LOGICRUNCHER

A

Logistics Planning and Scheduling Decision Support System for Emerging EMS

and 3PL Business Practices

Raymund J. Lin, Jack Huang

Institute for Information Industry, Taipei, Taiwan, R.O.C.

Norman Sadeh-Koniecpol, Benjamin Tsai

School of Computer Science, Carnegie Mellon University, Pittsburgh PA 15213, USA

Keywords: Logistics Planning and Scheduling, Web-based Supply Chain Management, Electronic trading, Mixed

Initiative Decision Support, Collaborative Planning.

Abstract: LogiCruncher is a dynamic logistics planning and scheduling module developed to support emerging third

party logistics practices. Given information about inventory profiles for different product types at different

locations, a set of transportation assets as well as a variety of quotes and contractual arrangements with

logistics service providers, the system is capable of generating or revising transportation plans and

schedules that meet changing customer requirements. These requirements are expressed in the form of

demands for delivering different types of SKUs in different quantities to different locations. The system is

capable of capturing a rich set of domain constraints and costs. It can be used to support the development

and dynamic revision of solutions as well as to support requests for quotes from prospective customers. This

includes support for “what-if” analysis through the creation and manipulation of solutions in different

contexts, each corresponding to possibly different sets of assumptions. This paper provides an overview of

LogiCruncher and summarizes results of initial evaluation.

1 INTRODUCTION

As manufacturing companies focus on their core

competencies and attempt to further reduce supply

chain costs and improve delivery performance, they

increasingly turn to third party logistics (3PL)

providers to manage both their inbound and

outbound logistics. Examples of current day 3PLs

include Fedex, UPS, DHL as well as many others.

Original Equipment Manufacturers (OEMs) such as

Cisco, Dell or Nokia go one step further and also

outsource key manufacturing activities to

Electronics Manufacturing Services (EMS)

contractors such as Flextronics, Sanmina-SCI or

Solectron to name just a few. EMS contractors are

faced with the delicate task of concurrently

coordinating manufacturing activities with inbound

and outbound logistics for a number of OEMs. This

involves dynamically orchestrating the activities of

hundreds, if not thousands, of suppliers with

operations at multiple manufacturing facilities and

with logistics and warehousing activities around the

globe - all to keep up with OEM demands that are

typically adjusted on a daily basis. To satisfy

demand from their OEM customers, EMS

contractors tend to rely on a combination of both in-

house and external warehouses and transportation

assets. Within such environments, supporting high

levels of product customization, increasingly short

product life cycles and tight delivery commitments

(all while minimizing costs) requires unprecedented

levels of supply chain visibility and coordination

(Figure 1). In this paper, we summarize ongoing

work on LogiCruncher, a logistics planning and

scheduling decision support tool aimed at supporting

tight integration between procurement,

manufacturing and logistics activities across the

global supply chain environments spawned by

emerging EMS and 3PL practices (Alp, 2003). In

particular, we detail the overall architecture of

LogiCruncher, focusing on the way in which it

176

J. Lin R., Huang J., Sadeh-Koniecpol N. and Tsai B. (2006).

LOGICRUNCHER - A Logistics Planning and Scheduling Decision Support System for Emerging EMS and 3PL Business Practices.

In Proceedings of the Eighth International Conference on Enterprise Information Systems - AIDSS, pages 176-181

DOI: 10.5220/0002464201760181

Copyright

c

SciTePress

supports dynamic coordination between

manufacturers, suppliers and logistics providers

under constantly changing conditions. This includes

a description of the system’s mixed initiative

functionality to enable users to collaboratively

explore alternative supply chain arrangements. We

also detail the system’s powerful modeling

framework, which enables it to capture both in-

house logistics and warehousing resources as well as

quotes obtained by third party providers.

Specifically, the remainder of this paper is

organized as follows. Section 2 provides a brief

review of the literature and highlights key innovative

aspects of LogiCruncher. Section 3 gives an

overview of the system’s overall architecture,

including a discussion of different ways in which it

can be configured to capture different possible

business practices. An overview of the

LogiCruncher logistics and warehousing model is

provided in Section 4. Section 5 focuses on heuristic

search procedures developed to support the rapid

generation and revision of large-scale logistics and

warehousing solutions under dynamic business

conditions. Empirical results obtained with these

procedures are summarized in Section 6. Section 7

contains some concluding remarks.

2 RELATED WORK

Traditionally, operations research has focused on

somewhat stylized models of logistics planning and

scheduling problems, favoring models that lend

themselves to the computation of optimal or near-

optimal solutions (e.g. (Cordeau, 2002; 2004; Li,

2005)). Over the past ten years, in parallel with this

work, a number of research efforts have attempted to

increasingly relax many of the assumptions made in

more classical models. This has included looking at

larger-scale problems (e.g. (Sadeh, 1996; Kott,

1998; 1999; Smith, 2004)), more dynamic models

(e.g. (Sadeh, 1996), (Kott, 1999; Smith, 2004)),

more complex constraints(e.g. (Sadeh, 1996; Kott,

1998; Smith, 2004)) along with support for more

flexible mixed initiative decision models (e.g. (Kott,

1999; Becker, 2000; Sadeh, 2003)).

LogiCruncher is a logistics planning and

scheduling decision support system that builds on

our own work on a mixed-initiative decision support

tool for collaborative supply chain planning and

scheduling in the context of the MASCOT system

(Sadeh, 2003), as well as our earlier research on

developing iterative improvement techniques to

build and dynamically update large-scale planning

and scheduling solutions (Sadeh, 1997).

LogiCruncher is unique in the way in which it

combines these techniques within a flexible

modeling framework capable of capturing a rich set

of emerging EMS/3PL practices. This includes the

ability to model hybrid networks of plants,

warehouses, distribution centers and multi-modal

transportation assets that include a mix of assets

directly under the control of an EMS organization

and assets made available by third party partners

under different contractual arrangements.

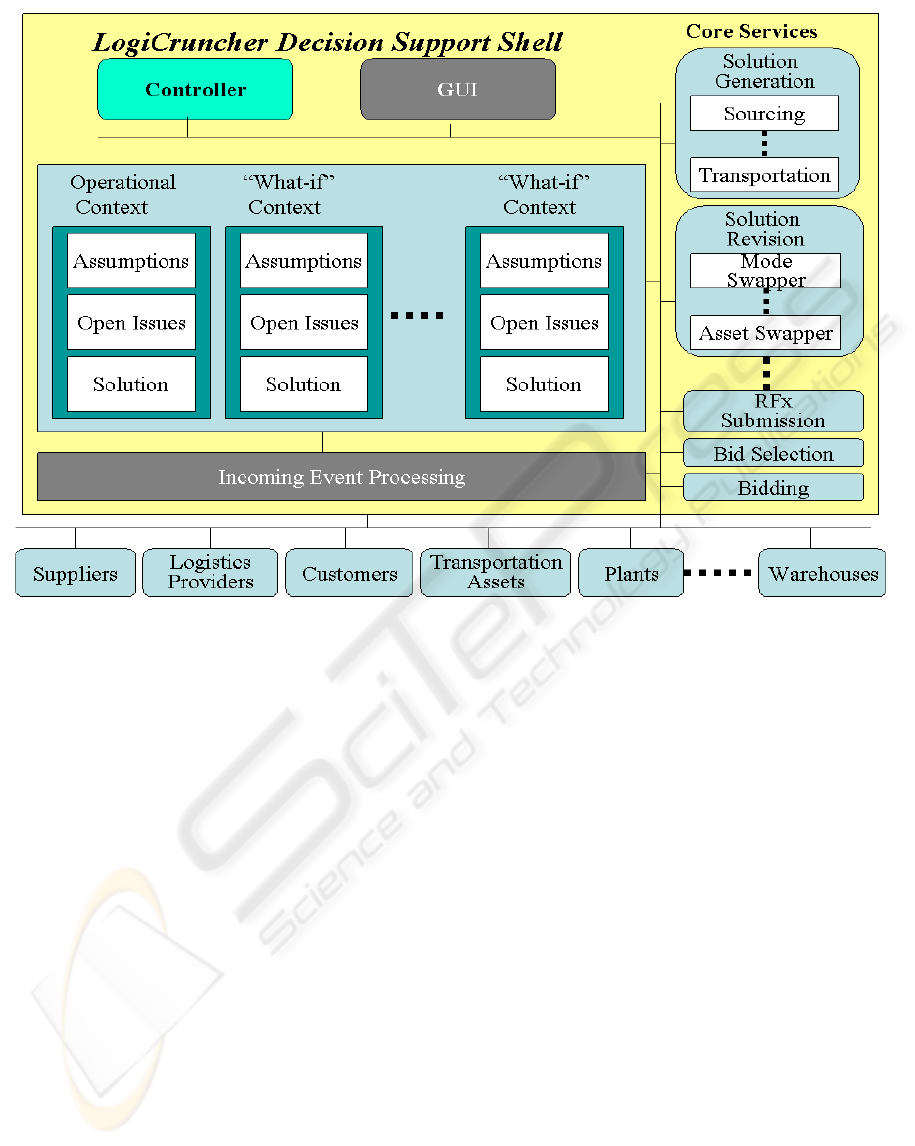

3 OVERALL ARCHITECTURE

LogiCruncher is a decision support shell aimed at

supporting mixed initiative planning and scheduling

functionality required by emerging EMS/3PL

business practices. The shell, which can be deployed

at the level of an EMS or a third party logistics

provider, aims to support users as they interact with

other participants across the supply chain. This

includes provisions for developing and revising

logistics plans and schedules that cut across multiple

suppliers, plants, warehouses and transportation

assets. Some of these assets may be directly under

the control of the user organization, while others

may be provided by third party organizations subject

to different types of contractual arrangements. This

includes both long-term arrangements as well as

more dynamic arrangements identified by issuing

Requests for Quotes (RFQs – or more generally

RFxs) and evaluating bids– see Figure 2. In

particular, the shell gives its user access to a number

of problem solving services, ranging from solution

generation and revision services to services aimed at

submitting RFQs, evaluating bids and even

submitting bids (e.g. in the case of a large third party

logistics provider). Using these services,

Figure 1: Effective supply chain management in emerging

OEM/EMS practices requires unprecedented levels o

f

visibility and coordination across global logistics

networks.

LOGICRUNCHER - A Logistics Planning and Scheduling Decision Support System for Emerging EMS and 3PL Business

Practices

177

LogiCruncher users can concurrently develop, refine

and evaluate multiple solutions, using “what-if”

contexts that can differ in terms of working

assumptions and solutions (e.g. different customer

demand assumptions as well as different sourcing or

logistics arrangements). As new developments

unfold (e.g. changes in customer demands, arrival of

new bids from logistic service providers,

transportation contingencies, etc.), they are handled

by an incoming event processing module that

selectively updates relevant contexts (e.g. taking an

incoming bid and posting it in the context that

generated the corresponding request for quote). This

can be done either automatically or manually by the

user (e.g. if the user wants to selectively control

events that are visible within a given “what-if”

context). As they get posted into a given context,

events result in the generation or updating of “open

issues”. An “open issue” is a flag that is used to

identify aspects of a working solution that is either

incomplete, inconsistent or unsatisfactory (see

(Sadeh, 1998; 2003) for further details). Open issues

can be used to help the user compare contexts and

identify areas of a given solution that require further

work. They can also be used to support automated

decision support functionality that directly maps

problem solving services onto different sets of open

issues. Such mapping can be implemented through a

control module (“controller”) and can range from

providing suggestions to the user to automatically

invoking one or more services (e.g. in the form of

scripts) – see (Sadeh, 1998; 2003) for further details.

4 LOGISTICS PLANNING AND

SCHEDULING MODEL

A LogiCruncher Context corresponds to a set of

assumptions and possibly a planning and scheduling

solution developed under these assumptions.

Assumptions include customer demands (expressed

as “customer orders”) to be satisfied, a set of

available storage nodes, a set of transportation assets

as well as quotes obtained from providers of

transportation and warehousing services.

A Solution is an allocation of goods to customer

demands, including a selection of sourcing nodes

(e.g. plants, warehouses, distribution centers or some

combination of the above), a selection of

transportation modes and/or transportation assets to

Figure 2: LogiCruncher decision support shell: overall architecture.

ICEIS 2006 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

178

move these goods (“transportation plan”) and a

schedule for when each move is to take pace

(“transportation schedule”). A solution may be

complete or incomplete and may possibly include

some assumption and/or constraint violations, in

which case it is said to be inconsistent.

An Order represents a requirement for delivering

some quantity of a given SKU type to a point of

destination by a given date. An order will contain

information on due time, earliest acceptable delivery

time, latest acceptable time, and various penalty

costs. Each order is broken down into one or more

jobs that inherit the properties of the order, and

which together will satisfy the requirements of the

order. The fashion in which orders are split into jobs

may reflect an organization’s policy or contractual

arrangements or may be the result of limiting

sourcing and transportation conditions. Orders can

originate directly from actual customer requirements

or may reflect a company’s policies such as safety

stock policies.

LogiCruncher can capture constraints associated

with different transportation modes and be used to

model internal transportation assets as well as assets

operated by third party providers under different

contractual arrangements. This includes quotes

obtained from third party logistics providers as well

as longer-term contractual relationships.

Transportation modes as well as different classes

of transportation assets vary in terms of their

available routes, costs, speeds and capacities as well

as other idiosyncratic constraints (e.g. type of

products they can accommodate, setup constraints,

etc.).

Inventory Storage Resources represent resources

that can store components. These resources can be

used to model warehouses, suppliers, plants and

customer delivery sites. They can have capacity

constraints and restrictions on the different types of

SKUs they can accommodate. Each inventory

storage resource also has an inventory profile for

each SKU it can store. This profile indicates how

many units of each SKU is expected to be available

at that resource at any point in time, given existing

problem assumptions and decisions made in the

current context.

5 ITERATIVE SEARCH

TECHNIQUES

In LogiCruncher, solutions are developed and

refined through the activation of core problem

solving services, either manually or automatically.

Core problem solving services include (see Figure

2):

• Solution generation services such as services to

help optimize the nodes from which to source

SKUs required by different orders,

transportation planning and scheduling services,

etc.

• Solution revision services, which take an

existing solution (possibly partial or

inconsistent), and revise it to either resolve

some inconsistencies, complete the solution or

improve it. This includes services aimed at

exploring alternative sourcing options, the

selection of alternate transportation modes or of

different bids from logistics service providers. It

also includes finer revision services such as

services to swap resource allocations between

different orders in hope of producing a better

quality solution (e.g. lower inventory costs,

lower transportation costs, lower delivery

penalties, etc.)

• RFQ submission services that can be used to

issue requests for quotes to prospective business

partners (e.g. RFQs sent to third party logistics

providers)

• Bid selection services implementing logic that

can be used by LogiCruncher to select among

multiple bids (e.g. through what-if analysis in

multiple contexts and/or through the use of

solution revision services)

• Bidding services, in configurations where

LogiCruncher is deployed to assist a 3PL and

help the organization decide what to bid on and

help it determine optimal bid parameters.

This flexible architecture enables a number of

possible system configurations as well as a variety

of mixed initiative problem solving styles, where

solution construction and revision is interactively

controlled by an end-user, while tedious or complex

problem solving steps can selectively be delegated to

automated functionality (e.g. through control

heuristics embedded in the shell’s controller).

Experience with this mixed initiative architecture in

the context of collaborative supply chain planning

and scheduling scenarios is detailed in (Sadeh,

2003).

LOGICRUNCHER - A Logistics Planning and Scheduling Decision Support System for Emerging EMS and 3PL Business

Practices

179

In its simplest configuration, LogiCruncher can be

used to generate initial logistics planning and

scheduling solutions using its solution generation

services and can then be used to revise these

solutions as events unfold (e.g. as contingencies

occur, as demand changes or as new bids from

prospective business partners arrive). In its current

implementation, the LogiCruncher solution

generation services rely on a set of greedy heuristics

to rapidly generate initial solutions. Iterative

improvement techniques embedded in the form of

multiple neighborhood search heuristics can

selectively be invoked to further refine or improve

these solutions, whether in support of what-if

scenarios or to reflect changing conditions. The

following section briefly summarizes empirical

results obtained with these techniques.

6 EMPIRICAL EVALUATION

An initial version of LogiCruncher has been

implemented in Java. Experiments conducted on

scaled down logistics problems involving 600

customer requests, 10 to 20 warehouses, distribution

centers and customer delivery centers, multiple

classes of transportation assets, each with between

10 and 100 transportation units (e.g. 50 trucks, 100

vans, etc.) appear rather promising. Initial solutions

are generated in a matter of a few seconds. Iterative

improvement heuristics have been shown to

typically converge towards seemingly high quality

solutions within 30 to 120 seconds, though

admittedly additional experimentation is needed to

further evaluate the quality of these solutions. Figure

3 summarizes results obtained on eight problem sets

that differ in terms of logistics network layout, mix

of transportation assets and tightness of customer

requests. The results show improvement in solution

quality, starting from an initial solution generated by

the LogiCruncher solution generation heuristics, and

applying multiple rounds of iterative improvement

search.

7 CONCLUDING REMARKS

In this paper, we introduced LogiCruncher, a

logistics planning and scheduling decision support

shell aimed at supporting emerging EMS and 3PL

logistics scenarios. We focused in particular on key

elements of the LogiCruncher mixed initiative

decision support architecture as well as on its unique

modeling capabilities. These capabilities enable the

system to capture complex constraints and costs

under which EMS and 3PL service providers need to

operate, with logistics networks consisting of a mix

of transportation and warehouse assets, some

operated by these companies themselves and others

operated by third party players. Initial evaluation of

the system’s heuristics appear promising. As part of

our future work, we plan to further refine elements

of our model and evaluate an enhanced set of

heuristics on yet larger sets of problems to be

identified jointly with prospective end-user

organizations based in the Republic of China

(Taiwan).

ACKNOWLEDGEMENTS

The work reported herein has been supported in part

by the R.O.C.’s Institute for Information Industry

and in part by the US National Science Foundation

under ITR Grant 0205435.

REFERENCES

Alp, O., N.E. Ekrip, R. Gullu (2003). Outsourcing

Logistics: Designing Transportation Contracts

Between a Manufacturer and a Transporter,

Transportation Science 37(1) 23-29.

Becker, M. and S.F. Smith (2000, April). "Mixed-

Initiative Resource Management: The AMC Barrel

Allocator", Proceedings 5th International Conference

on Artificial Intelligence Planning and Scheduling

(AIPS-2000), Breckenridge, CO

Cordeau, J.-F., M. Gendreau, A. Hertz, G. Laporte, and J.-

S. Sormany, (2004). New heuristics for the vehicle

Figure 3: Performance of iterative improvement heuristics

on eight categories of logistics planning and scheduling

p

roblems. A total of 6 problems were generated in each

category.

ICEIS 2006 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

180

routing problem. In: Logistics systems: Design and

optimization. Eds.: A. Langevin and D. Riopel,

Kluwer Academic Publishers (to appear - earlier

version as Technical Report G-2004-33, GERAD,

Université de Montreal, Canada).

Cordeau, J.-F., M. Gendreau, G. Laporte, J.-Y. Potvin, and

F. Semet, (2002). A guide to vehicle routing

heuristics. Journal of the Operational Research Society

53(5) 512–522.

Kott, A., and V. Saks (1998, June). A Multi-

Decompositional Approach to Integration of Planning

and Scheduling – An Applied Perspective, in Proc. of

Workshop on Integrating Planning, Scheduling and

Execution in Dynamic and Uncertain Environments.

International Conference on Artificial Intelligence

Planning Systems, AAAI Press TR WS-98-02

Kott, A., V. Saks, and A. Mercer (1999, Spring). A New

Technique Enables Dynamic Replanning and

Rescheduling of Aeromedical Evacuation, AI

Magazine, Vol. 2, No. 1, pp. 43-54

Li, F., B. Golden, E. Wasil, (2005). Very large-scale

vehicle routing: New test problems, algorithms, and

results. Computers & Operations Research 32(5)

1165–1179.

Smith, S.F., M.A. Becker and L. Kramer (2004).

"Continuous Management of Airlift and Tanker

Resources: A Constraint-Based Approach",

Mathematical and Computer Modeling: Special Issue

on Defense Transportation

Sadeh, N.M., D.W. Hildum, and D. Kjenstad (2003).

"Agent-based e-Supply Chain Decision Support",

Journal of Organizational Computing and Electronic

Commerce, Vol. 13, No. 3

Sadeh, N.M., D.W. Hildum, T.J. Laliberty, J. McA'Nulty,

D. Kjenstad, and A. Tseng (1998, June). "A

Blackboard Architecture for Integrating Process

Planning and Production Scheduling". Concurrent

Engineering: Research and Applications, Vol. 6, No. 2

Sadeh, N.M. and A. Kott (1996). "Models and Techniques

for Dynamic Demand-Responsive Transportation

Planning", Technical Report CMU-RI-TR-96-09, The

Robotics Institute, Carnegie Mellon University,

Pittsburgh, PA 15213-3891.

Sadeh, N.M., Y. Nakakuki, and S. Thangiah (1997).

"Learning to Recognize (Un)Promising Simulated

Annealing Runs: Efficient Search Procedures for Job

Shop Scheduling and Vehicle Routing". Annals of

Operations Research, 75, pp.189-208

LOGICRUNCHER - A Logistics Planning and Scheduling Decision Support System for Emerging EMS and 3PL Business

Practices

181