Ideally, the

pasted cylinder boundary will be placed exactly on

top of this trim curve. This suggests that the pasted

cylinder edge should be constructed such that all the

trim points t

j

lie on it. By definition, surface Gre-

ville points lie on the surface they describe. There-

fore, Directional Displacement Paste maps the L

0

sur-

face Greville points onto the trim points. The cylin-

der’s pasted L

0

control points are then computed by

placing them relative to these pasted Greville point

A COMPARISON OF CYLINDRICAL PASTING METHODS

111

locations. The displacements are determined using

the L

0

Greville displacement vectors

d

j

(§3.2), which

are mapped through the base domain (s

j

) onto the

base surface. A point-vector addition of transformed

feature-to-base space L

0

Greville points and Greville

displacements gives the pasted cylinder’s boundary

control points.

A potentially useful modification to Directional

Displacement Paste came about from observing the

performance of the above described method on ini-

tial test data. Over a hump-like paste region, the

high surface curvature at the trim points displaced

the control points in a manner that pushed the pasted

feature boundary well below the base surface trim

curve. Therefore, we examined the pasting behavior

when the displacements are computed using a simple

approximation of average surface curvature over the

paste region instead of local curvature.

To incorporate an average surface curvature, we

perform a mapping of the paste curve’s centre point

onto the base, and compute base surface directional

derivatives at it. The pasted boundary control point

locations are then determined by applying the corre-

sponding Greville displacement vector’s components

along the centre point’s uv-directional vectors. The

local directional derivatives at each t

j

no longer need

to be computed. We refer to our original technique

as Local Directional Displacement and the modified

method as Average Directional Displacement.

3.4 Relative Displacement Paste

Relative Displacement Paste was motivated by Direc-

tional Displacement Paste. It too attempts to compute

the L

0

pasted cylinder control points by accounting

for Greville displacements in the base range space.

The difference is in how the displacement frame is

constructed at each mapped cylinder Greville point on

the base. Directional Displacement mapped each fea-

ture surface displacement frame F

j

onto the base sur-

face via the 2D base domain space (Figure 5). How-

ever, this mapping does not maintain the relation-

ship of displacement frame directions to correspond-

ing feature boundary points when the shape of a cylin-

der’s L

0

boundary curve distorts with pasting. Rela-

tive Displacement Paste maps the feature surface dis-

placement frame directly onto the base surface so as

to maintain the original F

j

relationships to the feature

boundary.

We describe this method in relation to Figure 6.

For all j = {0,...,N − 3}, F

j

,

d

j

, γ

0,j

= t

j

, and

t

j

= B(t

j

) are computed exactly as for Directional

Displacement Paste (§3.3). The pasting displacement

frame S

j

at each t

j

is then constructed such that

•

ˆ

S

x

j

is the unit difference vector between t

j

and the

new barycentre of pasted Greville points;

barycentre of

pasted L

0

control

points

pasted Greville

points

paste curve

γ

0,j

= t

j

ˆ

S

y

j

ˆ

S

x

j

pasted feature boundary

trim curve

Base Surface B(u, v)Base Domain

t

j

= B(t

j

)

P

0,j

= B(t

j

)+βa

ˆ

S

x

j

+ βb

ˆ

S

y

j

Figure 6: Relative Displacement Paste (Average).

•

ˆ

S

y

j

is the normalized tangent to the trim curve at t

j

,

given by the difference of slopes between t

j

and its

two neighboring pasted Greville points.

The local frame directions

ˆ

F

x

j

and

ˆ

F

y

j

are now

mapped to

ˆ

S

x

j

and

ˆ

S

y

j

respectively. The xy compo-

nents of

d

j

, i.e., a and b are applied along

ˆ

S

x

j

and

ˆ

S

y

j

respectively to give a control point placement relative

t

j

. A change of space scale factor β is applied to the

displacement vector to account for the transformation

from feature surface space to base surface space. β

is computed as the ratio of the average distance be-

tween original L

0

surface Greville points and their

barycentre to the average distance between pasted sur-

face Greville points and their barycentre.

Two variations of Relative Displacement Paste

were examined — Average Relative Displacement

uses the barycentre of all {t

j

}

N−3

j=0

to compute

ˆ

S

x

j

,

whereas Local Relative Displacement uses a local

barycentre given by t

j

and its two neighboring pasted

Greville points. The rationale for the local method be-

ing that when the curvature of a base surface has more

noticeable variations over the paste region boundary,

locally affected

ˆ

S

x

j

s may offer a better placement of

the control points.

4 COMPUTATIONAL ANALYSIS

The most significant computational cost in surface

pasting is the number of base surface evaluations that

need to be performed to position the feature’s pasted

control points. One surface position evaluation per

L

0

cylinder control point is the minimum C

0

require-

ment for any cylindrical pasting method. An approxi-

mation improvement technique such as knot insertion

rapidly becomes unacceptable as it doubles the num-

ber of control points at each level of refinement, in-

creasing evaluation costs exponentially. The methods

we have described in this paper attempt to improve a

feature cylinder’s pasted boundary approximation of

GRAPP 2006 - COMPUTER GRAPHICS THEORY AND APPLICATIONS

112

the trim curve for relatively small increases in cost. A

comparative summary of pasting costs per boundary

control point is given in Table 1 (refer to (Aggarwal,

2004) for a detailed analysis). It may be noted that

the cost of pasting a control point using any of our

methods is at most half as expensive as doubling the

number of control points using knot insertion to im-

prove the pasted join accuracy. To keep the relative

costs in perspective, we note that a de Boor position-

only surface evaluation for a bicubic tensor product

surface requires 30 affine combinations, a position-

with-derivatives evaluation takes 37 affine combina-

tions, and a vector difference of a pair of points is one

affine combination.

5 ERROR BOUNDS

To provide a bound on how fast the error in C

0

con-

tinuity is expected to converge with feature cylinder

refinement, we use the concept of linear reproduc-

tion. Given a polynomial function F and its approx-

imation P , a Taylor series expansion gives the error

as

∞

i=0

F

(i)

(ξ)−P

(i)

(ξ)

i!

h

i

. An interpolation method

is said to have linear precision if F (ξ)=P (ξ)

and F

(ξ)=P

(ξ). In this case, the first two

terms of the Taylor series cancel, leaving an error of

∞

i=2

F

(i)

(ξ)−P

(i)

(ξ)

i!

h

i

= O(h

2

), where h is the dis-

tance between samples. Standard surface pasting is

expected to have this property, as was verified empir-

ically by Conrad (Conrad, 1999).

Further mathematical analysis, as given in (Aggar-

wal, 2004), enables us to determine whether linear re-

production also holds for the cylindrical surface past-

ing methods described in this paper. Essentially, for

each scheme, we examine whether the pasted cylin-

der’s boundary is expected to be identical to its trim

curve on a linear base surface. The results of our the-

oretical analysis are summarized in Table 1.

6 RESULTS

The empirical error between the feature cylinder’s

pasted boundary and the base surface trim curve of-

fers an important comparison metric for evaluation of

the feature-on-base boundary quality. For our error

analysis, we examined the maximum position differ-

ence between these two closed curves, and the pro-

gressive refinement ratio of their differences describ-

ing the rate of error convergence. Our cylindrical

boundary pasting schemes were evaluated for three

different base surfaces of increasing complexity — a

planar base, a simple curved base, and a base with an

inflection. All the surfaces used (bases and feature

cylinder) were bicubic surfaces. We chose circular

paste curves defined by a center and radius in the base

domain. Also, our feature was constructed to have a

close-to-circular L

0

boundary.

C

0

continuity sampling information was generated

by sampling the pasted feature boundary at 10 dif-

ferent positions for each non-overlapping domain in-

terval in the cylinder’s v-parametric direction. These

points were compared against samples on the base

trim curve taken at points associated with each v-

parameter value of the cylinder domain. With each

level of feature refinement, the number of samples

taken was doubled.

Pasting the cylinder’s boundary onto a planar base

patch yielded a close to zero error for all methods ex-

cept Greville Paste. This is in keeping with the theo-

retical expectation of linear reproduction for all meth-

ods other than Greville Paste.

Pasting onto a curved, convex-only, bicubic base

that did not have any regions of negative Gaussian

curvature, gave results supporting quadratic error con-

vergence for all methods including Greville Paste. In

this case, Average Directional Displacement and both

Relative Displacement Paste methods were found to

perform a magnitude better than Greville Paste.

For our final test case, we pasted the boundary of

our feature cylinder onto a curved bicubic base over

a region of negative Gaussian curvature. Results are

given in Table 2 (Figure 7). The Relative Displace-

ment Paste methods appear to perform an order of

magnitude better when the feature knot structure is

approximately as coarse as that of the base. However,

one level of cylinder refinement improves Greville

Paste to be comparable to the Relative Displacement

techniques. The minor error reductions offered by the

alternatives to Greville Paste are clearly offset by their

extra computational costs. Further, even-though Gre-

ville Paste doesn’t have the linear reproduction prop-

erty, all our results indicate that it has O(h

2

) error

convergence. Therefore, it appears that as the com-

plexity of the base surface increases, the C

0

pasting

results obtained using Greville Paste are comparable

to all our other cylindrical pasting approaches.

7 CONCLUSION

In this paper, we have examined six different con-

trol point placements for describing the pasted cylin-

der boundary – Greville Paste, Control Point Paste,

Local Domain Displacement, Average Domain Dis-

placement, Local Relative Displacement, and Aver-

age Relative Displacement. Greville Paste was essen-

tially a direct application of the standard surface past-

ing algorithm to cylindrical pasting.

Greville Paste seemed intuitively inadequate for

A COMPARISON OF CYLINDRICAL PASTING METHODS

113

Table 1: Costs and linear reproducibility associated with pasting a m × 3 cylinder onto a bicubic patch. N is the number of

control points.

Method Affine combinations Linear reproduction satisfied

per control point

Greville Paste 30 no

Control Point Paste 40 yes

Local Directional Displacement 47 yes

Average Directional Displacement 40+

37

N−3

,N ≥ 9 yes

Local Relative Displacement 44 not necessarily

Average Relative Displacement 43 yes

pasting cylinders because its placement of pasted con-

trol points onto the desired join boundary could never

reproduce the corresponding closed curve. Based

upon the theory used in constructing our methods, we

expected that Local Domain Displacement would re-

sult in the most accurate C

0

paste for any base sur-

face irrespective of its complexity. Instead, an em-

pirical analysis of the error between the pasted cylin-

der boundaries and the desired trim curve indicates

that the less-intuitive Relative Displacement Paste

methods most consistently produce the best quality

join. However, the relative improvement over Gre-

ville Paste drops rapidly with every level of cylinder

refinement when pasting onto a complex base surface.

It comes as a surprise that, in general, Greville

Paste does as well as any of our other cylindrical

boundary pasting methods. Our results further con-

firm that the best possible error convergence offered

by the methods explored is quadratic in all cases.

Therefore, the original standard pasting technique is

a reasonable standard not only for patches, but also

for cylinders.

8 FUTURE WORK

Our work focused on establishing a simple and low-

cost cylindrical boundary pasting standard. It is rec-

ommended that another study be performed to as-

sess the results of cylindrical boundary pasting using

methods such as quasi-interpolation, least-squares fit-

ting, and Greville point interpolation. Although the

initial computation costs are expected to be notably

high for these methods, they may be effectively com-

pensated for by low re-evaluation costs when pasting

over the same region. The algorithmic complexity of

these alternate methods may still be a concern.

REFERENCES

Aggarwal, S. (2004). Comparison of cylindrical boundary

pasting methods. Master’s thesis, University of Wa-

terloo, Waterloo, Ontario, Canada N2L 3G1.

Barghiel, C., Bartels, R., and Forsey, D. (1995). Past-

ing spline surfaces. In Daehlen, M., Lyche, T., and

Schumaker, L., editors, Mathematical Methods for

Curves and Surfaces, pages 31–40. Vanderbilt Univer-

sity Press.

Bartels, R. and Forsey, D. (1991). Spline overlay surfaces.

Technical Report CS-92-08, University of Waterloo,

Waterloo, Ontario, Canada N2L 3G1.

Conrad, B. (1999). Better pasting through quasi-

interpolation. Master’s thesis, University of Waterloo,

Waterloo, Ontario, Canada N2L 3G1.

Conrad, B. and Mann, S. (2000). Better pasting via quasi-

interpolation. In Laurent, P.-J., Sablonni

`

ere, P., and

Schumaker, L., editors, Curve and Surface Design,

pages 27–36. Vanderbilt University Press.

Foley, J., vanDam, A., Feiner, S., and Hughes, J.

(1990). Computer Graphics Principles and Practice.

Addison-Wesley, second edition.

Forsey, D. and Bartels, R. (1988). Hierarchical B-Spline

refinement. In Computer Graphics (SIGGRAPH ’88),

volume 22(4), pages 205–212.

Leung, R. and Mann, S. (2003). Distortion minimization

and continuity preservation in surface pasting. In

Graphics Interface, pages 193–200.

Mann, S. and Yeung, T. (2001). Cylindrical surface pasting.

In Geometric Modeling, pages 233–248. Springer-

Wein.

Siu, S. and Mann, S. (2003). Computer aided ferret de-

sign. In Geometric Modeling and Graphics, pages

195–200. IEEE Computer Society.

Stollnitz, E., DeRose, T., and Salesin, D. (1996). Wavelets

for Computer Graphics: Theory and Applications.

Morgan Kaufmann, San Francisco.

Wells, D. (1991). The Penguin Dictionary of Curious and

Interesting Geometry. Penguin.

GRAPP 2006 - COMPUTER GRAPHICS THEORY AND APPLICATIONS

114

Table 2: Experimental errors from pasting a feature cylinder’s boundary onto a bicubic base over a region of negative Gaussian

curvature. The ratio in row i is the ratio of Max

i

to Max

i−1

for the corresponding method.

Greville Paste Control Point Paste Local Directional Displacement

Refinement Max Ratio Max Ratio Max Ratio

0 0.185416 na 0.067727 na 0.131738 na

1 0.049609 3.74 0.023591 2.87 0.037600 3.50

2 0.012585 3.94 0.006567 3.59 0.009219 4.08

3 0.003157 3.99 0.001600 4.10 0.002005 4.60

4 0.000790 4.00 0.000359 4.46 0.000473 4.23

5 0.000198 4.00 0.000089 4.05 0.000114 4.15

Avg Directional Displacement Local Relative Displacement Avg Relative Displacement

Refinement Max Ratio Max Ratio Max Ratio

0 0.123581 na 0.037246 na 0.039474 na

1 0.035348 3.50 0.014900 2.50 0.018923 2.09

2 0.008783 4.02 0.005125 2.91 0.004766 3.97

3 0.001984 4.43 0.001332 3.85 0.001232 3.87

4 0.000471 4.21 0.000299 4.45 0.000276 4.47

5 0.000113 4.18 0.000073 4.10 0.000067 4.10

(a) Greville Paste (b) Control Point Paste (c) Local Directional Displacement

(d) Average Directional Displacement (e) Local Relative Displacement (f) Average Relative Displacement

Figure 7: Pasting onto a curved bicubic base over a region of negative Gaussian curvature.

A COMPARISON OF CYLINDRICAL PASTING METHODS

115