Designing a New Layout for a Balanced Production Line: A Practical

Application

Marlene Br

´

as

1

and Ana Moura

1,2

1

Department of Economics, Management, Industrial Engineering and Tourism, University of Aveiro, Portugal

2

GOVCOPP – Systems for Decision Support Research Group, University of Aveiro, Portugal

Keywords:

Layout Design, Assembly Line Balancing, Systematic Layout Planning, Linear Programming.

Abstract:

In most manufacturing companies, the layout designs and line balancing problems are often based on per-

sonal experience and made without following a theoretical methodology. By applying those ad-hoc solutions,

various problems may arise when quick changes of capacity or any other constraints occur. This work was de-

veloped for a Portuguese SME in the electronics industry, that had some changes at the production level, which

caused limitations in terms of space on the factory floor. Furthermore, it was also revealed that an existing

production line with high production rates was gradually losing efficiency. Bringing these two issues together,

the idea was to design a new plant layout to improve the performance of this production line, considering the

new space constraints. To increase the production line efficiency, decisions such as the number of workers

and assembly task assignment to stations need to be optimized to increase its throughput and decrease cost.

An integer linear programming model was developed and used to solve the balancing problem. Considering

six different optimization criteria, five variants of the model were tested. Using the best solution according

to predefined Key Indicators Performance, the layout was developed using the Systematic Layout Planning

approach.

1 INTRODUCTION

The layout design problem is a strategic issue and has

a significant impact on the efficiency of a manufactur-

ing system (Islam et al., 2014). Layout design is con-

sidered one of the keys elements to operations man-

agement since it maximizes the resource usage and

the overall system throughput (Yemane et al., 2017).

A good layout determines the efficiency of all opera-

tions in a system.

This work presents a case study that takes place

in a Portuguese Small and Medium-sized Enterprise

(SME) in the electronics industry. To insert a new pro-

duction line on the factory floor, the company needs to

relocate an existing production line - Induction Cook-

ing Plates (ICP) production line - whose efficiency

has been decreasing due to lack of continuous im-

provement. Considering the product production pro-

cess, the company resources, and the available shop

floor area, a new layout for the ICP production line

was studied. The idea is, when designing the new lay-

out, to improve the efficiency of the production line

through its balancing and, simultaneously, adapt it to

the new available area. For this, two of the problems

that were addressed and solved were the layout design

and the assembly line balancing problems.

One of the most applied and successful method-

ology used to plan a proper layout is the Systematic

Layout Planning (SLP) technique. SLP is a proce-

dure layout design approach (Yang et al., 2000) de-

veloped in 1973 by Richard Muther (Muther, 1973),

and successfully implemented in SMEs, existing sev-

eral studies of its application (Naqvi et al., 2016;

Fahad et al., 2017; Tak and Yadav, 2012; Wiyaratn

et al., 2013). The SLP is a technique used to ar-

range a workplace in a plant by locating two areas

with high frequency and logical relationships close

to each other. It involves the collection of informa-

tion for the development of a relationship chart (step

1). This chart highlights the desirability levels of ad-

jacency between pairs of resources, classifying them

with the code A (absolutely necessary), E (especially

important), I (important), O (ordinary), U (unimpor-

tant), and X (undesirable). Through the analysis of

this information, a relationship diagram is elaborated.

This diagram shows the resources connected through

lines, in which the desirability levels of adjacency be-

tween the resources, dictates the lines characteristics

Brás, M. and Moura, A.

Designing a New Layout for a Balanced Production Line: A Practical Application.

DOI: 10.5220/0010827400003117

In Proceedings of the 11th International Conference on Operations Research and Enterprise Systems (ICORES 2022), pages 161-168

ISBN: 978-989-758-548-7; ISSN: 2184-4372

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

161

– thickness and color. The latter is analyzed in order

to elaborate the layout solutions (step 2). Finally, de-

pending on the predefined Key Performance Indica-

tors (KPIs), the most favorable layout is chosen (step

3).

Production activities in manufacturing industry

are closely related to the assembly line balanc-

ing (Syahputri et al., 2018). The combination of lay-

out design with line balancing techniques has already

proven to be quite advantageous (Syahputri et al.,

2018; Buchari et al., 2018). Therefore, a virtuous

layout can be designed, and productivity can be in-

creased through an appropriate assembly line balanc-

ing (Yemane et al., 2017). An assembly line is a set

of workstations arranged sequentially and intercon-

nected by a material conveyor system. At each work-

station, a set of predefined tasks (or operations) are

executed in an assembly process. Each task is defined

by its processing time (the time required to execute a

given task) and its precedence constraints (the set of

constraints that determines the sequence according to

which tasks can be executed).

The Simple Assembly Line Balancing Problem

(SALBP) was initially formulated by (Salveson,

1955). This problem consists of assigning a set of

tasks to a set of workstations, intending to minimize

the number of workstations or the cycle time of the

production line. The assignment of tasks to work-

stations is done to ensure that the assembly line can

meet the costumers’ demand. (Scholl and Becker,

2006) states that there are four formulations for the

SALBP: SALBP-1 (minimizing the number of work-

stations for a given cycle time), SALBP-F (estab-

lishing whether a feasible line balance exists for a

given combination of workstations and cycle time),

SALBP-2 (minimizing the cycle time for a given

number of workstations), and SALBP-E (minimizing

the cycle time and the number of workstations con-

sidering their interrelationship).

There are some considerations that can be in-

corporated in the assembly line balancing models:

assignment constraints (Task-related or zone con-

straints, Workstations constraints, Positioning con-

straints and Operators’ constraints), parallel lines,

parallel workstations, and U-shaped assembly lines.

So many researchers, over the last decades, have

studied the SALBP in many ways, depending on the

constraints and the goals considered. Most of the pub-

lished papers are focused on SALBP where the per-

formance measure is either minimizing the number of

stations or the cycle time. Using different preference

criteria to assign tasks to the workstations, results in

different heuristics. A simple heuristic refers to sort-

ing the tasks in descending order (MaxTime Heuris-

tic) or ascending order (MinTime Heuristic) of their

processing time. After this ordering, the tasks are

assigned to the workstations according to the estab-

lished order, considering that the defined cycle time

cannot be exceeded. In the heuristic designated by

the notation MaxG, the assignment of tasks to work-

stations is carried out in decreasing order of each task

processing time divided by the upper bound. Another

heuristic example is the MaxS (or Greatest), in which

the allocation is made by prioritizing the tasks with

the greatest number of successors. Finally, in the

Ranked Positional Weight (RPW) heuristic, the as-

signment of tasks is made in descending order of the

ranked positional weight of each task.

The paper is divided into four sections. This one

(section 1) is a brief introduction to the problem and a

review of approaches and studies available in the lit-

erature. In section 2, the case study is presented, as

well as the production line under study.It is followed

by the layout design approach explanation in section

3, in which the obtained results are showcased and an-

alyzed. Finally, in section 4, conclusions on the com-

parison of the solutions effectiveness are provided as

well some future work remarks.

2 CASE STUDY: PROBLEM

DESCRIPTION AND

CHARACTERIZATION

The practical case under study takes place in a

SME belonging to a group in the electronic in-

dustry. This group develops and produces effi-

cient, sustainable, and suitable solutions for the

Smart Cities/Utilities, Smart Buildings/Installations,

and Smart Homes/Appliances. The company is ded-

icated to the production of Induction Cooking Plates

(ICP), LED Lights and, more recently, a new prod-

uct, that for the sake of disclosure, will be referenced

throughout this paper as MWMs.

The insertion of the new production line for the

MWM production was an excellent opportunity to

study the optimization of the existing production line

whose efficiency has been decreasing, the ICPs pro-

duction line. The shop floor is divided between two

floors. With the insertion of the MWM production

line on the upper floor, there was a reorganization of

the remaining space on the same floor. With this reor-

ganization, the opportunity to separate the processes

of automatic insertion of electronic components from

the processes of manual insertion of electronic com-

ponents and ICP encapsulation arose. Therefore, at

the company’s request, the space available on the up-

ICORES 2022 - 11th International Conference on Operations Research and Enterprise Systems

162

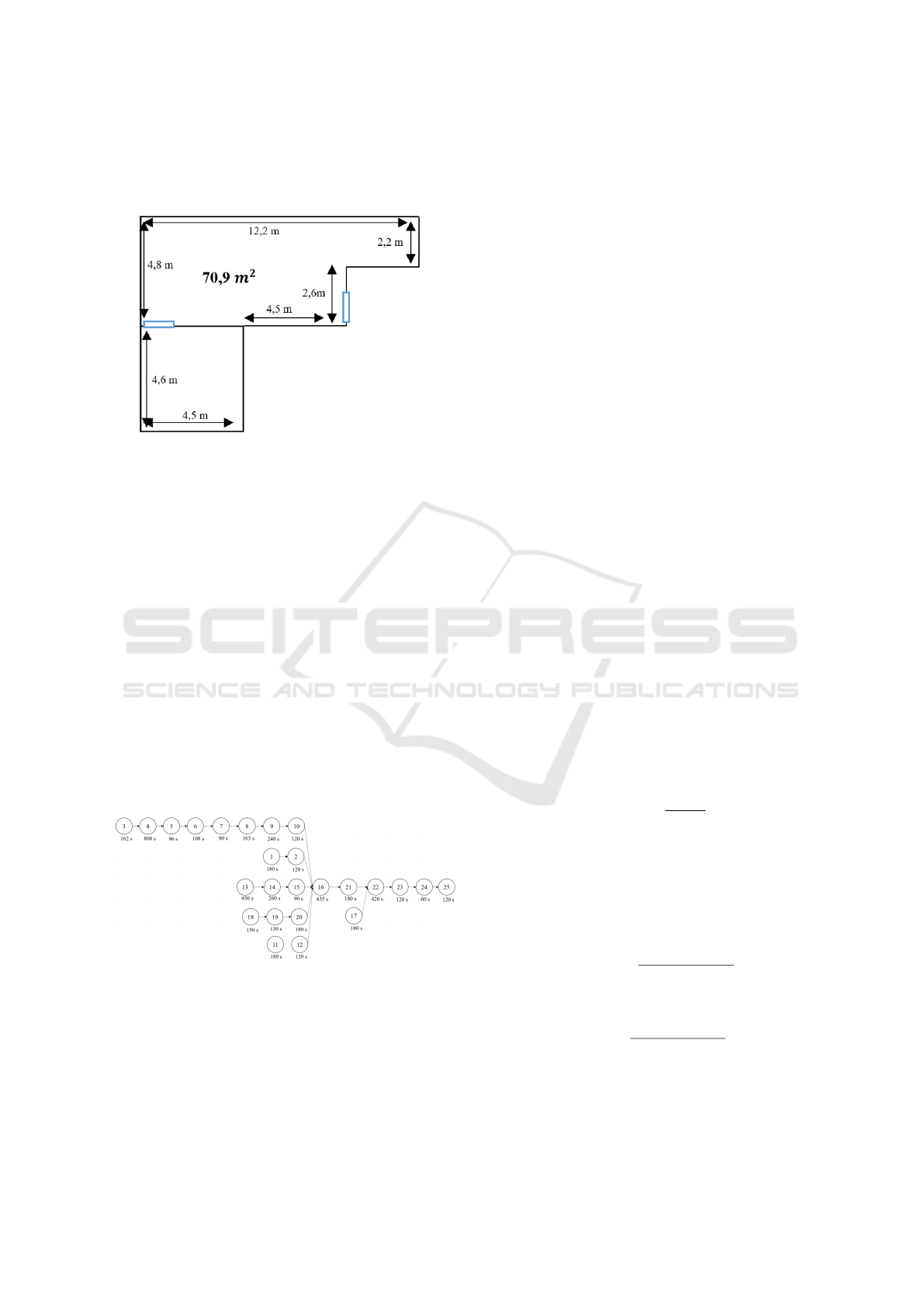

per floor (Figure 1) was studied, to insert the final pro-

cesses of manual insertion of components and encap-

sulation of the ICP production line.

Figure 1: Available space in the upper floor.

It is important to reinforce that there are processes

that will remain on the lower floor due to the sharing

of machines with other production lines. Therefore,

these processes will not be included in this study.

There are several models of induction cooking

plates available. The data used in this study corre-

spond to a model that, for the sake of disclosure, will

be referenced throughout this paper as PB. This model

uses all the available resources to produce any model

of ICPs.

The Induction Cooking Plates are composed by an

electronic components module called Main ICP, a set

of magnetic induction exchangers (MIEs), a support

base, a display module designated by IURI with an

interface called TecBit, and finally, a glass.

According to the ICP production process, a prece-

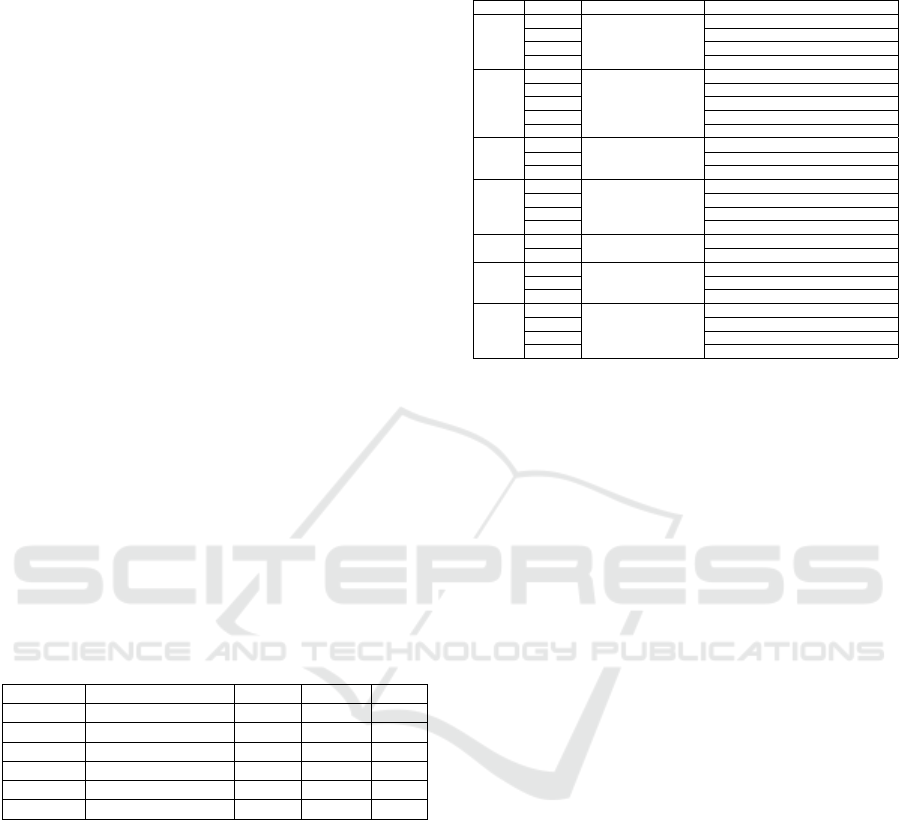

dence diagram was drawn and is presented in Figure

2.

Figure 2: ICP precedence diagram.

Considering the costumers’ demand, the company

aims to produce 5 units/hour, which implies a cycle

time of 720 seconds/unit. This means that each work-

station will have a cycle time of 720 seconds in which

all the tasks assigned to it must be carried out. How-

ever, when the precedence diagram is analyzed, it can

be seen that there is a task that has a processing time

greater than the desired cycle time (Task 4 - 808 sec-

onds). This means that whatever workstation this task

is assigned to, will have to be duplicated. Besides

this, there are some tasks assignment constraints that

must be considered, more specifically, task-related or

zone constraints. At the company’s request, the re-

sources associated with tasks 21 and 23 cannot be in

the same workstation due to safety conditions. Tasks

3 to 6 need to be in the same workstation due to re-

source constraints, and for the same reason, the same

happens for tasks 18 to 20. It is important to mention

that although these tasks require the same resources,

they are performed by different workers.

3 ICP LAYOUT DESIGN

The layout design methodology was divided into two

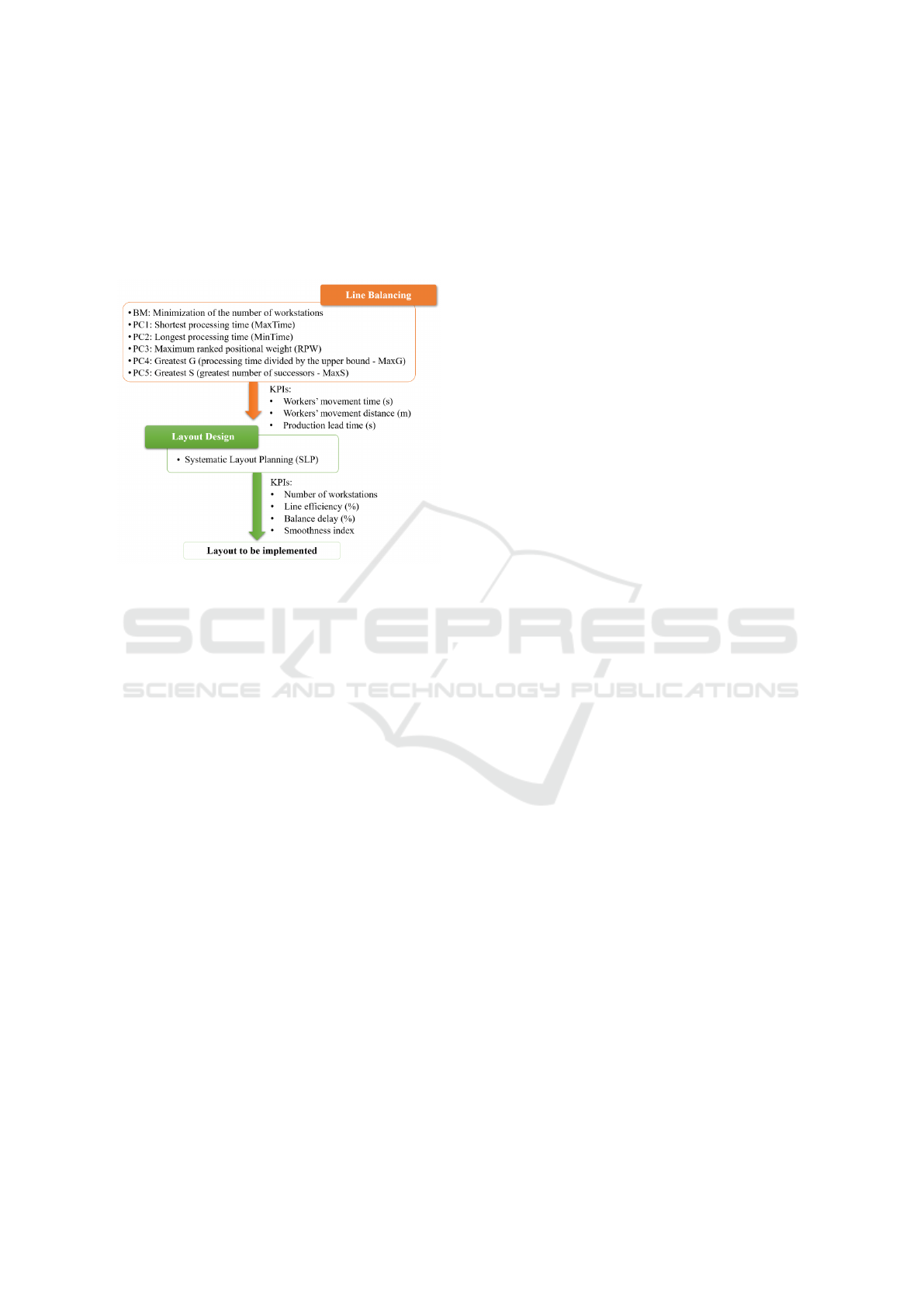

steps: line balancing and layout design (Figure 3).

In the first step, it was solved an assembly line

balancing problem using an integer linear program-

ming model (Section 4.4.1). Based on this base

model (BM), 5 variants were also used and tested, us-

ing different preference criteria (PC) to assign task

to the workstations: PC1-shortest Processing Time

(MinTime); PC2-longest Processing Time (Max-

Time); PC3-Greatest RPW (RPW); PC4-Greatest G

(MaxG) (maximum processing time divided by the

upper bound); PC5-Greatest S (MaxS or Greatest)

(Greatest number of successors). The line balancing

results were compared using the following KPIs:

• Number of Workstations;

• Line Efficiency (LE): is the ratio of workstations

time and the cycle time multiplied by the number

of workstations;

LE(%) =

∑

N

i=1

t

i

C ×W

; (1)

where t

i

is the processing time of task i in seconds

(i ∈ {1, . . . , N}), N is the number of tasks and W

is the number of workstations.

• Balance Delay (BD): is the ratio between the idle

time in the production line balancing and the time

available;

BD(%) =

C ×W −

∑

N

i=1

t

i

C ×W

; (2)

• Smoothness Index (SI): is an index that becomes

the relative refining index of a production line bal-

ance.

SI =

s

w

∑

j=1

(T

max

− T

j

)

2

(3)

where T

max

is the maximum workstation time, and

T

j

is the time of the j

th

workstations.

Designing a New Layout for a Balanced Production Line: A Practical Application

163

In the second stage, using the best solution found

in the previous stage, the facility layout problem

(FLP) was resolved using the Systematic Layout

Planning (SLP) approach. The layout was evaluated

using the standard KPIs related to production time

- workers’ movement time, workers’ movement dis-

tance, and production lead time.

Figure 3: ICP layout design.

3.1 ICP Production Line Balancing

Approach

This study deals with a SALBP-1 problem, that is re-

lated to allocation of tasks to workstations in a pre-

defined cycle time, while minimizing the number of

workstations needed. As presented in the Section 2.1,

this problem deals with some features related to the

tasks processing time, precedence relations and zone

constraints.

Considering the product characteristics, the prece-

dence diagram and all the constraints presented in the

Section 2.1, an integer linear programming model was

developed to solve the balancing problem of this pro-

duction line.

3.1.1 Mathematical Model

The proposed integer linear programming model is a

simple assembly line balancing model with parallel

jobs and zone constraints. This model is based on the

following assumptions:

• The line is dedicated to the production of a single

product;

• According to the production volume and the time

interval for production, there is a predefined cycle

time;

• The product assembly follows a set of tasks, each

with a predetermined execution time and with

precedence rules between them;

• The tasks are processed at a set of workstations;

• A task can only be allocated to a single station;

• There are zone constraints, which are related to

the compatibility and incompatibility of perform-

ing certain tasks in the same workstations;

• A workstation can be parallelized at most once,

but only if the processing time of one of the tasks,

assigned to that station, exceeds the predefined cy-

cle time;

A possible line balance, i.e., an assignment of

tasks to workstations, can be done according to dif-

ferent objectives, but the most common is to minimize

the number of workstations for a given cycle time and

simultaneously balancing the workloads between the

workstations.

The following notations and variables are used for

the proposed model:

Notations:

• N: Set of tasks, i ∈ {1, . . . , n};

• W: Set of workstations, j ∈ {1, . . . , w};

• P: Set of all immediate predecessors;

• (pre, post): Pair of precedence relations among

tasks, where task pre should immediately precede

task post;

• t

i

: Processing time of task i, in seconds;

• C: Cycle time, in seconds;

• AC: Assignment compatibility, set of tasks that

must be assigned to the same workstation;

• (tC1, tC2): Pair of compatibility relations among

tasks;

• AI: Assignment incompatibility, set of tasks that

cannot be assigned to the same workstation;

• (tI1, tI2): Pair of incompatibility relations among

tasks;

• MaxDW: Maximum number of stations duplica-

tion;

• M: Very high positive integer number.

Decision variables:

x

i j

=

(

1, if the task i is assigned to workstation j i ∈ N, j ∈ W

0, otherwise

r

j

=

(

1, if the workstation j is duplicated j ∈ W

0, otherwise

ICORES 2022 - 11th International Conference on Operations Research and Enterprise Systems

164

Considering all the assumptions, variables and

data, the idea is to assign all the tasks to worksta-

tions, ensuring all the constraints, while minimizing

the number of needed workstations. The mathemati-

cal model can be written as:

Min

W

∑

j=1

j × x

n j

(4)

subject to:

W

∑

j=1

x

i j

= 1;∀i ∈ N (5)

W

∑

j=1

j × x

i.pre j

≤

W

∑

j=1

j × x

i.post j

;∀i ∈ P (6)

x

i.tC1 j

= x

i.tC2 j

;∀i ∈ AC; ∀ j ∈ W (7)

x

i.tI1 j

+ x

i.tI2 j

≤ 1;∀i ∈ AI; ∀ j ∈ W (8)

N

∑

i=1

t

i

× x

i j

≤ C × (1 + r

j

× (MaxDW − 1));∀ j ∈ W

(9)

r

j

≤

N

∑

i=1,t

i

>C

x

i j

;∀ j ∈ W (10)

M × r

j

≥

N

∑

i=1,t

i

>C

x

i j

;∀ j ∈ W (11)

x

i j

∈ {0, 1}; (12)

r

j

∈ {0, 1}; (13)

The objective function given in Eq. (4) minimizes

the number of workstations.

According to Eq. (5), each task must be assigned

to only one workstation. Eq. (6) is associated with the

operations precedence, and prevents that a successor

task of task i, be assigned to a workstation before task

i is processed. Eq. (7) and (8) are the zone constraints

that define the sets of task pairs that must be allocated

to the same workstation (compatible tasks) and task

pairs that cannot be allocated to the same workstation

(incompatible tasks). If there are tasks that must be

performed at the same workstation, this is guaranteed

by Eq. (7). Eq. (8) ensures just the opposite, that

is, incompatible tasks are not assigned to the same

workstation.

Eq. (9), (10) and (11) are constraints concerning

parallel workstations: Eq. (9) ensures that the capac-

ity of each station is not exceeded; Eq. (10) ensures

that the predefined number of parallel workstations is

not exceeded; and Eq. (11) ensures that only work-

stations with assigned tasks, whose processing time

exceeds the cycle time, can be replicated.

Eq. (12) and (13) define the domain of the deci-

sion variables.

3.1.2 Different Criteria Approaches

In addition to this model, it was intended to test other

approaches to the problem using the well-known pref-

erence criteria (PC) presented in section 1. Each of

these PCs is a different way of assigning tasks to

workstations, each corresponding to a typical heuris-

tic of balancing problems. Considering five PC, five

variants of the previous model (named Base model -

BM) were created. For that, the following additional

notations must be considered:

Additional Notation:

• S: is the set of all immediate successors;

• RPW

i

= t

i

+

∑

r∈S

t

r

: is the Ranked positional

weight of task i;

• G

i

=

t

i

UB

i

: is the Greatest of task i, defined by the

processing time divided by the workstations upper

bound ((UB

i

= N + 1[

t

i

+

∑

r∈S

t

r

C

]

+

);

• S

i

: is the number of Successors of task i;

As mentioned before, it is important that the num-

ber of workstations is as small as possible, due to the

existing workforce in the company. However, the fair

distribution of work between the several workstations

is also important. So, since minimizing the number

of workstations (Eq. (4): Min

∑

W

j=1

jx

n j

) is one of

the company’s main priority and the main goal for the

plant layout, the optimal solution obtained by the BM

will be considered as an upper-bound for the number

of workstations.

Each PC approach has an objective function that

corresponds to the related preference criteria, which

dictates what tasks are preferred when assigning to

stations. As such, five more models were tested (PC1,

PC2, PC3, PC4 and PC5), differing only in the objec-

tive function.

• PC1, tasks with shortest processing times are

given priority:

Min

W

∑

j=1

N

∑

i=1

t

i

x

i j

(14)

Designing a New Layout for a Balanced Production Line: A Practical Application

165

• PC2, tasks with longest processing times are given

priority:

Max

W

∑

j=1

N

∑

i=1

t

i

x

i j

(15)

• PC3, tasks with bigger RPW are given priority:

Max

W

∑

j=1

N

∑

i=1

RPW

i

x

i j

(16)

• PC4, tasks with bigger G are given priority:

Max

W

∑

j=1

N

∑

i=1

G

i

x

i j

(17)

• PC5, tasks with bigger S are given priority:

Max

W

∑

j=1

N

∑

i=1

S

i

x

i j

(18)

An upper-bound on the number of workstations is

added to each model and settled to 8 workstations.

The mathematical model (BM) and its variants (from

PC1 to PC5) were implemented using the CPLEX

Studio IDE 20.1.0. The six models were tested with

different problems instances and the results related to

the ICP production line are presented in Table 1.

Table 1: Models variants quantitative results.

Approach No. of workstations LE (%) BD (%) SI

BM 8 89,6 10,4 274,6

PC1 8 89,6 10,4 384,6

PC2 8 89,6 10,4 296,8

PC3 8 89,6 10,4 391,4

PC4 8 89,6 10,4 274,6

PC5 8 89,6 10,4 301,5

All the model variants achieved the optimal solu-

tion of 8 workstations, having also the same line ef-

ficiency and balance delay. One way to evaluate this

solution is by comparing it with the theoretical mini-

mum number of workstations. This value is computed

according to the cycle time and the summation of the

tasks processing time. The theoretical minimum num-

ber of workstations is 7 (workstations lower-bound).

However, when computing this value, theoretically, it

is not consider all the problem constraints. As this

problem has a large set of constraints, the fact of ob-

taining 8 workstations with the models we can con-

sider it a very good solution. So, it could be stated

that in all the 6 approaches, the tasks are fairly di-

vided by all the workstations, and the line efficiency

is relatively good.

Table 2: Set of workstations resulting from the BM and

PC4.

Workst. Task No. Workst. Proc. Time (s) Resource required

1

1

600

CT1 w/ computer

2 CT2 w/ platform 1

11 CT6

12 CT6 w/ platform 3

2 and 3

3

632

CT3 w/ supporting tool

4 CT3 w/ supp. tool and wind. machine

5 CT3 w/ supp. tool

6 CT3 w/ supporting tool

7 CT4 (CT4.1)

4

8

523

CT4

9 CT4

10 CT5 w/ platform 2

5

17

640

CT8

18 CT9 w/ platform 4

19 CT9 w/ platform 4

20 CT9 w/ platform 4

6

13

710

CT7 (CT7.1)

14 CT7 (CT7.1)

7

15

705

CT7

16 CT7

21 CT13; WR1; WR2; HP

8

22

720

CT10

23 CT12 w/ platform 5

24 CT11

25 CT11

The minimum value of the smoothness index is

0 which indicates a perfect balance, i.e., a smaller

smoothness index indicates a production line closer

to a perfect balance. Therefore, by analysing the re-

sults, it was possible to conclude that the best solution

is achieved when considering both the BM and the

PC4 model, i.e., considering only the minimization of

the number of workstations, and when the priority is

given to the tasks with bigger G (processing time di-

vided by the upper bound). Both approaches have the

same solution related to the number of workstations,

and these workstations also have the same assigned

tasks (Table 2). For any of the models the processing

times were quite short, always reaching the optimal

solution in less than one minute.

In order to implement the solutions obtained by

the BM and its variants (PC1 to PC5 models) on the

shop floor, it turns out that, according to the task

grouping, some resources (marked in bold in Table

2) must be duplicated. That is, there were tasks that

need the same resources, but they were allocated to

different workstations (Table 2). To solve this prob-

lem, a duplication of resources (CT4 and CT7) was

carried out. Important to mention that this duplica-

tion did not incur in significant costs for the layout

implementation.

3.2 ICP Layout Design Approach

As mentioned previously, the Facility Layout Prob-

lem was solved through the application of the Sys-

tematic Layout Planning method.

ICORES 2022 - 11th International Conference on Operations Research and Enterprise Systems

166

3.2.1 Systematic Layout Planning

As explained in Section 1, after some information

collection, the SLP methodology can be divided into

three major phases. In the first phase, occurs the anal-

ysis of production processes information. The layout

design take place in the second phase, in which the in-

formation related to the needed resources and the pro-

duction workflow are used to elaborate a relationship

chart. In this study, it was also created a code that de-

picts the reason for the respective degree of proximity

(Table 3).

Table 3: Numerical Code used in the ICP relationship chart.

Numerical Code Reason

1 Resources used in the same task

2 Workflow within the same workstation

3 Workflow between workstations

4 Resources from the same workstation

5 Resources that cannot be close to each other for safety reasons

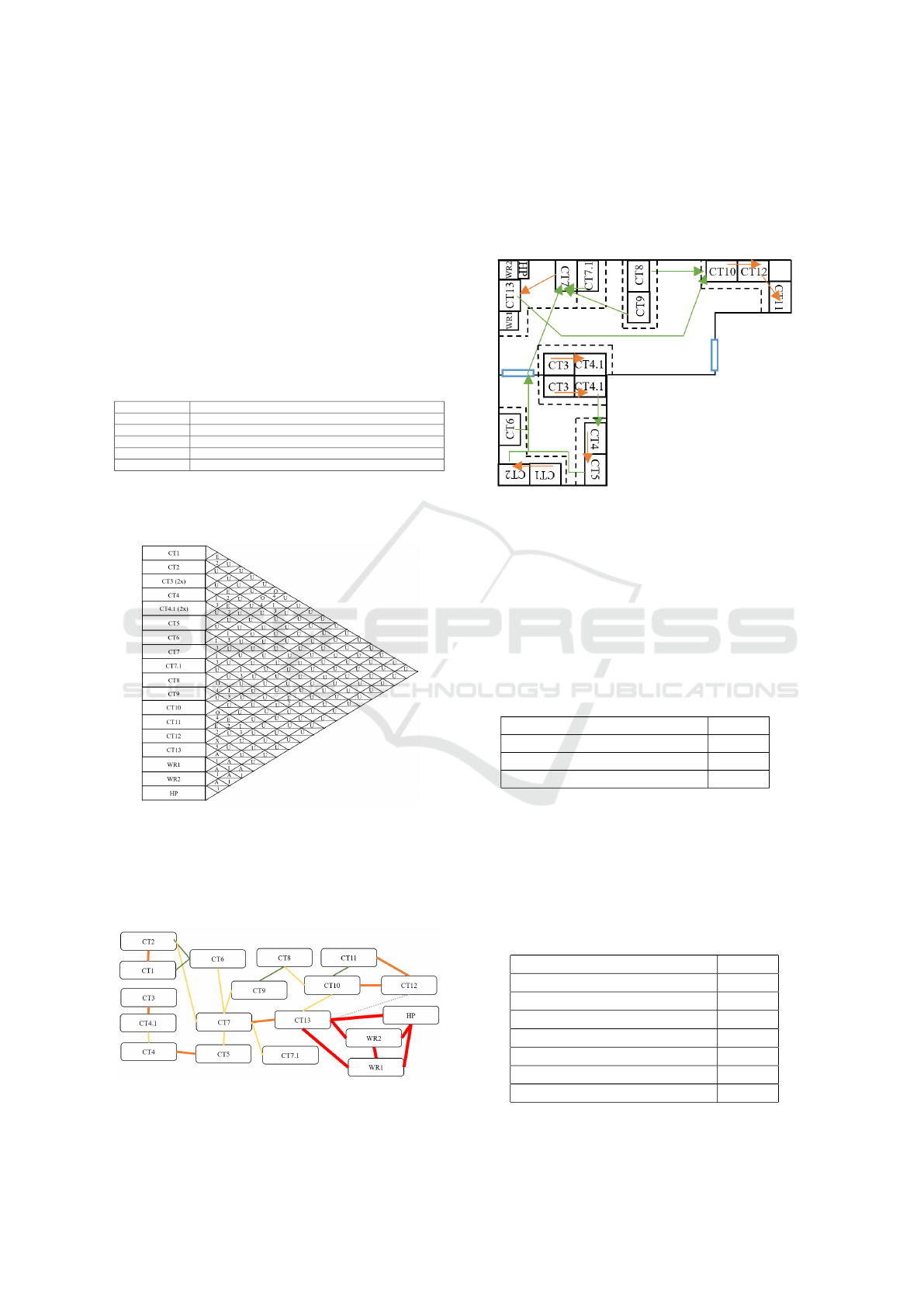

Figure 4 shows the relationship chart obtained for

the ICP production line.

Figure 4: ICP relationship chart.

Through the analysis of this relationship chart, the

relationship diagram was drawn (Figure 5). Consid-

ering this last one, the necessary resources and the

available space, the layout options were elaborated.

Figure 5: ICP relationship diagram.

In the third and last phase, the developed layouts

options were evaluated and the most suitable one was

chosen (Figure 6). The orange line represents the

workflow into the same workstation, and the green

line represents the workflow between workstations.

Figure 6: ICP production line layout resulting from the SLP

approach.

The previously defined KPIs were measured for

the obtained layout, being the results present in Table

4. Analyzing the KPIs, it is noticeable that the work-

ers’ movement time represents a small percentage of

the production lead time, only 1,7%. This means that

the workers’ movement time can be considered in-

significant in the production lead time, being the lay-

out obtained evaluated as efficient.

Table 4: KPIs results from the SLP layout.

KPI SLP

Workers’ moving distance (m) 41,1

Workers’ moving time (s) 88,3

Production lead time (s) 5079,2

3.3 Final Layout

Table 5 summarizes the KPIs obtained for the ICP

production line layout.

Table 5: KPIs summary from the ICP production line lay-

out.

KPI SLP

No. of workstations 8

Line efficiency (%) 79

Balance delay (%) 21

Smoothness index 301,5

Workers’ moving distance (m) 41,1

Workers’ moving time (s) 88,3

Production lead time (s) 5079,2

Designing a New Layout for a Balanced Production Line: A Practical Application

167

Regarding the balancing KPIs, the results are con-

sidered satisfactory. The number of workstations ob-

tained is very close to the theoretical minimum num-

ber of workstations, i.e., 7 workstations. This lower-

bound calculation does not consider any constraint

present in this problem (for example, zone restrictions

and parallel workstations), having this in mind, we

can consider that the number of stations obtained is

quite satisfactory. The high efficiency of the produc-

tion line is reflected into an uniform distribution of the

workload among the workstations. This also means a

decrease in the risk of bottlenecks occurring in pro-

duction. Consequently, and as expected, the balance

delay obtained is low, which implies a low idle time,

caused by some not so good job assignments due to

the problem constraints. The KPIs related to produc-

tion time are also considered satisfactory, since the

percentage of workers’ movement time is insignifi-

cant compared to the production lead time. There-

fore, the layout obtained can be considered efficient

both in terms of resource/space optimization and line

optimization.

4 CONCLUSIONS

A case study of a production line layout design was

presented. The idea was to take advantage of the need

to optimize the efficiency of an existing production

line, by redesigning and studying a new production

line. The methodology implemented was divided into

two major steps: line balancing and layout design.

In the first step, an assembly line balancing prob-

lem was solved, using an integer linear programming

model. Besides this BM, five variants, based on dif-

ferent preference criteria to assign task to worksta-

tions, were created. All the models variants achieved

the optimal solution of 8 workstations, with an effi-

ciency of 79% and balance delay of a 21%. Since

the theoretical value of the number of workstations -

lower bound is 7, and considering the existing con-

straints, it could be stated that the production line has

a relatively good efficiency. Comparing the smooth-

ness index, it was possible to conclude that the best

solution was achieved when considering the BM and

the PC4 variant model.

In the second step, the facility layout problem was

solved by applying the SLP method. The final lay-

out obtained was evaluated using KPIs related to pro-

duction time. When the results were analysed, it was

concluded that the KPI that was thought to be most

important - the workers’ movement time, only repre-

sented a small percentage of the production lead time

(1,7%), which can be considered an insignificant per-

centage.

It is important to note that, with the new layout,

the space is optimized and the production efficiency

increases. However it is advisable that the company

maintains a Lean culture and whenever possible the

layout should be revised. Having this in mind, as fu-

ture work, other layout design methodologies can be

tested to see if further improvements can be made.

REFERENCES

Buchari, Tarigan, U., and Ambarita, M. B. (2018). Produc-

tion layout improvement by using line balancing and

systematic layout planning (slp) at pt. xyz. In Materi-

als Science and Engineering Conference Series.

Fahad, M., Naqvi, S. A. A., Atir, M., Zubair, M., and She-

hzad, M. M. (2017). Energy management in a manu-

facturing industry through layout design. In Procedia

Manufacturing.

Islam, M. M., Mohiuddin, H., H.Mehidi, S., and Sakib, N.

(2014). An optimal layout design in an apparel indus-

try by appropriate line balancing: A case study. In

Global Journal of Researches in Engineering: G In-

dustrial Engineering.

Muther, R. (1973). Systematic Layout Planning. Cahners

Books, 2nd edition.

Naqvi, S. A. A., Fahad, M., Atir, M., Zubair, M., and She-

hzad, M. M. (2016). Productivity improvement of a

manufacturing facility using systematic layout plan-

ning. In Cogent Engineering.

Salveson, M. E. (1955). The assembly line balancing prob-

lem. In Journal of Industrial Engineering.

Scholl, A. and Becker, C. (2006). State-of-the-art exact and

heuristic solution procedures for simple assembly line

balancing. In European Journal of Operational Re-

search.

Syahputri, K., Sari, R. M., Rizkya, A. I., Leviza, J., and

Siregar, I. (2018). Improving assembly line balancing

using moodie young methods on dump truck produc-

tion. In IOP Conference Series: Materials Science

and Engineering.

Tak, C. S. and Yadav, L. (2012). Improvement in layout

design using slp of a small size manufacturing unit: A

case study. In IOSR Journal of Engineering.

Wiyaratn, W., Watanapa, A., and Kajondecha, P. (2013).

Improvement plant layout based on systematic layout

planning. In International Journal of Engineering and

Technology.

Yang, T., Su, C. T., and Hsu, Y. R. (2000). Systematic layout

planning: A study on semiconductor wafer fabrication

facilities. In International Journal of Operations &

Production Management.

Yemane, A., Haque, S., and Malfanti, I. S. (2017). Opti-

mal layout design by line balancing using simulation

modeling. In Proceedings of the International Confer-

ence on Industrial Engineering and Operations Man-

agement.

ICORES 2022 - 11th International Conference on Operations Research and Enterprise Systems

168