A Classification of Process Mining Bottleneck Analysis Techniques for

Operational Support

Rob Bemthuis

1 a

, Niels van Slooten

1 b

, Jeewanie Jayasinghe Arachchige

2 c

,

Jean Paul Sebastian Piest

1 d

and Faiza Allah Bukhsh

1 e

1

University of Twente, Drienerlolaan 5, 7522 NB, Enschede, The Netherlands

2

University of Ruhuna, Matara, Sri Lanka

Keywords:

Process Mining, Bottleneck, Classification.

Abstract:

A bottleneck usually is a sub-process in the main process which delays the process. The performance of a

process can be increased by eliminating the bottlenecks. To this end, opportunities to analyze and mitigate

bottlenecks by using process mining techniques can be an interesting direction to utilize. This paper aims

to classify literature on process mining bottleneck analysis techniques and propose a model for operational

support regarding bottleneck analysis utilizing process mining. To this end, we first propose a model for

classifying bottleneck analysis techniques. Then, we conduct a systematic literature review to identify existing

papers that address bottleneck analysis by utilizing process mining techniques. The results indicate that many

researchers are focusing on detecting bottlenecks, while limited attention is paid to predicting bottlenecks or

recommending actions on what to do with bottlenecks. The proposed classification model is validated through

a demonstration, showing how process mining bottleneck analysis techniques can be applied to a logistics case

study.

1 INTRODUCTION

There are many bottlenecks that can impede the effi-

cient functioning of processes. If no action is taken, a

bottleneck can cause delays, impact productivity, and

waste resources. There is a multitude of reasons why

a bottleneck may develop, but the effects it can have

are almost always negative. For example, a big con-

tainer ship was blocking global traffic (Samaan et al.,

2021), causing a significant backlog of ships waiting

in the area. More generally, bottlenecks determine the

throughput of a process. The resources that require

the longest time in operations play a critical role in

mitigating bottlenecks. It is key to know what causes

bottlenecks and how to address them.

One way to detect or analyze bottlenecks is by us-

ing process mining. Process mining is a discipline

that aims to discover, check conformance, and en-

hance processes by using knowledge extracted from

event logs (Van der Aalst et al., 2010). Event logs

are used to discover a process model (Van der Aalst,

a

https://orcid.org/0000-0003-2791-6070

b

https://orcid.org/0000-0003-4403-3149

c

https://orcid.org/0000-0001-8619-6523

d

https://orcid.org/0000-0002-0995-6813

e

https://orcid.org/0000-0001-5978-2754

2016). In turn, those process models can be used to

analyze bottlenecks.

Bottleneck analysis have been performed in sev-

eral domains, such as concurrent environments (Chen

et al., 2020), traffic monitoring (Dabir and Matrawy,

2007), and supply chains (Buddas, 2014; Subra-

maniyan et al., 2018). However, to our knowledge,

limited research has been done on the identification

and resolution of bottlenecks by utilizing process

mining. Therefore, the objective of this paper is to

map papers that utilize process mining for the anal-

ysis of bottlenecks. We focus on the use of process

mining for operational support (see Section 2). To

achieve this goal, we first propose a model for classi-

fying bottleneck analysis techniques. Then, we con-

duct a systematic literature study on existing papers

and, consequently, map the papers to the classification

model. As a means of validating the proposed model,

we give a demonstration of a logistics case study. The

contribution of this paper is threefold: (1) a bottleneck

classification model, (2) a literature mapping, and (3)

preliminary insights in the state of research on process

mining techniques concerning bottleneck analysis.

Let us briefly address some related work. A re-

cent systematic mapping study about process mining

techniques and their applications has been carried out

by Garcia in (dos Santos Garcia et al., 2019). That

Bemthuis, R., van Slooten, N., Arachchige, J., Piest, J. and Bukhsh, F.

A Classification of Process Mining Bottleneck Analysis Techniques for Operational Support.

DOI: 10.5220/0010578601270135

In Proceedings of the 18th International Conference on e-Business (ICE-B 2021), pages 127-135

ISBN: 978-989-758-527-2

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

127

paper provides an overview of domains in which pro-

cess mining is applied and the used algorithms. In

(Jacobi et al., 2020), a maturity model is proposed for

the application of process mining in supply chains.

Their work mainly focuses on the transport and logis-

tic domain. Although this can indicate that the logis-

tic domain seems a promising demarcation, supported

by other initiatives such as the open trip model (Piest

et al., 2021), we do not restrict ourselves to a particu-

lar domain. Furthermore, both works do not focus on

process mining techniques concerning bottlenecks. A

classification model could be useful, because one may

check how mature bottleneck analysis techniques are

within the state-of-the-art. Our classification can also

be used as a direction for future research. Further-

more, we describe a brief case study for demonstrat-

ing our classification model. The majority of papers

that address bottleneck analysis by using process min-

ing contain specific case studies (e.g., (Stefanini et al.,

2018; Seara and De Carvalho, 2019)), while our paper

shows a more general approach on how the process

mining techniques can be applied to address multiple

views on bottleneck analysis.

The used methodology for the present work is the

design science research methodology (Peffers et al.,

2007). Figure 1 explains the methodology in detail.

Above, we addressed the problem identification and

objective of this position paper. Section 2 addresses

background materials. In Section 3, we describe the

proposed model for classifying bottleneck analysis

techniques that use process mining. Section 4 dis-

cusses the systematic literature review and findings

with respect to the mapping. To validate the proposed

model (i.e., the artifact), a demonstration is given in

Section 5. Finally, Section 6 concludes this paper.

2 BACKGROUND

Process mining is a relatively young discipline that at-

tempts to bridge the gap between data mining and pro-

cess modeling (Van der Aalst, 2016). The goal of pro-

cess mining is to discover, check conformance, or en-

hance processes by using knowledge extracted from

event logs (Van der Aalst et al., 2011). Event logs can

be gathered from information systems (e.g., ERP sys-

tem) (Van der Aalst et al., 2010). Consequently, pro-

cess mining discovery algorithms can transform the

data from the event logs into a process model. With

these process models bottlenecks can be identified. In

the following subsections, we will define and discuss

bottlenecks and bottleneck classification levels.

2.1 Bottlenecks

There have been several studies performed on bottle-

neck analysis. For example, in (Mizgier et al., 2013),

a method is proposed that can be used to detect bot-

tlenecks within supply chain networks. That study

uses network theory and their proposed method can

be used to find on which supplier a company relies

the most and, therefore, might be a bottleneck. This

study focuses on classifying the bottlenecks.

To find bottlenecks, a clear definition of a bot-

tleneck is needed. There are multiple definitions of

bottlenecks. According to Roser, bottlenecks are pro-

cesses that influence the throughput of the entire sys-

tem (Roser et al., 2015). The larger the influence, the

more significant the bottleneck. The concept bottle-

neck might also be linked to constraint. In (Heo et al.,

2018), a constraint is described as “anything that lim-

its a system from achieving higher performance ver-

sus its goal. Every system should have at least one

constraint”. Heo defines the bottleneck of a process

as “the resource pool that has the minimum capacity

among all the resource pools that have been involved

in the process” (Heo et al., 2018). Based on these

definitions, a bottleneck can be described as a sub-

process within a system that stops or slows down the

entire process. If this bottleneck can be improved, the

overall performance of the process can become bet-

ter, which can result in, e.g., increased performance

or reduced costs.

2.2 Classification Phases

One of the concepts used in this research is classifi-

cation. We will describe classification as the extent

to which a certain concept is implemented or applied.

In this research, classification will mean how far bot-

tleneck analysis and resolution steps have been ap-

plied. We define three phases of classification, based

on operational support as described by Van der Aalst

(Van der Aalst, 2016): detect, predict, and recom-

mend.

As a first step, it is important to identify the bot-

tleneck. Therefore, the first classification phase will

be to detect. Bottleneck identification provides the

foundation towards many improvement paths, such as

avoiding and resolving bottlenecks. The second phase

includes the prediction of bottlenecks. That is, saying

or estimating that a bottleneck will happen in the fu-

ture (or that it will be a consequence of something).

The third classification phase involves recommenda-

tion, which is about suggesting that someone or some-

thing would be suitable for managing (e.g., mitigat-

ing) a bottleneck, or to suggest that a particular action

ICE-B 2021 - 18th International Conference on e-Business

128

Problem

Identification:

Identification of

papers that address

bottlenecks by using

process mining

Define objectives

of solution:

Identify relevant

literature and map

the papers

Design and

Development:

Model for classifying

bottleneck analysis

techniques

Demonstration:

Case study

Validation:

Technical action

research (case study

discussion)

Communication:

This publication

Literature

Bottleneck

analysis mapping

based on existing

literature

Logistics case

study

Process iteration

Demonstration

and research

design cycles

Figure 1: Research methodology.

should be done. An example is a route planning al-

gorithm that can predict how long a route will take or

that can suggest avoiding a sudden traffic jam (e.g.,

the bottleneck) by taking a different route.

3 BOTTLENECK

CLASSIFICATION MODEL

Our model, which we describe hereafter, is based on

activities of the refined process mining framework.

The refined process mining framework is described

in (Van der Aalst, 2011). One element of the frame-

work consists of activities that can be performed us-

ing process mining. These activities are divided into

three categories: cartography, auditing, and naviga-

tion. Some activities can be related to bottlenecks,

e.g., to predict or recommend certain activities. How-

ever, these activities are general process mining activ-

ities and do not show how advanced the application

or development of those activities with respect to bot-

tlenecks are. Our model can show to which extent

process mining activities are applied.

Figure 2 presents our proposed bottleneck classi-

fication model. The model relies on one of the funda-

mentals of process mining, namely event logs. Based

on event logs, process mining can be used to extract

data about what happened in a process and when.

These event logs are the input for what we describe as

the Business Process Management (BPM) step. BPM

covers the design, implementation, usage, and adjust-

ment of processes from end to end. It concerns tech-

niques to better organize and automate operational

processes and keeping operations aligned with goals

and strategies. We used BPM here and not, for exam-

ple, process mining only, because (1) we do not want

to limit ourselves to process model and event log anal-

ysis only and (2) BPM covers a broader field of study

including also KPIs which go beyond the typical con-

siderations within the process mining discipline.

The classification phases shown in Figure 2 are

Detect (phase 1)

Predict (phase 2)

Recommend (phase 3)

Operational support for

bottleneck analysis

Event logs

BPM

Figure 2: Bottleneck analysis classification model.

based on the three types of operational support: de-

tect, predict, and recommend, as described by Van der

Aalst in (Van der Aalst, 2016). Process mining can be

used to perform those operational support activities.

The first operational support activity is detecting bot-

tlenecks. This activity is about detecting behavior that

is different from the modeled behavior (Van der Aalst

et al., 2011). The other two operational support activ-

ities are predicting and recommending. Predictions

can help in making decisions about the next step to

take (e.g., predict remaining flow time or total costs)

(Van der Aalst et al., 2011). With a recommendation,

the system will suggest the best decision based on a

goal (e.g. minimize remaining flow time, minimize

costs, or resource usage) automatically (Van der Aalst

et al., 2011). A combination of multiple goals is also

possible (Van der Aalst, 2016).

4 LITERATURE REVIEW

In this section, we describe the literature review con-

ducted to gather papers of relevance. We followed

the guidelines for performing a systematic litera-

ture review as proposed by Kitchenham (Kitchenham,

2004). Below, we first describe the search process.

Then, we discuss the assessment criteria for deter-

mining relevant papers. This section closes with dis-

cussing the findings.

A Classification of Process Mining Bottleneck Analysis Techniques for Operational Support

129

4.1 Search Process

An overview of the literature search process is shown

in Figure 3. Two scientific article databases were ex-

amined, namely Scopus and Web of Science. As the

initial step of the selection, a search query was de-

fined as TITLE-ABS-KEY ((“process* mining” OR

“workflow* mining”) AND (bottleneck*)) covering

the search in the title, abstract, and keywords. There

were 111 and 67 research articles found in Scopus and

Web of Science respectively.

Include only English

articles

Web of Science (67) Scopus (111)

Remove duplicates

(98)

First screening (title

and abstract) (50)

Second screening

(full text) (42)

Final result (45)

Manually added (3)

Figure 3: Literature review process.

Following inclusion and exclusion criteria, the

search result was narrowed down by excluding non-

English articles and eliminating duplication. Among

the rest of the articles, on-line accessible papers were

included which has concluded to 98 papers.

As a result of a first screening, based on the title,

the abstract, and the keywords, several papers were

excluded due to insufficient details of the required

context. More precisely, 48 papers were excluded that

do not address topics of process mining. After the

first screening, only 50 papers were selected for fur-

ther study.

4.2 Determining Relevance

In the next step, a full-text screening was carried

out. The papers were screened under three criteria

to check if and, possibly, to which degree the papers

cover any of the classification phases. That is, we as-

sessed the “maturity” of the phases detect, predict and

recommend according to three criteria. The criteria

are as follows:

• Criteria 0: The document does not mention con-

cepts related to bottleneck analysis using process

mining.

• Criteria 1: The document describes concepts re-

lated to bottleneck analysis using process mining.

• Criteria 2: The document is a complete study re-

lated to bottleneck analysis using process mining.

Each paper was assessed based on the criteria.

Each paper was assessed by two authors and in the

case no consensus was reached, a third author was in-

volved. The results are discussed in the next subsec-

tion. The papers which are assigned to criteria 0 for

all the phases, were not relevant for our study and are,

therefore, eliminated from the sample set. The result

of the systematic literature review was a list of 42 rel-

evant documents with an indication of which extend

bottleneck analysis techniques using process mining

were addressed. Additionally, we added three papers

that were suggested by the authors of this paper (Be-

mthuis et al., 2019; Badakhshan and Alibabaei, 2020;

Bemthuis et al., 2020). The papers from (Bemthuis

et al., 2019; Bemthuis et al., 2020) were added be-

cause some of the authors and project partners are also

involved in the present work and considered the pa-

pers as relevant within the realm of the present paper.

Although those papers did not explicitly focus on the

term bottleneck, a manual assessment and discussion

among the authors resulted in the inclusion. The use-

fulness of (Bemthuis et al., 2019) is also illustrated in

the demonstration of Section 5.

4.3 Findings

Following the three criteria proposed in the previous

section, we classified all the filtered papers using the

three phases (detect, predict and recommend). How-

ever, as we have to align with the limited number of

pages, only the summary of the classification is de-

scribed in this section. The results show that none of

the papers satisfied criteria 2 for all three bottleneck

phases. There were papers that are aligned with cri-

teria 2 for one classification phase and criteria 1 for

other classification phases.

Table 1 shows the papers that meet criteria 1 and

Table 2 shows the papers that meet criteria 2. It can

be observed that some papers (e.g., (Van der Aalst,

2013; Trinkenreich et al., 2015)) were classified into

multiple maturity phases. The results show that 44

unique papers are classified to the first phase (detect),

14 unique papers were classified to the second phase

(predict) and only 7 unique papers were at phase three

(recommend). Therefore, it may be observed that de-

tecting bottlenecks using process mining techniques

is fairly mature.

The papers classified according to criteria 1 are

depicted in Table 1. A total of 17 papers match this

criteria, and out of that 11 and 9 papers have discussed

the bottleneck phase 1 and 2 respectively. Only 6 pa-

pers are classified into the phase 3. Some of the pa-

pers are classified into more than one phases, such as

(Van der Aalst, 2013; Spott et al., 2013; Trinkenreich

et al., 2015).

This study found that 36 papers can be catego-

ICE-B 2021 - 18th International Conference on e-Business

130

Table 1: Papers that meet criteria 1, categorized per year.

Year Phase 1: detect Phase 2: predict Phase 3: recommend Number of

unique papers

2012 - - - 0

2013 (Bose et al., 2013;

Lee et al., 2013;

Spott et al., 2013;

Van der Aalst, 2013)

(Spott et al., 2013; Van der Aalst, 2013) (Van der Aalst, 2013) 4

2014 - - - 0

2015 - (Trinkenreich et al., 2015) (Trinkenreich et al., 2015) 1

2016 (Saelim et al., 2016;

Senderovich et al.,

2016)

(Senderovich et al., 2016) - 2

2017 - (Belo et al., 2017) - 1

2018 (Rold

´

an et al., 2018) (Caballero-

Hern

´

andez et al.,

2018; Ribeiro et al.,

2018)

(Caballero-

Hern

´

andez et al.,

2018)

3

2019 (Li and

De Carvalho, 2019;

Wu et al., 2019;

Seara and

De Carvalho, 2019)

(Armas et al., 2019;

Shani et al., 2019)

(Armas et al., 2019;

Shani et al., 2019)

5

2020 (Bemthuis et al., 2020) - (Bemthuis et al., 2020) 1

Total 11 9 6 17

rized under criteria 2. However, the majority of them

are classified only to the detect phase. Table 2 shows

the papers which have a complete study on bottleneck

analysis at the detect, predict and recommend phases.

Yet, in 2019 a series of papers were using process

mining addressing the predict phase (Ahmed et al.,

2019; Seara and De Carvalho, 2019; Li and De Car-

valho, 2019; Neira et al., 2019; Spenrath and Has-

sani, 2019). Only 1 paper (Ahmed et al., 2019) cov-

ers the recommendation phase. Therefore, it can be

observed that predicting bottlenecks and making rec-

ommendations using process mining techniques are

only marginally addressed in the literature.

5 DEMONSTRATION

This section demonstrates how process mining bot-

tleneck analysis techniques can be applied in a case

study. This demonstration entails a way to validate

the artifact, intending to discuss how the three phases

of bottleneck analysis could be examined. More pre-

cisely, we demonstrate how the detect phase can be

operationalized. We further describe how the predict

and recommend phase may be executed.

We use a logistic case study of (Bemthuis et al.,

2019), involving event logs of activities that took

place during the movements of Autonomous Guided

Vehicles (AGVs). Collaborative AGVs make sure that

products flow from a start station to one or more inter-

mediate stations and, ultimately, reach a final station.

It would be of interest to know what bottlenecks

exist and how bottlenecks could play a role in ob-

taining an efficient workflow of the AGVs as well as

the throughput of the system. Systems using AGV

technology are known for their complexity and can

involve many aspects such as vehicle scheduling, ve-

hicle routing, conflict resolution, obstacle avoidance,

and battery management. Bottlenecks hindering an

effective workflow may be present in any of these cir-

cumstances. Let us consider a bottleneck as an activ-

ity that is causing a relatively high throughput time of

the products.

Please notice that below we give some hypotheti-

cal examples supported by the case study. These ex-

amples may not fully represent practice, because one

may base the actual implementations/decisions on the

business logic of the use case. Instead, we decide

to illustrate the functioning of process mining bot-

tleneck techniques by using examples. This can be

justified because of (1) the limited amount of mature

literature on predict and recommend techniques, (2)

the demonstration fulfills a proof-of-concept imple-

mentation only and not a thorough validation study

(hence, this paper only outlines intentions regarding a

particular matter), and (3) the data relies on a simula-

tion model resembling a simplified optimization prob-

lem, which is easily verifiable.

For the execution of process mining algorithms,

we used the ProM Lite 1.1 tool. We pre-processed the

raw data by first converting the CSV-file to a standard

format for event log files (XES-file). Consequently,

A Classification of Process Mining Bottleneck Analysis Techniques for Operational Support

131

Table 2: Papers that meet criteria 2, categorized per year.

Year Papers Number of

unique papers

2012 Phase 1: (Anuwatvisit et al., 2012) 1

2013 - 0

2014 Phase 1: (Porouhan et al., 2014; Gupta and Sureka, 2014; Gupta et al., 2014) 3

2015 Phase 1: (Mahendrawathi et al., 2015; Premchaiswadi and Porouhan, 2015;

Trinkenreich et al., 2015)

3

2016 Phase 1: (Juneja et al., 2016) 1

2017 Phase 1: (Caesarita et al., 2017; Ganesha et al., 2017b; Meincheim et al., 2017;

Abo-Hamad, 2017; Belo et al., 2017; Ganesha et al., 2017a; Mahendrawathi et al.,

2017; Shrivastava and Pal, 2017)

8

2018 Phase 1: (Caballero-Hern

´

andez et al., 2018; Gerhardt et al., 2018;

Gonzalez-Dominguez and Busch, 2018; Heo et al., 2018; Rahardianto et al., 2018;

Ribeiro et al., 2018; Stefanini et al., 2018)

7

2019 Phase 1: (Bemthuis et al., 2019; Armas et al., 2019; Ahmed et al., 2019; Dzihni

et al., 2019; Fitriansah et al., 2019; Shani et al., 2019; Neira et al., 2019)

Phase 2: (Ahmed et al., 2019; Seara and De Carvalho, 2019; Li and De Carvalho,

2019; Neira et al., 2019; Spenrath and Hassani, 2019)

Phase 3: (Ahmed et al., 2019)

10

2020 Phase 1: (Kouhestani and Nik-Bakht, 2020; Badakhshan and Alibabaei, 2020; Yazici

and Engin, 2020)

3

Total - 36

we filtered the event log using the ‘Filter Log using

Simple Heuristics’ plug-in.

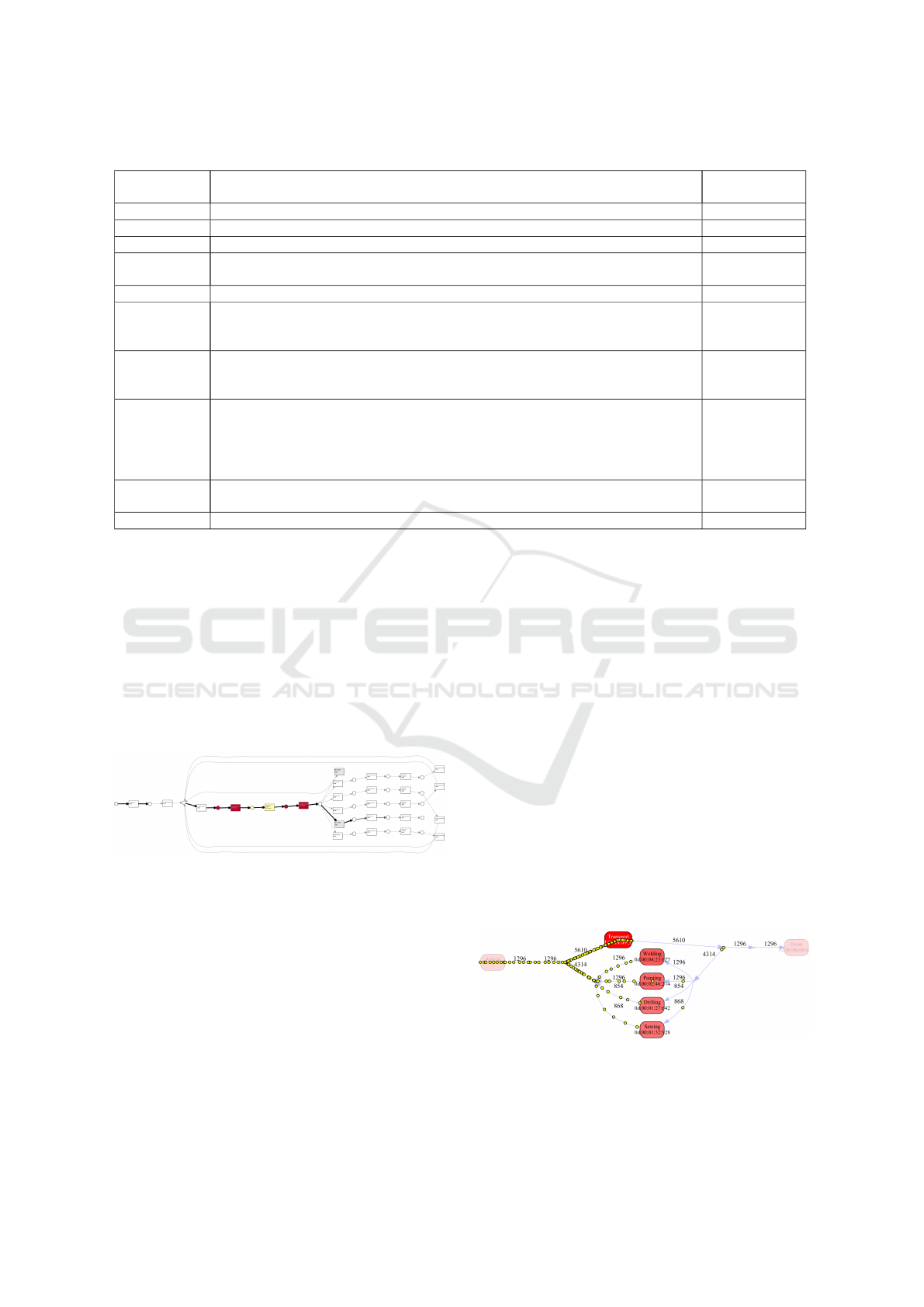

Let us start with the bottleneck detection. From

the filtered event log, we discovered a process model

using the inductive miner plug-in. Then, the con-

structed Petri net and the event log are used for perfor-

mance and conformance checking by using the ‘Re-

play a Log on Petri net for Performance/Conformance

Analysis’ plug-in. The resulting model is shown in

Figure 4 (for illustration purposes).

Figure 4: Discovered Petri net indicating bottlenecks.

The figure indicates (with red color) that there are

bottlenecks present within the transportation process.

Identifying bottlenecks is a first step to identify im-

provement potential. One may for instance come up

with evasive actions that go beyond the use/exploit of

event logs only. For instance enforcing new strategies

to shorten the time-span of a particular activity (e.g.,

better collision avoidance maneuvers). Yet, the matu-

rity phase detect is solely about the identification of

one or more (potential) bottlenecks.

Bottleneck Prediction can be considered as fol-

lows. Using a process mining tool (e.g., ProM), one

can predict the remaining throughput time. Suppose

that a trace is partially finished and that the remaining

time in the system of a product can be predicted. This

predicted remaining time can be used when making

projections of what is going to happen and, conse-

quently, support in making better-informed decisions.

For example, based on past experiences one may ob-

serve that the predicted remaining time of a product

to be finished is too high. This insight can be used to

decide which activity (or intervention) could be incor-

porated to eliminate or reduce a bottleneck’s obstruc-

tive impact.

Consider the visualized process model of Figure 5.

Suppose that a product is planned to go from the saw-

ing activity to the painting activity. After the prod-

uct has been processed at the sawing station, an AGV

decides to pick up this product. Imagine now that

another AGV’s events log indicates that the route in-

between those two stations is suddenly facing traffic

congestion. Hence, the expected remaining time in

the system for this product has increased.

Figure 5: Visualized process model indicating sojourn times

per activity.

As bottleneck recommendation technique, con-

sider again the example above of a partially finished

ICE-B 2021 - 18th International Conference on e-Business

132

trace. The approach could suggest what is the best

activity to do while taking into account the (accu-

mulated) effects of bottlenecks or expected bottle-

necks. A strategy could include avoiding bottlenecks

as much as possible. In the example of Figure 5, one

could decide to change the sequence of visiting the

processing stations. For example, the AGV can de-

cide to travel first to the drilling station instead of the

painting station. In the recommendation approach,

one can base decisions on multiple goals, such as a

trade-off between minimizing the remaining time in

the system versus the total costs. It may be promising

to deploy such decision-making capabilities by using

agent-based modeling techniques, such as shown in

(Bemthuis et al., 2020).

6 CONCLUSION

This paper gives an overview of literature on bot-

tleneck analysis techniques utilizing process mining.

Based on operational support activities, we proposed

a classification model to categorize papers. The clas-

sification model entails three phases: detect, predict,

and recommend. A systematic literature review was

conducted to identify relevant papers that could be

categorized according to the bottleneck “maturity”

phases. Lastly, a demonstration showed how the three

phases of bottleneck analysis could be considered.

The results give insights into how mature the lit-

erature is on process mining bottleneck analysis tech-

niques. The majority of the papers are about detect-

ing bottlenecks, while limited research is done when

it comes to predicting and recommending activities.

With a demonstration, we aimed to provide a direction

on how bottlenecks can be detected and predicted, but

also what next steps could be done to, ultimately, mit-

igate the impact of bottlenecks or prevent the occur-

rence of bottlenecks. Despite its exploratory nature,

this study offers some insight into how bottlenecks

could be classified, how mature the literature is, and

what research directions were given limited attention.

There are certain limitations when it comes to this

research. The model needs more validation. There

may be more suitable maturity phases. Also, only a

concise demonstration was given that showed how the

techniques can be applied, whereas a comprehensive

case study based on real-life data could be more valu-

able. Another issue concerns that the model may not

be complete. However, it was not the intention to pro-

vide a conclusive model, but this research provides a

way to analyze the state-of-the-art.

A possible direction for future research, which re-

sulted from our literature study, is to focus more on

prediction and making recommendations on bottle-

necks by using process mining. Currently, the number

of papers in that regard is limited. Lastly, the devel-

opment of a taxonomy or implementation guidance

based on the classification model may be promising.

ACKNOWLEDGEMENTS

This research is funded by the Dutch Research Coun-

cil (NWO) (grant 628.009.015), project Datarel.

REFERENCES

Abo-Hamad, W. (2017). Patient pathways discovery and

analysis using process mining techniques: An emer-

gency department case study. In International Con-

ference on Health Care Systems Engineering, pages

209–219. Springer.

Ahmed, R., Faizan, M., and Burney, A. I. (2019). Pro-

cess mining in data science: A literature review. In

2019 13th International Conference on Mathematics,

Actuarial Science, Computer Science and Statistics

(MACS), pages 1–9. IEEE.

Anuwatvisit, S., Tungkasthan, A., and Premchaiswadi, W.

(2012). Bottleneck mining and petri net simulation in

education situations. In 2012 Tenth International Con-

ference on ICT and Knowledge Engineering, pages

244–251. IEEE.

Armas, J., Aguirre, S., Coronado, A., and Evangelista, M.

(2019). Evaluation of operational process variables in

healthcare using process mining and data visualization

techniques. In Proceedings of the 17th LACCEI Inter-

national Multi-conference for Engineering, Education

and Technology. Latin American and Caribbean Con-

sortium of Engineering Institutions, Montego Bay.

Badakhshan, P. and Alibabaei, A. (2020). Using Pro-

cess Mining for Process Analysis Improvement in Pre-

hospital Emergency, pages 567–580. Springer Inter-

national Publishing, Cham.

Belo, O., Dias, N., Ferreira, C., and Pinto, F. (2017). A

process mining approach for discovering etl black

points. In World Conference on Information Systems

and Technologies, pages 426–435. Springer.

Bemthuis, R., Mes, M., Iacob, M.-E., and Havinga, P.

(2020). Using agent-based simulation for emergent

behavior detection in cyber-physical systems. In 2020

Winter Simulation Conference (WSC), pages 230–241.

Bemthuis, R. H., Koot, M., Mes, M. R., Bukhsh, F. A.,

Iacob, M.-E., and Meratnia, N. (2019). An agent-

based process mining architecture for emergent be-

havior analysis. In 2019 IEEE 23rd International

Enterprise Distributed Object Computing Workshop

(EDOCW), pages 54–64. IEEE.

Bose, R. J. C., Maggi, F. M., and van der Aalst, W. M.

(2013). Enhancing declare maps based on event cor-

A Classification of Process Mining Bottleneck Analysis Techniques for Operational Support

133

relations. In Business process management, pages 97–

112. Springer.

Buddas, H. (2014). A bottleneck analysis in the ifrc supply

chain. Journal of Humanitarian Logistics and Supply

Chain Management.

Caballero-Hern

´

andez, J. A., Dodero, J. M., Ruiz-Rube, I.,

Palomo-Duarte, M., Argudo, J. F., and Dom

´

ınguez-

Jim

´

enez, J. J. (2018). Discovering bottlenecks in a

computer science degree through process mining tech-

niques. In 2018 International Symposium on Comput-

ers in Education (SIIE), pages 1–6. IEEE.

Caesarita, Y., Sarno, R., and Sungkono, K. R. (2017). Iden-

tifying bottlenecks and fraud of business process using

alpha++ and heuristic miner algorithms (case study:

Cv. wicaksana artha). In 2017 11th International Con-

ference on Information & Communication Technology

and System (ICTS), pages 143–148. IEEE.

Chen, D., Li, H., Chen, M., Dai, Z., Li, H., Zhu, M.,

and Zhang, J. (2020). Pebao: A performance bottle-

neck analysis and optimization framework in concur-

rent environments. In Silhavy, R., editor, Intelligent

Algorithms in Software Engineering, pages 248–260,

Cham. Springer International Publishing.

Dabir, A. and Matrawy, A. (2007). Bottleneck analysis of

traffic monitoring using wireshark. In 2007 Innova-

tions in Information Technologies (IIT), pages 158–

162.

dos Santos Garcia, C., Meincheim, A., Junior, E. R. F., Dal-

lagassa, M. R., Sato, D. M. V., Carvalho, D. R., San-

tos, E. A. P., and Scalabrin, E. E. (2019). Process min-

ing techniques and applications–a systematic mapping

study. Expert Systems with Applications, 133:260–

295.

Dzihni, A. S., Andreswari, R., and Hasibuan, M. A. (2019).

Business process analysis and academic information

system audit of helpdesk application using genetic al-

gorithms a process mining approach. Procedia Com-

puter Science, 161:903–909.

Fitriansah, I. A., Andreswari, R., and Hasibuan, M. A.

(2019). Business process analysis of academic in-

formation system application using process mining

(case study: Final project module). In 2019 5th In-

ternational Conference on New Media Studies (CON-

MEDIA), pages 189–194. IEEE.

Ganesha, K., Dhanush, S., and SM, S. R. (2017a). An ap-

proach to fuzzy process mining to reduce patient wait-

ing time in a hospital. In 2017 International Confer-

ence on Innovations in Information, Embedded and

Communication Systems (ICIIECS), pages 1–6. IEEE.

Ganesha, K., Raj, S. S., and Dhanush, S. (2017b). Process

mining approach for efficient utilization of resources

in a hospital. In 2017 International Conference on

Innovations in Information, Embedded and Commu-

nication Systems (ICIIECS), pages 1–5. IEEE.

Gerhardt, R., Valiati, J. F., and dos Santos, J. V. C. (2018).

An investigation to identify factors that lead to de-

lay in healthcare reimbursement process: A brazilian

case. Big data research, 13:11–20.

Gonzalez-Dominguez, J. and Busch, P. (2018). Automated

business process discovery and analysis for the inter-

national higher education industry. In Pacific Rim

Knowledge Acquisition Workshop, pages 170–183.

Springer.

Gupta, M. and Sureka, A. (2014). Nirikshan: Mining bug

report history for discovering process maps, ineffi-

ciencies and inconsistencies. In Proceedings of the 7th

India Software Engineering Conference, pages 1–10.

Gupta, M., Sureka, A., and Padmanabhuni, S. (2014). Pro-

cess mining multiple repositories for software defect

resolution from control and organizational perspec-

tive. In Proceedings of the 11th Working Conference

on Mining Software Repositories, pages 122–131.

Heo, G., Lee, J., and Jung, J.-Y. (2018). Analyzing bottle-

neck resource pools of operational process using pro-

cess mining. ICIC express letters. Part B, Applica-

tions: an international journal of research and sur-

veys, 9(5):437–441.

Jacobi, C., Meier, M., Herborn, L., and Furmans, K. (2020).

Maturity model for applying process mining in sup-

ply chains: Literature overview and practical implica-

tions. Logistics Journal: Proceedings.

Juneja, P., Kundra, D., and Sureka, A. (2016). Anvaya:

An algorithm and case-study on improving the good-

ness of software process models generated by min-

ing event-log data in issue tracking systems. In 2016

IEEE 40th Annual Computer Software and Applica-

tions Conference (COMPSAC), volume 1, pages 53–

62. IEEE.

Kitchenham, B. (2004). Procedures for performing sys-

tematic reviews. Keele, UK, Keele University,

33(2004):1–26.

Kouhestani, S. and Nik-Bakht, M. (2020). Ifc-based process

mining for design authoring. Automation in Construc-

tion, 112:103069.

Lee, S.-k., Kim, B., Huh, M., Cho, S., Park, S., and Lee, D.

(2013). Mining transportation logs for understanding

the after-assembly block manufacturing process in the

shipbuilding industry. Expert Systems with Applica-

tions, 40(1):83–95.

Li, G. and De Carvalho, R. M. (2019). Process mining in

social media: applying object-centric behavioral con-

straint models. IEEE Access, 7:84360–84373.

Mahendrawathi, E., Astuti, H. M., and Wardhani, I. R. K.

(2015). Material movement analysis for warehouse

business process improvement with process mining: a

case study. In Asia-Pacific Conference on Business

Process Management, pages 115–127. Springer.

Mahendrawathi, E., Zayin, S. O., and Pamungkas, F. J.

(2017). Erp post implementation review with process

mining: A case of procurement process. Procedia

Computer Science, 124:216–223.

Meincheim, A., dos Santos Garcia, C., Nievola, J. C., and

Scalabrin, E. E. (2017). Combining process min-

ing with trace clustering: Manufacturing shop floor

process-an applied case. In 2017 IEEE 29th Interna-

tional Conference on Tools with Artificial Intelligence

(ICTAI), pages 498–505. IEEE.

Mizgier, K. J., J

¨

uttner, M. P., and Wagner, S. M.

(2013). Bottleneck identification in supply chain net-

works. International Journal of Production Research,

51(5):1477–1490.

ICE-B 2021 - 18th International Conference on e-Business

134

Neira, R. A. Q., Hompes, B. F. A., de Vries, J. G.-J., Mazza,

B. F., de Almeida, S. L. S., Stretton, E., Buijs, J. C.,

and Hamacher, S. (2019). Analysis and optimization

of a sepsis clinical pathway using process mining. In

International Conference on Business Process Man-

agement, pages 459–470. Springer.

Peffers, K., Tuunanen, T., Rothenberger, M. A., and Chat-

terjee, S. (2007). A design science research method-

ology for information systems research. Journal of

management information systems, 24(3):45–77.

Piest, J. P. S., Cutinha, J., Bemthuis, R. H., and Bukhsh,

F. A. (2021). Evaluating the use of the open trip model

for process mining: An informal conceptual mapping

study in logistics. In Proceedings of the 23rd Interna-

tional Conference on Enterprise Information Systems,

pages 290–296. INSTICC.

Porouhan, P., Jongsawat, N., and Premchaiswadi, W.

(2014). Process and deviation exploration through

alpha-algorithm and heuristic miner techniques. In

2014 Twelfth International Conference on ICT and

Knowledge Engineering, pages 83–89. IEEE.

Premchaiswadi, W. and Porouhan, P. (2015). Process mod-

eling and bottleneck mining in online peer-review sys-

tems. SpringerPlus, 4(1):1–18.

Rahardianto, R., Sarno, R., and Budiawati, G. I. (2018).

Performance time evaluation of domestic container

terminal using process mining and pert. In 2018 Inter-

national Seminar on Application for Technology of In-

formation and Communication, pages 469–475. IEEE.

Ribeiro, R., Analide, C., and Belo, O. (2018). Improv-

ing productive processes using a process mining ap-

proach. In World Conference on Information Systems

and Technologies, pages 736–745. Springer.

Rold

´

an, J. J., Olivares-M

´

endez, M. A., del Cerro, J., and

Barrientos, A. (2018). Analyzing and improving

multi-robot missions by using process mining. Au-

tonomous Robots, 42(6):1187–1205.

Roser, C., Lorentzen, K., and Deuse, J. (2015). Reliable

shop floor bottleneck detection for flow lines through

process and inventory observations: the bottleneck

walk. Logistics Research, 8(1):1–9.

Saelim, N., Porouhan, P., and Premchaiswadi, W.

(2016). Improving organizational process of a hos-

pital through petri-net based repair models. In 2016

14th International Conference on ICT and Knowledge

Engineering (ICT&KE), pages 109–115. IEEE.

Samaan, M., Tawfeeq, M., and Smith-Spark,

L. (2021). Syria forced to ration fuel as

stricken ship keeps suez canal blocked. CNN.

https://edition.cnn.com/2021/03/28/africa/suez-canal-

ship-blockage-intl/index.html.

Seara, L. G. and De Carvalho, R. M. (2019). An ap-

proach for workflow improvement based on outcome

and time remaining prediction. In MODELSWARD,

pages 473–480.

Senderovich, A., Weidlich, M., Yedidsion, L., Gal, A.,

Mandelbaum, A., Kadish, S., and Bunnell, C. A.

(2016). Conformance checking and performance

improvement in scheduled processes: A queueing-

network perspective. Information Systems, 62:185–

206.

Shani, A. H. M., Sarno, R., Sungkono, K. R., and Wahyuni,

C. S. (2019). Time performance evaluation of agile

software development. In 2019 International Semi-

nar on Application for Technology of Information and

Communication (iSemantic), pages 202–207. IEEE.

Shrivastava, S. and Pal, S. N. (2017). A big data analytics

framework for enterprise service ecosystems in an e-

governance scenario. In Proceedings of the 10th Inter-

national Conference on Theory and Practice of Elec-

tronic Governance, pages 5–11.

Spenrath, Y. and Hassani, M. (2019). Ensemble-based pre-

diction of business processes bottlenecks with recur-

rent concept drifts. In EDBT/ICDT Workshops.

Spott, M., Nauck, D., and Taylor, P. (2013). Modern ana-

lytics in field and service operations. In Transforming

field and service operations, pages 85–99. Springer.

Stefanini, A., Aloini, D., Benevento, E., Dulmin, R., and

Mininno, V. (2018). Performance analysis in emer-

gency departments: a data-driven approach. Measur-

ing Business Excellence.

Subramaniyan, M., Skoogh, A., Salomonsson, H., Banga-

lore, P., Gopalakrishnan, M., and Sheikh Muhammad,

A. (2018). Data-driven algorithm for throughput bot-

tleneck analysis of production systems. Production &

Manufacturing Research, 6(1):225–246.

Trinkenreich, B., Santos, G., Confort, V. T., and Santoro,

F. M. (2015). Toward using business process intelli-

gence to support incident management metrics selec-

tion and service improvement. In SEKE, pages 522–

527.

Van der Aalst, W. (2011). Process mining - discovery,

conformance and enhancement of business processes.

Springer.

Van der Aalst, W. (2016). Process mining - data science in

action. Springer.

Van der Aalst, W., Adriansyah, A., De Medeiros, A. K. A.,

Arcieri, F., Baier, T., Blickle, T., Bose, J. C., Van

Den Brand, P., Brandtjen, R., Buijs, J., et al. (2011).

Process mining manifesto. In International Confer-

ence on Business Process Management, pages 169–

194. Springer.

Van der Aalst, W. M. (2013). Process mining in the large:

a tutorial. In European Business Intelligence Summer

School, pages 33–76. Springer.

Van der Aalst, W. M., Pesic, M., and Song, M. (2010). Be-

yond process mining: From the past to present and fu-

ture. In International Conference on Advanced Infor-

mation Systems Engineering, pages 38–52. Springer.

Wu, Q., He, Z., Wang, H., Wen, L., and Yu, T. (2019). A

business process analysis methodology based on pro-

cess mining for complaint handling service processes.

Applied Sciences, 9(16):3313.

Yazici, I. E. and Engin, O. (2020). Use of process mining

in bank real estate transactions and visualization with

fuzzy models. In International Conference on Intelli-

gent and Fuzzy Systems, pages 265–272. Springer.

A Classification of Process Mining Bottleneck Analysis Techniques for Operational Support

135