Quality Analysis and Colour Decoding of Printed Matters using a

Portable 2D Chroma Meter

Cheng-Ru Li

1

, Chih-Chung Yang

1

, Chun-Han Chou

1

, Ming-Yen Lin

2

and Yu-Hsuan Lin

1,*

1

Taiwan Instrument Research Institute, National Applied Research Laboratories, Hsinchu, Taiwan

2

Division of Nephrology, Department of Internal Medicine, Kaohsiung Medical University, Kaohsiung, Taiwan

Keywords: Chroma Meter, Colour Distribution, Printed Matters.

Abstract: The paper presents an optical imaging system for the colour distribution measurement of objects. It has the

advantages of portable, accuracy and high resolution. The lens barrel and the ring sunlight LEDs are

designed to achieve regional darkroom, high illumination uniformity and high color rendering. After using a

small color chart for calibration, the average color deviation (ΔE*ab) of the imaging system will be lower

than 3. The uniformity of the printed papers could be successfully analysed and achieve color encryption

application. This technology provides a useful solution for imaging and print technology that is very

demanding on color correctness.

1 INTRODUCTION

Color is a kind of human visual characteristic. In the

visible spectrum, all the wavelengths of light mixed

together is known as white light. The eyes collect

the lights bounced off by the objects and form a

color perception in the brain (Nathans, 1999). The

color reflects the spectral results of the interaction of

light and material. Colors categories can be

numerically identified by the coordinates in various

color space or the wavelength range of

electromagnetic radiation. In physical space, the

presentation reproduces of color need to compare the

measured result and traceable standard sample by a

calibration device. The color space is an effective

mathematical model to serve as the basis for the

calibration process (Connolly, 1997). The CIELAB

color space defined by the International Commission

on Illumination (CIE) in 1976 is a commonly used

standard because it contains all colors that humans

can see (Luo,2001) (Schanda, 2007). The LAB color

space expressed through three parameters: L for the

lightness and a and b for the green–red and blue–

yellow components. In general, the color measuring

instrument of object is a chroma meter or

spectrophotometer (Gras, 1990) (Martínez, 2001)

(Smith, 1931). An optical sensor with filters or a

spectrometer was used to separate the wavelength of

light, and then calculate an accuracy numerical value

of color (Zhang, 1997). They can measure the color

of flat material such as paper, plastics and metal, to

help the people to specify and communicate the

color accuracy. However, these devices have a non-

negligible disadvantage. That is, each measurement

can only obtain a single value. We believe that the

single point of measurement cannot represent the

condition of entire sample.

In this study, an optical imaging system for the

color distribution measurement of objects was

developed. The purpose is to make a specific chroma

meter that can obtain two-dimensional information

of samples. This system is composed of white light

LED, darkroom tube and optical imaging device.

The system achieves color analysis capability with

high accuracy, repeatability and resolution

characteristics through a complete color calibration

process. Compared to conventional chroma meter,

the developed system was designed for multi-point

measurement. Therefore, the uniformity and

distribution of color on objects can be measured and

analyzed. This system has advantage of being

portable and is not affected by the external

environment during measurement. In the experiment,

the measured samples are standard color charts and

printed papers. The printing industry has always

attached great importance to color deviation.

However, many kinds of printing equipment may

not be able to supply stable and consistent color

quality for paper. In this system, the average ΔE*ab

between the measured results and the standard color

Li, C., Yang, C., Chou, C., Lin, M. and Lin, Y.

Quality Analysis and Colour Decoding of Printed Matters using a Portable 2D Chroma Meter.

DOI: 10.5220/0010853600003121

In Proceedings of the 10th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2022), pages 123-127

ISBN: 978-989-758-554-8; ISSN: 2184-4364

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

123

chart is less than 3 (Xu, 2012) (Gómez-Polo, 2016).

This means that the system can identify color

difference which is hard to recognize by human eyes.

After measuring the printed samples, the color

distribution and statistical contribution in LAB color

space was successfully acquired. For cipher

application, four colors with smaller ΔE*ab value was

picked up to make a special color card with them. In

addition, there are other similar colors that are

randomly distributed in the card. It is difficult to

distinguish from the naked eye. Through this system,

the color distribution of this color card can be

obtained correctly. The RGB values of the top five

major colors are used as a tool for encryption coding.

Inaccurate color measurement will not get the correct

private key. The development of this instrument will

contribute to the researches of colorimetry in the field

of print, cipher and relative applications.

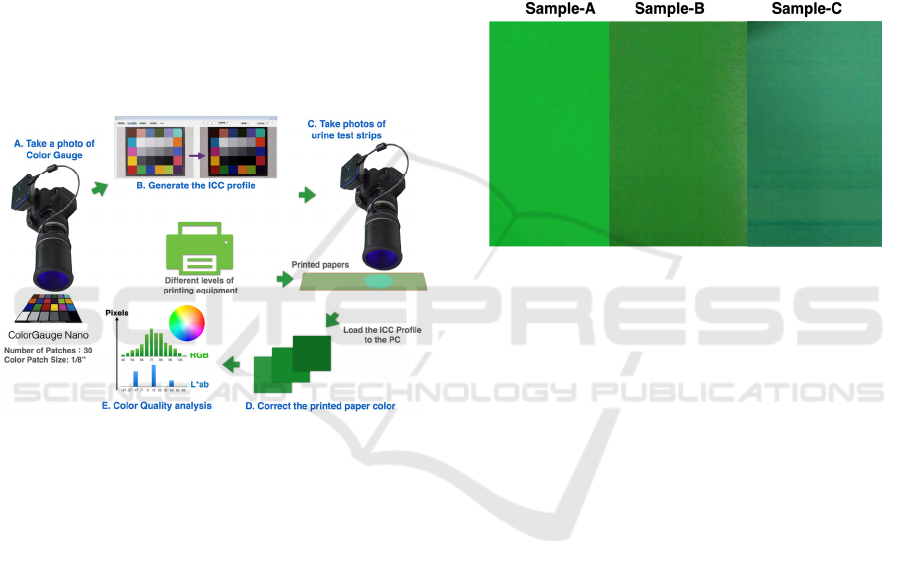

Figure 1: The experimental setup of the 2D chroma meter

for the measurement of printed papers.

2 EXPERIMENTAL SETUP AND

SAMPLE PREPARTION

Fig. 1 shows the schematic diagram of the color

correction procedure of the developed instrument.

The system is designed for the color distribution

measurement of printed papers. A CCD camera

(Canon, 77D)and a macro lens (EF-S 60 mm)were

used to capture the optical images of samples. The

field of view of this optical system is 50 mm × 30

mm, and the resolution is about 15 μm. For uniform

illumination and reflection measurement, a ring light

module that has sunlight LEDs was used. The

uniformity of lighting is better than 95% and the

spectrum of the LEDs is similar to sunlight. In order

to isolate the ambient light, a darkroom module was

used between the lens and sample. A small color

checker(ColorGauge Nano, Matte, Edumnd optics)

was measured by the system and provides a

calibration standard. Through the compensation of

ICC profile, the relatively accurate colors could be

obtained by the system. We have verified that the

system can achieve that the average ΔE*ab is less

than 3. The experimental samples are various printed

papers, as shown in Fig.2. The first one is a

commercial color chart without a rigorous

calibration standard. The second and third ones are

normal paper printed by the business and home

printer, respectively. The specified color parameter

when printing is R:0 G:255 B:0. This means that

they theoretically are all pure green.

Figure 2: Various printed papers were measured and

analysed by the 2D chroma meter.

3 RESULTS AND DISCUSSION

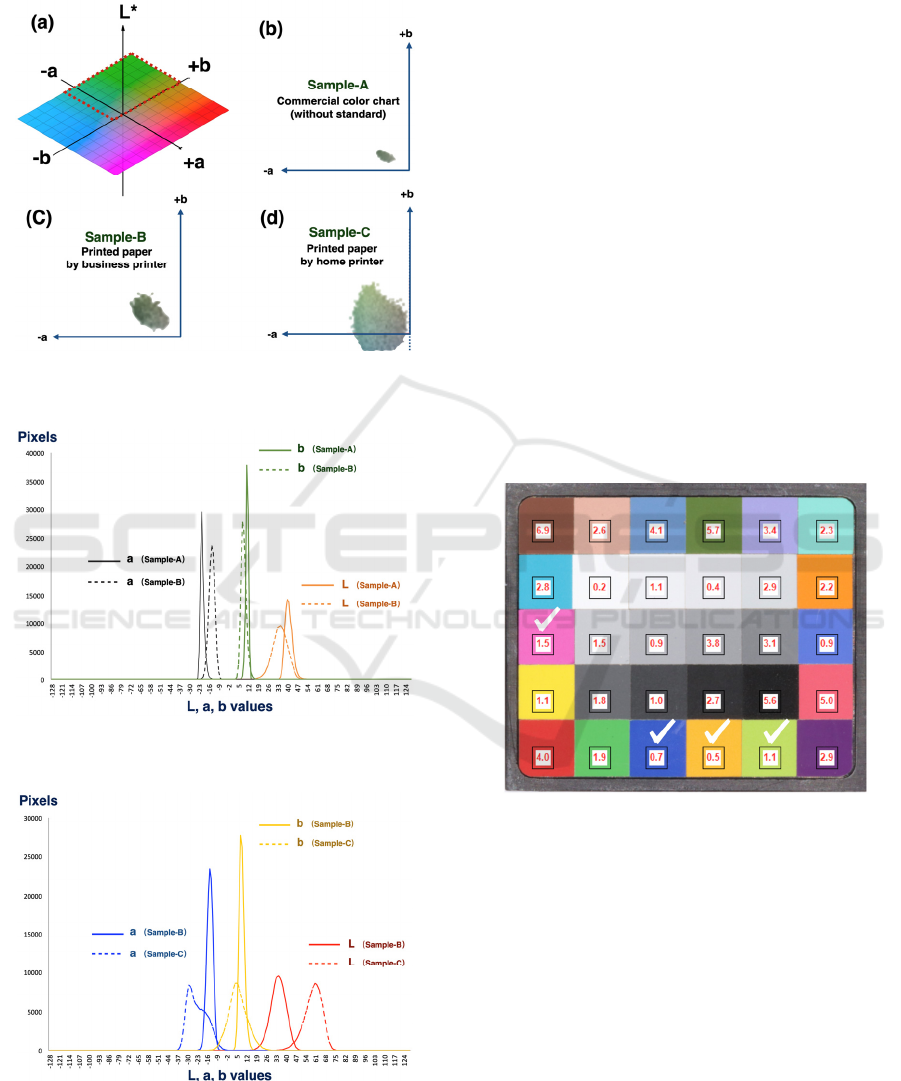

The measured results are shown in Fig. 3. The color

of each pixel in the measured optical image is

correctly described and located in the Lab color

space. Since the printed papers are green, the

measured values should be within the third and

fourth quadrants of color space, as shown in the red

frame of Fig 3(a). Figure (b), (c) and (d) indicate the

color distribution of color chart, professional print

and general print in Lab color space. For easy

viewing, only the a-b plane is shown. It indicates

that the 3D color space is flattened to display only

pure color information. Therefore, the lightness (L

value) in Figure 3 may not be correct. This does not

actually affect the results of the analysis. Obviously,

it can be found that a perfect monochrome does not

exist in all kinds of printed matter. The distributions

of colors are regional, not single points. Excellent

print quality of color chart allows color to be

concentrated in a very small area, as shown in Fig

3(a). High end and entry printer will also cause

obvious differences in the degree of color

centralizing, as shown in Fig 3(b) and (c). Although

the color uniformity should be related to printer

level, ink quality, paper material and environment,

PHOTOPTICS 2022 - 10th International Conference on Photonics, Optics and Laser Technology

124

this system provide people a 2D visualization

function to perform the quality judgment for the

final printing product.

Figure 3: Color distributions of the various printed papers

in Lab color space (Only ab plane).

Figure 4: Comparing the colour numerical distribution of

the color chart and paper printed by the business printer.

Figure 5: Comparing the colour numerical distribution of

the papers printed by the home and business printer.

The color distributions of samples were

quantified by drawing the statistical charts. Figure 4

shows the colour numerical distributions of the color

chart and paper printed by the business printer.

Figure 5 shows the colour numerical distributions of

the paper printed by the home and business printer.

The vertical axis of the figure is the amount of pixels,

and the horizontal axis is the values of Lab. In

contrast to the printed papers, most pixels of the

color chart image are concentrated in a narrow band.

It is easy to understand that the larger the bandwidth,

the poorer the print quality. The peak of each

distribution represents the dominant color of the

image in Lab color space. Therefore, the peak

deviation represents the degree of color difference

between the samples. The dominant color of any

kinds of sample could be easily decided by the

statistical chart. For example, the dominant color of

the color chart (sample-A) should be: a: -21, b: 11.

Also, the respective contribution of the border color

could be obtained by comparing the Fig. 3 and 4.

We believe that this 2D chroma meter is very useful.

The future work is improving the color accuracy to

ΔE*ab <1.

Figure 6: Four colors with relatively small color deviation

were selected for encoding.

In addition to the quality analysis of printed

materials, the system can also develop cryptography

in printing and display, such as anti-counterfeiting,

identification and digital keys. Password information

is hidden in the image in a color-distributed manner.

A precise two-dimensional colorimeter can get the

correct color values and perform subsequent

calculations. In order to select the color that is morer

suitable for encoding, we measured and calculated

the color deviation of the system. The smaller the

color deviation, the better the color is suitable for

decoding through the system. Figure 6 shows the

ΔE*ab values for 25 typical colors. Although white

Quality Analysis and Colour Decoding of Printed Matters using a Portable 2D Chroma Meter

125

has good color accuracy, it is not flexible for color

printing. In Fig. 6, the selected color is ticked. They

are blue (0.7), yellow (0.5), and green (1.1). The

color of the red series is generally not too small,

which is due to the original condition of the camera

itself. The pink with an ΔE*ab value of 1.5 is chosen.

These colors will be used as the primary colors for

encoding. If the print or display shows these colors,

the developed system will be able to morer

accurately distinguish its color.

Figure 7: Color blocks with data encryption: (a) Before

color calibration, (b) After color calibration.

Figure 7 shows a photograph printed with these

four colors. (a) is yellow, (b) is pink, (c) is blue, and

(d) is green. The image on the left represents the

image before the color calibration, and the image on

the right represents the image after the calibration.

It’s not easy to find the morer color information

were hidden in the photo. In other words, these color

blocks are not monochromatic. Each color block

contains other colors that are randomly distributed.

These colors are very similar to each other and are

difficult to distinguish. If the optical system for

measuring color has a large deviation (ΔE*ab >1.5),

the obtained color information will be wrong, and

the decoding will fail. The insertion of color for data

encryption can be designed according to the opinion

of each manufacturer. In this study, it is proposed to

perform coding or decoding in the form of color

quantity statistics. Since the encrypted information is

independent to visual perception of the human eye, it

is not represented by the statistical graph of Lab

color gamut. The RGB gamut is consistent with

digital sensation and easier for numerical processing.

The number of colors in each color block of Fig. 7 is

counted and analyzed.

Figure 8 shows the quantitative statistics of

colors in each color block of Fig. 7. Only the five

colors that contribute the most are displayed. The

horizontal axis is the RGB value of the color, and

the vertical axis is the pixel amount. Four square

blocks shown in Fig. 8 represents the color block of

Fig. 7 image described only in five main colors. It

can be found that these key colors are enough to

represent the entire image, but the differences

between them are indistinguishable to the naked eye.

If applied to image encryption, the image does not

have to be square, or it can be a cartoon image or

any geometric shape. Traditionally, the cipher colors

hidden in regular areas might be mistaken for

uneven printing. However, the system has high color

accuracy and resolution, and can distinguish very

small color differences. That is to say, the printed

matter can be made almost uniform. Data encryption

can be easily accomplished as long as a very small

color difference can be formed. Taking this method

as an example, the output of the color information is:

(R

,𝐺

,𝐵

)

~, ~

There are 20 numbers available. If you want to

establish a password of 009-075-010, you can

simply define as follows:

(R

,𝐺

,𝐵

)

,

− (R

,𝐺

,𝐵

)

,

Of course, the real password architecture is

always not so simple, and there are endless ways to

design this part. When the value measured by the

optical system is slightly deviated, the final

calculated value will be incorrect. Therefore, if the

darkroom module, high color rendering lighting and

color calibration program of the system are lacking,

this goal cannot be achieved. This study proposes an

innovative concept for color data encryption of print

matters using a two-dimensional colorimeter.

Printing technology also requires complete color

management to print images with the correct code. If

the home display will all have enough color

accuracy in the future, the concept of this study can

also be extended to related applications.

Figure 8: Quantitative statistics of colors in each color

block and the RGB values of the five most contributing

colors.

PHOTOPTICS 2022 - 10th International Conference on Photonics, Optics and Laser Technology

126

4 CONCLUSIONS

This study succeeded in developing a portable, rapid

and accurate system for the color measurement. The

information it captures is two-dimensional, so all

kinds of images can be directly measured. Through

darkroom modules, ring sunlight LED illumination

and standard color calibration procedures, the

average color deviation of the system is less than 3.

In experiment, various printed papers were measured

by the system. Color distribution in Lab space and

colour numerical distribution of the samples were

sucssufully analysed. This system can also be

applied to the field of color encoding or encryption.

Colors with data information are hidden in color

blocks and can be decoded correctly. This

technology can be widely used in the fields of

printing, display, cipher and relative applications.

ACKNOWLEDGEMENTS

The authors would like to express their appreciation

for financial aid from the Ministry of Science and

Technology, R.O.C under grant numbers MOST

109-2622-E-492-020. The authors would also like to

express their gratitude to the Instrument Technology

Research Center of National Applied Research

Laboratories for the support.

REFERENCES

Nathans, J. (1999). The evolution and physiology of

human color vision: insights from molecular genetic

studies of visual pigments. Neuron, 24(2), 299-312.

Connolly, C., & Fleiss, T. (1997). A study of efficiency

and accuracy in the transformation from RGB to

CIELAB color space. IEEE transactions on image

Luo, M. R., Cui, G., & Rigg, B. (2001). The development

of the CIE 2000 colour‐difference formula:

CIEDE2000. Color Research & Application: Endorsed

by Inter‐Society Color Council, The Colour Group

(Great Britain), Canadian Society for Color, Color

Science Association of Japan, Dutch Society for the

Study of Color, The Swedish Colour Centre

Foundation, Colour Society of Australia, Centre

Français de la Couleur, 26(5), 340-350.

Schanda, J. (Ed.). (2007). Colorimetry: understanding the

CIE system. John Wiley & Sons.

Gras, P. W., Bason, M. L., & Esteves, L. A. (1990).

Evaluation of a portable colour meter for assessment

of the colour of milled rice. Journal of Stored Products

Research, 26(2), 71-75.

Martínez, J. A., Melgosa, M., Pérez, M. M., Hita, E. A. I.

N. S., & Negueruela, A. I. (2001). Note. Visual and

instrumental color evaluation in red wines. Food

Science and Technology International, 7(5), 439-444.

Smith, T., & Guild, J. (1931). The CIE colorimetric

standards and their use. Transactions of the optical

society, 33(3), 73.

Zhang, X., & Wandell, B. A. (1997). A spatial extension

of CIELAB for digital color‐image reproduction.

Journal of the society for information display, 5(1),

61-63.

Xu, B. T., Zhang, B., Kang, Y., Wang, Y. N., & Li, Q.

(2012). Applicability of CIELAB/CIEDE2000 formula

in visual color assessments of metal ceramic

restorations. Journal of dentistry, 40, e3-e9.

Gómez-Polo, C., Muñoz, M. P., Luengo, M. C. L.,

Vicente, P., Galindo, P., & Casado, A. M. M. (2016).

Comparison of the CIELab and CIEDE2000 color

difference formulas. The journal of prosthetic

dentistry, 115(1), 65-70.

Quality Analysis and Colour Decoding of Printed Matters using a Portable 2D Chroma Meter

127