Three-step Approach for Localization, Instance Segmentation and

Multi-facet Classification of Individual Logs in Wooden Piles

Christoph Praschl

1 a

and Gerald Adam Zwettler

1,2 b

1

Research Group Advanced Information Systems and Technology (AIST), University of Applied Sciences Upper Austria,

Softwarepark 11, 4232 Hagenberg, Austria

2

Department of Software Engineering, School of Informatics, Communications and Media,

University of Applied Sciences Upper Austria, Softwarepark 11, 4232 Hagenberg, Austria

Keywords:

Instance Localization, Segmentation, Classification, Wooden Piles, Logs, Cross Faces, Deep Learning, Neural

Networks.

Abstract:

The inspection of products and the assessment of quality is connected with high costs and time effort in

many industrial domains. This also applies to the forestry industry. Utilizing state-of-the-art deep learning

models allows the analysis automation of wooden piles in a vision-based manner. In this work a three-step

approach is presented for the localization, segmentation and multi-facet classification of individual logs based

on a client/server architecture allowing to determine the quality, volume and like this the value of a wooden

pile based on a smartphone application. Using multiple YOLOv4 and U-NET models leads to a client-side

log localization accuracy of 82.9% with low storage requirements of 23 MB and a server-side log detection

accuracy of 94.1%, together with a log type classification accuracy of 95% and 96% according to the quality

assessment of spruce logs. In addition, the trained segmentation model reaches an accuracy of 89%.

1 INTRODUCTION

With the recent improvements in computer vision due

to availability of good deep learning paradigms, ma-

chine learning frameworks and improved GPU hard-

ware, the automated vision-based measurement be-

comes feasible in many industrial areas such as the

printing industry (Villalba-Diez et al., 2019), the food

industry (Kakani et al., 2020), the construction in-

dustry (Xu et al., 2020) or the steel production in-

dustry (Chen et al., 2020) among many others. This

development is also one of the fundamentals in au-

tonomous driving (Janai et al., 2020). However, in

forestry industry, for the domain of wood pile trad-

ing, key aspects for the price such as cross-sections of

the logs, quality and type of the wood are still mostly

manually assessed. As this is a very time-consuming

process, digitization is a key factor in cost reduction.

With a smartphone app, the log front faces can be au-

tomatically detected and segmented, besides precisely

assessing wood type and quality in an objective and

reproducible way, resulting in the possibility for de-

termining a first price estimation of the felled trees.

a

https://orcid.org/0000-0002-9711-4818

b

https://orcid.org/0000-0002-4966-6853

1.1 Research Questions and Approach

In this research paper we therefore introduce a

client/server based localization and instance segmen-

tation, as well as classification approach allowing live

application in the woods with subsequent server-side

refinement of the results. Besides it is analyzed, if

splitting into localization and segmentation allows to

achieve a higher level of accuracy overall.

2 RELATED WORK

Multiple publications are available in the context of

the individual, proposed pipeline steps for the ana-

lyzation of wooden piles using localization, segmen-

tation or classification approaches. Regarding the lo-

calization of individual logs in wooden piles Gutzeit

and Voskamp (Gutzeit and Voskamp, 2012) as well as

Auersperg-Castell (Auersperg-Castell, 2018) are able

to identify instances using Haar Cascade classifica-

tions. Multiple authors (Chiryshev and Atamanova,

2016; Knyaz et al., 2004; Kruglov, 2016) use ge-

ometric form based approaches by detecting circles

or ellipses to detect logs in wooden piles. In con-

Praschl, C. and Zwettler, G.

Three-step Approach for Localization, Instance Segmentation and Multi-facet Classification of Individual Logs in Wooden Piles.

DOI: 10.5220/0010892100003122

In Proceedings of the 11th International Conference on Pattern Recognition Applications and Methods (ICPRAM 2022), pages 683-688

ISBN: 978-989-758-549-4; ISSN: 2184-4313

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

683

trast to the previous mentioned publications, Her-

bon et al. (Herbon et al., 2014) combine local binary

patterns, together with histograms of oriented gradi-

ents (HOG) for detecting individual logs in a wooden

pile. Based on the localized logs, the authors use

the watershed algorithm based on a Gaussian mix-

ture model to segment the logs. Chiryshev and Ata-

manova (Chiryshev and Atamanova, 2016) continue

the idea of using HOG features and combine this ap-

proach with the Random Forest learning method.

In the context of segmenting an individual log,

classic approaches such as the watershed algorithm

as proposed by Herbon et al. (Herbon et al., 2014)

or similarity based methods as described by Schraml

and Uhl (Schraml and Uhl, 2014) are used. In con-

trast to that, Decelle and Jalilian (Decelle and Jalilian,

2020) juxtapose multiple neural network architectures

to separate the image foreground (log) from the back-

ground based on images of wooden cross-sections.

Like in the present work, the authors use among oth-

ers an U-NET architecture for the separation of the

logs’ cut face from the remaining background with a

comparable accuracy of 92% based on a non-public

image dataset of 2381 wooden logs.

According to the last remaining step of the pro-

posed pipeline, in the context of the classification

of the wood type and quality, recent approaches

have been published. Kryl et al. (Kryl et al., 2020)

compare different methodologies in this area us-

ing classic computer vision methods such as gray

level covariance matrices or k-nearest neighbor, but

also more advanced methodologies using deep learn-

ing. This review, shows that previous publica-

tions differ from the present approach by carry-

ing out the classification using images of the tree’s

bark (Carpentier et al., 2018; Fiel and Sablatnig,

2010), using cut out wooden boards instead of the

raw cross-sections (Shustrov, 2018), based on macro-

scopic images of the wood (Khalid et al., 2008; Tou

et al., 2009; Tou et al., 2007; Paula Filho et al., 2014;

Paula Filho et al., 2010; Gunawan et al., 2018; Seng

and Guniawan, 2018; Yusof et al., 2013; Yadav et al.,

2013; Nasirzadeh et al., 2010; Urbonas et al., 2019)

or utilizing infrared (Cao et al., 2017) and even x-ray

images (Mu et al., 2008) instead of RGB images of

the log’s cross section.

To the best of the authors’ knowledge, none of

the related works have proposed such a client/server

based architecture using deep learning approaches in

the context of individual log cross-sections of wooden

piles for localizing, segmenting and tree type as well

as quality classification and for this reason differ from

the present approach.

Log

Spruce Fir

Douglas

fir

Pine Larch

AC BR CX K

Pile group 1

Pile group 2

Quality

Type

Wooden Pile

Figure 1: Ontology for the classification of logs of a wooden

pile with two levels: (1) the type of tree and (2) the qual-

ity. The types of trees are grouped according to their occur-

rences in the Austrian forestry landscape.

3 ONTOLOGY

In the Austrian wood market, two kinds of wooden

piles are typical for construction work or product

packaging, such ones with spruces and firs, and the

second group with douglas firs, pines and larchs, as

shown in Figure 1. Next to the actual tree type, a log

can be classified to its quality based on e.g. cracks or

color differences, but always in association with the

type of tree. This separate consideration is necessary,

because of the situation, that for example a red discol-

oration of a log may be a bad indicator for most types

of trees but is a typical feature of douglas fir logs. For

this reason, we have decided to create a classification

system based on the wood classes used in Austrian

sawmills. We have reduced the original number of

classes, which e.g. differs between logs of quality A

to C, to the following four final classes based on the

associated price segment:

• AC: These are the best qualities A through C with

no or only few flaws and are usually paid the same

price, so they are combined into one class.

• BR: This quality class contains logs of minor

quality with partially rooten spots mostly due to

fungus and for this generate lower revenues.

• CX: The class of CX contains logs of minor qual-

ity with cracks or irregular shape that are crooked

or knotty. This class can be only partially classi-

fied from a photograph of the cutting area, since

the crucial features can also occur along the whole

remaining log.

• K: The last class contains wood that is infested

by bark beetle and for this has a blue/gray shade

at the rim on the cutting surface. However, the

infestation has not progressed that far to impair

the structural quality and is for this still sellable.

ICPRAM 2022 - 11th International Conference on Pattern Recognition Applications and Methods

684

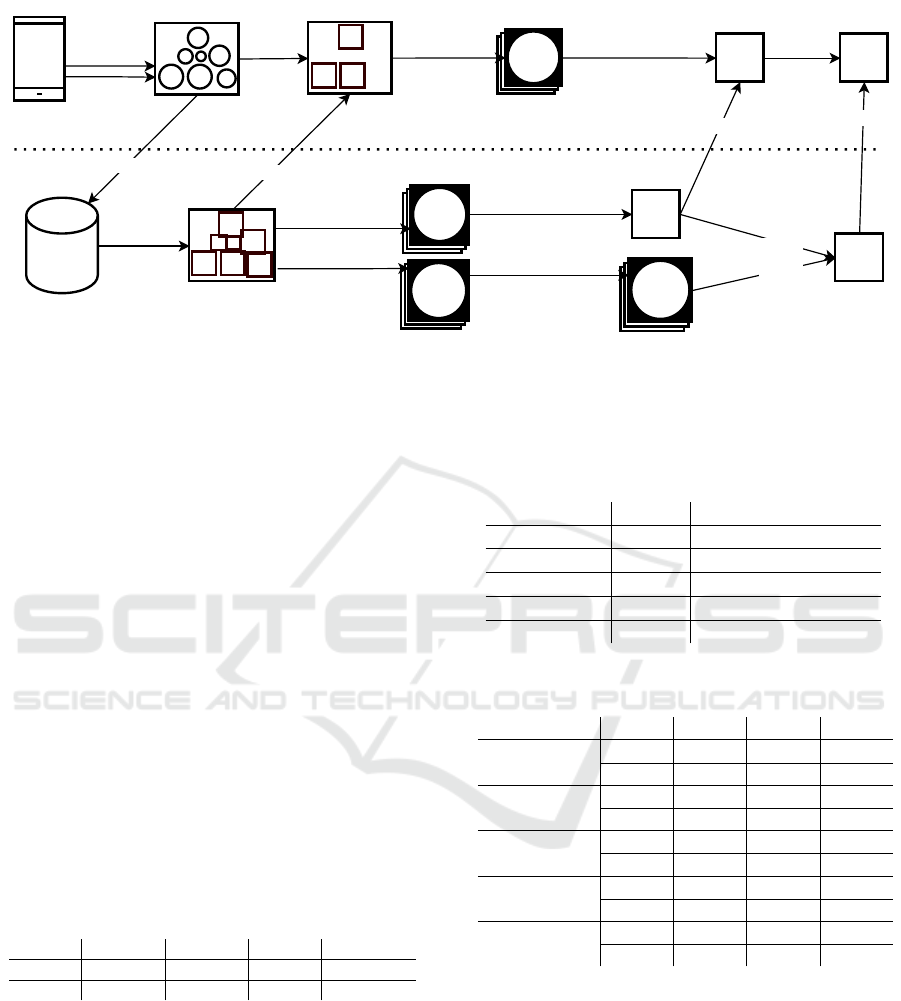

4 METHODOLOGY

Based on the proposed ontology, a process is sug-

gested as shown in Figure 2, that is designed for

foresters and forest owners, who are interested in the

value of wooden piles. Due to the situation that a net-

work connection may not be available on the site of

a forest, the process is based on a separated architec-

ture using a client, as well as a server application. To

do so, two pipelines are considered, with one local

pipeline for a first assessment that happens on e.g. a

smartphone or tablet, and a complementary pipeline

on an external server for a more accurate result. The

idea of the local pipeline is to have a very slim and fast

method to get a first estimation of the number of logs

in a pile, the volume of the logs and a rough estima-

tion of the pile’s value. These first results are further

refined on the server. Consequently, a two step in-

put process is used. First, the user takes an image of

the wooden pile, which is distorted according to the

camera model and additional sensor data as tilt and

orientation. Second, the user is asked for meta infor-

mation: (I) the distance to the pile of the image, (II)

the forest type (hardwood, softwood) as well as (III)

the pile’s length, which is defined by the harvester or

lumberjack.

4.1 Client Pipeline

In a first step of the local pipeline, a tiny

YOLO (Wang et al., 2020) model is used to detect

the logs in the image. Based on the resulting num-

ber i ∈ N of bounding boxes the Grab Cut algorithm

is utilized to segment the actual logs from the clipped

bounding boxes. The resulting mask images I

i

contain

0 for background, and 1 for foreground pixels respec-

tively. The mask images with a width w and a height

h are used in a next step to estimate the logs’ trunk ar-

eas a

i

as shown in Equation 1. The areas a

i

are in turn

a

i

=

w−1

∑

x=0

h−1

∑

y=0

I

i

(x,y) (1)

used together with the user inputs, the pile’s length p

and a pixel to mm conversion factor d to approximate

the log volume v

i

as shown in Equation 2. The con-

version factor d can be determined by the size ratio

of one sample log i in px o

px

i

and mm o

mm

i

as shown

in Equation 4. To do so, the log’s size in mm can be

calculated via the image’s metadata and the user input

using the distance to the log d

mm

, the sensor height s

h

,

the image height h and the focal length f l as shown in

Equation 3. Using the determined volume and a for-

est type specific volume price price

f t

, the pipeline is

able to estimate a first rough value v

pile

for the given

pile as shown in Equation 5, where logs is the number

of logs in the current pile as detected by the YOLO

model.

v

i

= a

i

· p · d (2)

o

mm

i

=

d

mm

∗ o

px

i

∗ s

h

h ∗ f l

(3)

d = o

mm

i

/o

px

i

(4)

v

pile

=

logs

∑

i=1

v

i

· price

f t

(5)

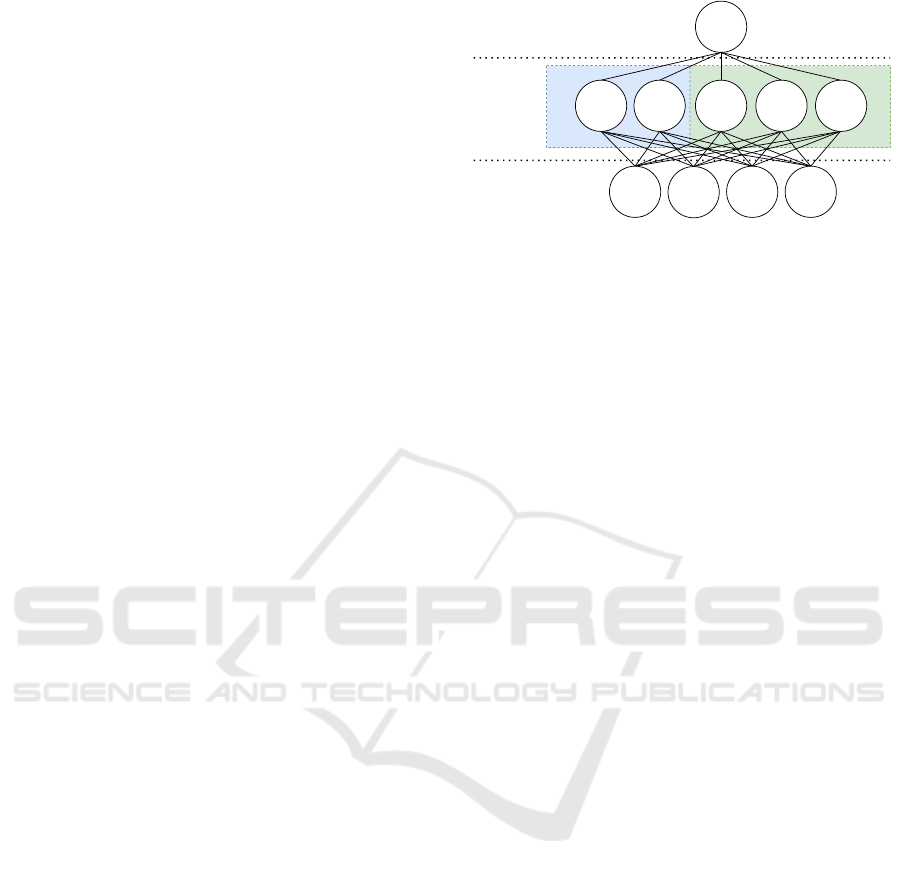

4.2 Server Pipeline

The server-side pipeline basically pursues the same

goal as the local one, calculating the value of a

photographed pile and for this task uses the same

input. In difference to the local pipeline, not a tiny

YOLO model, but a classic YOLO model is used to

detect the logs. The reason for this design decision

is that the tiny YOLO model is faster than the classic

model and has lower storage requirements, while

the classic model leads to a better accuracy. These

characteristics make it possible to realize a small

and fast local version for a first user preview. In the

second step of the server-side pipeline, two tasks

are executed in parallel based on the detected log

bounding boxes of the classic YOLO. On the one

hand an U-Net model is used to segment the indi-

vidual logs in a more accurate way compared to the

Grab Cut method of the client side, and on the other

hand a log classification process is executed. Based

on the U-Net result, the pile’s volume is calculated

identically to the local process. The classification is

in turn done in two successive steps (I) the tree type

classification and (II) the log quality classification.

The reason for this separated classification process is

attributed to the ontology shown in Figure 1, since

the quality classes are basically the same for every

log, but the features (e.g. color) that determine the

actual quality are dependent of the type of tree.

Using the classification results, a type specific price

t

i

and a quality depended factor q

i

in combination

with the volume of the associated log, the value of

the pile can be calculated as shown in Equation 6.

v

pile

=

logs

∑

i=1

v

i

· q

i

· price

t

i

(6)

Three-step Approach for Localization, Instance Segmentation and Multi-facet Classification of Individual Logs in Wooden Piles

685

take

image

tiny

YOLO

local-

ization

to server

volume

approx-

imation

m³

YOLO

local-

ization

update

pile image + meta info bounding boxes binary masks

bounding

boxes

client

server

binary masks

tree type classes log quality classes

volume

approximation

update

m³

update

€

value

approx-

imation

value

approx-

imation

€

volume value

volume

value

additional

user

input

Grab Cut

segmen-

tation

(per log)

spruce

spruce

(AC)

U-NET

segmentation

(per Log)

tree type

classification

via YOLO

(per log)

log quality

classification

via YOLO

(per log)

Figure 2: The overall process of determining the value of a wooden pile based on the volume and optional the class of

individual logs, consisting of a client-side for a first user preview and the server-side for a more accurate calculation.

5 MATERIAL

To the best of the authors’ knowledge, there is nei-

ther a wooden pile nor a log data set publicly avail-

able, that is suitable for the evaluation of the proposed

methodologies. There was the HAWKwood database,

which is not available anymore (Herbon, 2014). For

this reason, a data set of 440 pile images from the

project partners’ archives is created with a resolution

between 640 × 480 pixels and 4032 × 3024 pixels.

The images are distributed according to the seasons,

with 42 images in spring, 125 in summer, 97 in au-

tumn, 133 in winter and 43 remaining images, which

cannot be associated with the recording time, because

of a missing timestamp. This distribution is shown

in Table 1 and leads to different visual conditions of

the logs related with the seasonal weather events, like

moist wood or partially snow or mud covered logs.

Table 1: The distribution of the data set according to the

seasons.

Spring Summer Autumn Winter Unknown

42 125 97 133 43

9.5% 28.4% 22% 30.2% 9.8%

The data set is manually labelled with bounding

boxes, classes and binary masks of the individual

logs. The pile images contain in total 18521 and on

average 42 individual logs, with a minimum amount

of 1 log, a maximal amount of 395 logs and a stan-

dard deviation of 63.95. Currently, 2243 spruces, 15

firs, 346 douglas firs, 75 pines and 1135 larchs are

manually classified, as shown in Table 2. These logs

are mostly also classified according to their quality, as

listed in Table 3. In addition to that, cross-sections are

segmented for 166 individual logs.

Table 2: The distribution of manually classified logs and

their types relative to the 18521 source logs.

Type of Tree # Logs Relative Distribution

Spruce 2243 12.1%

Fir 15 0.1%

Douglas Fir 346 1.9%

Pine 75 0.4%

Larch 1135 6.1%

Table 3: The distribution of the log quality per type based

on the manually classified logs shown in Table 2.

Type of Tree AC BR CX K

Spruce 1464 214 13 543

65.3% 9.5% 0.6% 24.2%

Fir 11 0 4 0

73.3% 0% 26.7% 0%

Douglas Fir 270 55 2 18

78% 15.9% 0.6% 5.2%

Pine 74 1 0 0

98.7% 1.3% 0% 0%

Larch 886 76 35 52

78.1% 6.7% 3.1% 4.6%

6 PRELIMINARY RESULTS

The following preliminary results are based on a sub-

set of the mentioned dataset, that was not considered

for the training of the proposed models. This subset

is used, because of the situation that no comparable

dataset is publicly available to our knowledge. Using

a tiny, scaled YOLOv4 (Wang et al., 2020) model on

the client-side results in a real-time capable log de-

tection accuracy of 82.9% with 23 MB storage usage

ICPRAM 2022 - 11th International Conference on Pattern Recognition Applications and Methods

686

Figure 3: Sample of a wooden pile highlighting the results

for a single log with (a) its localization, (b) its segmentation

and (c) its tree type as well as (d) its quality classification,

together with the detection confidences.

only. On the server, a classic, scaled YOLOv4 model

results in an accuracy of 94.1% with storage require-

ments of 250 MB (Praschl et al., 2021). Using the

resulting bounding boxes, an U-NET (Ronneberger

et al., 2015) model for the segmentation and multi-

ple YOLOv4 classification models are used in paral-

lel. A detailed evaluation of these networks is still

pending, but first results (compare Figure 3) show a

mean average precision of 95% for the type model,

96% for a spruce quality model and 89% for the seg-

mentation model. The quality model shows storage

requirements of 250 MB and the segmentation model

330 MB.

7 CONCLUSION AND OUTLOOK

The preliminary results show that state-of-the-art

computer vision algorithms for localization, segmen-

tation and classification can be combined to a mul-

tiprocess analysis approach for wooden piles and for

this push the digitization of the forestry industry. The

separation of the problem into localization with sub-

sequent segmentation / classification allows to boost

the overall quality of results and further facilitates

a client / server infrastructure where preview results

can be provided on common smartphones in real-time

while further analysis and higher accuracy are asyn-

chronously performed on a server. Especially, the

consideration of the proposed ontology, allows im-

proving the classification accuracy and makes the pro-

cess more robust. In future the extension of the train-

ing data set, especially with logs of underrepresented

wood and quality types, as well as evaluations of clas-

sification and segmentation models are planned.

ACKNOWLEDGEMENTS

Our thanks to the province of Upper Austria

for facilitating the project Woodmaster+ with the

easy2innovate funding program.

The authors thank Philipp Auersperg-Castell and

Brigitte Forster-Heinlein for their contributions to the

research, as well as Ulrich and Luis Hainberger for

providing the labeled test data set and for the valuable

input.

REFERENCES

Auersperg-Castell, P. (2018). Photooptische holzpolterver-

messung mittels haar-kaskaden. Bachelor’s thesis,

University of Passau, Germany.

Cao, J., Liang, H., Lin, X., Tu, W., and Zhang, Y. (2017).

Potential of near-infrared spectroscopy to detect de-

fects on the surface of solid wood boards. BioRe-

sources, 12(1):19–28.

Carpentier, M., Giguere, P., and Gaudreault, J. (2018). Tree

species identification from bark images using convo-

lutional neural networks. In 2018 IEEE/RSJ Interna-

tional Conference on Intelligent Robots and Systems

(IROS), pages 1075–1081. IEEE.

Chen, W., Chen, S., Guo, H., and Ni, X. (2020). Weld-

ing flame detection based on color recognition and

progressive probabilistic hough transform. Concur-

rency and Computation: Practice and Experience,

32(19):e5815.

Chiryshev, Y. V. and Atamanova, A. S. (2016). Automatic

wood log detection based on random decision forests

learning algorithm and histogram of oriented gradi-

ents. In Proceedings of the 3rd International Young

Scientists Conference on Information Technologies,

Telecommunications and Control Systems, pages 7–

12.

Decelle, R. and Jalilian, E. (2020). Neural networks for

cross-section segmentation in raw images of log ends.

In 2020 IEEE 4th International Conference on Image

Processing, Applications and Systems (IPAS), pages

131–137.

Fiel, S. and Sablatnig, R. (2010). Automated identification

of tree species from images of the bark, leaves or nee-

dles. na.

Gunawan, P., Prakasa, E., Sugiarto, B., Wardoyo, R.,

Rianto, Y., Damayanti, R., Dewi, L. M., et al.

(2018). Wood identification on microscopic image

with daubechies wavelet method and local binary pat-

tern. In 2018 International Conference on Computer,

Control, Informatics and its Applications (IC3INA),

pages 23–27. IEEE.

Gutzeit, E. and Voskamp, J. (2012). Automatic segmenta-

tion of wood logs by combining detection and seg-

mentation. In Bebis, G., Boyle, R., Parvin, B.,

Koracin, D., Fowlkes, C., Wang, S., Choi, M.-H.,

Mantler, S., Schulze, J., Acevedo, D., Mueller, K., and

Papka, M., editors, Advances in Visual Computing,

Three-step Approach for Localization, Instance Segmentation and Multi-facet Classification of Individual Logs in Wooden Piles

687

pages 252–261, Berlin, Heidelberg. Springer Berlin

Heidelberg.

Herbon, C. (2014). The hawkwood database. arXiv preprint

arXiv:1410.4393.

Herbon, C., T

¨

onnies, K., and Stock, B. (2014). Detection

and segmentation of clustered objects by using itera-

tive classification, segmentation, and gaussian mixture

models and application to wood log detection. In Ger-

man Conference on Pattern Recognition, pages 354–

364. Springer.

Janai, J., G

¨

uney, F., Behl, A., Geiger, A., et al. (2020).

Computer vision for autonomous vehicles: Prob-

lems, datasets and state of the art. Foundations and

Trends

R

in Computer Graphics and Vision, 12(1–

3):1–308.

Kakani, V., Nguyen, V. H., Kumar, B. P., Kim, H., and Pa-

supuleti, V. R. (2020). A critical review on computer

vision and artificial intelligence in food industry. Jour-

nal of Agriculture and Food Research, 2:100033.

Khalid, M., Lee, E. L. Y., Yusof, R., and Nadaraj, M.

(2008). Design of an intelligent wood species recogni-

tion system. International Journal of Simulation Sys-

tem, Science and Technology, 9(3):9–19.

Knyaz, V., Visilter, Y., and Zheltov, S. (2004). Photogram-

metric techniques for measurements in woodworking

industry. International Archives of the Photogramme-

try, Remote Sensing and Spatial Information Sciences

Proceedings, V. XXXIII. Part B5/2, pages 42–47.

Kruglov, A. V. (2016). Development of the rounded objects

automatic detection method for the log deck volume

measurement. In First International Workshop on Pat-

tern Recognition, volume 10011, page 1001104. Inter-

national Society for Optics and Photonics.

Kryl, M., Danys, L., Jaros, R., Martinek, R., Kodytek, P.,

and Bilik, P. (2020). Wood recognition and quality

imaging inspection systems. Journal of Sensors, 2020.

Mu, H., Qi, D., Zhang, M., and Yu, L. (2008). Image edge

detection of wood defects based on multi-fractal anal-

ysis. In 2008 IEEE International Conference on Au-

tomation and Logistics, pages 1232–1237. IEEE.

Nasirzadeh, M., Khazael, A. A., and bin Khalid, M. (2010).

Woods recognition system based on local binary pat-

tern. In 2010 2nd International Conference on Com-

putational Intelligence, Communication Systems and

Networks, pages 308–313. IEEE.

Paula Filho, P., Oliveira, L. S., Britto, A. d. S., and

Sabourin, R. (2010). Forest species recognition using

color-based features. In 2010 20th International Con-

ference on Pattern Recognition, pages 4178–4181.

IEEE.

Paula Filho, P. L., Oliveira, L. S., Nisgoski, S., and Britto,

A. S. (2014). Forest species recognition using macro-

scopic images. Machine Vision and Applications,

25(4):1019–1031.

Praschl, C., Auersperg-Castell, P., Brigitte, F.-H., and Zwet-

tler, G. A. (2021). Multi-resolution localization of in-

dividual logs in wooden piles utilizing yolo with tiling

on client/server architectures. Proceedings of 33rd

European Modeling & Simulation Symposium.

Ronneberger, O., Fischer, P., and Brox, T. (2015). U-net:

Convolutional networks for biomedical image seg-

mentation.

Schraml, R. and Uhl, A. (2014). Similarity based cross-

section segmentation in rough log end images. In

Iliadis, L., Maglogiannis, I., and Papadopoulos, H.,

editors, Artificial Intelligence Applications and Inno-

vations, pages 614–623, Berlin, Heidelberg. Springer

Berlin Heidelberg.

Seng, L. K. and Guniawan, T. (2018). An experimental

study on the use of visual texture for wood identifica-

tion using a novel convolutional neural network layer.

In 2018 8th IEEE International Conference on Con-

trol System, Computing and Engineering (ICCSCE),

pages 156–159. IEEE.

Shustrov, D. (2018). Species identification of wooden ma-

terial using convolutional neural networks. Master’s

thesis, Lappeenranta University of Technology School

of Engineering Science.

Tou, J. Y., Lau, P. Y., and Tay, Y. H. (2007). Computer

vision-based wood recognition system. In Proceed-

ings of International workshop on advanced image

technology, pages 197–202. Citeseer.

Tou, J. Y., Tay, Y. H., and Lau, P. Y. (2009). Ro-

tational invariant wood species recognition through

wood species verification. In 2009 First Asian Con-

ference on Intelligent Information and Database Sys-

tems, pages 115–120. IEEE.

Urbonas, A., Raudonis, V., Maskeli

¯

unas, R., and

Dama

ˇ

sevi

ˇ

cius, R. (2019). Automated identification of

wood veneer surface defects using faster region-based

convolutional neural network with data augmentation

and transfer learning. Applied Sciences, 9(22):4898.

Villalba-Diez, J., Schmidt, D., Gevers, R., Ordieres-Mer,

J., Buchwitz, M., and Wellbrock, W. (2019). Deep

learning for industrial computer vision quality control

in the printing industry 4.0. Sensors, 19(18).

Wang, C.-Y., Bochkovskiy, A., and Liao, H.-Y. M. (2020).

Scaled-yolov4: Scaling cross stage partial network.

arXiv preprint arXiv:2011.08036.

Xu, S., Wang, J., Shou, W., Ngo, T., Sadick, A.-M., and

Wang, X. (2020). Computer vision techniques in con-

struction: a critical review. Archives of Computational

Methods in Engineering, pages 1–15.

Yadav, A. R., Dewal, M., Anand, R., and Gupta, S. (2013).

Classification of hardwood species using ann clas-

sifier. In 2013 fourth national conference on com-

puter vision, pattern recognition, image processing

and graphics (NCVPRIPG), pages 1–5. IEEE.

Yusof, R., Khalid, M., and M. Khairuddin, A. S. (2013).

Application of kernel-genetic algorithm as nonlinear

feature selection in tropical wood species recognition

system. Computers and Electronics in Agriculture,

93:68–77.

ICPRAM 2022 - 11th International Conference on Pattern Recognition Applications and Methods

688