MARE: Semantic Supply Chain Disruption Management and Resilience

Evaluation Framework

Nour Ramzy

1 a

, S

¨

oren Auer

2 b

, Hans Ehm

1 c

and Javad Chamanara

2 d

1

Infineon Technologies AG, Am Campeon 1-15, 85579 Munich, Germany

2

TIB: Technische Informationsbibliothek Welfengarten 1B, 30167 Hannover, Germany

Keywords:

Supply Chain Resilience, Disruption Management Process, Knowledge Graphs, Semantic Data Integration,

Ontologies.

Abstract:

Supply Chains (SCs) are subject to disruptive events that potentially hinder the operational performance. Dis-

ruption Management Process (DMP) relies on the analysis of integrated heterogeneous data sources such as

production scheduling, order management and logistics to evaluate the impact of disruptions on the SC. Ex-

isting approaches are limited as they address DMP process steps and corresponding data sources in a rather

isolated manner which hurdles the systematic handling of a disruption originating anywhere in the SC. Thus,

we propose MARE a semantic disruption management and resilience evaluation framework for integration of

data sources included in all DMP steps, i.e. Monitor/Model, Assess, Recover and Evaluate. MARE, leverages

semantic technologies i.e. ontologies, knowledge graphs and SPARQL queries to model and reproduce SC be-

havior under disruptive scenarios. Also, MARE includes an evaluation framework to examine the restoration

performance of a SC applying various recovery strategies. Semantic SC DMP, put forward by MARE, allows

stakeholders to potentially identify the measures to enhance SC integration, increase the resilience of supply

networks and ultimately facilitate digitalization.

1 INTRODUCTION

In highly globalized and complex SCs, performance

analysis is essential as the change in behavior due

to disruptive events does not only affect one or-

ganization but a highly connected network (Singh

et al., 2019). The importance of systematic Disrup-

tion Management for Supply Chains was just recently

again stressed in the course of the COVID-19 pan-

demic, but also already earlier in the light of events

such as natural disasters, transportation blockages,

sanctions etc. Therefore, a vast share of enterprises

rely on a Disruption Management Process (DMP) to

monitor, model, assess and recover from disruptions.

The management and the evaluation of disruptions

and their consequences on the SC require the inte-

gration of various distributed data sources, e.g. from

manufacturing, order and inventory management. SC

semantic models, i.e. ontologies, enable SC data in-

tegration by providing a common and explicit under-

a

https://orcid.org/0000-0002-7109-8784

b

https://orcid.org/0000-0002-0698-2864

c

https://orcid.org/0000-0001-6392-8269

d

https://orcid.org/0000-0001-6390-1584

standing for business-related concepts (Pal, 2019).

Existing approaches address core DMP aspects but

still in an isolated form, hence, limiting integrated

SC behavioral analysis. Compared to previous work,

our main contribution in this paper is MARE, MARE

is a semantic disruption management and resilience

evaluation framework, to integrate data covered by

all DMP steps Monitor/Model, Assess, Recover and

Evaluate.

MARE leverages a disruption ontology to model

disruptive events and a knowledge-graph to repre-

sent specific disaster scenarios and the entailed ef-

fect on the SC. MARE includes production schedul-

ing data and disruption knowledge-graphs to detect

the implication of the disruption on the SC operations,

during the assessment phase. Thus, MARE imple-

ments SPARQL-based recovery strategies to resolve

the impairment caused by the disruption. Moreover,

MARE incorporates a semantic evaluation framework

to quantify the effect of recovery in terms of cost and

delay on the SC. Based on the evaluation results, and

the recovery behavior analysis, SC stakeholders po-

tentially make decisions to redesign the SC or estab-

lish new operational strategies ensuring a more re-

484

Ramzy, N., Auer, S., Ehm, H. and Chamanara, J.

MARE: Semantic Supply Chain Disruption Management and Resilience Evaluation Framework.

DOI: 10.5220/0010983500003179

In Proceedings of the 24th International Conference on Enterprise Information Systems (ICEIS 2022) - Volume 2, pages 484-493

ISBN: 978-989-758-569-2; ISSN: 2184-4992

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

silient SC.

As a result, companies can rely on MARE to inte-

grate SC data sources to model and map the SC be-

havior, to examine the effect of disruption and the

consequences of applying various mitigation strate-

gies. Ultimately, we deem that better simulation and

analysis, as put forward by MARE, will contribute to

mastering more complex SC scenarios, control dis-

ruption accelerators e.g. the bullwhip effect and in-

crease the resilience of supply networks.

The remainder of the paper is divided as follows:

first we introduce the background of the DMP and

existing semantic implementation for SC disruption

handling in Section 2 and the motivation behind our

proposed work. Second, we present MARE in Sec-

tion 3, a framework to semantically model and man-

age disruptions and evaluate SC resilience. In Sec-

tion 4, we elaborate on MARE’s semantic artifacts

to model and assess disruptions, i.e, the first two

stages of DMP. In Section 5, we introduce SPARQL-

based recovery strategies to restore the SC to the pre-

disruption behavior. Also, we propose an evaluation

framework to analyze recovery performance. In Sec-

tion 6, we evaluate MARE to simulate the behavior

of a synthetic SC under various exemplary disrupted

events. Finally, we conclude and present an outlook

for further steps to extend MARE in Section 7.

2 BACKGROUND AND RELATED

WORK

2.1 Supply Chain Disruption

Management Process

SC disruptions as described by (Craighead et al.,

2007) are events that modify the flow of goods and

materials, hindering the SC’s overall objective to pro-

duce and deliver services and goods to end-customers.

In fact, (Blackhurst et al., 2005) define SC DMP as the

process to discover the disruptive event, recover from

the effect and potentially redesign the system trig-

gered by recovery learning outcomes. Namely, dis-

covery refers to the point in time when SC stakehold-

ers become aware of the disruption (Macdonald and

Corsi, 2013). Then, disruption modeling of the sys-

tem dynamics, e.g. via Petri nets, in simulation tools,

is essential in order to analyze expected consequences

and effects of the discovered event (Bugert and Lasch,

2018). For instance, (Jaenichen et al., 2021) rely on

the system dynamics simulation model implemented

in AnyLogic 8 tool (Ismail and Ehm, 2021) to demon-

strate the behavior of a multi-echelon SC responding

to different end market scenarios.

Further, SC stakeholders choose the most effective

recovery strategy to minimize the impacts of the dis-

ruption (Macdonald and Corsi, 2013). Thus, the re-

covery performance analysis evaluates the SC ability

to repair and return to the pre-disruption phase. Based

on the evaluation’s learning effects, SC stakeholders

can rethink the SC design and operation processes

and potentially decide on changes allowing more re-

silience e.g. increasing production capacity or apply-

ing a multiple sourcing strategy. The ability to both

resist disruptions and recover the operational capa-

bility after disruptions occur, is defined as SC Re-

silience (Simbizi et al., 2021).

DMP entails the integration of highly heteroge-

neous data sources. (Samaranayake, 2005) elaborate

that the integration provides visibility, flexibility and

maintainability of SC components. Consequently,

stakeholders can make more informative decisions to-

wards enhancing SC performance and increasing re-

silience. For instance, (Simchi-Levi et al., 2015) inte-

grate data from bill of material, part routing, inven-

tory levels, and plant volumes to map the SC and

accordingly assess the impact of a disruption origi-

nating anywhere on product manufacturing and de-

livery. Also, (Sabouhi et al., 2018) examine data from

raw materials procurement along with inventory man-

agement systems to test the effect of various strate-

gies in establishing resilience. (Ivanov and Dolgui,

2020) add that SC digital twins enable integration to

discover the link between SC disruption and perfor-

mance deterioration. Namely, semantic models, one

sort of digital twins, facilitate information exchange

and allow SCs to reach full and agile information in-

tegration.

2.2 Semantic SC Disruption

Management

In (ASCM, 2021) the authors explain that the view of

SCs is based on internal data and seemingly relies on

siloed or outdated data-sets. Consequently, detecting

emerging threats or calculating how disruption will

unfold across the whole SCs and business units is gen-

erally possible but to a rather limited extent. How-

ever, semantic modeling of SCs allows to overcome

the siloed paradigm and to blend and consolidate data

from dispersed data sources (Ye et al., 2008).

There exist several articles in the literature that

devise semantic implementations to analyze SC per-

formance during disruptions. (Emmenegger et al.,

2012) create an ontology model to monitor and model

risks, give early warning and propose a procedure

for assessing impacts on SC. Also, (Palmer et al.,

MARE: Semantic Supply Chain Disruption Management and Resilience Evaluation Framework

485

2018) present an ontology-supported risk assessment

approach for a resilient configuration of supply net-

works. Moreover, (Singh et al., 2019) provides an

ontology-based decision support system to intensify

the SC resilience during a disruption. Despite these

developments, we note that existing approaches ad-

dress DMP process steps in a rather isolated way, i.e.,

only one step of the process is incorporated e.g. to

model the disruption risk or to assess its impact. Thus,

we introduce MARE that, to the best of our knowl-

edge, is the first work to integrate various data sources

incorporated by all the DMP steps to Monitor/Model,

Assess, Recover and Evaluate.

3 METHODOLOGY

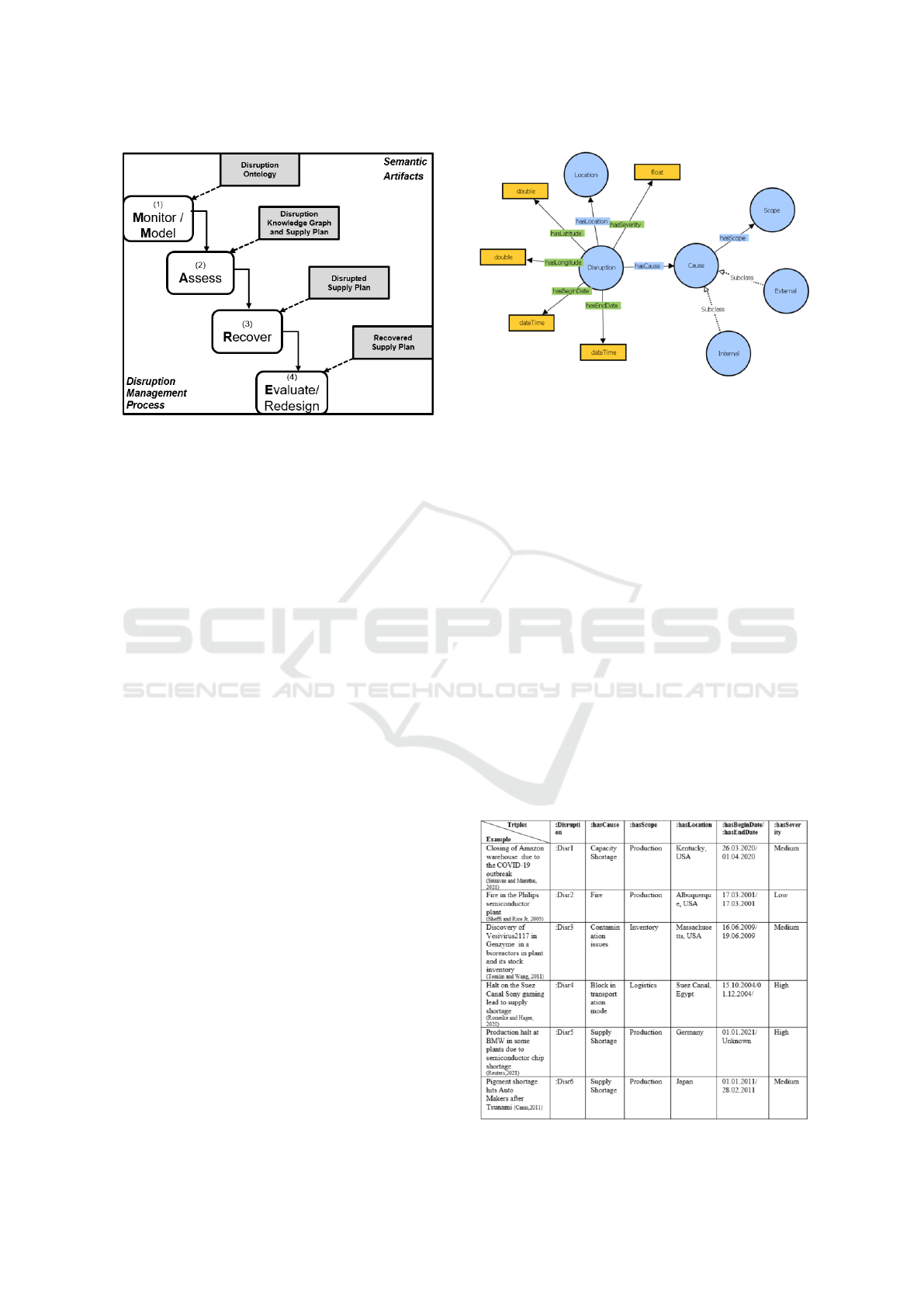

In this section, we describe our semantic disruption

management and resilience evaluation framework,

MARE. Moreover, we elaborate on MARE’s seman-

tic artifacts i.e., ontologies, knowledge graphs and

SPARQL to implement the DMP. As shown in Fig-

ure 1, the DMP starts with Monitoring and Modeling

SC disruptions. This phase is to discover the event

that disrupts the SC and to create a semantic model

incorporating the disruption’s attributes e.g. severity,

cause and duration. We rely on the Disruption On-

tology model, where the information is represented

in the form of RDF triples

1

, to establish a common

understanding of a disruption event. Consequently,

we create a specific instance of a disruption event i.e.

Disruption Knowledge Graph (KG). The output of the

Monitor/Model process step, the Disruption KG, is

used in the following step to assess the effect of the

disruption on the SC.

The target of a SC is to fulfill end-customers’ de-

mand. Namely, SC planning defines a scheduled ca-

pacity allocation for products among production facil-

ities as well as the needed parts among suppliers i.e.,

Supply Plan. In previous work (Ramzy et al., 2021),

we devised a semantic model for demand, production

scheduling data and corresponding supply plan as fol-

lows:

• Demand: SC demand is represented by the triples

of the following form Customer makes Order. An

order includes details about the product, deliv-

ery time and quantity: Order hasProduct Prod-

uct, Order hasDeliveryTime xsd:dateTime and

Order hasQuantity xsd:integer. Based on the

customer segmentation paradigm, customers are

given a priority, entailing a certain sequence in

demand fulfillment, i.e., Customer hasPriority

1

https://www.w3.org/TR/rdf-concepts/

xsd:integer.

• Supply Plan: A supply plan is defined as the al-

location of demand for parts among suppliers or

the allocation of demand for products among pro-

duction facilities (Sawik, 2019). Order hasSup-

plyPlan Plan and Plan needsPartner Partner de-

scribe the needed SC partners to fulfill this order.

Each partner is responsible for providing a prod-

uct, i.e. << Plan needsPartner Partner >> get-

sProduct Product at a certain time hasTimeStamp

xsd:date. The mentioned product can either be the

final product or intermediary parts used to man-

ufacture the final product. The quantity and the

price are modeled using hasQuantity xsd:double

and hasUnitPrice xsd:double

Disrupted SC partners potentially cannot fulfill

their role in the plan, which affects the whole SC per-

formance. Therefore, during the disruption Assess-

ment phase, we leverage queries adhering to the W3C

SPARQL standard to identify affected SC partners

that are located in the same regions as the disruptions

and who participate in the supply plan at the same

time of the disruption (as described in detail in Sec-

tion 4). In this process step, we integrate data sources

from production scheduling (Supply Plan) and disrup-

tion models (Disruption KG) to output the Disrupted

Supply Plan.

The following step in the DMP is to apply Recov-

ery strategies to attempt a return to the pre-disruption

performance of the SC. In this phase, we rely on

SPARQL endpoints to integrate data from production

scheduling, order processing, inventory management,

and suppliers assignment in order to find alternative

allocations for the disrupted plans.The output of this

step is one or more proposed Recovered Supply Plans

that include the updated scheduled allocations.

The last step of the DMP is to Evaluate the SC

recovery performance. We propose a resilience Eval-

uation framework based on SPARQL queries to ex-

amine the time and the cost entailed by the Recov-

ered Supply Plan and required for the SC to return

to the pre-disruption state. In fact, SC stakeholders

rely on this evaluation to potentially identify needs to

redesign SC or apply new operational strategies e.g.

supplier diversification.

4 SUPPLY CHAIN DISRUPTION

MODELING AND ASSESSMENT

In this section, we present the first two steps of MARE

to model and assess the effect of monitored disrup-

tions on the SC.

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

486

Figure 1: Overview in the MARE semantic disruption man-

agement and resilience evaluation framework.

4.1 Modeling Disruption

4.1.1 Disruption Ontology

We propose the Disruption Ontology shown in Fig-

ure 2 to establish a model for disruptive events. The

ontology is based on RDF where the information is

represented in triples. First, a triple of the following

form Disruption hasCause Cause, describes the main

cause that led to the disruption. In fact, (Messina

et al., 2020) classifies disruption causes as internal

and external. The first is caused by events happening

within internal boundaries and the business control of

the organizations e.g. malfunctioning of a machine

or inventory corruption. While the latter is driven

by events either upstream or downstream in the SC

e.g. supplier insufficient capacity, interruptions to the

flow of product, or significant increase/decrease in de-

mand.

Moreover, disruptions impact various SC scopes

e.g. production, logistics, inventory (Macdonald and

Corsi, 2013). This, is reflected by triples of the form:

Cause hasScope xsd:string. Additionally, the struc-

ture Disruption hasSeverity xsd:string incorporates fi-

nancial losses caused by the disruption and their ef-

fect on the reduction or elimination of the produc-

tion quantities. Further, disruption events can be of

short or long duration. We use the following triple

representation to model the disruption beginning and

end Disruption hasBeginDate xsd:date and Disrup-

tion hasEndDate xsd:date. Also, we use Disruption

hasLocation Location to represent the geographical

location where the disruption occurs. We rely on

geo-coordinates system to resolve locations using the

properties hasLongitude, hasLatitude.

Figure 2: Overview on the core concepts of the Disruption

Ontology for modeling disruptive event characteristics.

In fact, classifying the modeled characteristics of

the disruption enables SC stakeholders to determine

suitable recovery strategies for this event. For exam-

ple, in case of an external disruption due to the lack

of a supplier’s capacity, the recovery means can be to

find an alternative supplier. Whereas, to recover from

an internal malfunctioning machinery within an own

facility, one needs to fix it by retrieving spare parts

from a machine of the same brand.

4.1.2 Instantiated Examples

The proposed disruption ontology incorporates dis-

ruption attributes to create a specific instantiation of

a disruption event, represented by the Disruption KG.

We present in Table 1 various examples from past

events to highlight possible variations in disruptions

in terms of cause, scope, location, duration and sever-

ity.

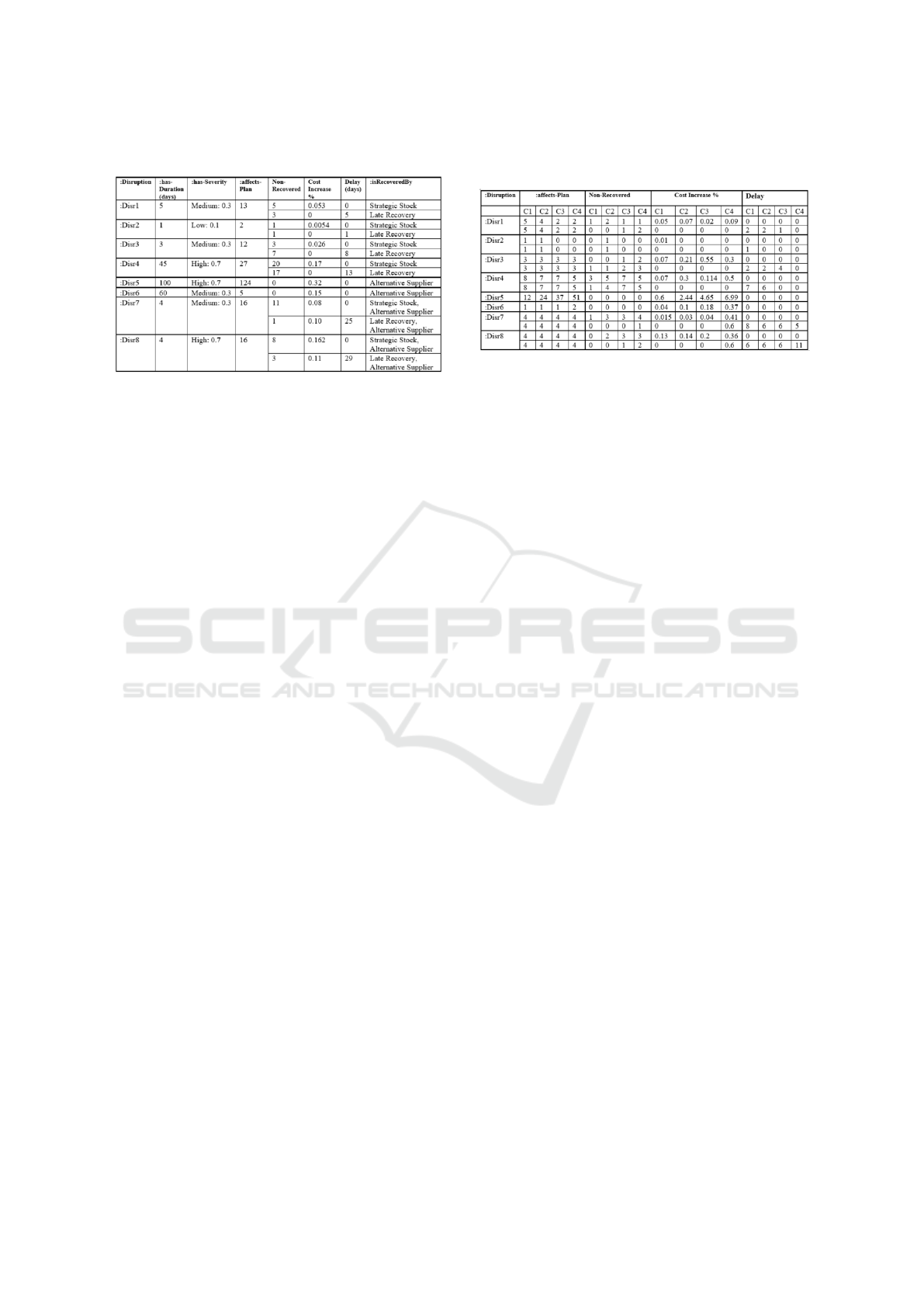

Table 1: Disruption examples and corresponding triple rep-

resentation.

MARE: Semantic Supply Chain Disruption Management and Resilience Evaluation Framework

487

:Disr1 is an example of capacity scarcity caused

by labor shortage after a COVID-19 outbreak that led

to a complete shutdown of production lasting four

days. :Disr2 shows a very short disruption, as the fire

lasted for 10 minutes and the physical damages were

minimal i.e., the severity is low. Further, the medium

contamination described by :Disr3 affected not only

the production plant but also the stockpile inventory.

Moreover, due to a halt in maritime transporta-

tion mode caused by a blockage in the Suez Canal,

Sony sales dropped from 70,000 a week to around

6,000, i.e. :Disr4. In fact, supply shortage includes

scarcity in raw material or any event (bankruptcy,

over-demand) that leads to a reduction or discontin-

uation in supply. In 2020, due to the COVID-19 pan-

demic, automotive industry suffered from substantial

drop in demand that led to slowing their semiconduc-

tor orders. Meanwhile, the semiconductor manufac-

turers faced a significant increase in demand due to

the rising need for personal computers, servers, and

equipment while their own facilities were shutting

down because of COVID-19 outbreaks (Burkacky

et al., 2021). For instance, :Disr5 representing over-

demand, halted production and unstable orders, leads

BMW to recognize a loss of 30,000 units in produc-

tion so far in 2021. This disruption has an undefined

end date. Similarly, :Disr6 models the missing color

pigments produced by factories in Japan affected by

the Tsunami in 2011. :Disr6 has medium severity

since car manufacturers limit ordering vehicles only

in specific shades.

4.2 Disruption Assessment and Effect

After identifying and modeling the disruption, the fol-

lowing step is to assess the impact. SC disruptions

potentially hurdle SC entities from achieving opera-

tional goals i.e. fulfilling end customers orders. We

leverage data from production scheduling and order

processing i.e. Supply Plan along with the modeled

disruption from the previous step i.e. the Disruption

Knowledge Graph.

The first step to assess the disruption effect

is to identify the SC partners that are part of a

supply plan, yet fall within the disruption loca-

tion and time frame. Listing 1

2

retrieves and la-

bels SC partners and corresponding Disrupted Sup-

ply Plan. Also, the effect of the disruption is de-

fined by how many supply plans are affected. We

insert Disruption affectsPlan xsd:integer i.e. the

2

For simplicity, the query is just using a standard lon-

gitude/latitude matching, but in our implementation we ac-

tually implemented a geo-spacial rectangular containment

matching between supplier and disruption locations.

count of disrupted plans identified in Listing 1.

Listing 1: Identify Disrupted Partners.

INSERT {

? plan : is D i s r upt e d ’ True ’ .

< <? p l an : n eeds P a r tner ? p artner >>

: i s D i srup t e d ’ T rue ’.

? d i s r uptio n : aff e c t sPa r t n er ? p a r t ner .}

WHERE {

< <? p l an : n e e dsPa r t n er ? partn e r >>

: h a s Time S t a mp ? t .

? pa r t n e r : h a s Long i t u de ? long .

? pa r t n e r : h a s L atit u d e ? lat .

? d i s r uptio n : hasL a t i t ude ? la t i t u d e .

? d i s r uptio n : hasL o n g itud e ? lon g i t u d e .

? d i s r uptio n : hasS t a r tTim e ? star t .

? d i s r uptio n : hasEn d T i m e ? en d .

FILTER (? t >=? st a r t && ?t <? end &&

? longit =? l o ng & & ? lat =? la t itude )

}

The second step is to size the effect of the dis-

ruption on the disrupted SC partners. The sever-

ity of the disruption determines the impact of the

event on the partner’s capacity to fulfill the sup-

ply plan. For simplicity, we model the sever-

ity as a numerical factor that shows the reduc-

tion in production capacities caused by the disrup-

tion. As shown in Listing 2, the pre-disruption

allocated quantity is reduced by the severity fac-

tor. The difference between the original and the re-

duced quantities represents the quantity to be sup-

plied or produced by alternative partners and means.

Listing 2: Determine Disruption Impact.

SELECT * W H E RE {

< <? p l an : n eeds P a r tner ? p artner >>

: i s D i srup t e d ’ True ’ ;

: g e t s Prod u c t ? product ;

: h a s Time S t a mp ?t ;

: h a s Q uant i t y ?q .

? d i s r uptio n : aff e c t sPa r t n er ? p a r t ner .

? d i s r uptio n : hasS e v e r ity ? factor .

BIND (? q *? factor AS ? redu c e d ) .

BIND (?q -? reduce d AS ? t o R ecove r )

}

After modeling and assessing the disruption effect on

the supply plans, the next steps in the DMP are to

implement recovery strategies and evaluate the SC re-

silience and recovery performance.

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

488

5 RECOVERY AND RESILIENCE

EVALUATION

5.1 Supply Chain Recovery

In this section, we describe the implementation of the

third step of MARE i.e., Recovery. Recovery strate-

gies are actions applied to regain the pre-disruption

state of the SC, capable of delivering products to cus-

tomers on time while minimizing the cost. Via in-

tegrating data sources about inventory management,

resources procurement, supply management and lo-

gistics, we aim to recover disrupted supply plans.

We present recovery strategies that rely only on the

change in the SC planning and do not require any

physical modification in the industrial process as the

latter are highly dependent on the industry. For in-

stance, increasing production capacity or allowing

faster production are not realistic in capital intense

or complex industries like semiconductor production.

We propose the following SPARQL-based recovery

strategies

3

capable of adapting the supply plan de-

pending on the disruption cause and scope. For all

the following queries we assume the recovery is for

Product P, at time T in quantity Q.

S1: Strategic Stock is defined as a stockpile of

inventory that can be used to fulfill demand dur-

ing a disruption (Tomlin and Wang, 2011). List-

ing 3 verifies if the partner has strategic stock

and returns the required price. We use inven-

tory management data sources to implement this

strategy. In fact, storing the strategic stock en-

tails costs for warehousing, labor and insurance.

Listing 3: Strategic Stock Strategy.

SELECT * W H E RE {

: Pa r t n e r : has S t art e g icS t o ck ? s t o c k

? stock : h a s Tim e S t a mp : T .

? stock : h a s Quan t i t y ? q .

? stock : h a s P r i c e ? price .

? stock : h a s P rodu c t :P .

FILTER (? q >= Q )

}

S2: Alternative Shipment in case of a disruption

affecting the transport mode e.g. flights, trains, a

company can switch to another shipment mode to de-

liver products. The query in Listing 4 retrieves the

shipment modes employed by a partner and the en-

tailed costs caused by the change of transportation

3

We show only exemplary SPARQL queries for the re-

covery strategies and refer to the accompanying GitHub

repository (MARE, 2022) for the complete set.

modes, usually incorporated in logistics data sources

(Messina et al., 2020).

Listing 4: Alternative Shipment Recovery Strategy.

SELECT * W H E RE {

: Pa r t n e r : has T r ans p o r tM o d e ? mode .

? mode : hasCost ? c ost .

}

S3: Delayed Recovery this recovery strategy con-

sists of verifying the status of the disrupted partner in

case it can deliver slightly later than planned. List-

ing 5 checks for five days after the planned delivery

time, if a SC partner has enough capacity, lower than

saturation, to fulfill the plan. In fact, small delays

in deliveries can mitigate financial losses due to dis-

ruption (Paul et al., 2019). Whereas, delays greater

than five days (a week) potentially lead to fines of

great amounts. Production management and schedul-

ing data sources incorporate data about the continuous

state of capacity production.

Listing 5: Delayed Recovery Strategy.

SELECT * W H E RE {

: Pa r t n e r : hasC a p a c ity ? cap .

: Pa r t n e r : ha s C a pa c i ty S a t ur a t io n ? s at .

? ca p : h asPr o d u c t : P .

? ca p : h asPrice ? p r i c e .

? ca p : ha sTi m e S tamp t _ f u t ure .

? ca p : h asQ u a n t ity ? q.

FILTER (? sat >= ?q + Q && t_ f u ture < T +5 )

}

S4: Alternative Supplier this strategy applies in

case of an external disruption that hinders the supplier

from providing the required products at the time in-

cluded in the supply plan. In fact, (Sawik, 2019) elab-

orates that suppliers have production flexibility that

allows them to deliver a contingency quantity in case

other suppliers fail. However, the alternate source

of supply can be more expensive than the firms’ pri-

mary suppliers, but it is deemed necessary, in or-

der to recover the disrupted supply plan (MacKen-

zie et al., 2014). To reduce purchasing prices and

benefit from the high performance, suppliers that

are capable of supplying the same products, are ex-

changeable (Hofstetter and Grimm, 2019). We model

this via the property hasGroup. Listing 6 shows

the query to find alternative, exchangeable suppli-

ers that have the capacity (lower than saturation)

to provide the same intermediate products or mate-

rials, for the same time as the disrupted supplier.

We rely on data from supply management and re-

sources procurement to make decisions about suppli-

MARE: Semantic Supply Chain Disruption Management and Resilience Evaluation Framework

489

ers belonging to the same group and their capacities.

Listing 6: Alternative Supplier Recovery Strategy.

SELECT * W H E RE {

: Pa r t n e r : hasGroup ? g r o u p .

? s u p p l i e r : h a s G r o u p ? group .

? s u p p l i e r : h a s C apa c i t y ? ca p .

? ca p : h asPr o d u c t ? p .

? ca p : ha sQua n t i ty ? q .

? ca p : h asPrice ? p r i c e .

? ca p : ha sTi m e S tamp : T.

? s u p p l i e r : h a sC a p a ci t y Sa t u rat i o n ? sat .

FILTER ( ? sat >= ?q + Q )

}

The output of this phase is a proposed Recovered

Supply Plan that minimizes recovery delays and costs.

We identify a successful recovery as the case where

all missing/reduced quantities from disrupted plans

are provided alternatively. In this case, we insert

the triple in the form Plan isRecoveredBy xsd:string,

where we explicit which recovery strategy applied.

5.2 Resilience Evaluation Framework

In this section, we introduce step 4 in MARE i.e., the

evaluation framework for SC resilience and recovery.

Thus, we compare the pre-disruption supply plans to

the recovered supply generated in the recovery phase.

We rely on the recovery performance evaluation met-

rics proposed by (Macdonald and Corsi, 2013).

Recovery Cost Increase: is the extra expense

caused by the disruption and the recovery as com-

pared to the original price of the pre-disruption sup-

ply plans. First we calculate the price of the recovered

plan for each order and we retrieve the order original

price. By summing the difference, we get the total

cost increase for all orders in Listing 7. We do not

consider the cost to rebuild anything lost physically

as this is included in the severity factor.

Listing 7: Evaluate Recovery Cost Increase.

SELECT ( SUM (? curr e n t pri c e -

? o r i gin a l P ric e ) as ? co s t I ncre a s e ) {

SELECT ? o r igi n a l Pri c e ( SU M (? p r i c e )

as ? c urr e n t pric e

WHERE {

? order : hasPlan ? plan ;

: h a sOr i g i na l P r ice ? orig i n a lPr i c e .

< <? p l an : n eeds P a r tner ? p artner >>

: h a s Q uant i t y ?q ;

: h a s Unit P r i ce ?p ;

: h a s Time S t a mp ?t .

BIND (? p *q AS ? p rice )

} GROUP BY (? plan )

}

Recovery Speed: is the time taken till recovery is

complete i.e., for S3, it is the next available day where

there is enough production capacity, entailing a new

delivery time. In Listing 8, we calculate the number

of orders where the delivery time in the supply plan

is later than the original delivery time, pre-disruption.

These orders are considered late orders, delayed by

the difference between the original and the late deliv-

ery times.

Listing 8: Evaluate Recovery Speed.

SELECT

SUM ( IF (? t > dt ) ,1 ,0 )) AS ? lateorders ,

SUM ( IF (? t <= dt ) ,1 ,0) ) AS ? ontimeorders ,

SUM (? t -? dt ) AS ? del a y

WHERE {

? order : hasPlan ? plan .

? order : has D e liv e r D ate ? dt .

< <? p l an : n eeds P a r tner ? p artne r >>

: h a s Time S t a mp ?t

}

Unsuccessful Recovery: The ultimate goal of the

SC is to deliver finished products to end customers,

yet the result of disruption caused by unplanned

events can be unfulfilled orders as described by (Car-

valho et al., 2012). This metric is the count of the sup-

ply plans where all missing/reduced quantities from

disrupted plans are not provided alternatively i.e.,

Plan isRecoveredBy xsd:string does not exist. This

situation occurs in case there is no alternative ship-

ment mode or there was no strategic stock available

or if there were no substitute suppliers to supply al-

ternatively. Moreover, when we apply S3: Delayed

Recovery if there was no free capacity within the next

five days, we consider this recovery unsuccessful.

Customer Impact: The previous metrics can be

calculated by SC stakeholders to analyze the im-

pact of the disruption on specific customers. Within

customer relationship management paradigm, SC

decision-makers apply recovery strategies in a way to

attempt and reduce the impact of the disruption on

high-priority customers.

6 EVALUATION AND

DISCUSSION

In this section, we simulate the behavior of an ex-

emplary SC under various disruptions scenarios and

evaluate the SC recovery performance.

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

490

Table 2: Resilience evaluation framework.

6.1 Experimental Setup

The following details the experimental setup for the

proposed evaluation.

Supply Chain Structure: We consider a three-tier

SC network consisting of one central node, i.e, an

OEM (Original Equipment Manufacturer) directly

linked to four suppliers in supplier tier 1 and four cus-

tomers in customer tier 1, where C1 is the customer

with the highest priority.

Supply Chain Data: We rely on the data generated

and provided by the synthetic generator described in

the technical report (SC Generator, 2021). We simu-

late 400 orders and their corresponding supply plans,

generated for a time-frame of 178 days, i.e., half a

year.

Disruptions: We simulate the disruptions listed in

Table 1. :Disr1-4 have internal causes, accordingly,

we apply S1: Strategic Stock, S2: Alternative Ship-

ment, S3: Delayed Recovery consecutively. While

:Disr5 and :Disr6 are external, i.e., affecting suppli-

ers, thus we apply S4: Alternative Supplier. Addi-

tionally, we create :Disr7,8 that occur internally and

externally, thus we rely on a combination of the men-

tioned recovery strategies. Moreover, for conciseness,

we show hasDuration which represents the length of

the disruption in days, i.e, hasEndDate minus has-

BeginDate. The OEM in question relies on one trans-

portation mode thus we cannot apply S3: Alternative

Shipment.

6.2 Results

We propose a resilience evaluation framework as

shown in Table 2 that incorporates the disruption char-

acteristics i.e. duration, severity and the number of af-

fected plans. Also, the framework includes the recov-

ery metrics to evaluate the number of non-recovered

plans i.e., unsuccessful recovery, the percentage of

total cost increase and the delay. From the results

in Table 2, we note that applying the strategic stock

Table 3: Customer impact evaluation with C1: customer

with highest priority.

strategy leads to an increase in cost, whereas apply-

ing late recovery leads to delays in delivery. This im-

pact varies based on the duration and the severity of

the disruption as well as the number of affected plans.

For instance, :Disr2 has a duration of one day and a

low severity affecting only two plans, thus the cost

increase and the delays entailed are minimal. How-

ever, :Dis1 and :Disr3 have medium severity and a

duration of three and five days respectively, therefore,

the cost and delay are more significant than in :Disr2.

Likewise, :Disr4 has a high severity and lasts for 45

days affecting 27 plans. Consequently the entailed

cost and delay are higher than the previously men-

tioned disruptions. Also, we note that for :Disr5 and

:Disr6, there is a significant cost increase, since alter-

native suppliers can be more expensive than the firms’

primary suppliers.

In case a disruption affects internally and exter-

nally :Disr7 and :Disr8, there is a cost increase due

to finding alternative suppliers and a delay in case

of later recovery application. (Macdonald and Corsi,

2013) explain that the longer it takes to fully re-

cover, the more expensive the entire recovery process

is likely to be. The delays caused by :Disr8 are bigger

than :Disr7. Thus, the cost increase is greater as with

high severity disruptions, the consequences are more

severe.

In order for stakeholders to make more informed

decisions, they can rely on the customer impact anal-

ysis as shown in Table 3 to examine the correspond-

ing impact on specific customers. Consequently, they

can decide which recovery strategy or combination of

several to apply.

It is important that while applying recovery strate-

gies, orders made by customers with high priorities

whose plans are disrupted, are recovered first. There-

fore, we note that high-priority customers (C1) have

fewer non-recovered plans. Therefore, their corre-

sponding cost increase is higher than low-priority cus-

tomers. Moreover, customers with low priority have

longer delays because more important customers are

recovered before, it might take more time periods to

find the needed quantity to recover.

MARE: Semantic Supply Chain Disruption Management and Resilience Evaluation Framework

491

6.3 Impact and Discussion

MARE is used to simulate the SC behavior under var-

ious disruption scenarios. SC stakeholders can make

informed decisions based on the performance analysis

to redesign into a more resilient SC coping with unex-

pected events. We provide the following managerial

insights:

• Behavior analysis, put forward by MARE, en-

ables SC stakeholders to decide on creating or

modifying existing strategies. In fact, some re-

covery strategies are only applicable in case pre-

implementation approaches are established. For

instance, the OEM in the shown simulation did

not support any alternative shipment mode, and

consequently S3 was not viable. Similarly, a com-

pany can only apply S4: Alternative Supplier

if the company has established a multiple sourc-

ing strategy. Also, the strategic stock recovery

strategy requires the implementation of inventory

management systems as well as replenishment.

Likewise, decision-makers can decide to invest in

extending the maximum capacity saturation to al-

low spare production capacity usable during dis-

ruption (Chen et al., 2021).

• MARE supports supplier exchangeability, thus

the cost increase caused by alternative suppliers

can be reduced by establishing a wide SC where

suppliers are exchangeable. Consequently, the

choice of an alternate source of supply is made

easier in case of a disruption.

• MARE provides SC partners with knowledge

about the impact of changes occurring in the pro-

duction plan. Thus, MARE allows to reach full

information integration to improve the selection

of recovery strategies in future disruption occur-

rences. Also, MARE enhances SC visibility to

mitigate the bullwhip effect.

Nevertheless, MARE is limited as it only consid-

ers external disruptions that affect the supply. While

sudden demand drops or surges can impact the SC

badly if the SC is not equipped with suitable recov-

ery strategies. Moreover, we focus only on recovery

performance, whereas recovery structure and defining

who from the SC stakeholders is responsible and in-

cluded in recovery, can potentially also be considered

as explained by (Macdonald and Corsi, 2013).

7 CONCLUSION AND OUTLOOK

Recent events such as the COVID-19 pandemic, nat-

ural disasters, transportation blockages and politi-

cal tensions resulting in sanctions have revealed the

fragility of our highly globalized and complex SC net-

works. Performance assessment for pre-disruption,

during and post-disruption phases is needed to de-

velop a resilient SC network. Namely, SC integra-

tion, visibility and interoperability are essential for

enriched SC analysis to evaluate the behavior and fa-

cilitate decision making especially during irregular

circumstances. Semantic models enable SC data in-

tegration and thus allow deep analysis while provid-

ing an overall perspective of the SC. Existing seman-

tic DMP approaches address process steps in a rather

isolated manner, i.e., only one step of the process is

incorporated e.g. to model the disruption risk or to

assess its impact.

With MARE we proposed a semantic disrup-

tion management and resilience evaluation frame-

work, aligned with existing DMP approaches, to in-

tegrate heterogeneous data sources (e.g. production

scheduling, order processing), covered by all DMP

steps. MARE relies on an ontology and KG to

M

onitor/Model a disruption. Then, MARE integrates

data from production scheduling and order manage-

ment to Assess, the effect of the disruption on the

SC. Next, MARE examines inventory management,

procurement and suppliers assignment data sources to

uncover various strategies to Recover.

The resilience framework is to Evaluate the effect

of the disruption on the SC in terms of cost, delay

and demand fulfillment. Also, customer-specific met-

rics calculation allows to size the respective impact on

customers.

To ensure and enhance SC resilience, SC stake-

holders can rely on the DMP and resilience evaluation

framework in MARE to extract decisions regarding

SC structure and operational strategies. MARE facil-

itates to grasp, control and ultimately enhance SC be-

havior in complex SC scenarios, tame disruption ac-

celerators e.g. the bullwhip effect and increase the

resilience of the supply network.

The solid MARE framework being openly avail-

able on GitHub (MARE, 2022) can be further ex-

tended to consider disruptions related to demand in-

crease or drops and to examine combinations of re-

covery strategies in the comparison framework. Also,

MARE can be extended to include more recovery

strategies e.g. spare capacity to check if the current

utilization rate of the partner is below the saturation

(Zsidisin and Wagner, 2010).

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

492

REFERENCES

ASCM (2021). Ready for anything? turbulence and the

resilience imperative. The Economist.

Blackhurst, J., Craighead, C. W., Elkins, D., and Handfield,

R. B. (2005). An empirically derived agenda of criti-

cal research issues for managing supply-chain disrup-

tions. International journal of production research,

43(19):4067–4081.

Bugert, N. and Lasch, R. (2018). Supply chain disrup-

tion models: A critical review. Logistics Research,

11(5):1–35.

Burkacky, O., Lingemann, S., and Pototzky, K. (2021).

Coping with the auto-semiconductor shortage: Strate-

gies for success. Technical report, McKinsey & Com-

pany.

Carvalho, H., Cruz-Machado, V., and Tavares, J. G. (2012).

A mapping framework for assessing supply chain re-

silience. International Journal of Logistics Systems

and Management, 12(3):354–373.

Chen, J., Wang, H., and Zhong, R. Y. (2021). A supply

chain disruption recovery strategy considering prod-

uct change under covid-19. Journal of Manufacturing

Systems.

Craighead, C. W., Blackhurst, J., Rungtusanatham, M. J.,

and Handfield, R. B. (2007). The severity of supply

chain disruptions: design characteristics and mitiga-

tion capabilities. Decision sciences, 38(1):131–156.

Emmenegger, S., Laurenzini, E., and Th

¨

onssen, B. (2012).

Improving supply-chain-management based on se-

mantically enriched risk descriptions. In KMIS, pages

70–80.

Hofstetter, J. S. and Grimm, J. H. (2019). Multi-tier sustain-

able supply chain management. In Handbook on the

Sustainable Supply Chain. Edward Elgar Publishing.

Ismail, A. and Ehm, H. (2021). Simulating and evaluating

supply chain disruptions along and end-end semicon-

ductor automotive supply chain amid covid-19 crisis.

In AnyLogic Conference.

Ivanov, D. and Dolgui, A. (2020). A digital supply chain

twin for managing the disruption risks and resilience

in the era of industry 4.0. Production Planning & Con-

trol, pages 1–14.

Jaenichen, F.-M., Liepold, C. J., Ismail, A., Martens, C. J.,

D

¨

orrsam, V., and Ehm, H. (2021). Simulating and

evaluating supply chain disruptions along an end-end

semiconductor automotive supply chain. In Proceed-

ings of the winter simulation conference, volume 1.

IEEE.

Macdonald, J. R. and Corsi, T. M. (2013). Supply

chain disruption management: Severe events, recov-

ery, and performance. Journal of Business Logistics,

34(4):270–288.

MacKenzie, C. A., Barker, K., and Santos, J. R. (2014).

Modeling a severe supply chain disruption and post-

disaster decision making with application to the

japanese earthquake and tsunami. IIE Transactions,

46(12):1243–1260.

MARE (2022). Semantic supply chain disruption manage-

ment. DOI: 10.5281/zenodo.6079007.

Messina, D., Barros, A. C., Soares, A. L., and Matopoulos,

A. (2020). An information management approach for

supply chain disruption recovery. The International

Journal of Logistics Management.

Pal, K. (2019). Integrating heterogeneous enterprise data

using ontology in supply chain management. In Big

Data and Knowledge Sharing in Virtual Organiza-

tions, pages 71–102. IGI Global.

Palmer, C., Urwin, E. N., Niknejad, A., Petrovic, D., Pop-

plewell, K., and Young, R. I. (2018). An ontology

supported risk assessment approach for the intelligent

configuration of supply networks. Journal of Intelli-

gent Manufacturing, 29(5):1005–1030.

Paul, S. K., Asian, S., Goh, M., and Torabi, S. A. (2019).

Managing sudden transportation disruptions in supply

chains under delivery delay and quantity loss. Annals

of Operations Research, 273(1-2):783–814.

Ramzy, N., Auer, S., Chamanara, J., and Ehm, H. (2021).

Sens: Semantic synthetic benchmarking model for in-

tegrated supply chain simulation and analysis. Unpub-

lished.

Sabouhi, F., Pishvaee, M. S., and Jabalameli, M. S. (2018).

Resilient supply chain design under operational and

disruption risks considering quantity discount: A case

study of pharmaceutical supply chain. Computers &

Industrial Engineering, 126:657–672.

Samaranayake, P. (2005). A conceptual framework for sup-

ply chain management: a structural integration. Sup-

ply Chain Management: An International Journal.

Sawik, T. (2019). A multi-portfolio approach to integrated

risk-averse planning in supply chains under disruption

risks. In Handbook of Ripple Effects in the Supply

Chain, pages 35–63. Springer.

SC Generator (2021). Semantic supply chain generator.

DOI: 10.5281/zenodo.5675085.

Simbizi, D., Benabbou, L., and Urli, B. (2021). Systematic

literature reviews in supply chain resilience: A sys-

tematic literature review. In 11th Annual International

Conference on Industrial Engineering and Operations

Management, IEOM 2021, pages 327–340.

Simchi-Levi, D., Schmidt, W., Wei, Y., Zhang, P. Y.,

Combs, K., Ge, Y., Gusikhin, O., Sanders, M., and

Zhang, D. (2015). Identifying risks and mitigating

disruptions in the automotive supply chain. Interfaces,

45(5):375–390.

Singh, C. S., Soni, G., and Badhotiya, G. K. (2019). Perfor-

mance indicators for supply chain resilience: review

and conceptual framework. Journal of Industrial En-

gineering International, 15(1):105–117.

Tomlin, B. and Wang, Y. (2011). Operational strategies

for managing supply chain disruption risk. The hand-

book of integrated risk management in global supply

chains, pages 79–101.

Ye, Y., Yang, D., Jiang, Z., and Tong, L. (2008). Ontology-

based semantic models for supply chain management.

The International Journal of Advanced Manufactur-

ing Technology, 37(11-12):1250–1260.

Zsidisin, G. A. and Wagner, S. M. (2010). Do perceptions

become reality? the moderating role of supply chain

resiliency on disruption occurrence. Journal of busi-

ness logistics, 31(2):1–20.

MARE: Semantic Supply Chain Disruption Management and Resilience Evaluation Framework

493