MUFF: A Low-cost Motorized Positioner Developed by Additive

Manufacturing to Obtain Multi-focus Images

Gustavo Lelis da Silva

1 a

, Jorge Stolfi

1 b

and Helena Cristina da Gama Leit

˜

ao

2 c

1

State University of Campinas (UNICAMP), Campinas, SP, Brazil

2

Federal Fluminense University (UFF) Niteroi, RJ, Brazil

Keywords:

Optical Microscopy, 3D Printing, Multi-focus Stereo, Photometric Stereo, Arduino.

Abstract:

Multifocal microscopy is an established technique to combine several reflected-light microscopy images of an

object, each with a limited depth of focus, into a single image that shows the whole object in focus. Photo-

metric stereo is an independent technique to recover the third dimension of an opaque object, given several

images taken from the same viewpoint with different illumination conditions. We describe a low-cost motor-

ized positioning device for the automatic acquisition of multiple reflected-light low-power microscope images

of an object for combined multifocal and photometric stereo capture of millimeter-scale objects. The device

automatically varies the microscope-to-object distance and the light direction, under control of an Arduino

microcontroller. The device consists of a supporting frame, a microscope holder with motorized vertical dis-

placement, an illumination stage with multiple light sources, and control electronics. The mechanical and

structural parts are largely 3D-printed. The electronics is based on the Arduino microcontroller. The device is

driven through an USB cable by a Python program that runs on a PC.

1 INTRODUCTION

Multi-focus Stereo: An optical microscope usually

can focus only on those points of the target object

that lie in a narrow range of distances from the ob-

jective lens; that is, between two close planes per-

pendicular to the optical axis. The distance ε be-

tween these planes, called depth of field, is inversely

proportional to the magnification and to the effective

aperture of the microscope (Ciciliato and Chiquito,

1995). If the target object cannot fit between these

two planes, it is necessary to acquire several images

J

i

for i = 1,2,..., n, varying the object-lens distance,

so that every visible point of the object is in focus in

at least one of the images. The number n of images

must be at least H/ε, where H is the total extent of

the object in the Z-direction. These images then can

be composited into a single multi-focus image (MFI)

e

J that shows the whole object in focus. See Figure 1

As a by-product, this technique also provides infor-

mation about the three-dimensional shape of the ob-

ject, in the form of a height map — an image

e

Z that,

a

https://orcid.org/0000-0002-3834-412X

b

https://orcid.org/0000-0002-3159-4839

c

https://orcid.org/0000-0002-4722-4963

for each pixel of the combined image, specifies the

approximate Z coordinate of the point on the object’s

surface that is visible at that pixel. This method to re-

cover the 3D shape of the object is known as shape

from focus (Nayar, 1989; Fernandes and Torre

˜

ao,

2010), depth from focus (Grossmann, 1987) or multi-

focus stereo (MFS).

The principles of multi-focus stereo were de-

scribed in 1987 by Grossmann (Grossmann, 1987)

and in 1989 by Nayar (Nayar, 1989). A brief sur-

vey of the field was provided in 2012 by Thiery and

Green (Thiery and Green, 2012), and also in 2003 by

Zamofing et al. (Zamofing and Hugli, 2004). Applica-

tions of MFI and MFS include the imaging of miner-

als (Thiery and Green, 2012), manufacturing (Zamof-

ing and Hugli, 2004), paleontology (Bercovici et al.,

2009), and archaeology (Plisson and Zotkina, 2015).

Photometric Stereo: Another technique for captur-

ing the three-dimensional shape of an object uses

several images J

(k)

for k = 1,2, ... ,m, taken from

the same viewpoint but under different illumina-

tions (Woodham, 1980; Coleman and Jain, 1982).

Analysis of these images yields surface normal map

b

N and an intrinsic color map

b

A, that specify the incli-

144

Lelis da Silva, G., Stolfi, J. and Leitão, H.

MUFF: A Low-cost Motorized Positioner Developed by Additive Manufacturing to Obtain Multi-focus Images.

DOI: 10.5220/0010913500003121

In Proceedings of the 10th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2022), pages 144-151

ISBN: 978-989-758-554-8; ISSN: 2184-4364

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

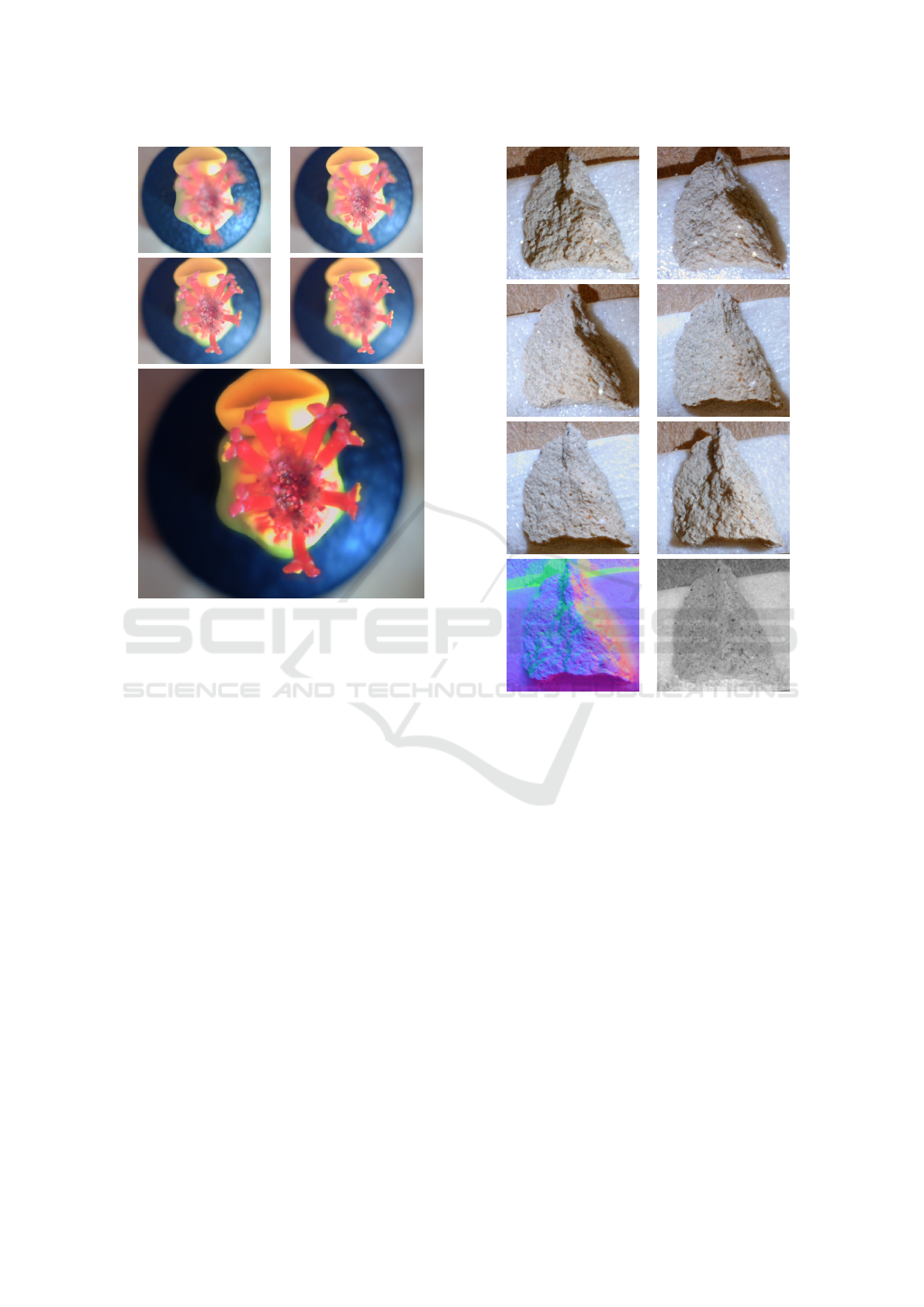

Figure 1: Illustration of the multi-focus imaging technique.

The four images at top are frames J

1

, J

9

, J

17

, and J

25

of

a 25-frame stack.The larger image at bottom is the sharp

composite image

e

J.

nation and per-channel albedo of the visible surface,

respecively, at each pixel. The slope information then

can be integrated to obtain a height map

b

Z (Sarac-

chini et al., 2012). The number m of images must be

at least 6 to provide sufficient data for this computa-

tion (Leit

˜

ao et al., 2008), but several more are needed

if there are complicating factors like projected shad-

ows, glossy highlights, significant self-lighting, etc.

See figure 2. This technique is called Photometric

stereo (PMS).

The physical principles of photometric stereo have

been known since the development of photometry in

1760 by Lambert (Lambert, 1760), and their use by

astronomers in the early 20th century (Rindfleisch,

1966). The first mathematically sound formulation

was given by Woodham in 1980 (Woodham, 1980).

The method has since been improved and generalized,

e. g. by Hertzmann (Goldman et al., 2010), Sarac-

chini et al. (Saracchini et al., 2011), and Qu

´

eau et

al. (Qu

´

eau et al., 2015). Photometric stereo can be

used for scenes of arbitrary size, from planets (with

the sun as light source) (Rindfleisch, 1966) to bacte-

ria (by varying the position of the backscatter detector

in a scanning electron microscope) (Miyamoto et al.,

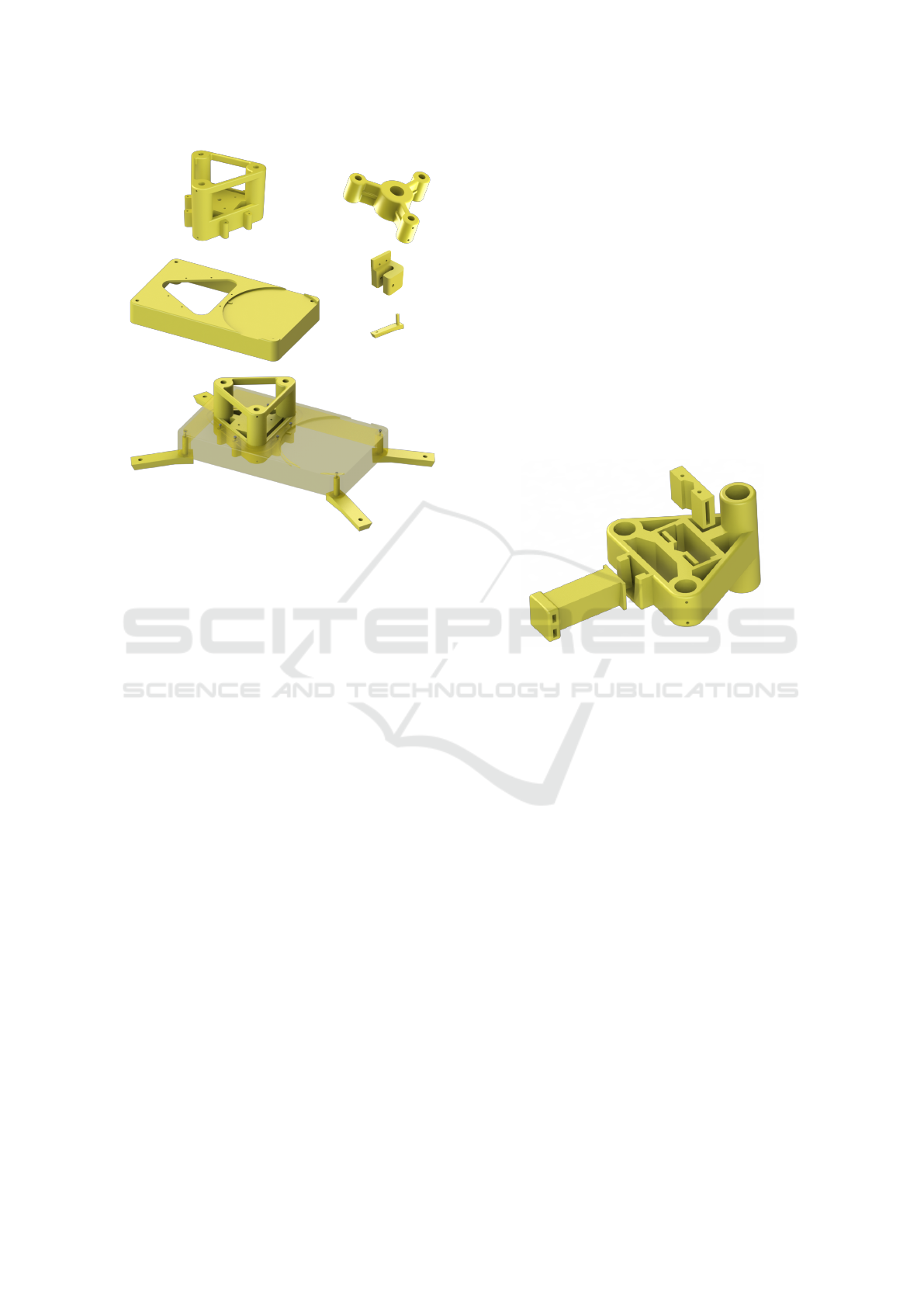

Figure 2: Example of the photometric stereo technique.

The top six images are photos J

(1)

,.. .,J

(6)

of a small

rock/plaster fragment under different lighting conditions.

The images at bottom are is the color-coded surface nor-

mal map

b

N and the intrinsic color map

b

A computed from

the above.

2017).

The two techniques are largely complementary,

because MFS works best when the object’s surface

is discontinuous or has sharp details, wheres PMS

works best when the surface is smooth and fea-

tureless. Therefore, combining the two techniques

promises to yield better reconstructions that what

each method can provide on its own. For this com-

bined approach, one must obtain images J

(k)

i

for n

microscope-to-object distances i = 1,2,. .., n and m

illumination sources k = 1,2, ... ,m. The multifocal

stereo technique is used to obtain a combined sharp

image

e

J

(k)

for each light source k, and a tentative

height map

e

Z

(k)

. Then the photometric stereo tech-

nique is applied to these images, to obtain a single

final height map

b

Z and the intrinsic color map

b

A.

MUFF: A Low-cost Motorized Positioner Developed by Additive Manufacturing to Obtain Multi-focus Images

145

2 THE POSITIONER

One obstacle to this combined multi-

focus/photometric stereo idea is the large number

(mn) of images that must be obtained, which may

reach a hundred or more. In order to alleviate this

problem, we built a simple motorized positioning

device that captures all those images automatically,

varying the distance between the microscope and the

object and the illumination of the same. See Figure 3.

Figure 3: Image of the motorized positioner, with a Cele-

stron Mini Handheld Digital Microscope installed.

The frame is built from 3D-printed plastic ele-

ments and other easily-obtained parts. The stepper

motor (that varies the focus plane) and the LED light

sources (that provide the variable illumination) are

controlled by an Arduino processor and by software

running on a PC. This original design may be a vi-

able alternative to commercial motorized microscope

stands (Silva, 2020).

As seen in Figure 3, the positioner consists of a

stationary supporting frame, a moving carriage that

holds the microscope, and a light box that surrounds

the target object and holds the light sources. The car-

riage is displaced vertically along three fixed guide

rails by a screw, driven by a stepper motor in the

base of the frame. A separate box contains the ded-

icated electronics that control the stepper motor and

the light sources. The electronics and the camera are

connected to the PC by two separate USB cables.

2.1 Operation

Once the positioner is powered up and the operating

software is running, all further user interaction takes

place through a program running on the hosting PC,

that continually displays the image seen by the cam-

era, in real-time.

Specifically, for each job the user commands the

positioner to raise the camera out of the way, places

the target object on the stage inside the light-box, and

commands the positioner to lower the camera until its

focus plane is completely below the visible parts of

the target. That action defines the first focus plane

position z

1

= 0. The user then specifies the number

n of focus positions, the vertical spacing δ between

them, and the number m of illumination conditions.

The program then automatically captures the nm im-

ages J

(k)

i

, looping on k for each camera position i.

Each captured image is displayed by the program, on

a separate window, and saved as a disk file on the PC’s

disk.

3 STRUCTURAL AND

MECHANICAL PARTS

Most structural parts of the frame and carriage

are made of polylactic acid (PLA) thermoplastic,

and were manufactured with a desktop 3D printer

(MAKERBOT REPLICATOR 2). The geometric mod-

els were created by us, using the CAD software sup-

plied with the printer.

Other major structural and mechanical compo-

nents of the system include three vertical steel rails, a

threaded rod and its sliding nut, two clamping springs,

a stepper motor, and six roller bearings (two rotary

and four linear). These parts are held together mostly

by set screws that are self-threaded into the plastic

parts.

3.1 Static Frame

The static frame of the positioner consists of a base

with four extended feet, a lower rail support, an up-

per rail support, a limit switch holder, and three ver-

tical steel columns. See Figure 4. The columns are

smooth solid steel bars, 8mm in diameter, that double

as structural elements and as rails for the carriage.

The lower rail support is a single 3d-printed piece

consisting mainly of three thick-walled tubular rail

holders, with 8 mm internal diameter, connected by

straps in an equilateral triangular prism; and a cubical

motor enclosure, open at the bottom, nestled between

PHOTOPTICS 2022 - 10th International Conference on Photonics, Optics and Laser Technology

146

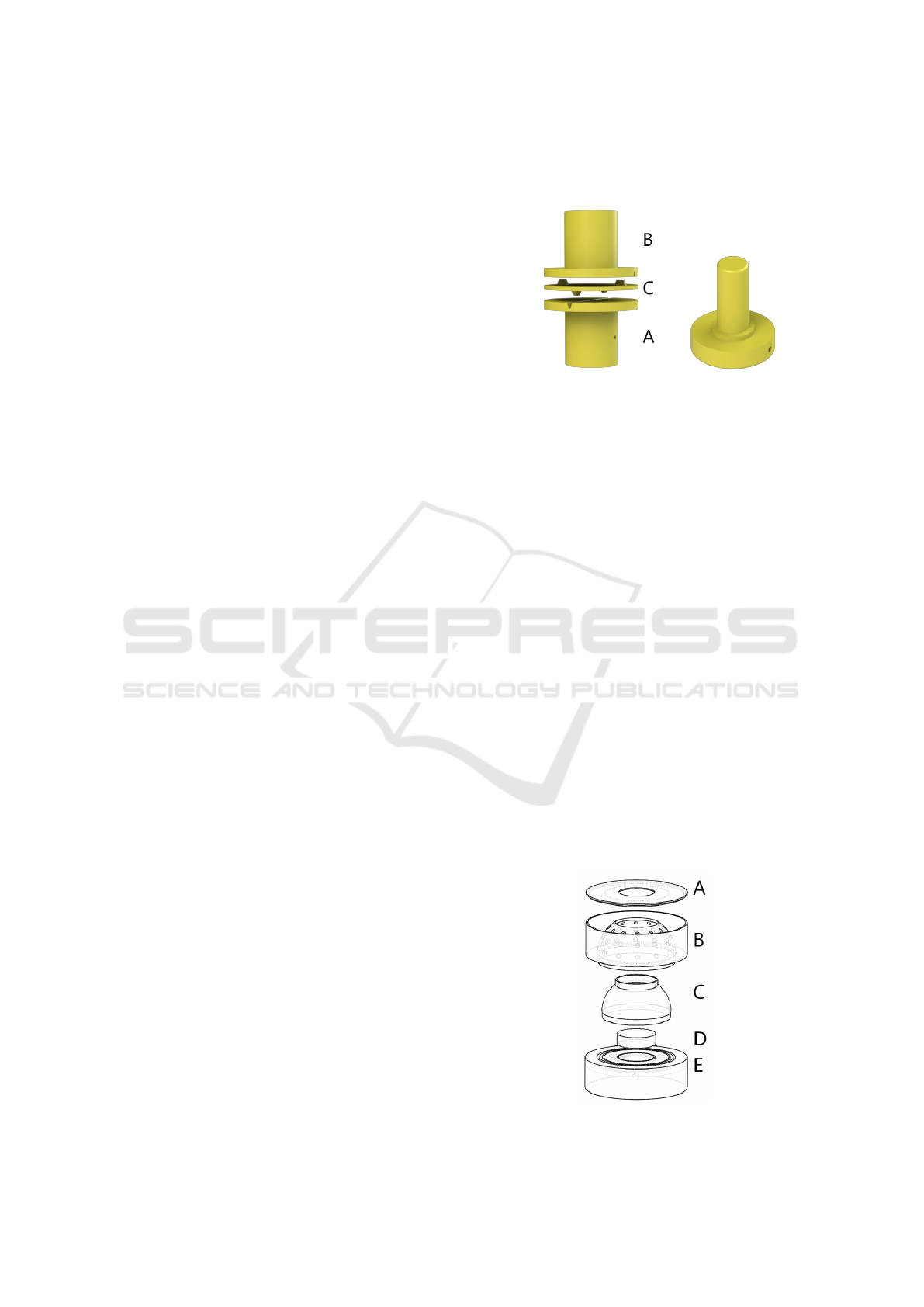

Figure 4: The plastic parts of the frame. Top row: the lower

and upper rail supports. Middle row: the base, limit switch

holder, and one of the four feet. Bottom: how the lower rail

support and the feet are attached to the base.

those tubes. Each rail fits snugly in the vertical hole

of its holder, and is secured by two set screws. The

position and radial orientation of the set screws helps

to ensure that the guides are parallel and equidistant,

in spite of play in the vertical hole and deformation of

the plastic.

The upper rail support too is a single 3D-printed

piece. Its purpose is to hold upper ends of the three

rail guides and of the driving screw in the proper rela-

tive positions. It consists of three thick-walled tubular

guide holders, arranged in an equilateral triangle; and

a central bearing holder. These four sections are held

together by three radial arms. As in the lower sup-

port, each rail is secured to the upper support by two

self-threading set screws.

The base is a hollow rectangular box, measuring

240mm × 140 mm × 33 mm and 3mm thick, fully

open at the bottom. On the top side it has a triangular

opening where the lower support fits, and a circular

depression to hold the light box (see below). Attached

at each corner, on the inside, there is a short vertical

tube that can hold a plastic foot, secured by a screw

from the top of the box. The lower rail support is at-

tached to the base by six screws.

The limit switch holder is a plastic part that is

clamped around one of the guide rails, near the bot-

tom. It holds a microswitch that is positioned and

wired in such a way that the motor turns off imme-

diately when the carriage reaches the lower end of its

range. This detail is meant to protect the motor from

overheating and to prevent the camera from hitting the

target object inside the light box. The vertical position

of the holder can be adjusted according to the camera

dimensions.

3.2 The Carriage

During use, the camera is firmly attached to a plas-

tic carriage that slides on the three rails, driven by

a threaded rod connected to the stepper motor in the

base. It has three separately printed plastic parts: a

chassis, a nut counter-plate, and an interchangeable

camera holder. See Figure 5.

Figure 5: The three plastic parts of the carriage. The bush-

ings, springs, and split nut are not shown.

The chassis, somewhat similar to the lower support,

consists of three vertical tubes connected by straps

in an equilateral triangle. However, the vertical hole

in each tube is wider, and the tube in the back is

more than twice as long as the other two. Two

stainless steel linear motion bearings (type LM08UU,

15mm × 24 mm, with 8 mm internal diameter) are in-

serted in the two tubes at the front and secured by

two set screws each. Two teflon bushings with the

same dimensions are inserted at opposite ends of the

rear tube and each is held by a set screw. All six

set screws are oriented radially. This configuration

of bearings and bushings provides four non-coplanar

points of contact with the rails, that prevent the chas-

sis from tilting in any direction; but still allows the

chassis to slide up and down with low static and dy-

namic friction.

At the center of the chassis there is an opening

with a vertical channel that is meant to hold am M8

hexagonal nut, about 28mm long, split lengthwise

through two opposite faces. In the assembled car-

riage, the halves of the nut are pressed against the

drive screw by a plastic plate with a matching verti-

cal channel, and two steel springs (two 25 mm binder

MUFF: A Low-cost Motorized Positioner Developed by Additive Manufacturing to Obtain Multi-focus Images

147

clips without the handles). One leaf of each spring

is fixed to the pressure plate by a self-threaded screw,

while the other leaf slides down into a slot in the chas-

sis. The pressure from these springs removes any play

that might have existed between the nut and the chas-

sis, thus ensuring that the vertical position of the latter

accurately tracks the rotation of the screw.

The front of the chassis has a pair of slots where

the camera holder can be inserted. The main purpose

of the latter is to position the camera so that its opti-

cal axis matches the axis of the light box. This two-

part design rigidly fixes the camera to the chassis, but

still allows it to be quickly removed for other uses,

or swapped by a different camera, without disassem-

bling the positioner. Also, a camera with different di-

ameter or shape can be accommodated by fabricating

just a new holder (rather than a new chassis).

For the hand-held digital microscope that we used

in out tests, we fabricated a holder (shown in Figure 5)

with an arm about 100 mm long ending with a con-

cave plate. The camera was secured against that plate

by two nylon zip-ties, inserted through a pair of hori-

zontal holes.

3.3 The Driving Mechanism

The mechanism that drives the carriage consists of a

stepper motor, mounted inside the lower support, and

a drive screw that for the full height of the frame, with

plastic connectors at each end. The motor is a NEMA

17 model with 1.1 Nm of torque and 200 steps per

turn. The drive screw is a coarse-threaded M8 (8 mm

diameter, 1.25mm pitch) steel rod bought at a hard-

ware store.

Torque Coupler: Experiments with previous iter-

ations of the device led us to suspect that, because

of the frame’s rigidity, slight misalignments between

the motor axis and the axis of the carriage’s nut were

generating excessive lateral forces greatly increased

friction in the latter, causing slippage in the stepper

motor.

To avoid this potential problem, we designed a

plastic torque coupler to connect the motor to the

drive screw. See Figure 6 (left). It consists of two

“flanges” attached to the motor’s shaft (A) and to the

lower end of the screw (B) by set screws. These two

parts are connected through a transfer disk (C), with

two small teeth on each face. Each pair of teeth slides

along a slots cut into the flat face of the adjacent

flange. The teeth pairs on the two sides are 90 de-

grees offset to each other. Two thin disks of a hard

and smooth PET-like plastic, with slots cut out for the

teeth, are inserted between the three disks to reduce

friction.

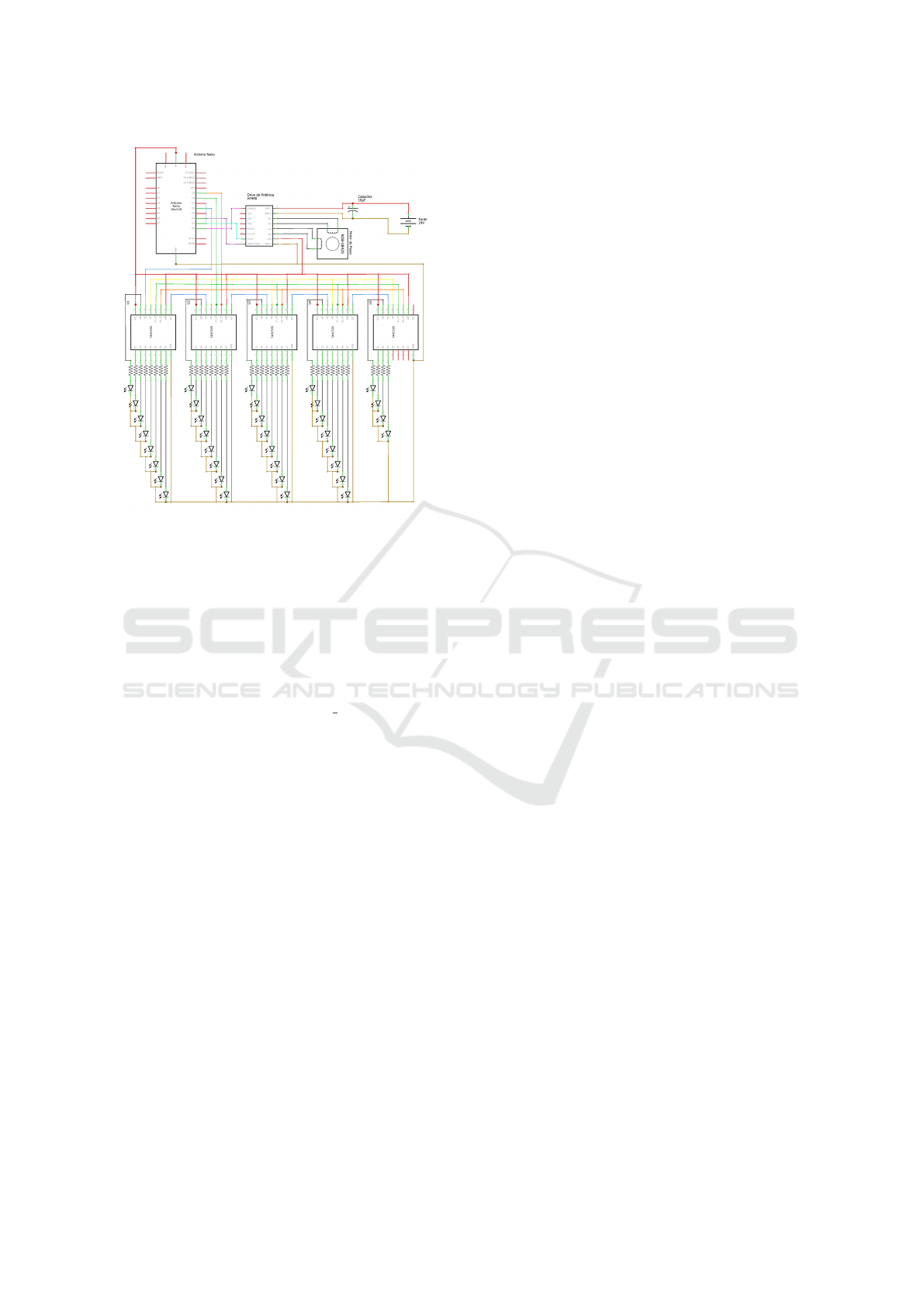

Figure 6: Left: the torque/angle coupler between motor and

drive screw. Right: the adapter for the top of the drive screw.

The teeth and slots tightly couple the rotation an-

gle of the screw to that of the motor shaft, and transmit

the full torque of the latter to the former. However,

any misalignment of the two will be accommodated

by lateral shifts of the middle disk, even as the screw

turns, with little lateral stress being felt by either of

them.

Upper Bearing Adapter: The upper end of the

drive screw is inserted in a plastic adapter (Figure 6,

right), that fits into a standard roller bearing that in

turn fits into a cavity on the bottom side of the upper

support.

3.4 The Light-box

The purpose of the light-box is to provide a con-

trolled and repeatable illumination for the target ob-

ject, that is automatically varied as required by the

PMS method. See Figure 7. It consists of a low cylin-

drical platform (E), a specimen stage (D), a light dif-

fuser dome (C), an illumination section (B), and a lid

(A).

Figure 7: Exploded diagram of the light box.

PHOTOPTICS 2022 - 10th International Conference on Photonics, Optics and Laser Technology

148

These parts, printed in white PLA, are not fastened

together, so that the stage can be easily accessed, and

any part of the light box can be excluded, replaced, or

modified if necessary. The platform E is open at the

bottom and fits into a circular depression on top of the

base; its purpose is to ensure that, when the carriage

is at its lowest position, the focus plane of the camera

lies below the target object. The stage D raises the the

target object a bit further so as to improve its illumina-

tion. The diffusing dome C, thin and translucent, may

be used to obtain more uniform and smoother lighting

of the target, if so desired.

The illumination section B is a single plastic part

consisting of a dome that holds the LED light sources

and a cylindrical enclosure that, together with the lid

A, protects their terminals and wiring. The lid has an

opening just wide enough for the camera. The internal

surfaces facing the target are painted matte black.

The device currently has 24 LEDs, arranged in

two rings of 12. A third ring of holes on the dome

could hold another 12 light sources. Each LED

has an independent connection to the electronics box

through a flat 40-wire data cable that exits through a

slot in the back of the section. For greater flexibility,

each LED is held by an individual 3D printed sleeve

(not shown) that is plugged into the corresponding

hole of the light dome. This arrangement can ac-

commodate LEDs of various sizes, holds them more

firmly, and allows their orientation to be individually

adjusted.

4 ELECTRONICS

The main component of the dedicated electronics are

two 10cm × 10 cm printed circuit boards (PCBs) of

the stripboard type, a power supply, and a motor

power drive unit. The electronics circuitry spans also

the 24 LEDS in the light box, the overrun sensing

miscroswitch, and the windings of the stepper motor.

See Figure 8. These components are housed in a low

20cm by 25 cm MDF box, seen in Figure 3.

The central component of the electronics is an Ar-

duino Nano V3 microcontroller (AG, 2017) mounted

on one of the PCBs. All components, except the mo-

tor driver, are powered by the +5V line from the USB

cable, through the Arduino. The rest of the electron-

ics can be conceptually divided into two subsystems:

motion control and lighting control.

4.1 Motion Control

The motion control subsystem applies current pulses

with the proper polarity and timing to the motor wind-

ings. A standard power drive unit (Texas Instruments

DRV8825), fed by a switching power supply type

MS-50-12 (10 A, 12 V, 60 W) is used to convert the bi-

nary 0/5V output signals of the Arduino to the ±12V

voltage and high currents required by the motor, and

also to provide over-current and temperature overload

protection. The Arduino output ports D2, D3, and D4

are connected to the drive’s Enable, Step, and Direc-

tion input pins of the power drive. Outputs 1A, 1B,

2A, and 2B of the drive are connected to the motor

winding terminals.

The motion control circuitry includes the carriage

travel limit sensor, a type MSW-14B micro switch

connected to the Arduino +5V and D10 ports. When

the switch is activated, the Arduino firmware will pre-

vent the motor from turning any further in the direc-

tion that lowers the carriage. This safety feature could

also be used by the controlling script to place the car-

riage at a specified absolute position, independently

of its current state.

4.2 Lighting Control

The light sources currently in use are 24 LEDs, each

producing 10000 mcd of white light with color tem-

perature 5500–6000 K. They are driven by a chain of

three serial-to-parallel demultiplexers (Texas Instru-

ments 74HC595), each with 8 binary 0/+5V outputs.

A 270 Ω resistor limits the current through each LED

to the nominal maximum of 18.5umA. The state of

the LEDs can be changed by the Arduino by sending

24 bits serially through port D6.

5 SOFTWARE

The device’s software consists of a firmware stored

and executed by the Arduino, and a script that runs on

a PC.

5.1 Arduino Firmware

The embedded program muff firmware was writ-

ten in the standard Arduino C-like programming

language. It uses various free libraries, including

the AccelStepper module for stepper motor con-

trol (McCauley, 2017). It receives encoded com-

mands and parameters through the Arduino’s serial

communication (USB) port. Each command consists

of one byte of operation code, and (depending on the

operation) up to four bytes of operand. The avail-

able commands include starting the motor in cruise

(constant speed) mode, up or down, stopping the mo-

tor, raising or lowering the carriage by a specified

MUFF: A Low-cost Motorized Positioner Developed by Additive Manufacturing to Obtain Multi-focus Images

149

Figure 8: Circuit diagram of the dedicated electronics. Cur-

rently only 24 of the 36 LEDs are installed, thus only the

first three multiplexers are needed.

distance, and turning a specific LED on or off. The

complete list is provided in the software’s documen-

tation (Silva et al., 2019).

5.2 Image Acquisition Script

The image acquisition script muff capture is writ-

ten in the Python language (Silva et al., 2019). It per-

forms two main functions: (a) send to the Arduino the

commands needed to position the camera and turn on

the proper LEDs for each image J

(k)

i

to be acquired;

and (b) capture the image from the camera, saving it

to disk. Currently the script relies on the open-source

software uvccapture for the latter task. These ac-

tions are fully automatic, as described in section 2.1.

The script also lets the user issue individual firmware

commands, e. g. for testing or debugging.

6 CONCLUSIONS

We described a simple device to facilitate capture of

the large number of images required to combine the

techniques of multi-focus and photometric stereo for

millimers-scale objects, by automatically varying the

position of the microscope camera and the sample il-

lumination conditions. The device requires access to

a 3D printer and a few cheap and easily obtainable

parts. The device can position the camera with sub-

millimeter precision and provide up to 24 independent

lighting conditions. These parameters are usually suf-

ficient for good MFS/PMS analysis.

Many possible improvements to the positioner

suggest themselves, such as a more precise driving

mechanism and an angular encoder to remove the risk

of slippage. Indeed, a copy of this device incorporat-

ing these improvements was recently built by Alysson

Mazoni for use at the Geosciences Department of

UNICAMP.

Another very desirable improvement would be a

mechanism to move the speciment stage horizontally,

so that centimeter-scale objects can be automatically

digitized with overlapping MFS/PMS stacks Also, a

mechanism to tilt the stage, even if only by 10-30 de-

grees, would make it possible to combine MFS and

PMS with geometric stereo (GMS), that infers the

third dimension fro multiple images taken from dif-

ferent directions.

ACKNOWLEDGMENTS

This project was partly funded by CNPq (grant

301016/92-5), FAPERJ, UFF (grant PIBINOVA/PDI-

2018), and FAPESP (grant 2013/07699-0).

REFERENCES

AG, A. (2017). Getting started with the ARDUINO NANO.

At https://www.arduino.cc/en/Guide/ArduinoNano.

Bercovici, A., Hadley, A., and Villanueva-Amadoz, U.

(2009). Improving depth of field resolution for pa-

lynological photomicrography. Palaeontologia Elec-

tronica, 12(2):12.

Ciciliato, V. and Chiquito, J. G. (1995). Modelamento do

microsc

´

opio

´

optico como um sistema linear variante

com o deslocamento. In Anais do 13

o

Simp. Bras. de

Telecomunicac¸

˜

oes (SBrT 1995), volume I, pages 258–

263.

Coleman, E. and Jain, R. (1982). Obtaining 3-dimensional

shape of textured and specular surface using four-

source photometry. Computer Graphics and Image

Processing, 18:308–328.

Fernandes, J. L. and Torre

˜

ao, J. R. A. (2010). Shape from

shading through photometric motion. Pattern Anal.

Appl., 13(1):35–58.

Goldman, D. B., Curless, B., Hertzmann, A., and Seitz,

S. M. (2010). Shape and spatially-varying BRDFs

from photometric stereo. IEEE Transactions on Pat-

tern Analysis and Machine Intelligence, 32(6):1060–

1071.

Grossmann, P. (1987). Depth from focus. Pattern Recogni-

tion Letters, 5(1):63–69.

PHOTOPTICS 2022 - 10th International Conference on Photonics, Optics and Laser Technology

150

Lambert, J. H. (1760). Photometria, sive de Mensura et

Gradibus Luminis, Colorum et Umbrae. E. Klett.

Leit

˜

ao, H. C. G., Saracchini, R. F. V., and Stolfi, J.

(2008). Matching photometric observation vectors

with shadows and variable albedo. In Proc. the 21st

Braz. Symp. on Computer Graphics and Image Pro-

cessing (SIBGRAPI 2008), pages 179–186.

McCauley, M. (2017). Accelstepper library for Ar-

duino. At http://www.airspayce.com/mikem/arduino/

AccelStepper/.

Miyamoto, A., Matsuse, H., and Koutaki, G. (2017). Robust

surface reconstruction by design-guided SEM photo-

metric stereo. Measurement Science and Technology,

28(4).

Nayar, S. K. (1989). Shape from focus. Technical Re-

port CMU-RI-TR-89-27, Robotics Institute, Carnegie

Mellon Univ.

Plisson, H. and Zotkina, L. V. (2015). From 2D to 3D at

macro- and microscopic scale in rock art studies. Dig-

ital Applications in Archaeology and Cultural Her-

itage, 2(2–3):102–119.

Qu

´

eau, Y., Lauze, F., and Durou, J.-D. (2015). A L

1

-TV al-

gorithm for robust perspective photometric stereo with

spatially-varying lightings. In Intl. Conf. on Scale

Space and Variational Methods in Computer Vision,

pages 498–510.

Rindfleisch, T. (1966). Photometric method for Lunar to-

pography. Photometric Engineering, 32(3):262–276.

Saracchini, R. F. V., Stolfi, J., and Leit

˜

ao, H. C. G. (2011).

A uniform grid structure to speed up example-based

photometric stereo. IEEE Trans. on Image Processing,

20(12):3495–3507.

Saracchini, R. F. V., Stolfi, J., Leit

˜

ao, H. C. G., Atkinson,

G. A., and Smith, M. L. (2012). A robust multi-scale

integration method to obtain the depth from gradient

maps. Computer Vision and Image Understanding,

116(8):882–895.

Silva, G. L. (2020). Posicionador automatizado para

aplicac¸

˜

ao das t

´

ecnicas de multifocal stereo e photo-

metric stereo para objetos microsc

´

opicos. Final under-

graduate project, Federal Fluminense Univ., Electrical

Eng. Dept. (in Portuguese).

Silva, G. L., Stolfi, J., and Leit

˜

ao, H. C. G. (2019). Muff

positioner - software, diagrams, and stl files. At http:

//www.ic.uff.br/\

∼

hcgl/Muff-index.html.

Thiery, V. and Green, D. I. (2012). The multifocus imaging

technique in petrology. Computers & Geosciences,

45:131 – 138.

Woodham, R. J. (1980). Photometric method for determin-

ing surface orientation from multiple images. Optical

Engineering, 19(1):139–144.

Zamofing, T. and Hugli, H. (2004). Applied multifocus 3D

microscopy. In Proc. SPIE, volume 5265, pages 134–

144.

MUFF: A Low-cost Motorized Positioner Developed by Additive Manufacturing to Obtain Multi-focus Images

151