Personalized Hip Replacement: State of the Art and New Tools

Proposals

Isabel Moscol

1a

, William Solórzano-Requejo

1,2 b

, Carlos Ojeda

1c

and Ciro Rodríguez

3d

1

Department of Mechanical and Electrical Engineering, Universidad de Piura, Piura, Peru

2

ETSI Industriales, Universidad Politécnica de Madrid, Madrid, Spain

3

Department of Software Engineering, Universidad Nacional Mayor de San Marcos, Lima, Peru

crodriguezro@unmsm.edu.pe

Keywords: Hip Arthroplasty, Biomaterials, Short Stems, FEA Software, Artificial Intelligence.

Abstract: Hip replacement is one of the most successful surgical events that progressively more patients require because

of the better life expectancy and increase in the average age of several countries. It further promoted the

improvement of hip prosthesis lifespan in sciences such as materials, mechanics and, recently, computer

science with artificial intelligence (AI). The present investigation aims to make a systematic review of the

progress with recent developments and criteria to get optimal outcomes in the design and selection of hip

implants, emphasizing femoral stem parameters for their relevance to the entire prosthesis performance. New

software tools such as clustering, and a different finite element analysis (FEA) approach are introduced to

speed up customized design processes without sacrificing accuracy. Clustering algorithms delimited the

proximal femur properly according to its anatomical locations. Moreover, Altair SimSolid

®

software proved

satisfactory accuracy compared to NX

®

simulation values despite the complex morphology of the proximal

femur with a maximum deviation of 12.94% and a simulation time of less than 30%.

1 INTRODUCTION

One of the main and largest joints in the human body

is the hip. It constituted by the femoral head and the

acetabulum through the articular cartilage, acetabular

labrum and ligaments. Moreover, the femur is the

longest and heaviest bone, receives and

physiologically distributes the gravitational loads of

the body. Different conditions such as walking,

jogging, sitting, among others accentuate the loads, so

it requires high resistance; however, the arrangement

of the hip joint ensures a proper physiological transfer

of loads enabling stability and mobility at the same

time.

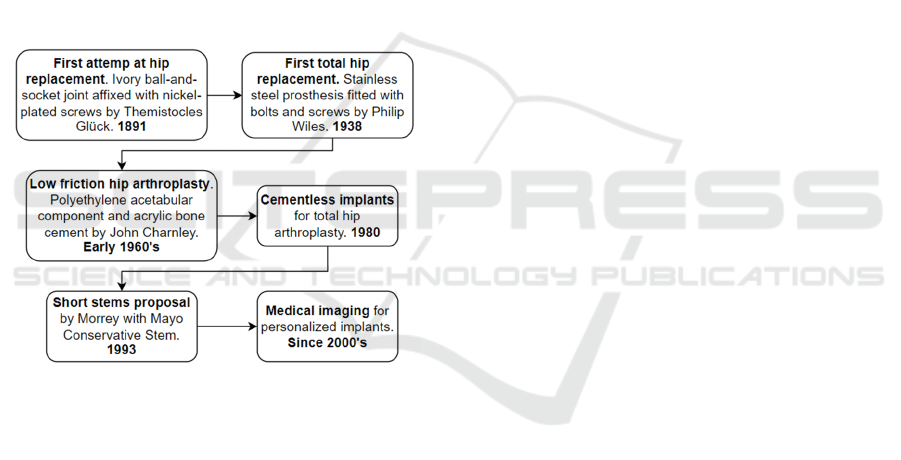

Total hip arthroplasty is one of the most

successful surgical procedures (Learmonth et al.,

2007). It has undergone extensive development

(Figure 1) due to its high demand because

increasingly younger patients require a hip

a

https://orcid.org/0000-0001-8959-9547

b

https://orcid.org/0000-0002-2989-9166

c

https://orcid.org/0000-0001-6163-5382

d

https://orcid.org/0000-0003-2112-1349

replacement, and also, in several countries, the

population is getting older.

This surgical procedure is performed when non-

invasive treatments fail to relieve pain or restore

mobility in the patient's hip. It mainly occurs when

there is a femoral neck fracture, intertrochanteric

fracture, coxarthrosis, or other pathology associated

with the hip joint, often linked to low bone quality or

cartilage degradation. Demand for a primary total hip

replacement among people less than 65 years old was

projected to exceed 52% by 2030 (Kurtz et al., 2010).

In young patients, hip fracture risk appears when

extremely high loads are transferred usually in a short

time due to accidents.

Hip replacement removes the damaged parts of

the femur and acetabulum to replace them with

artificial limbs named hip prosthesis, whose

components are the cup, insert, femoral head, and

stem. The latter has a crucial function in the success

46

Moscol, I., Solórzano-Requejo, W., Ojeda, C. and Rodríguez, C.

Personalized Hip Replacement: State of the Art and New Tools Proposals.

DOI: 10.5220/0010823100003123

In Proceedings of the 15th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2022) - Volume 1: BIODEVICES, pages 46-57

ISBN: 978-989-758-552-4; ISSN: 2184-4305

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

and duration of the implant since it will be in direct or

indirect (through cement) contact with the femoral

cavity, being in charge of proper load transferring to

the proximal femur. The objective is to make this

transfer as close as possible to the natural

biomechanical behaviour by the optimal design and

fixation.

Despite the technological advances, there are still

several postoperative pathologies related to multiple

incompatibilities caused by the external agent.

Corrosion and wear debris, associated with

biomaterial properties, are responsible for osteolysis

inducing bone inflammation and resorption that

eventually lead to periprosthetic loosening of the

implant (Eltit et al., 2019). Moreover, differences in

mechanical properties promote Stress/Strain

Shielding (SS) because of Young's modulus variation

between implant and bone (Table 1), this

phenomenon promotes bone resorption on the

periprosthetic region of the stem.

Figure 1: The temporal sequence of hip prostheses.

In the last two decades, development in

computational tools like CAD/CAE software and AI

have been valuable tools for more accurate and time-

optimized experimentation. Many design and

selection processes could now be automated so that

orthopaedic physicians or biomedical engineers save

time and reduce the number of possible solutions to

evaluate.

These tools can improve surgical outcomes by

ensuring precision in several parameters such as the

positional coordinates and forces to ensure adequate

initial fixation of the implant. Robotic hip surgery

was initiated in the 1980s with the DigiMatch

Robodoc surgical system produced by the company

then called Integrated Surgical Systems

(Subramanian et al., 2019). This system helps

preoperative planning in which patient’s Computed

Tomography (CT) guides the surgeon in the implant

selection and previews the postoperative outcomes.

Nowadays, there’ve been several improvements and

another part of the Robodoc performs the osteotomy

bone cut and inserts the implant minimizing human

error and the risk of bone fracture during the surgery

(Sugano, 2013).

2 TYPES OF HIP PROSTHESES

In 1959, Sir John Charnley proposed the low friction

total hip arthroplasty where a small-diameter socket

restores the total mobility of the joint and eradicates

pain. Despite the good technical skills of the

surgeons, there were still several failure cases. For

that reason, in 1962 Craven suggested the high-

density polyethylene (HMWP) as a material for the

socket that was an excellent complement for

Charnley’s design proposal. (Camacho & Fernandez,

2006)(Wroblewski, 1997). However, the failure rate

of the Charnley prosthesis was higher in young

patients, who are estimated to lead more physical

activity moving their hip around 5 million cycles per

year (Gallart et al., 2018). To recover the entire

mobility and mechanical demands, the cement goes

under high mechanical stresses which, in most cases,

led to its fracture.

Moreover, outcomes of cement fixation are not

the same for patients with good bone quality as in

patients with greater porosity. Better cement-bone

bond is achieved when the patient has a less bone

mass index. (Learmonth et al., 2007)(Cotogno, 2012).

This controversy promoted the introduction of

cementless fixation in 1980, whose target is to

guarantee long-term biological stability through bone

ingrowth on the stem walls, a process known as

osseointegration. It results from direct bone-implant

contact with biocompatible porous coating and

minimal interface micromotion (Nazari-farsani,

2015). Relative displacements are related to surgical

technique, implant geometry and stiffness, bone

quality, daily activities, and patient weight. The

appropriate geometry would enhance

primary/mechanical stability within 3 to 6 months

after surgery and the good engagement of the

prosthesis with the surrounding bone lead to

secondary/biological one due to good

osseointegration (Javed et al., 2013)(Ruben et al.,

2007). The proper implant would have a high rate of

success if the patient’s bone remodelling was also

good, that is why these types of implants are

recommended for young patients.

Personalized Hip Replacement: State of the Art and New Tools Proposals

47

Although cementless fixation showed remarkable

designs continued to be invasive since they occupy

from the proximal region to the upper part of the

femoral diaphysis. It would lead to obstructing the

bloodstream that provides oxygen and nutrients for

bone maintenance. Reducing bone remotion in the

surgical procedure and optimizing the load transfer,

through appropriate implant geometry and material,

would ensure bone preservation and a long prosthesis

lifespan (Gallart et al., 2018).

A study by (Jasty et al., 1993) showed that the

diaphyseal portion of the stem was rendered unusable

when the bone grew proximally. Other studies about

diaphyseal anchorage indicated it is associated with

anomalous load transfer, leading to thigh pain in the

short term and proximal bone loss by SS in the long

term (Amstutz & Duff, 2015). Therefore, the need

arises to shorten the stem length with designs that

span to the metaphyseal region of the proximal femur,

giving rise to the field of short-stem prostheses.

Short stems, also called metaphyseal stems, leave

more bone stock available for being smaller. They

could also preserve bone by distributing loads more

physiologically. Recent studies show less bone

mineral density loss in the proximal region for

patients with this type of stem and a reduced proximal

SS (Sköldenberg et al., 2006). Short stems have been

classified by different authors according to their

geometry and anatomical zones occupied in the

proximal femur, resulting in four main categories:

Type 1: Femoral neck stem.

Type 2: Calcar loading stem.

Type 3: Calcar loading with lateral flare stem.

Type 4: Shortened tapered conventional stem.

Short stems usually have a length between 40 and

135 mm, reaching at most to the superior diaphysis as

in the case of tapered-wedge designs. The best results

according to literature are related to the calcar loading

with lateral flare stems, whose tapered trapezoidal

design achieved adequate fixation and demonstrated

Figure 2: Proximal femur occupied by the Type 3 short stem

DePuy Proxima™ (Santori et al., 2007).

more effective load transfer in the proximal femur

than the other designs (Khanuja et al., 2014)(Kheir et

al., 2020).

Within the category of calcar short stems, load

bearing with lateral flare designs have shown the

highest rate of success. In this category, the DePuy

Proxima™ (DePuy, Leeds, UK) model (Figure 2) is

found standing out with overall survival of 100% for

4.5 years and 97.6% for 7 years according to follow-

up studies made by (Kim et al., 2013) and (Gombár et

al., 2019), respectively.

3 BIOMATERIALS

3.1 Importance and Influence

Biomaterials must meet several requirements that

vary according to whether the prosthesis is cemented

or uncemented. In the first category, usually,

Polymethylmethacrylate (PMMA) cement will be in

direct contact with the bone while, in the second, stem

walls, normally covered by a porous material, will

enable the stem fixation. Accordingly, biomaterials

will vary depending on their function either in the

body of the components or as a coating or bone

cement. In general, the body/internal component

material must be compatible with mechanical

properties as close as possible to the bone; otherwise,

stresses transmitted to the bone would be reduced to

such an extent that SS occurs. To achieve this, good

mechanical strength, as well as fatigue resistance are

required.

Cemented fixation guarantees primary stability

just after the bone cement has set due to the hardening

properties of the cement which mechanically fixes

and prevents relative mobility at the bone-implant

interface. A homogeneous cement layer with a good

setting improves mechanical fixation, contributing as

well to the physiological transfer of loads and

reducing SS (Cotogno, 2012). The cemented implant

proposed by Sir John Charnley has a probability of

success between 77% and 81% over a range of 25

years after THA, but the failure rate was higher for

young patients. The first problem was related to the

material of the acetabular component, polyethylene

(PE), whose debris infected the bloodstream due to

metallosis (Rieker, 2016)(Hu & Yoon, 2018). This

material was then replaced by high-density

polyethylene (UHMWPE, ultra-high molecular

weight polyethylene). However, the rate of failure

persisted because of incompatibilities between the

bone cement, the active lifestyle, and bone quality of

these patients.

BIODEVICES 2022 - 15th International Conference on Biomedical Electronics and Devices

48

A study made on 48 patients younger than 30

years with cemented hip implants showed a 10-year

survival of 83% with revision for any reason and 90%

with revision for aseptic loosening as the endpoint

(Busch et al., 2010). A post-study (Schmitz et al.,

2013) with the same population and revision criteria

showed a 15-year survival rate of 75% and 82%,

respectively. However, this option is more

recommended for young people with degenerative

cartilage disease in the hip joint and aseptic loosening

is accompanied sporadically by aggressive bone

destruction, a phenomenon termed cement disease

(Barrack, 2000).

As a result, cementless prostheses were proposed

to take advantage of the good bone quality that

younger patients have. Implant success is highly

correlated to initial stability which is essential to

promote bone ingrowth into the stem coating (Ruben

et al., 2012). The stem coating must enhance

osseointegration and be resistant to wear and

corrosion to minimize the release of particles into the

bloodstream and avoid toxicity. Most of the implants

commonly use a porous coating called

Hydroxyapatite [Ca₁₀(PO₄)6(OH)₂] whose bioactive

interaction accelerates the bone ingrowth process

through a series of reactions between the biomaterial

and the internal fluids of the femur that form a

biologically active carbonate layer, equivalent to the

bone mineral phase (Cotogno, 2012).

The primary stability is also related to stem

geometry and materials that likewise influence

biological stability where minimized stress shielding

is required. One of the main factors about implant

material is the stiffness level. Highly stiff implants

induce less micromotion compared to low-stiff ones,

nonetheless, high-stiff materials promote stress

shielding and adverse bone remodelling at the implant

surfaces (Chanda et al., 2020). The long-term stability

of cementless prostheses also depends on the patient's

health, especially bone quality, which influences on

bone remodelling rate in the periprosthetic region.

3.2 New Materials

Several types of materials like ceramics, polymers

and metals have been developed for implants

purposes. They classify based on their interaction

with the surrounding tissue in bio-tolerant, bioactive

and bioresorbable. Metals have shown good quality

outcomes being the most commonly used: stainless

steel (316L), cobalt-based alloys (Co-Cr-Mo) and

titanium-based alloys (Ti-6Al-4V, Ti-5Al-2.5Fe, Ti-

Al-Nb) (Aherwar et al., 2016). Nowadays, titanium is

the most used material in femoral stems manufacture,

it is characterized by low density, highly

biocompatible with good resistance to stress and

corrosion; the latter is since there is a rapid reaction

with oxygen that generates a thin protective layer. Its

alloys, especially Ti-6Al-4V, have shown good

results in reducing SS by having a lower Young's

modulus than other types of alloys; however, this is

approximately 110 GPa, still high compared to

cortical bone (Kunii et al., 2019) producing SS due to

a disproportionate bone remodelling.

Prior biomechanical studies (Kuiper & Huiskes,

1996) concluded that decreasing stem stiffness

reduces stress shielding and avoids severe bone

resorption. Nevertheless, it increases proximal

interface stresses, which may inhibit biological

fixation and cause loosening.

A non-homogeneous Young's modulus material

proposed in (Hanada et al., 2014) is β-Ti33.6Nb4Sn

(TNS) obtained after several cold working and local

heat treatments. It has high strength with Young's

modulus (45 GPa with cold rolling) much lower than

other β-type Titanium alloys: axial stiffness 56%

lower and bending stiffness 53% lower than

Ti6Al4V (Yamako et al., 2017). In studies with TNS,

a low Young’s Modulus in the distal part of the stem

and high fatigue strength (850MPa) in the neck region

were proposed. However, rather low Young's

modulus, although decreasing stiffness, could cause

excessive stresses at the bone-implant interface

inhibiting fixation; additionally in vivo studies must

include adaptative bone remodelling to determine

whether bone changes occur in the surrounding

tissue. Despite that, studies show that bone mineral

density would be 42.6% higher in the Gruen 7 zone

with a TNS stem than Ti-6Al-4V 10 years after

implant placement. Another new option is the Ti21S

alloy (Pellizzari et al., 2020), whose biocompatibility

is like Ti6Al4V, which generates more mechanical

advantages by having Young's modulus of

approximately half, as shown in Table 1.

Table 1: Mechanical properties of Titanium alloys for hip

prostheses.

Alloy

Young’s

Modulus

(GPa)

Tensile

Strength

(MPa)

Reference

Cortical

Bone

10 - 20 100 - 300

(Cotogno,

2012)

Ti-33.6Nb-

4Sn (TNS)

55 1270

(Yamako et

al., 2014)

Ti-6Al-4V 110 1095

(Facchini et

al., 2011)

β - Ti21S 52 831

(Pellizzari

et al., 2020)

Personalized Hip Replacement: State of the Art and New Tools Proposals

49

Recent studies are evaluating biomechanical

properties obtained with additive manufacturing where

adaptative cell topologies resemble bone local mecha-

nical properties. In (Arabnejad et al., 2017) obtained a

75% reduction in bone loss derived from stress

shielding (8% of bone resorption with the optimized

fully porous implant) compared to a solid implant.

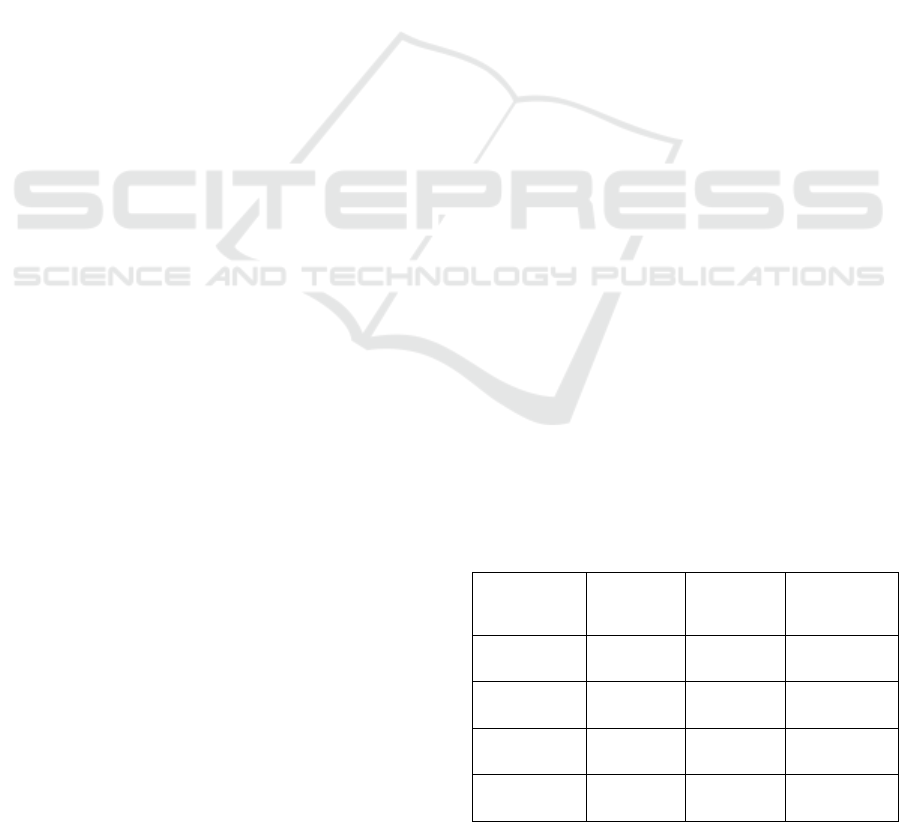

4 PERSONALIZED PROSTHESES

Hip implant longevity is increased by customizing the

prosthesis design. This implies considering the offset,

anteversion, and neck-shaft angle (Figure 3). Before

starting the design and the implant material selection,

it is necessary to know the host bone properties

(Solórzano et al., 2020) and the patient’s health

situation. This way, better performance outcomes and

durability of the hip prostheses can be guaranteed.

Figure 3: Femur parameters considered in a customized

design.

The most noticeable physiological changes are

due to the patient's age because, after a certain age,

bone quality begins a noticeable decline attributed to

metabolic changes in the bone tissue and a decrease

in bone osteocalcin content (Portal-Núñez et al.,

2012). Thus, if the patient is young, the hip joint will

be subjected to higher mechanical loads and is more

likely to undergo revision surgery compared to an

older patient. Therefore, a less invasive stem will be

required. Moreover, the more active bone tissue of

young patients makes them suitable for the use of

cementless prostheses, as it promotes

osseointegration, which accelerates primary stability

and increases implant life by forming a stronger bond

than cemented fixation (Sivasankar et al., 2016).

Another way to customize hip prostheses was

proposed in Milan around 1987 by Cremascoli

(Srinivasan et al., 2012). He suggested the modular

neck to give independence and adaptability according

to physical attributes of the patient's joint, such as

offset, femoral neck anteversion, and neck length.

Modular prosthesis presents two components (stem

and neck separately) coupled by a taper junction with

frictional bonding. The literature reveals no

noticeable variation in the long-term outcomes of

modular and non-modular prostheses; in contrast,

adverse effects such as fretting corrosion and fatigue

probably occur at the junction of modular prostheses

(Kheir et al., 2020)(Schaaff, 2004).

Therefore, monoblock customization of the

implants is recommended. It involves considering

proximal and distal morphologies of the femur for

more accurate stem personalization. In this regard,

CT allows virtual reconstruction of a patient’s femur

(Figure 4). Uncemented prostheses adapted to the

inner part of the femur provide a better fit due to their

optimized volume, which also reduces the weight of

the implant. In this way, the stress distribution and

biomechanics of the joint resemble its natural state

(Katoozian et al., 2001).

Figure 4: Femoral geometry and properties from computed

tomography.

In 2009, (Ojeda, 2009) verified by numerical

simulation the preponderance of customized

prostheses. The study was performed with the

computed tomography (CT) of a 40-year-old woman

from Piura, Peru. Primary stability in a conventional

cementless prosthesis was assessed through micro-

displacements at the femur-stem interface. The

custom design was superior to the CLS Spotorno

®

model, but the relative micromotion in the posterior

lateral proximal zone remained high, ranging from

150 to 200 microns. It is therefore important to

evaluate the lateral zone on the stem design.

The stem is crucial to improving prosthesis

performance because it is subjected to the highest

mechanical stresses and manage the physiological

transfer of loads to the surrounding bone. Firstly,

stem length affects the mechanical stability; hence the

longer, the better. However, this implies greater

invasion of the marrow cavity leaving less bone

available for possible revision surgery. As a

consequence, shorter stems are recommended for

patients younger than 65 years (Cotogno, 2012). The

BIODEVICES 2022 - 15th International Conference on Biomedical Electronics and Devices

50

custom design of short stems is performed with the

same methodology as conventional stems. However,

load distribution along the femur should be taken into

account, especially in the calcar and lateral regions of

the proximal femur due to its preponderance to the

SS. (Rawal et al., 2011)(Gómez-García et al., 2016).

(Solórzano, 2021) evaluated by FEA personalized

short stems with Ti21S material resulting in a SS of

0.285 and 0.073 for each of two patients; those

prostheses would improve mechanical response and

remodelling of the proximal femur than commercial

hip implants (Yamako et al., 2014)(Yan et al., 2020)

which could produce a SS between 0.61 and 0.93.

5 TECHNOLOGIES

5.1 Statistics and Artificial Intelligence

in Hip Arthroplasty

Initially, statistical methods (Otomaru et al., 2012)

introduced automation to segment the marrow cavity

and ensure prosthesis implantability. They combined

tolerance criteria of experienced surgeons and a map of

distances at the bone-implant interface based on a set

of medical images to create an atlas with the

delimitation of the maximum areas within the channel

cross-section where the stem geometry could be fitted.

Last decade, Artificial Intelligence has been

progressively gaining more space in the healthcare

field. In 2020, (Kang et al., 2020) applied

Convolutional Neural Networks (CNNs) with X-Ray

imaging to build a stem detection model to classify

and cluster different commercial models. The

algorithm could help to collect large-scale stem

information and to make comparisons among

different geometries which in the future would save

time for orthopaedists to identify and make new

selections among commercial prostheses.

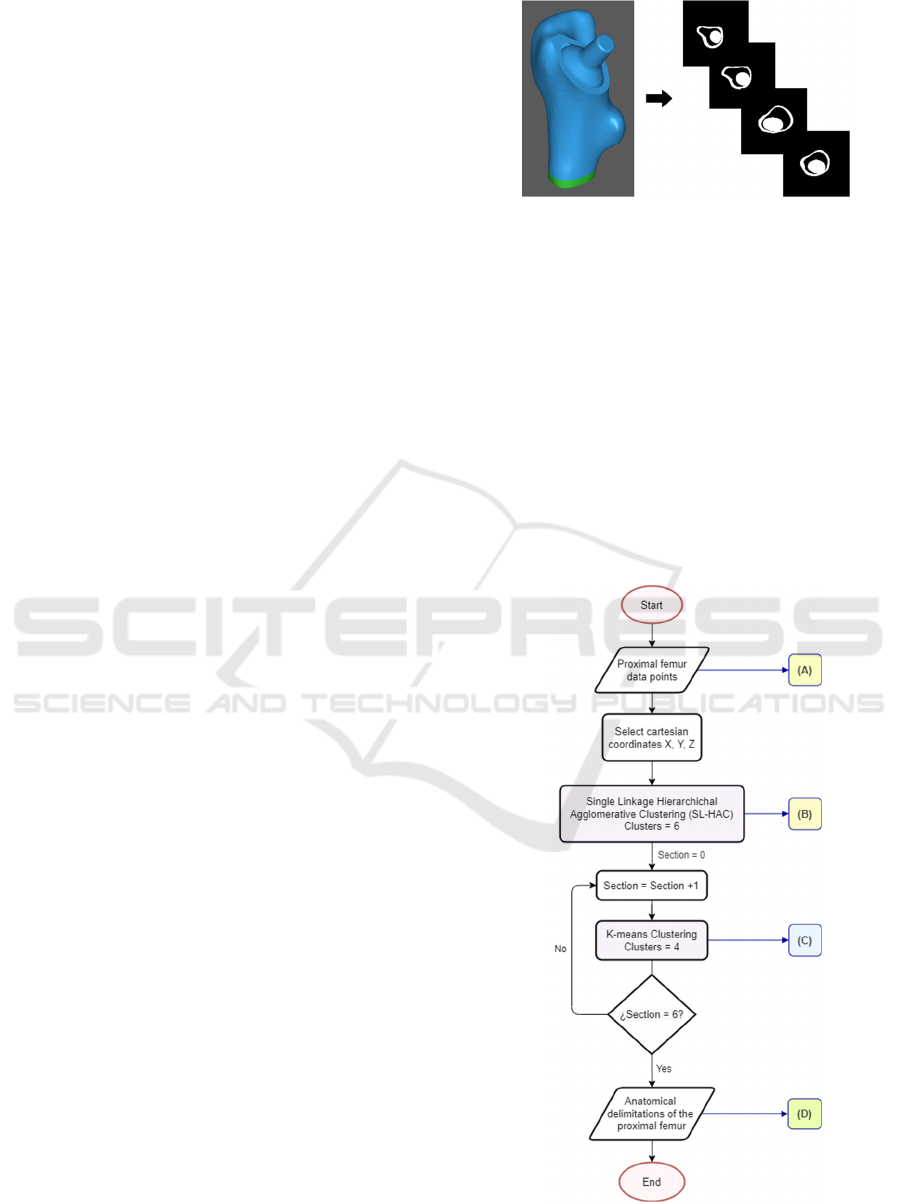

Recently, Chitubox

®

, a 3D printing software,

allowed (Bermejillo et al., 2021) to slice CAD models

obtaining a set of white and black pictures that

resemble CT images. That methodology can be used

in the design of femoral stems to acquire information

not only from the stem but also from the medullary

cavity. The slices of the proximal femur (Figure 5)

would be used to train a CNN that predicts femoral

response, like SS. Customization would be done by

evaluating femur response changing the pixel status

of stem portions. Then, after training AI models for

optimization, it could be used with real CT scans to

make personalized stems that restore bone

biomechanics with ideal performance concerning

physiological load transfer.

Figure 5: CT-like slices of a femur with hip replacement

using Chitubox

®

software.

Advanced AI tools are required to make a more

complete description of complex geometries. More-

over, ML-based methodologies may be applicable

when the computational costs of numerical simulation

are unaffordable. Several studies are underway to

improve the performance of AI-based systems to

streamline design processes with adequate accuracy.

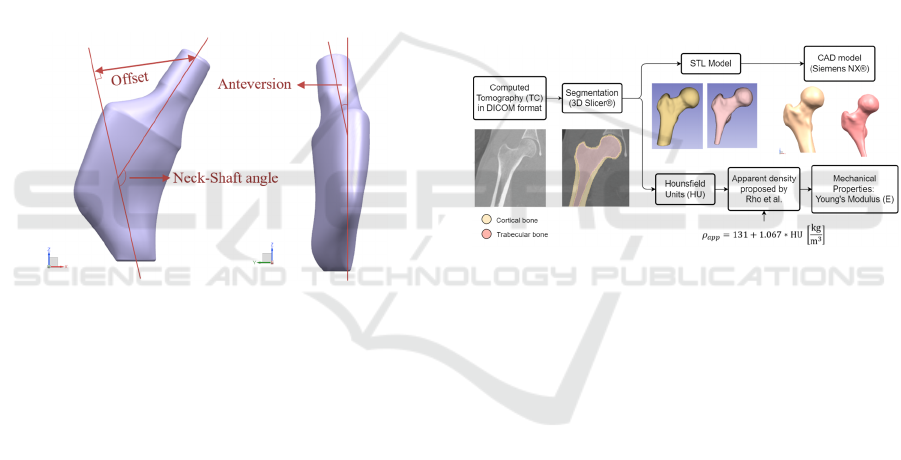

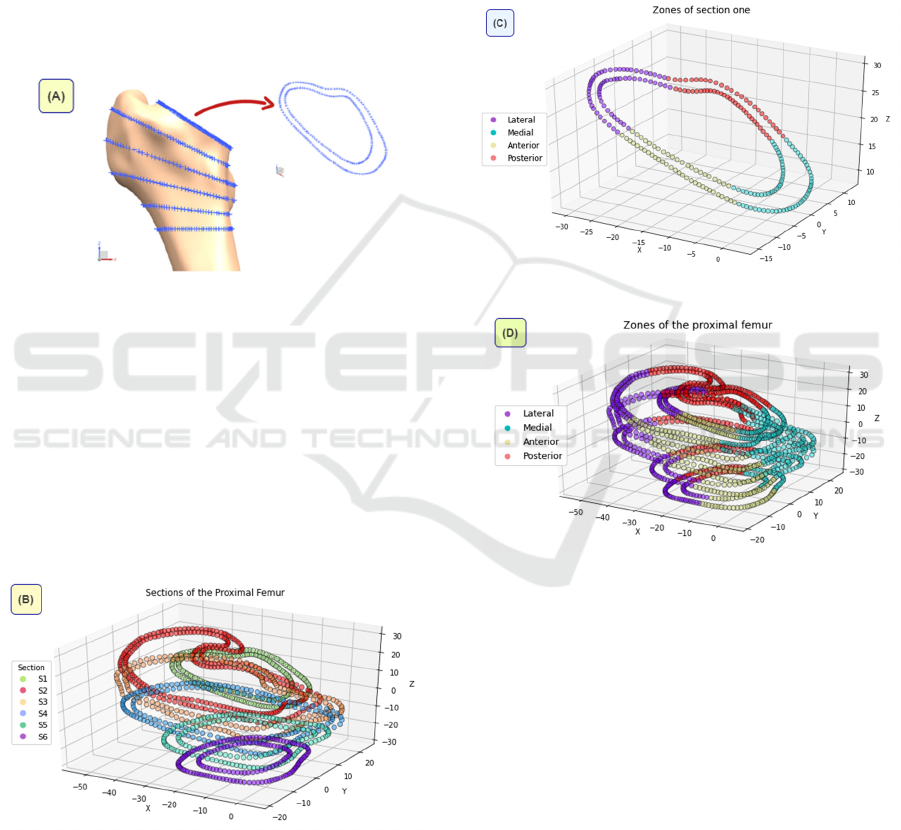

The present investigation proposes clustering

techniques (Figure 6) to make a more accurate and

time-saving assessment of the proximal femur. It

aims to get local information about the physiological

load transfer according to femoral anatomical

locations: lateral, medial, anterior, and posterior.

Figure 6: Flowchart to anatomically demarcate proximal

femur.

Personalized Hip Replacement: State of the Art and New Tools Proposals

51

The angular association among the proximal

femur planes is based on (Solórzano, 2021) proposal

of an innovative methodology for short stem designs

that guarantees stem implantability by acquiring

information of the medullary cavity and surgery

approach. The first plane corresponds to the

osteotomy plane taken from the CAD model of the

proximal femur of the patient, whose CT scans were

downloaded from an open-access medical image

repository (Raymond, 2019). The second reference is

a horizontal plane located 10mm below the lesser

trochanter. Finally, with equal division of the

osteotomy angle, six planes are obtained as is shown

in Figure 7.

Figure 7: Cortical bone points to be classified.

Through the SL-HAC, bone sections can be

identified without manually labelling each one

(Figure 8). Initially, all samples are individual

clusters, then the algorithm calculates the distance

between the most similar for each pair of clusters to

then combine those who are closer. This division

allows working with points that contain not only

rectangular coordinates but also the local femur

response to mechanical stimuli in stress, strain,

among others values.

Figure 8: Sections generated by the SL-HAC algorithm.

The final clustering shown in Figure 9 is made

automatically by a K-Means algorithm through an

iterative update of the centroids, identified randomly

at the beginning. This ML technique is good at

dealing with data of spherical distribution. Same K-

Means specifications were applied to each of the six

planes in Figure 7.

One of the main benefits of this approach relies on

increasing ML-based models, where speeding up data

acquisition with high accuracy is required. These

delimitations (Figure 10) provide insight into changes

in physiological load distribution and bone

biomechanics as a function of varying load patterns.

SS can also be quantified and analyzed in detail with

this demarcation of the proximal femur.

Figure 9: Zones of one section by K-Means algorithm.

Figure 10: Proximal femur completely delimited according

to the anatomical locations.

Regarding mechanical design, in 2015, (Chanda

et al., 2015) designed an Artificial Neural Network to

relate geometric parameters of the stem to micro-

displacements at the bone-implant interface. They

also included optimization through Genetic

Algorithms (GA) to improve mechanical stability, but

SS is not guaranteed due to its micromotion approach

that doesn’t quantify the loads received by the femur.

In 2017, (Cilla et al., 2017) studied whether the

geometry of a commercial femoral prosthesis could

be effectively optimized to reduce the SS. They

compared Support Vector Machines (SVM) and

Artificial Neural Networks (ANNs) after combining

them with Pattern Search minimization algorithm

(Table 2). SVM gave better results; however, the

BIODEVICES 2022 - 15th International Conference on Biomedical Electronics and Devices

52

effectiveness may vary from patient to patient and

depending on the amount of data.

A recent innovation regarding the improvement in

optimization algorithms was raised in 2019, where

(Chatterjee et al., 2019) introduced the concept of the

composite desirability function to solve the problem

of obtaining a single value as output from ANNs. This

function made it possible to consider the

susceptibility to significant stress variations in each

proposed region after the prosthesis was placed. They

also parameterized the patient's bone quality,

quantifying its influence on the same problem.

Table 2: Algorithms for Design Optimization.

Al

g

orithms Hi

g

hli

g

hts

To estimate the femur response to the supported loads

Artificial Neural

Networks (ANN)

Attempts to mimic the human

brain for solving specific tasks

finding

complex associations

among data like a black box.

Support Vector

Machines (SVM)

SVM do not retrain the model to

estimate a new value once it has

already been trained and tested. It

adds the new remark directly and

updates itself.

To find the optimal geometry optimizing a cost function

Genetic

Algorithms (GA)

Stochastic global search method

based on the Darwinian concept of

survival. It uses the principle of

natural selection and genetic

inheritance by evaluating a fitness

score.

Pattern Search

(PS)

Numerical optimization method

that computes objective function

(OF) for the points in a grid. It

explores more than it exploits by

changing iteration with the first

point exceeding the best OF.

5.2 FEA Software

Requirements of large amount of data have also

turned attention to fast simulation software and to

understanding how they work. In conventional

analysis, simulation of a virtual femur could take

from 5 to 15 minutes depending on computer

specifications, the geometric complexity of the model

and boundary conditions as well as the meshing

characteristics.

Around 2018, a meshless software called

SimSolid

®

from Altair Engineering Inc. was

launched. It proposes a new FEA approach where no

discretization in finite elements is done but takes any

type of geometry, whether simple, amorphous or

complex such as the proximal femur and considers it

as a finite element (FE) (Altair, 2019). Furthermore,

this software works with contour functions that

generate the degrees of freedom (DOF) of the

FE/component, unlike the conventional approach

where the number of nodes of the discretized finite

element defines its DOF. In addition, the contour

DOF are not the only ones produced when developing

the external approximations in SimSolid

®

, but also

the internal DOF associated with the volume are

generated automatically. Meshless software performs

adaptive solutions where the number of DOF of the

boundary is automatically assigned to meet the

convergence criteria.

Simulation time is another advantage of meshless

simulation. For femoral analysis, SimSolid

®

takes

from 30 seconds to 1 minute depending on default

solution settings and it could take from 3 to 6 minutes

with increased refinement level. In addition, not using

meshing saves time for model pre-processing,

whereas in conventional FEA simulation the element

size must be defined according to h-method and p-

method through convergence analysis.

The mathematical formulation of the meshless

approach, specifically SimSolid

®

, dates to 1908 when

Ritz proposed an approximate solution to the

boundary value problem with the linear combination

of simple functions (𝑝

). In (1), 𝑎

are factors without

physical representation defined when the energy

function, 𝐹𝑈

,

in (2), is assigned to a

minimum value, 𝑛 is the number of nodes of the FE.

𝑈

ℎ,𝑒𝑙𝑒𝑚𝑒𝑛𝑡

𝛴𝑎

𝑖

.𝑝

𝑖

, ∀ 𝑖1,2,3,… ,𝑛

(1)

𝐹𝑈

,

𝐹

𝛴𝑎

.𝑝

min (2)

Equation (3) is satisfied for the FE approximation

to be external of the element. , refers to the pairs

that lie on the element boundary. δ and 𝛾 are

operators,

𝑈 and are approximation functions defined

inside the element. Altogether in (3) guarantees that

the boundary of the limit approximation functions of

𝑈 belong to the Sobolev space which guarantees their

existence only to a certain degree so 𝐹𝑈 provides

finite energy. (SimSolid Corporation, 2015)

𝛿,𝛾𝑈0

(3)

In (4) boundary DOF are also defined, which have

no physical meaning. Their function is to guarantee

that the approximation functions (𝑈) of each FE are

compatible when 𝐵

tends to infinity.

Personalized Hip Replacement: State of the Art and New Tools Proposals

53

𝐵

𝐷𝑂𝐹

𝑔

𝑘

𝛾𝑈𝑑𝛾

𝛾

, ∀ 𝑘1,2,… ,𝑛

(4)

𝛾: the boundary of the finite element.

𝑔

: simple functions on the boundary of the FE.

In (3), 𝑈 is the function to be approximated in the

element like stresses or displacements in structural

analysis. When it comes to external analysis, the 𝑈

function from (5) and (6) not only incorporates the

element but also considers its boundary.

𝑈

ℎ

𝑈

𝑒𝑙𝑒𝑚𝑒𝑛𝑡

𝑈

𝑏𝑜𝑢𝑛𝑑𝑎𝑟

𝑦

(5)

𝑈

ℎ

𝛴𝑎

𝑖

𝑈

𝑝

𝑖

𝛴

𝑔

𝑘

𝛾𝑈𝑑𝛾

𝛾

𝑝

𝑘

(6)

In equation (6),

𝑎

: internal DOF of the element.

𝑝

: basis functions within the internal DOF.

𝑝

: basis functions of the boundary DOF.

Literature shows that SimSolid

®

presents a

deviation concerning other numerical simulation

software lower than 1% in the high-stress

concentration elements, reaching values lower than

5% in all cases (skew plate, plate with hole, U-shaped

notch) with the maximum precision setting. reducing

variation from 29.3% to 2.8% compared to the default

configuration (Symington, 2020). The only study

found with human geometry (Rivera et al., 2020)

evaluated a mandible reconstructed from a CT scan

getting 2-7% of deviation when compared with other

FEA software.

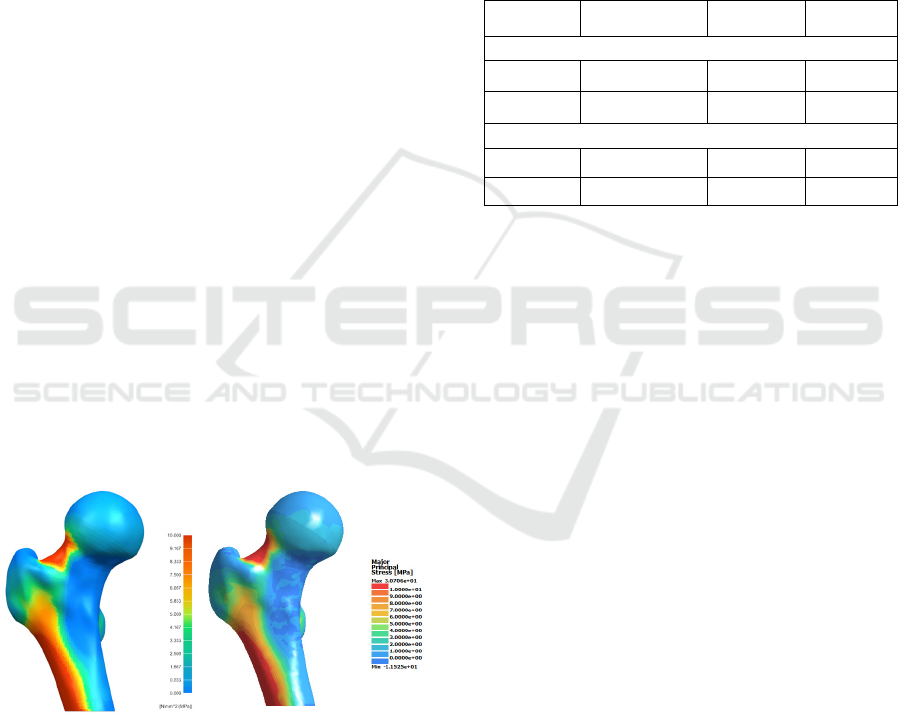

Figure 11: Maximum principal stresses of the intact femur

under ISO load with NX

®

and SimSolid

®

.

Figure 11 shows simulation results with the

following boundary conditions: rigid fixation at the

bottom, adherence of cortical and trabecular bone

contact surfaces and a 2300N force established by the

International Standardization Organization (ISO)

under the ISO 7206-4 standard.

Maximum Principal Stress is suggested for

analyzing stress distribution in bones (Solórzano et

al., 2020)(Jung & Kim, 2014)(Schileo et al., 2008).

Likewise, Von Misses stress was considered due to its

previous use as a reference to compare the accuracy

of SimSolid

®

(Symington, 2020) even in a

biomechanical study on the mandibular structure

(Rivera et al., 2020). Von Misses stresses are also

used to assess the implant fracture risk that in the

proximal femur customization approach could have

relatively complex geometries.

Table 3: Results comparison between both software.

NX

®

SimSolid

®

Deviation

Maximum Principal Stress

Maximum 35.270 30.706 12.94%

Minimum -12.796 -11.525 9.93%

Von Misses Stress

Maximum 30.482 30.740 0.85%

Minimum 0.033 0.036 9.09%

The maximum deviation was 12.94% and the rest

were less than 10%, which is acceptable if we deal

with a complex morphology such as a femur (Table

3). Von Misses stress ranges from 1-9%

approximately which is close to (Rivera et al., 2020)

study whose results ranged from 1-7% compared to

the Inventor

®

software. In any case, the trade-off for

obtaining precise solutions in a short time offered by

SimSolid

®

is a good alternative if you are looking to

generate a large amount of data with CAE software.

6 CONCLUSIONS

Ti21S is a good alternative to Ti-6Al-4V, currently

used in most stems. Although both materials are

biocompatible due to their titanium content,

aluminium in small quantities could produce toxicity

effects when its debris enter the patient’s

bloodstream. The most notorious difference between

both materials is Young's modulus, since the lower its

value, the better, because it will more closely

resemble the mechanical properties of the patient's

cortical bone, producing a better load transfer and

distribution. In this regard, Ti21S would be more

likely to increase the implant’s lifespan.

Currently, there is a growing demand for data in a

short time for orthopaedic implants where the

likelihood of successful outcomes and for a patient to

acquire medical complications or pathologies

(pneumonia, urinary tract infection, etc.) are

BIODEVICES 2022 - 15th International Conference on Biomedical Electronics and Devices

54

influenced by the preoperative time. Therefore, more

research should be done on computational tools such

as SimSolid

®

, which with a validated good accuracy

could help to speed up the data acquisition process.

Likewise, it can be complemented with ML-based

models to extract local information from the femur

and improve the process of prosthetic design

customization.

Due to the complex morphology of the proximal

femur, it is reasonable that deviations in results from

simulations are greater than in the literature reviewed

about SimSolid

®

, where common geometries, such as

bars, cylinders, or spheres, were analysed.

Furthermore, since these are approximate solutions,

there will always be a simulation error, even between

different FEA software working with conventional

finite elements.

Although recently there has been extensive

research on the design of short stem prostheses,

studies on conventional cemented stems should not be

neglected since they present better fixation in older

adults and accelerate postoperative recovery. In

addition, conventional prostheses are usually used in

revision surgery, where short anterior stems help

guarantee success, leaving sufficient good-quality

bone stock improving the fixation of the new implant.

ACKNOWLEDGEMENTS

This work was funded by CONCYTEC-

PROCIENCIA under the financial scheme "Becas de

Mentorías María Reiche 2021-01" [Contract N°E053-

2021-PROCIENCIA].

The authors express their gratitude to the

Biomechanics Group of the Universidad de Piura for

all their support in the development of this research.

The authors acknowledge the support of reviewers

and their relevant questions, which led to a more

detailed and consistent paper.

REFERENCES

Aherwar, A., Singh, A. K., & Patnaik, A. (2016). Cobalt

based alloy: A better choice biomaterial for hip

implants. Trends Biomaterials and Artificial Organs,

30(1), 50–55.

Altair. (2019). Simulation-Driven Design: Solving the

Geometry Problem.

Amstutz, H. C., & Duff, M. J. Le. (2015). Hip resurfacing:

history, current status, and future. Wichtig Publishing,

25(4), 330–338. https://doi.org/10.5301/hipint.50

00268

Arabnejad, S., Johnston, B., Tanzer, M., & Pasini, D.

(2017). Fully porous 3D printed titanium femoral stem

to reduce stress-shielding following total hip

arthroplasty. Journal of Orthopaedic Research, 35(8),

1774–1783. https://doi.org/10.1002/jor.23445

Barrack, R. L. (2000). Early failure of modern cemented

stems. Journal of Arthroplasty, 15(8), 1036–1050.

https://doi.org/10.1054/arth.2000.16498

Bermejillo, M., Franco-Martínez, F., & Díaz, A. (2021).

Artificial intelligence aided design of tissue

engineering scaffolds employing virtual tomography

and 3D Convolutional Neural Networks. Materials,

14(5278). https://doi.org/https:// doi.org/10.3390/

ma14185278

Busch, V., Klarenbeek, R., Slooff, T., Schreurs, B. W., &

Gardeniers, J. (2010). Cemented hip designs are a

reasonable option in young patients. Clinical

Orthopaedics and Related Research, 468(12), 3214–

3220. https://doi.org/10.1007/s11999-010-1355-z

Camacho, J., & Fernandez, J. (2006). Sir John Charnley

(1911-1982). Sociedad Mexicana de Ortopedia, AC,

20.

Chanda, S., Gupta, S., & Pratihar, D. K. (2015). A

combined neural network and genetic algorithm based

approach for optimally designed femoral implant

having improved primary stability. Applied Soft

Computing Journal, 38, 296–307. https://doi.org/

10.1016/j.asoc.2015.10.020

Chanda, S., Mukherjee, K., Gupta, S., & Pratihar, D. K.

(2020). A comparative assessment of two designs of hip

stem using rule-based simulation of combined

osseointegration and remodelling. Proceedings of the

Institution of Mechanical Engineers, Part H: Journal of

Engineering in Medicine, 234(1), 118–128.

https://doi.org/10.1177/0954411919890998

Chatterjee, S., Dey, S., Majumder, S., RoyChowdhury, A.,

& Datta, S. (2019). Computational intelligence based

design of implant for varying bone conditions.

International Journal for Numerical Methods in

Biomedical Engineering, 35(6), 1–17.

https://doi.org/10.1002/cnm.3191

Cilla, M., Borgiani, E., Martínez, J., Duda, G. N., & Checa,

S. (2017). Machine learning techniques for the

optimization of joint replacements: Application to a

short-stem hip implant. PLoS ONE, 12

(9), 1–16.

https://doi.org/10.1371/journal.pone.0183755

Cotogno, G. (2012). Total hip arthroplasty: State of the art,

prospects and challenges (Issue July). Joint Research

Centre of the European Commission. https://doi.org/

10.2788/31286

Eltit, F., Wang, Q., & Wang, R. (2019). Mechanisms of

Adverse Local Tissue Reactions to Hip Implants. Front.

Bioeng. Biotechnol, 7, 176. https://doi.org/

10.3389/fbioe.2019.00176

Facchini, L., Magalini, E., Robotti, P., Molinari, A., Höges,

S., & Wissenbach, K. (2011). Ductility of a Ti-6Al-4V

alloy produced by selective laser melting of prealloyed

powders. Rapid Prototyping Journal. https://doi.org/

10.1108/13552541011083371

Personalized Hip Replacement: State of the Art and New Tools Proposals

55

Gallart, X., Riba, J., Bori, G., Mu, E., & Combalia, A.

(2018). Hip prostheses in young adults . Surface

prostheses and short-stem prostheses. Revista Española

de Cirugía Ortopédica y Traumatología, 62(2), 142–

152.

Gombár, C., Janositz, G., Friebert, G., & Sisák, K. (2019).

The DePuy Proxima

TM

short stem for total hip

arthroplasty – Excellent outcome at a minimum of 7

years. Journal of Orthopaedic Surgery, 27(2), 1–6.

https://doi.org/10.1177/2309499019838668

Gómez-García, F., Fernández-Fairen, M., & Espinosa-

mendoza, R. (2016). A proposal for the study of

cementless short-stem hip prostheses. Acta Ortopédica

Mexicana, 30(4), 204–215.

Hanada, S., Masahashi, N., Jung, T., & Yamada, N. (2014).

Fabrication of a high-performance hip prosthetic stem

using β Ti–33 . 6Nb–4Sn. Journal of the Mechanical

Behavior of Biomedical Materials, 30, 140–149.

https://doi.org/10.1016/j.jmbbm.2013.11.002

Hu, C. Y., & Yoon, T. R. (2018). Recent updates for

biomaterials used in total hip arthroplasty. Biomaterials

Research, 22(1), 1–12. https://doi.org/10.1186/s40824-

018-0144-8

Jasty, M., Krushell, R., Zalenski, E., Connor, D. O.,

Sedlacek, R., & Harris, W. (1993). The contribution of

the nonporous distal stem to the stability of proximally

porous-coated canine femoral components. 8(1), 33–

41.

Javed, F., Ahmed, H., Crespi, R., & Romanos, G. (2013).

Role of primary stability for successful

osseointegration of dental implants: Factors of

influence and evaluation. Interventional Medicine and

Applied Science, 5(4), 162–167. https://doi.org/

10.1556/IMAS.5.2013.4.3

Jung, J. M., & Kim, C. S. (2014). Analysis of stress

distribution around total hip stems custom-designed for

the standardized Asian femur configuration.

Biotechnology and Biotechnological Equipment, 28(3),

525–532.

https://doi.org/10.1080/13102818.2014.928450

Kang, Y. J., Yoo, J. Il, Cha, Y. H., Park, C. H., & Kim, J.

T. (2020). Machine learning–based identification of hip

arthroplasty designs. Journal of Orthopaedic

Translation, 21, 13–17. https://doi.org/10.1016/

j.jot.2019.11.004

Katoozian, H., Devy, D. T., Arshi, A., & Saadati, U. (2001).

Material optimization of femoral component of total hip

prosthesis using fiber reinforced polymeric composites.

Medical Engineering & Physics, 4533(October), 0–9.

https://doi.org/10.1016/S1350-4533(01)00079-0

Khanuja, H. S., Banerjee, S., Orth, M. S., Glasg, M., Jain,

D., & Orth, M. S. (2014). Short Bone-Conserving

Stems in Cementless Hip Arthroplasty. Bone & Joint

Surgery, 96-A, 1742–1752.

Kheir, M. M., Drayer, N. J., & Chen, A. F. (2020). An

Update on Cementless Femoral Fixation in Total Hip

Arthroplasty. Journal of Bone and Joint Surgery

, 1646–

1661.

Kim, Y., Park, J., & Kim, J. (2013). Is Diaphyseal Stem

Fixation Necessary for Primary Total Hip Arthroplasty

in Patients with Osteoporotic Bone (Class C Bone)?

Journal of Arthroplasty, 28(1), 139-146.e1.

https://doi.org/10.1016/j.arth.2012.04.002

Kuiper, J. H., & Huiskes, R. (1996). Friction and stem

stiffness affect dynamic interface motion in Total Hip

Replacement. Journal of Orthopaedic Research, 14,

36–43.

Kunii, T., Mori, Y., Tanaka, H., Kogure, A., Kamimura, M.,

Mori, N., Hanada, S., Masahashi, N., & Itoi, E. (2019).

Improved Osseointegration of a TiNbSn Alloy with a

Low Young’s Modulus Treated with Anodic Oxidation.

Scientific Reports, 9(1), 1–10. https://doi.org/

10.1038/s41598-019-50581-7

Kurtz, S. M., Ms, E. L., Ong, K., Ma, K. Z., Kelly, M., &

Bozic, K. J. (2010). Future young patient demand for

primary and revision joint replacement: National

projections from 2010 to 2030. Clinical Orthopaedics

and Related Research, 2009, 2606–2612.

https://doi.org/10.1007/s11999-009-0834-6

Learmonth, I. D., Young, C., & Rorabeck, C. (2007). The

operation of the century: total hip replacement. Lancet,

370(9597), 1508–1519. https://doi.org/10.1016/S0140-

6736(07)60457-7

Nazari-farsani, S. (2015). Precision and Accuracy of

Marker-Based and Model-Based Radiostereometric

Analyses in Determination of Three-Dimensional

Micromotion of a Novel Hip Stem (Issue December).

Åbo Akademi University.

Ojeda, C. (2009). Estudio de la influencia de estabilidad

primaria en el diseño de vástagos de prótesis femorales

personalizadas: aplicación aplicación a paciente

específico. In Tesis doctoral, Universidad Politécnica

de Madrid.

Otomaru, I., Nakamoto, M., Kagiyama, Y., Takao, M.,

Sugano, N., Tomiyama, N., Tada, Y., & Sato, Y.

(2012). Automated preoperative planning of femoral

stem in total hip arthroplasty from 3D CT data: Atlas-

based approach and comparative study. Medical Image

Analysis, 16(2), 415–426. https://doi.org/10.1016/

j.media.2011.10.005

Pellizzari, M., Jam, A., Tschon, M., Fini, M., Lora, C., &

Benedetti, M. (2020). A 3D-Printed Ultra-Low

Young’s Modulus β -Ti Alloy for Biomedical

Applications. Materials, 1–16.

Portal-Núñez, S., Lozano, D., De la Fuente, M., & Esbrit,

P. (2012). Fisiopatología del envejecimiento óseo.

Revista Española de Geriatría y Gerontología, 47(3),

125–131. https://doi.org/10.1016/j.regg.2011.09.003

Rawal, B. R., Ribeiro, R., Malhotra, R., & Bhatnagar, N.

(2011). Design and manufacture of short stemless

femoral hip implant based on CT images. Journal of

Medicine on Science, 11(8), 296–301.

Raymond, D. (2019, June 28).

FemurFracture - Lower

Extremity CTs. Embodi3D.Com. https://www.embodi

3d.com/files/file/25956-femurfracture/

Rieker, C. B. (2016). Tribology of total hip arthroplasty

prostheses. EFORT Open Reviews, 1(2), 52–57.

https://doi.org/10.1302/2058-5241.1.000004

Rivera, A. F., Castro, F. De, Moreno, A., & Rubio, J. C.

(2020). Assessment of the Highest Stress Concentration

BIODEVICES 2022 - 15th International Conference on Biomedical Electronics and Devices

56

Area Generated on the Mandibular Structure Using

Meshless Finite Elements Analysis. Bioengineering, 1–

11.

Ruben, R. B., Fernandes, P. R., & Folgado, J. (2012). On

the optimal shape of hip implants. Journal of

Biomechanics, 45(2), 239–246. https://doi.org/10.1016/

j.jbiomech.2011.10.038

Ruben, R. B., Folgado, J., & Fernandes, P. R. (2007). A

Three-Dimensional Model for Shape Optimization of

Hip Prostheses Using a Three-dimensional shape

optimization of hip prostheses using a multicriteria

formulation. Springer-Verlag Berlin Heidelberg,

September. https://doi.org/10.1007/s00158-006-0072-4

Santori, F. S., Learmonth, I., Grifka, J., Valverde, C., &

Kim, Y. H. (2007). DePuy PROXIMA Hip - Surgical

Technique.

Schaaff, P. (2004). The role of fretting damage in total hip

arthroplasty with modular design hip joints - evaluation

of retrieval studies and experimental simulation

methods. Journal of Applied Biomaterials &

Biomechanics, 2, 121–135.

Schileo, E., Taddei, F., Cristofolini, L., & Viceconti, M.

(2008). Subject-specific finite element models

implementing a maximum principal strain criterion are

able to estimate failure risk and fracture location on

human femurs tested in vitro. Journal of Biomechanics,

41(2), 356–367. https://doi.org/10.1016/j.jbiomech.20

07.09.009

Schmitz, M. W., Busch, V. J., Gardeniers, J. W., Hendriks,

J. C., Veth, R. P., & Schreurs, B. W. (2013). Long-term

results of cemented total hip arthroplasty in patients

younger than 30 years and the outcome of subsequent

revisions. BMC Musculoskeletal Disorders, 14.

https://doi.org/10.1186/1471-2474-14-37

SimSolid Corporation. (2015). SimSolid Technology

Overview (pp. 1–33).

Sivasankar, D. M., Arunkumar, S., Bakkiyaraj, V.,

Muruganandam, A., & Sathishkumar, S. (2016). A

Review on Total Hip Replacement. International

Research Journal In Advanced Engineering and

Technology (IRJAET), 2(April), 589–642.

https://doi.org/10.13140/RG.2.2.13686.80969

Sköldenberg, O. G., Bodén, H. S. G., Salemyr, M. O. F.,

Ahl, T. E., & Adolphson, P. Y. (2006). Periprosthetic

proximal bone loss after uncemented hip arthroplasty is

related to stem size DXA measurements in 138 patients

followed for 2 – 7 years. Acta Orthopaedica, 77(3),

386–392. https://doi.org/10.1080/17453670610046307

Solórzano, W. (2021). Innovación en el diseño

personalizado de vástagos femorales cortos.

Universidad de Piura.

Solórzano, W., Ojeda, C., & Lantada, A. D. (2020).

Biomechanical study of proximal femur for designing

stems for total hip replacement. Applied Sciences

(Switzerland), 10(12), 1–17. https://doi.org/10.3390/

APP10124208

Srinivasan, A., Jung, E., & Levine, B. R. (2012).

Modularity of the Femoral Component in Total Hip

Arthroplasty. Journal of the American Academy of

Orthopaedic Surgeons

, 20, 214–222.

Subramanian, P., Wainwright, T. W., Bahadori, S., &

Middleton, R. G. (2019). A review of the evolution of

robotic-assisted total hip arthroplasty. HIP

International, 29(3), 232–238. https://doi.org/10.1177/

1120700019828286

Sugano, N. (2013). Computer-assisted orthopaedic surgery

and robotic surgery in total hip arthroplasty. Clinics in

Orthopedic Surgery, 5(1), 1–9. https://doi.org/

10.4055/cios.2013.5.1.1

Symington, I. (2020). Designer Oriented Software - Is it

Accurate? The International Magazine for Engineering

Designers & Analysts from NAFEMS, The

Electromagnetics Issue, 32–44.

Wroblewski, B. M. (1997). Wear of the high-density

polyethylene socket in total hip arthroplasty and its role

in endosteal captation. Proceedings of the Institution of

Mechanical Engineers, Part H: Journal of Engineering

in Medicine, 211(1), 109–118. https://doi.org/

10.1243/0954411971534737

Yamako, G., Chosa, E., Totoribe, K., Hanada, S.,

Masahashi, N., Yamada, N., & Itoi, E. (2014). In-vitro

biomechanical evaluation of stress shielding and initial

stability of a low-modulus hip stem made of Beta type

Ti-33.6Nb-4Sn alloy. Medical Engineering and

Physics, 36(12), 1665–1671. https://doi.org/10.1016/

j.medengphy.2014.09.002

Yamako, G., Janssen, D., Hanada, S., Anijs, T., Ochiai, K.,

Totoribe, K., Chosa, E., & Verdonschot, N. (2017).

Improving stress shielding following total hip

arthroplasty by using a femoral stem made of β type Ti-

33.6Nb-4Sn with a Young’s modulus gradation.

Journal of Biomechanics, 63, 135–143.

https://doi.org/10.1016/j.jbiomech.2017.08.017

Yan, S. G., Chevalier, Y., Liu, F., Hua, X., Schreiner, A.,

Jansson, V., & Schmidutz, F. (2020). Metaphyseal

anchoring short stem hip arthroplasty provides a more

physiological load transfer: a comparative finite

element analysis study. Journal of Orthopaedic Surgery

and Research, 15(1), 1–10. https://doi.org/10.1186/

s13018-020-02027-4

Personalized Hip Replacement: State of the Art and New Tools Proposals

57