SIMULATION MODELLING OF IRON ORE PRODUCTION

SYSTEM AND QUALITY MANAGEMENT

J. E. Everett

Faculty of Economics and Commerce, University of Western Australia, Nedlands, Western Australia

Keywords: Decision Support Systems, Simulation, Operational logistics, Modelling methodologies.

Abstract: Iron ore is railed several hundred kilometres from open-cut mines inland, to port facilities, then processed to

lump and fines products, blended and the lump product re-screened ready for shipment, mainly to Asia.

Customers use the ore as principal feed in steel production. Increasing demand and price, especially from

China, requires expansion of existing mines and planning of new operations. Expansion planning of the

operational logistics, maintaining acceptable product quality, has been greatly helped by simulation

modelling described in this paper.

1 INTRODUCTION

Ore from open-cut mines in the Pilbara region of

Western Australia is railed a few hundred kilometres

to a port where the ore is processed and blended for

shipment, mainly to Asia. Customers use the ore as

feed in steel production. Figure 1 shows a simplified

ore flow, although many operational variations exist.

Increased iron ore demand has required a review

of capacity. To increase tonnage safely, at minimum

cost and acceptable quality, processes need to be

upgraded, existing mines and infrastructure

expanded, and new mines brought on line.

Assessment requires informed choices between

operation and infrastructure development options

that differ in capital and operating costs. Many

alternatives exist for mining, ore processing,

stockpiling, railing and ship loading operations.

Expansion options must be assessed for their

effect on product quality. Customers assess quality

by cargo grade, and inter-cargo grade variability. As

well as iron, several impurities, principally

phosphorus, silica, and alumina are important.

Simulation models of expansion options enable

mining and handling alternatives to be compared.

They consider tonnage capabilities and the variation

in product quality, a vector of iron, phosphorus,

silica, and alumina grades. These grades shows

complex serial and cross correlations, so synthetic

data cannot readily be constructed. Production was

simulated from historic data of geologically similar

ore, statistically adjusted to match potential

operations.

The models were written in Excel™, with Visual

Basic (VBA) macros, making full use of the

graphical capabilities. Simulations described here

have been used to evaluate expansion and

development options. The results have helped assess

the effect on product quality for many processing

and equipment options for capacity expansion.

2 THE PRODUCTION SYSTEM

The Pilbara produces about 200 million tones of iron

ore per year, sold as two product types; lump (6 to

31mm) and fines (under 6mm). Increased demand

for iron ore, mainly by China, requires producers to

increase tonnage, by upgrading existing mines and

opening new mines. Assessment requires informed

choices between alternative modes of operation and

development, which differ greatly in expected

capital and operating costs. Reviewing the many

options that exist is complex, and greatly aided by

simulation. This paper describes simulations carried

out to assess product grade quality for potential

expansion developments. Simulations were based on

proposed infrastructure and capacity options

identified from engineering studies. They were set

up so the impact of changes to operating practices on

product grade quality could also be assessed.

300

E. Everett J. (2006).

SIMULATION MODELLING OF IRON ORE PRODUCTION SYSTEM AND QUALITY MANAGEMENT.

In Proceedings of the Eighth International Conference on Enterprise Information Systems - AIDSS, pages 300-303

DOI: 10.5220/0002443203000303

Copyright

c

SciTePress

2.1 Production Flow

At the mine, monthly mine plans are designed for

cost efficient use of the resource. Ore blocks are

blasted and assigned into floor stocks of consistent

geology and composition using analysis from

samples taken during the drilling of the blast holes.

Each day, ore to mine is selected from floor stocks,

based on target grade, current deviation from target,

and cost efficient mine development. In our

example, ore from four mines goes 400 kilometres to

the port to be crushed, screened into lump and fines

products and blended by stacking onto 150 kilotonne

stockpiles. Ore from completed stockpiles is

reclaimed, loaded onto ships, and transported to

customers. Everett (1996, 2001) discusses iron ore

quality control. Kamperman et al (2002) describe

application of the methods to a Pilbara operation.

2.2 The Cost of Quality

The objective is to deliver the required ore tonnage,

at minimum total cost and of quality acceptable to

the customer. Quality is based on iron content and

the percentage of impurities such as phosphorus,

silica and alumina. There are two key criteria: cargo

grade and inter-cargo variability. Customers require

each shipment to be close to target composition.

Agreed tolerances are used to guide decisions,

throughout the production process. Excessive inter-

cargo variation potentially affects price and sales

tonnages. This cost, containing an element of risk, is

hard to evaluate quantitatively. Blending and re-

handling to improve uniformity adds to operating

cost, a potential trade off against quality.

3 SIMULATION METHODS

Expansion options were developed, for alternative

production and handling concepts from mine to ship

loading. Their quality implications were evaluated

by simulation. Long-term grade variability (> one

month) is controlled by the mine plan. Short-term

inter-cargo variability is controlled by the

operational process, and is the assessment metric.

3.1 Data Preparation

Production data show complex serial and cross

correlation (for iron, silica, alumina and phosphorus)

that is ascribed to the orderly mining of blast blocks

and the daily decisions to control grade.

Historic data were used to generate the required

input data for modelling future mining production in

the simulations, so that the existing serial and cross

correlations were maintained. However, historic data

contained long-term variation that could mask any

incremental improvements identified in the

simulations; planned new mines lacked historic data,

and had expected means grades differing from

existing mines.

Synthetic data for new mines were created from

existing mines of similar geology. Long-term trends

were filtered out using Fourier analysis. Means and

standard deviations were then adjusted to create

synthetic data matching planned production. The

data preparation model allowed the standard

deviation to be reduced, simulating increased effort

within the mine to control short-term variability,

through such activities as selective mining and pre-

crusher stockpiling.

Figure 1: A Typical Iron Ore Production System.

SIMULATION MODELLING OF IRON ORE PRODUCTION SYSTEM AND QUALITY MANAGEMENT

301

4 SIMULATION MODELS

Dedicated simulation packages need specialists to

run and interpret the results, usually with cost and

licensing restrictions. They represent a barrier to

practitioners who must learn a new package if they

are to run the models independently.

Developing the system in Excel

TM

allowed

mining engineers and operators to explore

alternative policies and scenarios, using domain

knowledge unavailable to the designer of the

simulation model. Graphing and analysing of results

was built in, so minimal ongoing assistance was

required from the simulation provider.

Constructing a simulation model in a spreadsheet

workbook, run by VBA macros, is as easy as in a

dedicated simulation package. The spreadsheet’s

data input and output reporting and graphing

capabilities are fuller than are generally found in a

simulation package. The industry user, familiar with

spreadsheets and their potential, can suggest

improvements to the simulation model. The VBA

macro coding is hidden from the practitioner, who

can use it by means of inbuilt buttons and menus.

The simulation model comprised three VBA

macros: reading in parameters to set up the

simulation; running the simulation the required

number of time periods, and finally using Excel’s

statistical and graphing power to report the results.

The models were used to study the effects of

controllable variables (such as stockpile sizes and

stockpiling methods) and uncontrollable variables

(such as cargo sizes). The worksheets specified

parameters and policy choices, displayed simulation

progress, and reported and graphed a performance

summary for any simulation run. For reproducible

results, a year or more of production had to be

simulated.

The simulation was time-sliced (at six hour

intervals) rather than event-driven. In each time

interval, ore is mined and trains loaded, while at the

port trains arrive and are unloaded, crushed and

stacked to stockpiles, ships can arrive, commence

being loaded from an available stockpile (or wait if

none are available) continue being loaded, and

depart when full. Simulations were run to explore

the effect of steadily changing the values of a

particular parameter, or a set of parameters.

Separate workbook models were written to

simulate the Mine and Port operations. They could

be run individually, or be run together by a Master

model, for a sequence of scenarios. Space limitation

limits discussion here to the Port model.

5 PORT MODEL EXAMPLE

The Port model has six worksheets, simulating stack

and reclaim of ore from train to ship.

The “Input Rakes” sheet imports a set of 2,048

train rakes from the “Output” sheet of the Mine

model file. Incoming trains are from either of two

pits that have systematically different mean grade, to

reflect planned trends in mining.

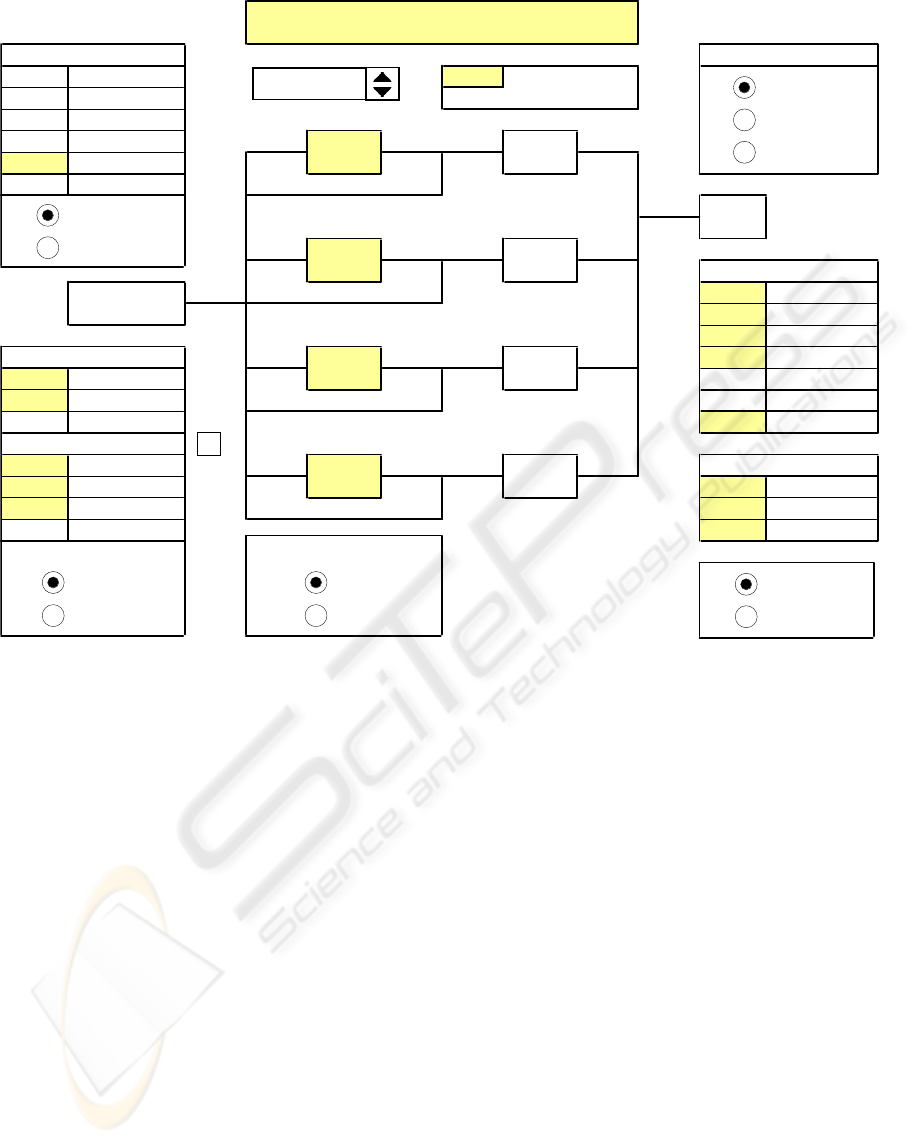

Figure 2 shows the Port “Specify” sheet. Settable

parameters are in yellow cells. In the example, the

ore arrives at 40 million tonnes per year, with a train

every six hours (generated in the Mine model). This

model explores a plan of up to four ship berths, with

each berth fed from a stockpile of nominated

capacity. Stockpiles can be fully Blended in Blended

Out (BIBO) or built First In First Out (FIFO).

Stockpile sizes are here set 240kt and 360kt. Train

and ship arrivals be equally spaced or random. The

cargo capacities distribution is specified. Each

incoming train can be direct loaded (with chosen

probability) to a ship, or sent to a stockpile, chosen

by a weighted composite of four criteria.

A “Progress” worksheet allows the system to be

tracked, at a chosen multiple of 6 hours, for a chosen

time range. This is useful for debugging, and also for

better understanding the system behaviour.

For each mineral, the “Cargoes” worksheet

graphs the cargo compositions varying around

target. For example, Figure 2 shows that the

“Process Capability” (the Tolerance divided by

twice the Standard Deviation) for Fe is 1.15.

The “Audit” worksheet reports the full simulation

history, with product flows and stockpile and ship

berth states for each time interval. Tonnage aspects

of the simulation history are plotted to aid

interpretation, and validate the parameter values

selected on a particular run.

58.0

58.2

58.4

58.6

58.8

59.0

0 120 240

+/- Ship Tolerance

95% Confidence

Days

Fe Cargoes

Process Capability=1.15 (2% Out of Tolerance)

Figure 2: The “Cargoes” Report.

ICEIS 2006 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

302

6 CONCLUSIONS

As an example of the results, one simulation run

showed that to ship ore of acceptable quality at the

planned production rate required

1) 10% reduction of Mine short-term variability by

selective mining or pre-crusher stockpiling.

2) 30% priority to the use of Intelligent Stacking.

3) More accurate train composition estimates.

This solution was compared to installing blending

stockpiles at the mine and a cost/quality risk analysis

carried out. Without the simulation studies, many

capacity-related options such as this would have

been virtually impossible to evaluate.

The simulation models described are a valuable

aid to examine the effect on product chemical

quality of alternative potential development options,

to meet the potential capacity expansion required for

the rapidly increasing iron ore market.

The particular benefit in using Excel™ based

VBA simulation models is that it provides a familiar

mode of working for the company personnel,

enabling them efficiently to contribute domain

knowledge during running of the simulations,

without the assistance of the simulation developer.

In addition, the use of ExcelTM allows easy

interrogation of data and generation of reports.

REFERENCES

Everett, J. E., 1996, Iron ore handling procedures enhance

export quality.

Interfaces, 26/6, 82-94.

Everett J.E., 2001, Iron ore production scheduling to

improve product quality.

European Journal of

Operational Research,

129, 355-361.

Kamperman, M., Howard, T. and Everett, J.E., (2002),

Controlling product quality at high production rates.

Proceedings of the Iron Ore 2002 Conference, Perth,

Western Australia, 9-11 September 2002, ed. Holmes,

R., Australasian Inst. of Mining and Metallurgy:

Carlton, Victoria, ISBN 1 875776 94 X, 255-260.

Figure 3: The Port Model “Specify” Worksheet.

1

2048 Rakes, 12kt

890 Trains

224 Da

y

s 1 E

q

ual Interval

40.3 Max Mt/

y

ear

40.0 Mt/

y

ear

99% Train Slots

1

1 Random

0% 36 kt

0% 72 kt

0% 108 kt

0% 144 kt

70% Correct 100% 180 kt

30% Nei

g

hbou

r

Mean 180 kt

0% Random 96 hrs to 1st Car

g

o

FALSE

40% Low Tonna

g

e

30% Mine 0 Interval

(

hrs

)

30% Grade Estimate 0.00 Start

(

da

y)

0% Random 0.00 End

(

da

y)

1

11

As Stress BIBO 1 Track Stress

Stock

p

iles Shi

p

berths

Berth 2

240 kt

Shi

p

Car

g

oes

Shi

p

Arrival

Steady Cargo

Cargos

RandomBerth 1

Track GradeAs Grade

Show Train Rakes

Allocation Wei

g

ht

Track Pro

g

ress

LIFO

Build Stock

p

iles

240 kt Berth 4

360 kt

Run 1. 25% Direct Load

360 kt

Rake Grade Estimate

Trains

Equal Spaced

Direct Loadin

g

(

when

p

ossible

)

Berth 3

Ore Arrival

Menu

SIMULATION MODELLING OF IRON ORE PRODUCTION SYSTEM AND QUALITY MANAGEMENT

303