ELIMINATION OF TIME DEPENDENCE OF INFORMATION

VALIDITY BY APPLICATION OF RFID TECHNOLOGY

Vladimir Modrak, Viaceslav Moskvic

Faculty of Manufactuirng Technologies, Technical University of Kosice, Bayerova 1,08001 Presov,Slovakia

Keywords: Information time dependence, ERP, MES, RFID technology.

Abstract: Following article deals with certain aspects of data acquisition for MRP, ERP and MES type of information

systems from a shop floor level. Problems of time dependence of data validity are discussed and method of

their elimination by application of radio frequency identification technology (RFID) is suggested.

1 INTRODUCTION

Since introduction of information systems for general

management of processes at manufacturing companies,

major obstacle on the way to their optimal performance

was a lack of reliable and on time information. Shop floor

level information was inaccessible directly for information

systems and until nowadays inserted into the system by

intermediary subject (e.g. human operator). Development

of radio frequency identification technology or RFID for

short, for the first time makes processes at shop floor

visible for these systems. Following article will explain

the major hindrances information system face during

management of company processes. It will point out the

drawbacks of current information acquisition for MRP,

ERP and MES types of information systems. Then it will

propose a way in which time dependence of information

validity and amount could be eliminated by use of RFID

technology. Subsequently implementation problems,

benefits and goals of RFID technology use are discussed.

Finally future development and application of RFID are

indicated.

2 BACKGROUND OF RESEARCH

Product innovation is the greatest driver of company

growth. Product proliferation and customization

leads to greater fulfillment of customer demands and

therefore the growth of market share. On the other

hand customization of products adds greater

complexity to product identification and company

logistics by increasing assortment (Viswanadham,

2002).

Competitive market environment force

companies to cut their costs and thus reduce their

prices. For last decade main philosophy for cost

reduction for OEMs was a lean manufacturing

(Taylor & Brunt, 2000).

The key to lean

manufacturing is to compress time by eliminating

waste and thus continually improve processes inside

the company (Czarnecki & Lloyd, 2000) .

Waste can

be

defined as any element of production that only

increase cost without adding value the customer is

willing to purchase (Ohno, 1988).

There are seven basic wastes in manufacturing

process:

• overproduction

• excess inventory

• idle machine or operator time

• manipulation

• non-value added material flow

• defects

• extra processing

To eliminate excess inventory, manipulation and

non-value added processes just-in-time (JIT)

deliveries were applied in conjunction with lean

manufacturing philosophy. In reality JIT deliveries

were conducted in small batches several times a day.

Basically JIT system moved a stock from OEMs to

their suppliers. Consequently, to resolve the

problem, just-in-sequence (JIS) system was

introduced (ALTA/AS Whitepaper, 2003).

Philosophy behind just-in-sequence supply means

deliveries of the products directly to the assembly

line of OEM not only at exact amount

130

Modrak V. and Moskvic V. (2006).

ELIMINATION OF TIME DEPENDENCE OF INFORMATION VALIDITY BY APPLICATION OF RFID TECHNOLOGY.

In Proceedings of the Eighth International Conference on Enterprise Information Systems - DISI, pages 130-135

DOI: 10.5220/0002450001300135

Copyright

c

SciTePress

and time (like in JIT) but also at right configuration

and right order - sequence. If part or module is not

delivered in right sequence and time, it cannot be

assembled on the individually configured product,

coming to the assembly line in certain sequence and

therefore it will cause an assembly line to stop.

Interruption of the assembly process will induce a

considerable financial loss not only for OEM but

also for all elements in supply chain [6]. This means

that 100% on time, right sequenced deliveries for

elimination of excess inventory; manipulation and

non-value processes should have a highest priority

for the management of OEM (ALTA/AS

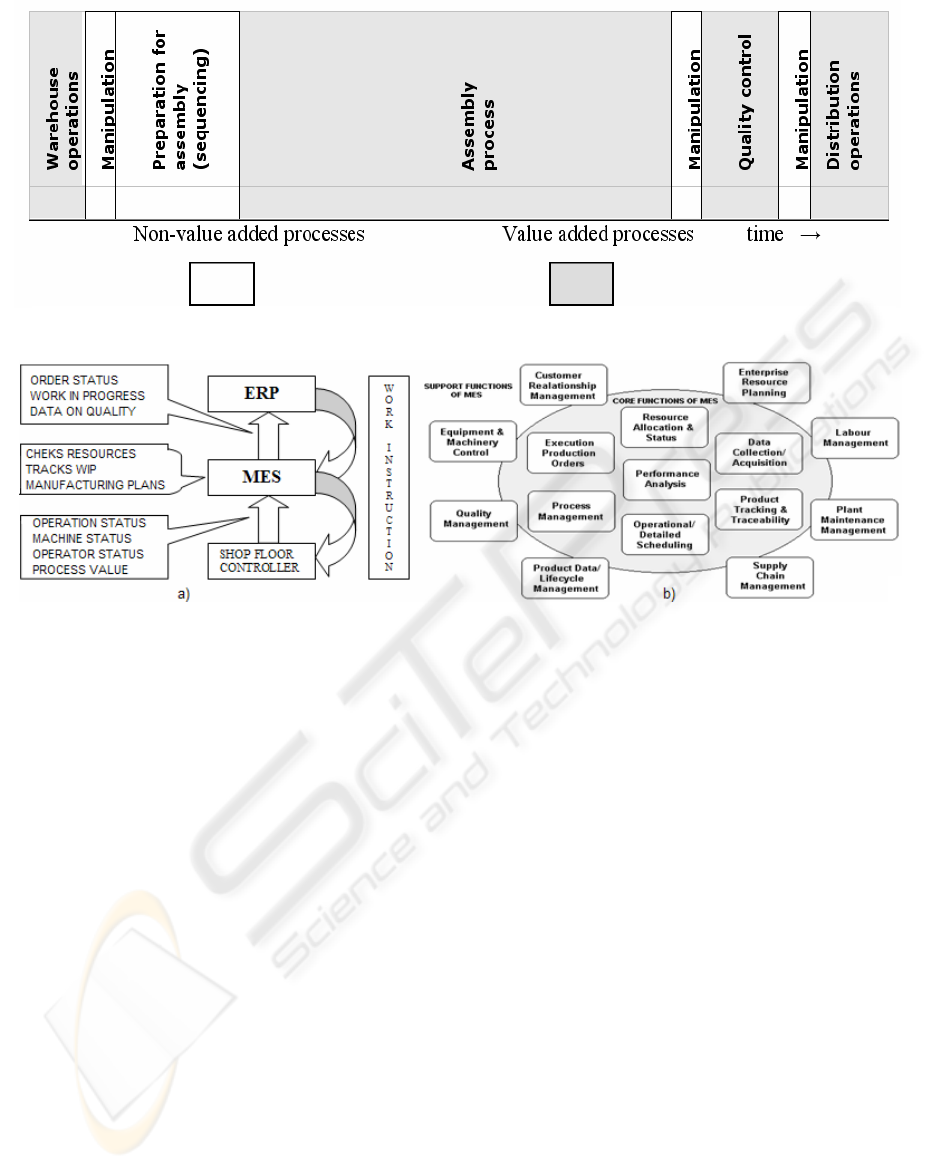

Whitepaper, 2003). Figure 1 shows the basic

processes of OEM.

As it is evident the most time consuming non-

value added process is preparation of delivered

products for assembly process that rarely means

more then placing them in right order – sequencing.

Management of OEM has two possibilities to

eliminate non-value added processes. First is to

apply philosophy of reengineering and change the

structure of processes (Silva, Ramos

&Vilarinho,2003). Effective and global,

process

restructuring is very time consuming and is usually

associated with the considerable investment into

the

infrastructure (Kumar, 1996). Second one is to

improve the performance of company’s information

system trough which processes are managed

(Lawless, 2000). OEMs usually use Material

Requirement Planning/ Manufacturing Resource

Planning (MRP/MRP II), Enterprise Resource

Planning (ERP) and Manufacturing Execution

System (MES) type of systems for general

management of the company processes

(Bernroider&Koch, 2000). MES type systems

represents a mid-layer between MRP/ERP and shop

floor controllers (Choi&Kim, 2002) (see fig.2a).

There are several general models of typical MES

functions that are principally divided into core and

support functions. The core functions deal primarily

with actual management of the work orders and the

manufacturing resources. Other functional

capabilities of MES may be required to cover

support aspects of the manufacturing operations. A

MES system by Kisiel (Kisiel, 2001) conducts

following functions according to fig. 3b. MESA

International (MESA Whitepaper 2, 1997) presents

another attitude to MES functionalities that is more

or less based on the assumption of profitability to

begin to deal with wider model of basic elements to

Figure 1: Scheme of processes at OEM.

Figure 2: a) Scheme of information flow between ERP,MES and shop floor controllers, b)MES functional model.

ELIMINATION OF TIME DEPENDENCE OF INFORMATION VALIDITY BY APPLICATION OF RFID

TECHNOLOGY

131

ensure incorporating all-important functions into

MES.

Product Tracking and Traceability as a core function

of MES (figure 2b) is aimed to provide “first hand”

information about real material flow inside the company

for MES and ERP systems. ERP/MES systems at OEM

usually require following information on products and

material flow:

• type of item

• individual identification number

• manufacturer/ supplier

• date of manufacturing

• location (current)

• item path

• batch details

• package details

The sum of all mentioned information ERP/MES

system depends on, can be characterized as 100%

requirement of those system in certain discrete

period of time

. Based on the mentioned information

on material flows all other functions, such as

planning and analysis of performance, are

conducted. An important function of MES is to

provide a feed back to ERP with aim to adjust their

scheduling data and algorithms in more realistic

manner (Modrak, 2005). Major drawback of

MES/ERP systems is that they do not have an access

to detailed information (Vokorokos, Adam & Petrik,

2004). Therefore they have no idea of what is really

happening to material flow on the shop

floor (e.g.

subcomponents not being where they were expected

etc.) (Chappell & Ginsburg, 2003). Also they do not

have an ability to collect information

independently.

Basically it means that all data that information

systems operate with are “fed” to

them by

intermediary

subject, usually human operator

(Rockwell Automation Whitepaper, 2004).

Mentioned drawback leads to insufficient

coordination between material and accompanying

information flows and so-called bull-whip-effect

(Donovan, 2005). Apart of bad coordination,

information on material flow is time dependent so it

is already outdated when inserted into the

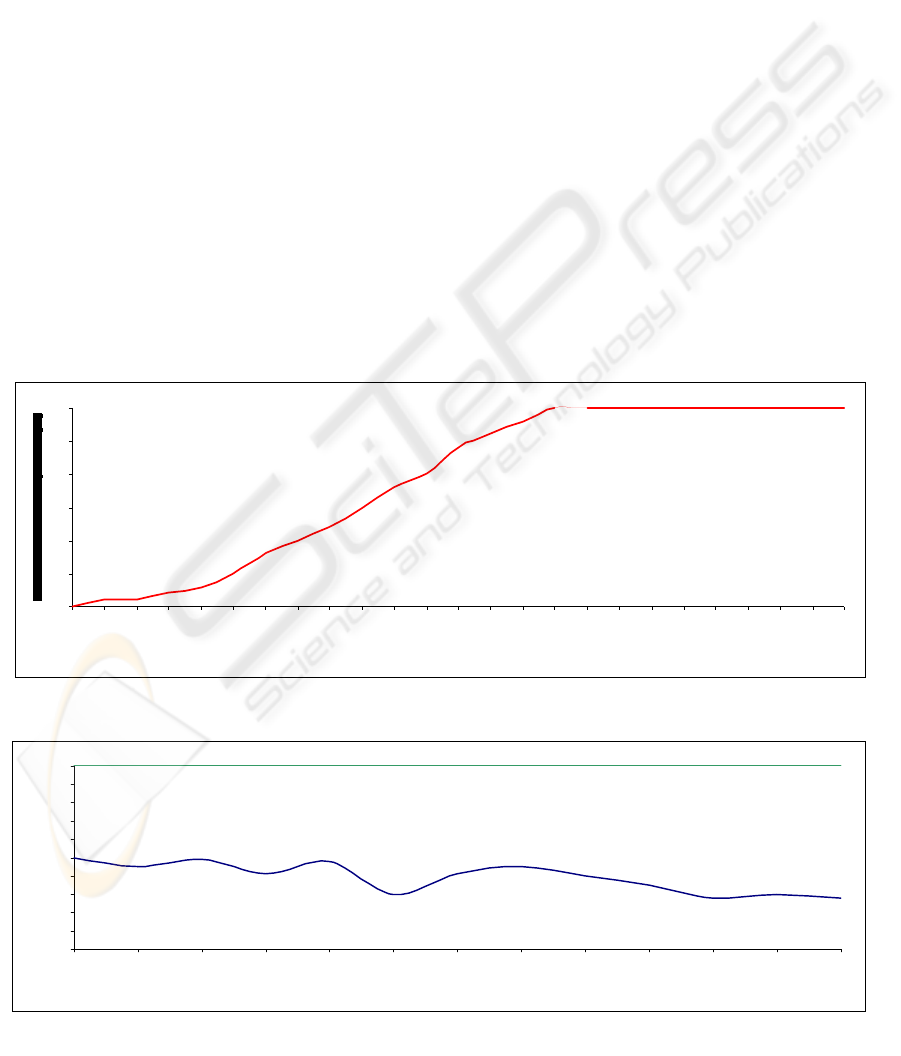

information system by human operator. In time 0,

we will call it a synchronization of flows, when

information is put into the system, validity error ∆

= 0. Until the next synchronization information

become more and more outdated. Application

of the

standard mathematical procedure of data validity

and reliability calculation and proposed by Werner,

0

5

10

15

20

25

30

0 1 2 3 4 5 6 7 8 9 10 111213 1415 1617 181920 2122 2324

Time [h]

maximal acceptable er r or

0

10

20

30

40

50

60

70

80

90

100

0 102030405060708090100110120

Working time [min]

Amount of data [%

]

Amount of data available to human operator

Amount of data required by ERP/MES system

Fi

g

ure 3a: Time de

p

endence of data content validit

y

.

Fi

g

ure 3b: Time de

p

endence of data availabilit

y

.

ICEIS 2006 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

132

Wigert & Hampel 24-hour cycles of synchronization

used for simulation of manufacturing processes

allows us to compile the estimated data content

validity error curve

, shown in fig.3a. Another

problem of information on material flow is its

availability and amount. Human operator can input

into the system only certain amount of information

in discrete period of time if they are available. The

information on material flow available to human

operator at every point of manufacturing process

without tracking & tracing of items is type of item,

supplier, batch details and package details.

Assuming those information as a part of 100% data

required by ERP/MES systems and estimated

periodicity of error occurrence during the 120 min.

discrete period of operator’s working time (Ohuchi

& Okuda, 2001) following curve of time dependence

of data availability can be compiled (see figure 3b).

It is obvious that there’s a considerable, time

dependent gap between amount of information on

material flow required by ERP/MES system and

amour available to operator.

3 SMART LABELLING AS A

SOLUTION

Tracking & tracing of products trough whole

manufacturing process at OEM is one of the

solutions for delivery of missing information on

material flow (e.g. individual identification number

of item, current location, date of manufacturing etc.)

to ERP/MES system to bridge the information gap.

Tracking & tracing of items was associated with

“heavy metal” factory automation or labor-intensive

bar code labeling systems for last decade (Chappell

& Ginsburg, 2003). “Heavy metal” automation

always means “heavy” infrastructure investments

(Kumar, 1996). Bar codes have several drawbacks

such as being a line-of-sight technology,

environment sensitive and carry only a small amount

of information.

Another step in tracking & tracing of products at

every point of manufacturing process is an

application of radio frequency technology or RFID

(AutoID, 2002). RFID technology eliminates nearly

all drawbacks of the bar codes and if correctly

applied, is able to provide ERP/MES systems with

correct, reliable, on-time information. Usual scheme

of RFID industrial system is shown in fig.4.

RFID tags could provide 100% of above-

mentioned information to ERP/MES

systems

because they could store much more data then a bar

code

and they could pass them to the information

system at every point of manufacturing process

(even directly from the manufacturing equipment or

assembly line) since they do not require to be in

sight of an optical sensor. Information between

RFID tag placed on the item and ERP/MES system

is shared by so-called Electronic Product Code

(EPC). There are several types of codes known by

their bit memory (64 bit, 96 bit etc.) but 96bit code

is considered as most perspective one (AutoID,

2002) 96bit code provides a possibility to uniquely

identify 68 billions of products types manufactured

by 268 millions of companies (AutoID, 2002).

Exchange of information is conducted automatically,

without any intervention by a human operator. This

can reduce sequencing, paper form fulfillment and

checking time by up to 62%. Higher level of

information on material flow, received by

information system will lead to reduction of

manipulation and internal transport operations by 6-

Figure 4: Basic scheme of RFID system configuration.

ELIMINATION OF TIME DEPENDENCE OF INFORMATION VALIDITY BY APPLICATION OF RFID

TECHNOLOGY

133

13%. This also depends on the degree of current

OEM factory automation. Case studies proved that

RFID technology reduced usual error rate (e.g.

delayed supplies and even incorrect deliveries) of

1% to 0,1%.

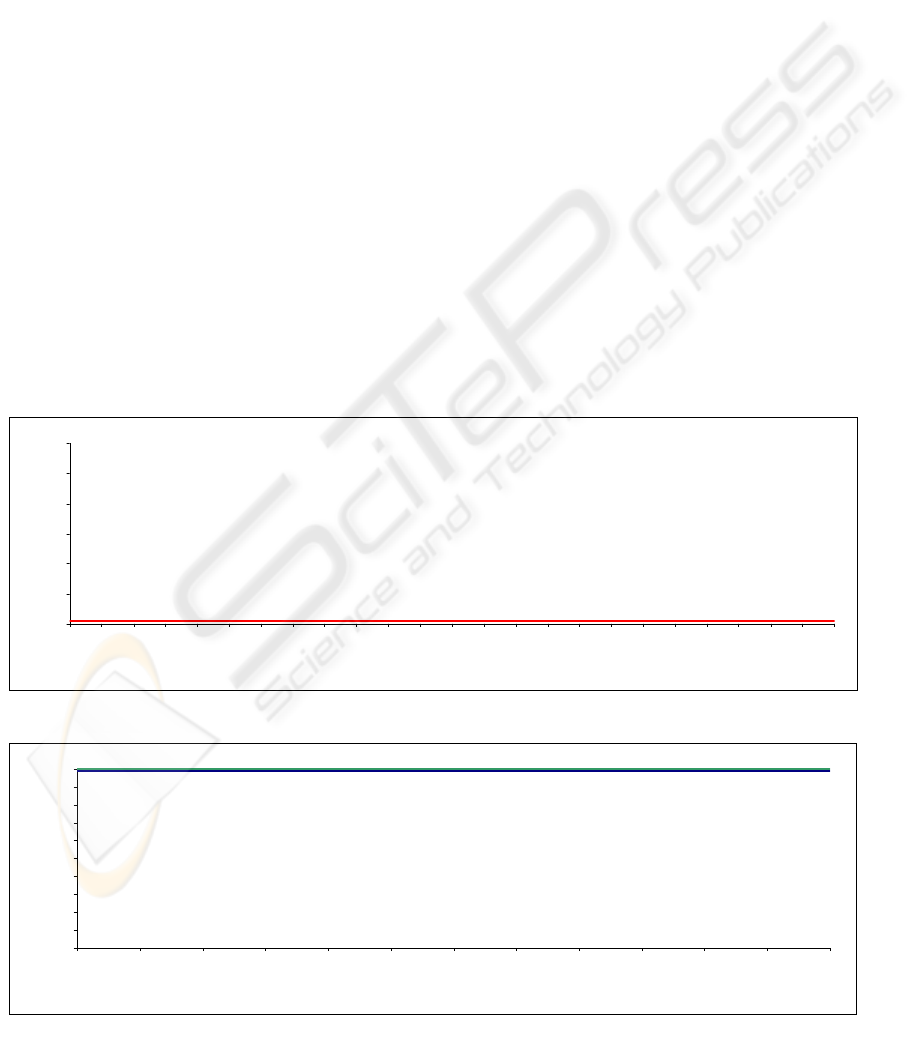

Application of RFID technology for tracking and

tracing of material flow will impact the whole

performance of information systems in terms of

information validity, availability and amount. Use of

RFID system will eliminate time dependence of

amount and quality of information available for

ERP/MES systems.

4 DISCUSSION

Implementation of RFID technology into the OEM

factory and whole supply chain can face certain

problems associated with introduction of cutting

edge technology as phenomenon. Although far less

expensive then “hard” automation RFID technology

requires considerably greater investments then

simple bar coding. Advantages of RFID technology

over bar coding are not always explicit and

calculable. Major companies such Proctor &

Gamble, Wall Mart or U.S. ministry of Defense

already appreciated benefits of such a system.

Proctor &Gamble, for example, expects to reduce its

$3 billion inventory cost to $2 billion by application

of RFID technology (Rockwell automation

Whitepaper, 2004). Although market leaders

expressed their trust to RFID technology it is

speculative whether smaller OEMs can achieve the

same level of effectiveness and cost saving. Without

clear vision of profit they will not cover adoption

costs of RFID technology by their own will. More

likely they will be forced to introduce RFID by

their market leader customers like in a case with

U.S. DoD’s RFID mandate released in January

2004. Department of Defense required its top 100

suppliers to introduce RFID tags into their supplies

(DOD Information guide, 2005). Then it will be up

to OEM to create new business models and find new

a scope of RFID application to maximize a level of

profit. For OEMs there are many areas of RFID use

in-house. Not only tracking & tracing but also

product genealogy, plant asset management,

inventory visibility and labor usage could be greatly

improved by introduction of RFID technology. Last

but not least problem is a lack of widely accessible

information on profits of this technology. Only 35%

of consumers are aware of RFID in some way

(Stageman, 2004).

0

10

20

30

40

50

60

70

80

90

100

0 102030405060708090100110120

Working time [min]

Amount of data [%]

Amount of data available trough tracking&tracing via RFID Amount of data required by ERP/MES system

0

5

10

15

20

25

30

0123456789101112131415161718192021222324

Time [h]

data content validity erro

[%]

Figure 6a: Time dependence of information validity after application of RFID technology.

Fi

g

ure 6b: Time de

p

endence of available data amount after a

pp

lication of RFID technolo

gy

.

ICEIS 2006 - DATABASES AND INFORMATION SYSTEMS INTEGRATION

134

5 FUTURE TRENDS

If RFID technology is to succeed in today’s competition, it

must be economically viable. Although RFID already

found its place in supply chain and warehouse

operations it is arguable if its short-term return of

investment justifies initial cost of implementation.

A major problem of today’s RFID is a lack of

unified electronic product code, making RFID tags

an “internal inventory” of individual companies or

supply chains. Although EPC global standards were

adopted, for really wide spread use of RFID it will

be necessary to introduce certain standardized

format of codes as it was in case with bar codes. To

make tags economically sensible for item-level

tagging of low cost products it is essential to cut

their costs from current ¢ 50 - $2 to maximum ¢ 5

(Sarma, 2003).Mentioned future development of

RFID technology will allow better management of

in-house and supply chain processes with greater

accuracy and provide unprecedented visibility to the

material flows.

ACKNOWLEDGEMENTS

This work was supported by European Commission

programme INTERREG IIIC, ECO4LOG

international project.

REFERENCES

Auto-ID center, 2002. Technology guide, Massachusetts

Institute of Technology, Cambridge

ALTA A/S,2003. White paper, Strategies for in sequence

supply, Copenhagen

Bernroider, E., Koch,S., 2000. Differences in

Characteristics of the ERP System Selection Process

between Small or Medium and Large Organizations,

In AMCIS 2000, Sixth Americas Conference on

Information Systems, pp. 1022-1028, Long Beach, CA

Chappell, G., Ginsburg, L., Schmidt, P.,Smith, J.,

Tobolski, J, 2003. Auto-ID on the Line: The Value of

Auto-ID Technology in Manufacturing, Auto-ID

Center, Massachusetts Institute of Technology,

Cambridge

Choi, B., Kim, B., 2002. MES architecture for FMS

compatible to ERP. In International Journal of

Computer integrated manufactuirng, Vol.15, No.3

Czarnecki, H., Loyd, N., 2000. Simulation of Lean

Assembly Line for High Volume Manufacturing.

Center for Automation and Robotics, University of

Alabama

Donovan, R.M.,2005. SCM: Cracking the „Bullhip

Effect“, R.Michael Donovan & Co., Framingham

DoD suppliers passive RFID information guide,2005,

Version 6.0, January 17

Kisiel, T., 2001. Manufacturing Execution Systems: Steps

to a Successful Implementation. DAI White Paper,

Digital Applications International, London, United

Kingdom

Kumar, V., 1996. Introduction to automation, University

of Pennsylvania

Lawless, G., 2000. Information Technology (IT) For

Manufacturing: Where Has It Been, Where Is It

Heading?.In: Journal of Industrial Technology,Vol.16,

Numb.4

Modrak, V, 2005. Functionalities and Position of

Manufacturing Execution Systems. In Encyclopedia of

Information Science and Technology, Volume 1-5.

Idea Group Reference, Hershey, PA, USA

MESA #2,1997. MES functionalities and MRP to MES

Data Flow Possibilities White Paper 2, Manufacturing

Execution Systems Association, Pitsburgh, P.A.

Ohno, T., 1988. Toyota Production System, Productivity

Press

Ohuchi A., Okuda Y., Nakamura Y., Hitomi M. , H.

Tomita, 2001. A Study of Simulation Model of

Human-Oriented Production Process in Consideration

of Human Factors. In Publication of Industry

Applications Society, Vol. 121D, Numb. 6,

Rockwell automation white paper, 2004. A practical guide

on extracting measurable value from RFID

implementations in plant and warehousing

operations”, October issue

Sarma, S., 2003. Towards 5 cent tag. Auto-ID Center

Massachusetts Institute of Technology, Cambridge

Silva,L., Ramos, A.,Vilarinho,P., 2000. Using simulation

for manufacturing process reengineering. A practical

case study. In

Proceedings of the 2000 Winter

Simulation Conference

Stageman,L., 2004. Consumer Awareness and Concern

About RFID on the Rise. In Market Wire, December

issue

Strassner,M.,Fleisch,E., 2003. The Promise of Auto-ID in

the Automotive Industry. Auto-ID Center,

Massachusetts Institute of Technology, Cambridge

Taylor,D. ,Brunt,D., 2000. Manufacturing Operations and

Supply Chain Management The LEAN Approach”

Viswanadham,N., 2002. Past, present and future of Supply

chain automation. In IEEE Robotics and automation

magazine

Vokorokos, L., Adám, N., Petrík , S., 2004. Operating

Matching In dynamic Data flow Architectures. In

Proceedings of IEEE International conference on

Computational Cybernetics. Vienna, Austria

Weigert,G., Werner,S., Hampel,D., 2000. ROSI – Ein

Programmsystem zur Simulation und Optimierung von

Fertigungsprozessen. 9. ASIM-Fachtagung Simulation

in Produktion und Logistik“, Berlin

ELIMINATION OF TIME DEPENDENCE OF INFORMATION VALIDITY BY APPLICATION OF RFID

TECHNOLOGY

135