Reliability Estimation of a Smart Metering Architecture using a

Monte Carlo Simulation

Tobias Altenburg

a

, Matthias Volk

b

, Daniel Staegemann

c

and Klaus Turowski

Very Large Business Applications Lab, Faculty of Computer Science Otto-von-Guericke University Magdeburg, Germany

Keywords: Internet of Things, Reliability, Smart Meter Architecture, Monte Carlo Simulation, Reliability Block Diagram.

Abstract: The trend of connectivity dominates the technological progress. The number of networked devices is

constantly increasing and the use of smart meters has become more societally relevant. For that reason,

reliability is an important attribute of related architectures. To calculate reliability, it is required to do a

specific analysis for the entire system. This paper describes a structured approach for calculating the reliability

of smart meter architectures considering the limited data availability. For this, we combine Reliability Block

Diagrams with a Monte Carlo simulation. The result is a realistic approximation of the system reliability, that

can be used to evaluate optimization methods.

1 INTRODUCTION

The Internet of Things is the dominating megatrend

in current social change (Kaufmann, 2021). The

number of networked devices and the resulting

volume of data is constantly increasing worldwide.

Until 2025 there will be 75 billion networked devices

worldwide (Statista, 2018) with a data volume of

approximately 80 zettabytes (O'Dea, 2021). The

Internet of Things has become a key technology for

future-oriented scenarios. Driven by Murphy's Law –

“Anything that can go wrong will go wrong”, the

reliability of computer systems is becoming even

more important. The digitalization of civil

infrastructure facilities in particular is becoming

especially relevant to society (BSI, 2020). The

services that are provided like the supply of water or

electricity are increasingly dependent on available

and operating information technology. Smart meters

can record actual consumption data and forward it to

the higher-level systems so that the resulting

transparency can increase grid stability. A fault, an

impairment, or even a complete breakdown can have

a major impact on public safety or other dramatic

consequences (BSI, 2020). The dependency of

modern society on complex information systems,

a

https://orcid.org/0000-0002-1433-4912

b

https://orcid.org/0000-0002-4835-919X

c

https://orcid.org/0000-0001-9957-1003

especially in the above-mentioned infrastructures, is

growing steadily (BSI, 2021). The most significant

part of this is accounted to smart meters. These are

being implemented around the world, inter alia, to

improve the efficiency of power grids for emissions

control (Mordor Intelligence, 2020). The current

trend of electromobility and the resulting increase in

electricity consumption emphasize how important the

digitalization of the energy transition is for society.

Until 2023 the penetration rate of electrical smart

meters in the European Union (EU) is expected to

grow from 44% to 71% (Kochanski, Korczak,&

Skoczkowski, 2020). In order to push that forward,

the German Federal Ministry for Economics and

Energy (BMWi) has published a roadmap for the

ongoing digitalization of the energy transformation in

Germany (BMWi, 2020). This includes a step-by-

step rollout of smart metering systems for electricity,

water, and gas.

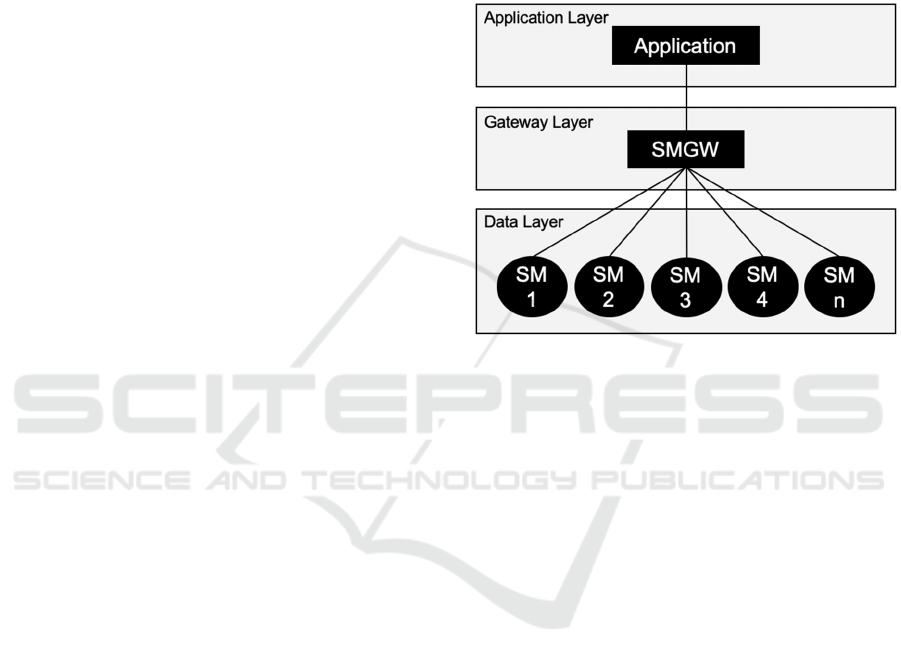

The proposed smart metering architecture in

Figure 1 shall being used as a standard for Europe,

which is based on a set of technical and data

protection requirements that are specified in various

official documents (BSI, 2013; BSI, 2014; BSI, 2015;

BSI 2016) of the German Federal Office for

Information Security. The central concept in these

specifications provides a separate unit called the

Altenburg, T., Volk, M., Staegemann, D. and Turowski, K.

Reliability Estimation of a Smart Metering Architecture using a Monte Carlo Simulation.

DOI: 10.5220/0010988100003194

In Proceedings of the 7th International Conference on Internet of Things, Big Data and Security (IoTBDS 2022), pages 47-54

ISBN: 978-989-758-564-7; ISSN: 2184-4976

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

47

smart meter gateway (SMGW) as a central

communication medium. It provides the interfaces

between the multiple domains and the smart metering

system. Figure 1 shows the schematic architecture.

Until 2032 all consumers in Germany should be

equipped with these modern measuring devices

(BMJV, 2016). The objective of digital data

collection is a more efficient and transparent energy

distribution as well as the sustainable control of

energy production and the overall network utilization

(EY, 2013; Huang, Grahn, Wallnerström,&

Jaakonantti, 2018).

Figure 1: BSI Smart Metering Infrastructure (BSI, 2014).

Hence, the contribution at hand focuses on the

reliability of smart metering architectures. The global

number of smart meters is expected to be

approximately 188 million in 2025 (Mordor

Intelligence, 2020). In Germany, the number of smart

meters is expected to increase to 53 million (BNetzA,

2021). To guarantee the required objectives of this

ecosystem the reliability is a fundamental design goal

(Müller, 2011). Basically, smart metering systems are

more failure-prone than traditional metering devices,

because of the more complex interaction between

hardware and software components (EY, 2013). To

obtain a validated value for the failure probability of

SMGWs and smart meters we screened 5 publicly

available databases and contacted 10 companies.

These 5 companies submitted a response and 2

companies were interviewed on a detailed level. The

investigations and interviews revealed that there are

currently no validated data for the probability of

failure or error. There is currently a lack of general

data from the practice and field level, which can be

explained by the delayed rollout (OVG NRW, 2020).

For the reason that analytical approaches of

general reliability issues at component or system level

were not available the approximative reliability

methods respective Monte Carlo simulation (MCS)

techniques became very popular (Wang,

Broccardo,& Song, 2019). Compared to other

reliability Methods MCS have the advantage of being

accurate and easy to implement. This means that

MCS is applicable for the reliability analysis of a

smart metering architecture. It also enables the

evaluation of the proposed reliability optimization by

using different methods identified in a literature

review (Altenburg, Bosse,& Turowski, 2020). Based

on the previous argumentation we would like to

answer the following research question: “How could

a valid reliability analysis on smart metering

architectures with limited data be facilitated by using

the Monte Carlo simulation?”

To answer the aforementioned research question,

in Section 2 the theoretical basis for reliability theory

and analysis is presented. Then, in Section 3, the

approach for the proposed reliability analysis is

described. The process of reliability simulation and

the presentation of the results are shown in Section 4.

Concluding remarks are given in Section 5 that

summarizes and illustrates the next steps to be taken.

2 FOUNDATIONS

This chapter presents the theoretical basis for the

reliability analysis of a smart metering architecture

that will be performed. The present paper use the

Design Science Research (DSR). A key feature of

DSR is solving social and real-world problems by

constructing and evaluating a scientific artefact (vom

Brocke, Hevner,& Maedche, 2020). Artefacts can be

classified as concepts, models, methods, or

realizations that contribute to a scientifically useful

outcome. According to Pfeffers (2008), the design

science process consists of 6 essential steps, namely

problem identification and motivation, definition of

the objectives for a solution, design and development,

demonstration, evaluation and communication. This

paper describes a practical problem, which can be

solved by a predefined reliability analysis based on

RBD and MCS. This approach will be described and

executed in the following chapters and the result will

be interpreted as well.

2.1 Basics of Reliability

The research field of reliability was formed by Jean-

Claude Laprié. He established a standard framework

and general terminology for reliable and fault-tolerant

systems (Laprié, 1995). According to Bertsche (2008)

and Laprié (1995), Reliability R(t) is defined as “the

probability that a system will perform its functions

satisfactorily and without failures under specified

functional and environmental conditions over a

specified period of time”.

According to a recently conducted literature

review conducted by Altenburg et al. (2020), the

design phase offers the highest potential for reliability

IoTBDS 2022 - 7th International Conference on Internet of Things, Big Data and Security

48

optimization. In order to demonstrate that these

identified methods (Altenburg et al., 2020) will

increase the reliability R(t) of a smart metering

architecture it is necessary to do a validated reliability

analysis. Reliability analysis is a methodical approach

to be able to determine the reliability of a system and

the number of failures. The approach to calculating

the system reliability starts with the design of the

model and ends with the statistical calculation of the

overall reliability (Yuan, Tang, Wang,& Li, 2019). In

the literature, there are several techniques for

quantitative and qualitative analysis of reliability

(Niknafs, Faridkhah,& Kazemi, 2018). The basis for

our approach is a combination of quantitative

methods, because we have limited data as described

aforementioned.

In quantitative methods the Reliability Block

Diagram (RBD) (Bobalo, Seniv, Yakovyna,&

Symets, 2019), the Network Diagram (Ridzuan,

Rusli,& Saad, 2020), Markov Modeling (Aggarwal,

Kumar,& Singh, 2015) and MCS (Wang et al., 2019)

are the most important methods for reliability

analysis. To perform the most exact calculation of

reliability it is also possible to combine these

techniques (Niknafs et al., 2018; Li& Zhang, 2011).

2.2 Reliability Block Diagram and

Monte Carlo Simulation

Our selected evaluation approach, which is detailed

in Section 3, uses RBD to model the overall system

and an MCS to calculate the reliability per

component. RBD is a schematic illustration of the

main components in a system, which represents the

hierarchy and mutual interaction to the overall

function of a system (Niknafs et al., 2018; Raso, de

Vasconcelos, Marques, Soares,& Mesquita, 2017).

After that, we use MCS as a simulation technique.

The execution of an MCS is based on repeated

random sampling and statistical analysis to estimate

results for complex system functions (Harrison, 2010;

Mason et al., 2008). This approximation can be used

to generate realistic results, that we will use for the

reliability analysis of the smart metering architecture.

3 AN APPROACH FOR

RELIABILITY ANALYSIS

To be able to perform a reliability analysis for the

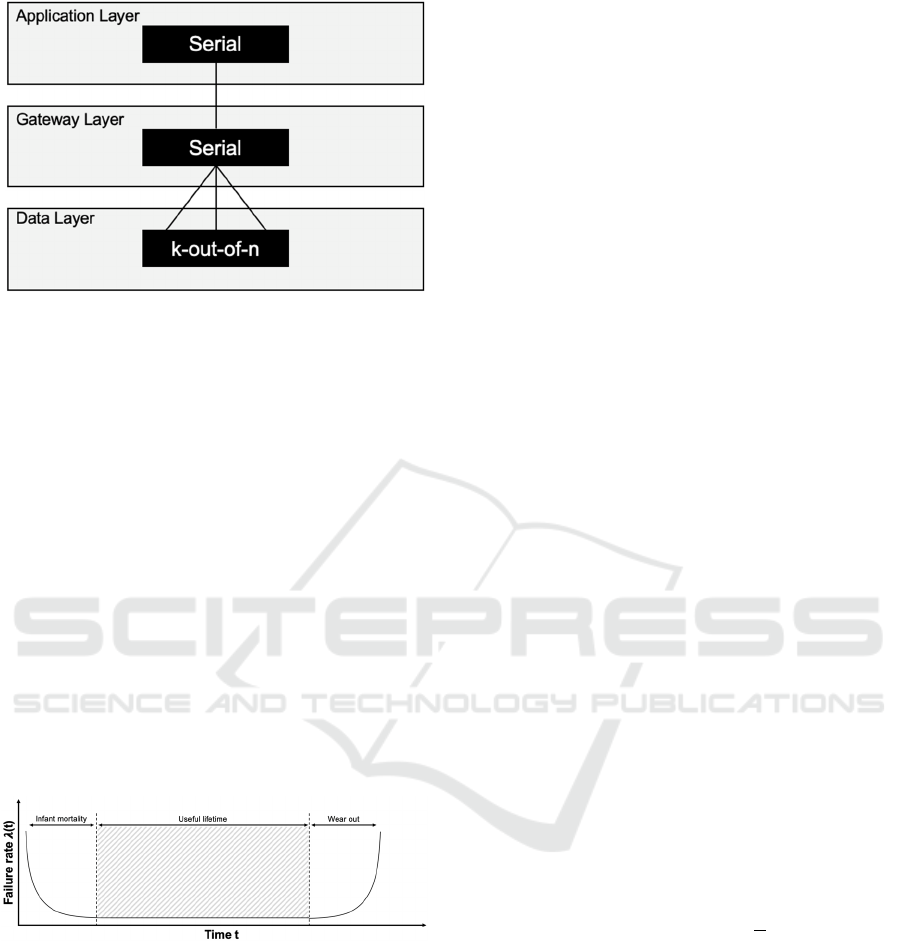

architecture in Figure 1, it is transformed into a

simplified model as shown in Figure 2. The Data

Layer is the equivalent of the Local Metrological

Network (LMN; cf. Figure 1), which includes all the

meters in a home or household and can be connected

or read out by the SMGW in the Gateway Layer

(Henneke, Freudenmann, Wisniewski,& Jasperneite,

2017). We have grouped the Home Area Network

(HAN; cf. Figure 1) and the Wide Area Network

(WAN; cf. Figure 1) into the Application Layer

because meter information can be read or configured

remotely in both domains (Henneke et al., 2017).

Figure 2: Simplified illustration of a smart metering

architecture for reliability analysis.

Figure 2 shows the simplification of the overall

system from Figure 1 into its basic components. We

assume five smart meters in our reliability analysis,

because in the future there will not only be smart

metering for electricity there will be also smart

metering for water or gas consumption. The next step

is to convert the simplified model from Figure 2 into

the logic of the RBD. Depending on the configuration

the failure of any component can trigger the failure of

the whole system, so that the required system

functions are not fulfilled (Ahmeda, Hasana,

Perveza,& Qadirb, 2016). An RBD design can

include three basic component connections, which

can be combined with each other - series connection,

active redundancy or standby redundancy (Ahmeda et

al., 2016). The following Figure 3 transformed into an

RBD from the simplified architecture in Figure 2.

To be able to calculate the quantitative reliability

of the overall system, the failure probabilities of each

component are required. There are currently no

validated data available for the failure probabilities

and the characteristic lifetime of a smart meter or

SMGW. For that reason, we use the failure

probabilities per component and an MCS to simulate

the different values.

Reliability Estimation of a Smart Metering Architecture using a Monte Carlo Simulation

49

Figure 3: Simulation model based on RBD.

In addition to the architecture, the Time t is an

important factor in the reliability domain, because it

is directly related to the Reliability R(t) (Laprié,

1995). In many practical use cases the reliability level

of an intact component depends mainly on the age

that the component has already reached. The so-

called bathtub curve shown in Figure 4 describes the

generic time course of the Failure Rate λ(t) (Bonart&

Bär, 2020). In the literature, the bathtub curve is

divided into three phases - infant mortality, useful

lifetime and wear out (Bonart& Baer, 2020; Alvarez-

Alvarado& Jayaweera, 2018). Most studies focus on

the useful life period (Li, 2014; Kim, Singh,&

Sprintson, 2015; Li, 2013). In our evaluation, we also

focus on the mid-period of the bathtub curve. In this

phase, the Failure Rate λ(t) is constant, which means

that the focus is on random failures. Furthermore, this

is usually also the longest time phase in the overall

lifetime of a system.

Figure 4: Bathtub curve (Neubeck, 2004).

4 EVALUATION

This section presents our incremental approach to

reliability analysis of a smart metering architecture.

Reliability distributions of systems must be modeled

with suitable mathematical functions to capture the

real world. The bathtub curve can be approximately

described as a sum of Weibull distributions. The

Weibull distribution is one of the most commonly

used reliability techniques because of its versatility.

Its distribution can be used to describe decreasing,

constant and increasing Failure Rates λ(t) in technical

systems. With this, it is possible to model different

failure types and so all phases from the bathtub curve

(Lienig& Brümmer, 2017). Depending on the life

phase of a component, the Weibull distribution can be

an exponential distribution or a logarithmic normal

distribution (Härtler, 2016).

As described in Section 3, the focus of our

reliability analysis is on the useful life phase where

Failure Rates λ(t) are constant. For this case, the

reliability distribution equals an exponential

distribution. The exponential distribution is

commonly used in the development of electronic

systems, because it is sufficiently accurate for

reliability calculations (Lienig& Brümmer, 2017).

This is the foundation for the following Formulas for

reliability calculations (Gelman, Martin, Malcolm,&

Liew, 2021; Ram& Davim, 2018; Dey, Bhale,&

Nandi, 2020):

Reliabilit

y

R

t

e

(1)

4.1 Smart Meter and Smart Meter

Gateway

For an overall reliability analysis, it is necessary to

split the system into independent components.

Because of the high technical similarities between

smart meters and SMGW (EY, 2013; Gährs, Weiß,

Bluhm, Dunkelberg,& Katner, 2021) it is possible to

run a common reliability analysis of the components.

The higher system complexity of smart meter

architectures implicates a higher Failure Probability

G(t) of the system. The typical average for this value

can be set as 2% (EY, 2013; Zhou, Zonghuan,&

Zhonghua, 2021). It serves as the basic for calculating

the Failure Rate λ(t) and the Lifetime t:

𝐹𝑎𝑖𝑙𝑢𝑟𝑒 𝑅𝑎𝑡𝑒

λ

t

1

𝑇

𝐿𝑖𝑓𝑒𝑡𝑖𝑚𝑒 𝑡 𝑇 𝐺𝑡

(2)

Afterward, the e-function can be used, which is an

exponential function with Euler's constant

(Humenberger& Schuppar, 2019) as basis to calculate

the Reliability R(t) for the two components by

Formula (1):

Reliabilit

y

𝑅

𝑡

𝟗𝟖,𝟎𝟐%

(3)

For a more realistic approximation of the

reliability, we use the principle of MCS. The

objective is to repeat the calculation of the Reliability

R(t) many times and to approximate a realistic result

IoTBDS 2022 - 7th International Conference on Internet of Things, Big Data and Security

50

using the law of Large Numbers (Hartbecke&

Schütte, 2005). For this we use the following function

(Ji, 2014):

𝐿𝑖𝑓𝑒𝑡𝑖𝑚𝑒 𝑡

𝑥,𝜇,𝜎

1

𝜎

√

2𝜋

𝑒

𝑥∈

0,1

; 𝜇 2081,52 ℎ; 𝜎 5256 ℎ

(4)

This function returns the percentile for a given

mean and the standard deviation. The parameters for

the reliability calculation are described below:

The parameter x indicates the probability in the

normal distribution and is created by a random

number between 0 and 1.

The parameter μ indicates the arithmetic mean

of the distribution and is the Lifetime t

MC

of our

calculated Reliability R(t) in Formula 3.

It is calculated as follows:

𝐿𝑖𝑓𝑒𝑡𝑖𝑚𝑒 𝑡

12 𝑎 𝑥 1,98%

𝐿𝑖𝑓𝑒𝑡𝑖𝑚𝑒 𝑡

2081,51 ℎ

(5)

The parameter σ indicates the standard deviation

of the distribution, which is empirically defined as 5%

(Zhou et al., 2021) and calculated into the

corresponding Lifetime t

𝜎

.

𝐿𝑖𝑓𝑒𝑡𝑖𝑚𝑒 𝑡

12 𝑎 𝑥 5%

𝐿𝑖𝑓𝑒𝑡𝑖𝑚𝑒 𝑡

5256 ℎ

(6)

The next step is to run Formula 4 for 80.769

random samples each to simulate the Lifetime t(x,μ,σ).

According to the law of Large Numbers (Hartbecke&

Schütte, 2005) and the paper by Liu (2017), we

assume that 80.769 random samples are an optimal

number of trials for the purposed MCS. Each

simulated Lifetime t(x,μ,σ) is now inserted into

Formula 1, so that we obtain the reliability R

SM

and

R

SMGW

for 80.769 smart meters and SMGW. In the

end, we calculate the average of the results and we get

approximately real reliability of the two components:

𝑅𝑒𝑙𝑖𝑎𝑏𝑖𝑙𝑖𝑡𝑦 𝑅

,𝑅

𝟗𝟔,𝟗𝟑% (7)

Figure 5 shows the result of the reliability

calculation based on the procedure described above

and illustrates the smoothed Reliability R

SM

and

R

SMGW

. Because of the large amount of samples only

every 741st random sample is included in the diagram

as these are exactly dividable and so a total of 109

measurements are presented. The red trend line

represents the moving average of the random

samples. As one can note, that the average reliability

of the component varies strongly, because there are

for example some early failures in the reliability

sample or there are also samples without failures.

Figure 5: Smoothed calculation of reliability using an MCS

of 80.769 samples.

4.2 Application

The WAN has the primary impact on system

reliability because it provides the overall information

that is needed to stabilize the grid. The services in the

WAN are operated in a cloud environment (BSI,

2014). To approximate the Reliability R

App

of the

application that is operated in a cloud environment,

we can use the characteristic availability of the three

big cloud providers. This is at least 99.9% (Hauer,

Hoffmann, Lunney, Ardelean,& Diwan, 2020; Wong,

Zavodovski, Corneo, Mohan,& Kangasharju, 2021;

Meinel, Schnjakin, Metzke,& Freitag, 2014) and is

used in section 4.3. with the consolidation of the

results.

4.3 Consolidation of Results

In this section, we will merge the Reliability R

SM

and

R

SMGW

that we determined above from the RBD

model defined in Figure 3 to get the Reliability R

Total

of the overall system. For the smart meters we

assumed a “k-out-of-n” dependency. The objective is

that all of the five smart meters do not fail. Therefore,

the Formula for the Reliability R

SM-Total

is as follows:

𝑅

𝑘,𝑛,𝑅

𝑛

𝑘

𝑅

1 𝑅

𝑘5;𝑛5;𝑅

96,93%

(8)

𝑅

𝑘,𝑛,𝑅

𝟖𝟖,𝟑𝟓%

The following applies for this:

The parameter x indicates the probability in the

normal distribution and is created,

Reliability Estimation of a Smart Metering Architecture using a Monte Carlo Simulation

51

n is the total number of units that are connected

in parallel,

and Reliability R

SM

is the determined reliability

of the smart meter.

The remaining components are connected in

series (see Figure 3). Therefore, there is a

multiplication of the determined reliabilities to

calculate the Reliability R

Total

of the entire system.

𝑅

𝑅

𝑅

𝑅

𝑅

88,35% 96,93% 99,90%

𝑅𝑒𝑙𝑖𝑎𝑏𝑖𝑙𝑖𝑡𝑦 𝑅

𝟖𝟓,𝟓𝟓%

(9)

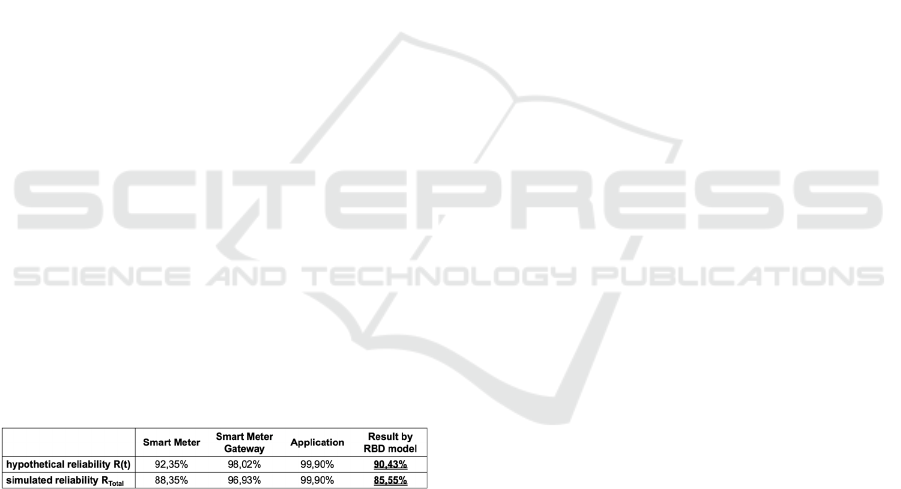

Eventually past, we can summarize the

calculations in Table 1 and compare them with each

other. It can be seen that the simulated Reliability

R

Total

is about 5% lower than the hypothetical

Reliability R(t). Following the above definition of

reliability according to Bertsche (2008) and Laprié

(1995) the result means that about 15% of smart meter

architectures could fail within the characteristic

lifetime of 12 years. As an example, based on current

forecasts for Germany of approximately 53 million

smart meters (BNetzA, 2021) that would affect nearly

660,000 metering installations per year just for

Germany in particular. In order to counteract this, it

is necessary to increase the reliability of smart meters

and smart meter gateways in particular. The design

phase offers the greatest potential for reliability

optimization (Altenburg et al., 2020). This is where

the diverse methods for reliability optimization can

already be implemented at the beginning and used

with sustainable benefits.

Table 1: Comparison of hypothetical and simulated

reliability.

5 CONCLUSION AND FUTURE

WORK

This paper presented a structured reliability analysis.

The theoretical foundations and the methodological

approach were presented at the beginning. After that,

we calculated the reliability of a smart meter

architecture based on a limited data set using an RBD

and an MCS. The result is a realistic reliability

evaluation of the analyzed overall system. Our

performed approximation demonstrates the need for

reliability optimization in the context of smart meter

architectures. Furthermore, the presented approach

answers our aforementioned research question and

verifies that the reliability of a smart metering

architecture can be calculated with the help of an

MCS for a limited dataset.

The largest optimization potential includes the

design phase of a system (Altenburg et al., 2020). We

will consolidate popular methods from the literature

into efficient design strategies. This will provide a

standard framework that can be used for reliability

optimization. Based on our presented approach it is

possible to validate the defined design strategies.

REFERENCES

Aggarwal, A.K., Kumar, S., Singh, V. (2015). Markov

modeling and reliability analysis of urea synthesis

system of a fertilizer plant. Journal of Industrial

Engineering International 11, 1-14.

Ahmeda, W., Hasana, O., Perveza, U., Qadirb, J. (2016).

Reliability Modeling and Analysis of Communication

Networks. Journal of Network and Computer

Applications, Volume 78, 191-215.

Altenburg, T., Bosse, S., Turowski, K. (2020). Safety in

distributed sensor networks – A literature Review. 5th

International Conference on Internet of Things, Big

Data and Security - IoTBDS, 161-168.

Alvarez-Alvarado, M.S., Jayaweera, D. (2018). Bathtub

curve as a Markovian process to describe the reliability

of repairable components. The Institution of

Engineering and Technology, Vol. 12, 5683-5689.

Bertsche, B., 2008. Reliability in Automotive and

Mechanical Engineering. Springer, 45–57.

Bobalo Y., Seniv M., Yakovyna V., Symets I. (2019).

Method of Reliability Block Diagram Visualization and

Automated Construction of Technical System

Operability Condition. CSIT 2018, vol. 871, Springer.

Bonart, Th., Bär, J. (2020). Quantitative

Betriebswirtschaftslehre Band II – Marketing und

Marktforschung, technische Zuverlässigkeit. Springer

Gabler, 1. Auflage, 242-280.

BMJV (Bundesministerium der Justiz und für

Verbraucherschutz) (2016). Gesetz über den

Messstellenbetrieb und die Datenkommunikation in

intelligenten Energienetzen, Messstellenbetriebsgesetz

- MsbG, §29.

BMWi (Bundesministerium für Wirtschaft und Energie)

(2020). Fahrplan für die weitere Digitalisierung der

Energiewende. Retrieved on November 20, 2021, from

https://www.bmwi.de/Redaktion/DE/Downloads/F/fah

rplan-fuer-die-weitere-digitalisierung-der-energie

wende.pdf

BNetzA (Bundesnetzagentur für Elektrizität, Gas,

Telekommunikation, Post und Eisenbahnen) (2021).

Monitoringbericht 2020, 305.

BSI (Bundesamt für Sicherheit in der Informationstechnik)

(2020). Die Lage der IT-Sicherheit in Deutschland

IoTBDS 2022 - 7th International Conference on Internet of Things, Big Data and Security

52

2020. Retrieved on November 20, 2021, from

https://www.bsi.bund.de/SharedDocs/Downloads/DE/

BSI/Publikationen/Lageberichte/Lagebericht2020.pdfb

si.bund.de.

BSI (Bundesamt für Sicherheit in der Informationstechnik)

(2021). IT-Sicherheitsgesetz, Bundesgesetzblatt Teil I

Nr.31, §8.

BSI (Bundesamt für Sicherheit in der Informationstechnik)

(2015). Protection profile for the security module of a

smart metering system–common criteria protection

profile BSI-CC-PP- 0077-V2-2015. Retrieved on

November 20, 2021, from https://www.bsi.bund.de/

SharedDocs/Zertifikate_CC/PP/aktuell/PP_0077+V2.h

tml.

BSI (Bundesamt für Sicherheit in der Informationstechnik)

(2014). Protection profile for the gateway of a smart

metering system–common criteria protection profile

BSI-CC- PP-0073-2014. Retrieved on November 20,

2021, from https://www.bsi.bund.de/SharedDocs/

Zertifikate_CC/PP/aktuell/PP_0073.html

BSI (Bundesamt für Sicherheit in der Informationstechnik)

(2021). Anforderungen an die Interoperabilität der

Kommunikationseinheit eines intelligenten

Messsystems (BSI TR- 03109-1). Retrieved on

November 20, 2021, from https://www.bsi.bund.de/

SharedDocs/Downloads/DE/BSI/Publikationen/Techni

scheRichtlinien/TR03109/TR03109-1.pdf

BSI (Bundesamt für Sicherheit in der Informationstechnik)

(2021). Anforderungen an die Funktionalität und

Interoperabilität Sicherheitsmoduls (BSI TR-03116-2).

Retrieved on November 20, 2021, from

https://www.bsi.bund.de/SharedDocs/Downloads/DE/

BSI/Publikationen/TechnischeRichtlinien/TR03116/B

SI-TR-03116-3.pdf

BSI (Bundesamt für Sicherheit in der Informationstechnik)

(2014). Kryptographische Vorgaben für die

Infrastruktur von intelligenten Messsystemen (BSI TR-

03109-3). Retrieved on November 20, 2021, from

https://www.bsi.bund.de/SharedDocs/Downloads/DE/

BSI/Publikationen/TechnischeRichtlinien/TR03109/T

R-03109-3_Kryptographische_Vorgaben.pdf

BSI (Bundesamt für Sicherheit in der Informationstechnik)

(2017). Smart Metering PKI–Public Key Infrastructure

für Smart Meter Gateways (BSI TR-03109-4).

Retrieved on November 20, 2021, from

https://www.bsi.bund.de/SharedDocs/Downloads/DE/

BSI/Publikationen/TechnischeRichtlinien/TR03109/T

R-03109-4_PKI.pdf

BSI (Bundesamt für Sicherheit in der Informationstechnik)

(2015). Smart Meter Gateway Administration (BSI TR-

03109-6). Retrieved on November 20, 2021, from

https://www.bsi.bund.de/SharedDocs/Downloads/DE/

BSI/Publikationen/TechnischeRichtlinien/TR03109/T

R-03109-6-Smart_Meter_Gateway_Administration.

html

BSI (Bundesamt für Sicherheit in der Informationstechnik)

(2021). Certificate Policy für die Smart-Meter-PKI.

Retrieved on November 20, 2021, from

https://www.bsi.bund.de/SharedDocs/Downloads/DE/

BSI/Publikationen/TechnischeRichtlinien/TR03109/P

KI_Certificate_Policy.pdf

Dey, S., Bhale, P., Nandi, S. (2020). ReFIT: Reliability

Challenges and Failure Rate Mitigation Techniques for

IoT Systems. I4CS, Springer International Publishing,

123-142.

Ernst & Young GmbH (2013). Kosten-Nutzen-Analyse für

einen flächendeckenden Einsatz intelligenter Zähler.

Gelman, L., Martin, N., Malcolm, A., Liew, E. (2021).

Advances in Condition Monitoring and Structural

Health Monitoring. WCCM 2019, Springer

International Publishing, 325-332.

Gährs, S., Weiß, J., Bluhm, H., Dunkelberg, E., Katner, J.

(2021). Erkenntnisse zu Umweltwirkungen von Smart

Metern - Erfahrungen aus dem Einsatz von Smart

Meter in Europa. Institut für ökologische

Wirtschaftsforschung, Berlin.

Harrison, R. L. (2010). Introduction to Monte Carlo

Simulation. AIP Conference Proceedings, 17-21.

Hartbecke, K., Schütte, C. (2005). Gesetze der Natur.

Historische und systematische Perspektiven. Mentis

Verlag, 291-317.

Hauer, T., Hoffmann, P., Lunney, J., Ardelean, D., Diwan,

A. (2020). Meaningful Availability. NSDI.

Henneke, D., Freudenmann, Ch., Wisniewski, L.,

Jasperneite, J. (2017). Implementation of Industrial

Cloud Applications as Controlled Local Systems (CLS)

in a Smart Grid Context. 22nd IEEE International

Conference on Emerging Technologies and Factory

Automation (ETFA), 1-7.

Huang, Y., Grahn, E., Wallnerström, C.J., Jaakonantti, L.

(2018). Smart meters in Sweden – lessons learned and

new regulations.

Humenberger, H., Schuppar, B. (2019). Mit Funktionen

Zusammenhänge und Veränderungen beschreiben -

Mathematik Primarstufe und Sekundarstufe I + II.

Springer-Verlag GmbH Deutschland, 75-118.

Härtler G. (2016). Wahrscheinlichkeitsmodelle der

Zuverlässigkeit- Statistik für Ausfalldaten. Springer

Spektrum, Berlin, 49-68.

Ji, X. (2014). Normal Inverse Function in teaching

inference about population mean and population

proportion. 9th International Conference on Teaching

Statistics (ICOTS9), USA.

Kaufmann, T. (2021). Megatrend- und Technologieanalyse

In: Strategiewerkzeuge aus der Praxis. Springer Gabler,

Berlin, 29-26.

Kim, H., Singh, C., Sprintson, A. (2015). Using clustering

to evaluate reliability of composite power systems. 18th

International Conference on Intelligent System

Application to Power Systems (ISAP), 1–7.

Kochanski, M., Korczak, K., Skoczkowski, T. (2020).

Technology Innovation System Analysis of Electricity

Smart Metering in the European Union. Energies 2020,

MDPI.

Laprié, J. C. (1995). Dependable Computing: Concepts,

Limits, Challenges. 25th IEEE International

Symposium on Fault-Tolerant Computing, 42-54.

Li, G., Zhang, K. (2011). A combined reliability analysis

approach with dimension reduction method and

Reliability Estimation of a Smart Metering Architecture using a Monte Carlo Simulation

53

maximum entropy method. Structural and

Multidisciplinary Optimization, Vol. 43, Springer,

121–134.

Li, W. (2014). Risk assessment of power systems: models,

methods, and applications. John Wiley & Sons, New

York, USA.

Li, W. (2013). Reliability assessment of electric power

systems using Monte Carlo methods. Springer Science

& Business Media, New York.

Lienig, J., Brümmer, H. (2017). Fundamentals of

Electronic Systems Design. Springer International

Publishing, 45-73.

Liu, M. (2017). Optimal number of trials for monte carlo

simulation. VRC, Value Research Report.

Mason, S. J., Hill, R. R., Mönch, L., Rose, O., Jefferson, T.,

Fowler, J. W. (2008). Introduction to Monte Carlo

Simulation. Winter Simulation Conference, 677-688.

Meinel, Ch., Schnjakin, M., Metzke, T., Freitag, M. (2014).

Anbieter von Cloud Speicherdiensten im Überblick.

Technische Berichte des Hasso-Plattner-Instituts für

Softwaresystemtechnik, vol. 84, 10-12.

Mordor Intelligence LLP (2020). Global Smart Meters

Market - Growth, Trends, Forecasts (2020 - 2025).

Müller, K.J. (2011). Sicherheit im Smart Grid, 18. DFN-

Workshop „Sicherheit in vernetzten Systemen“.

Neubeck, K. (2004). Practical Reliability Analysis. Pearson

Prentice Hall, New Jersey, USA.

Niknafs, H., Faridkhah, M., Kazemi, C. (2018). Analytical

Approach to Product Reliability Estimation Based on

Life Test Data for an Automotive Clutch System.

Mechanics and Mechanical Engineering Vol. 22, 845-

863.

O’Dea, S. (2021). Data volume of internet of things (IoT)

connections worldwide in 2019 and 2025. Retrieved on

November 20, 2021, from https://www.statista.com/

statistics/1017863/worldwide-iot- connected-devices-

data-size.

OVG Nordrhein-Westfalen, Decision from 04.03.2021. Az

21 B 1162/20.

Peffers, K., Tuunanen, T., Rothenberger, M.A., Chatterjee,

S. (2008). A Design Science Research Methodology for

Information Systems Research. Journal of Management

Information Systems, vol. 24 no. 3, 45-77.

Ram, M., Davim, J.P. (2018). Diagnostic Techniques in

Industrial Engineering. Springer International

Publishing, pp. 207-231.

Raso, A., de Vasconcelos, V., Marques, R., Soares, W.,

Mesquita, A. (2017). Use of reliability engineering

tools in safety and risk assessment of nuclear facilities.

International Nuclear Atlantic Conference – INAC.

Ridzuan, M. I. M., Rusli, M. A. Z., Saad, N. M. (2020).

Reliability Performance of Low Voltage (LV) Network

Configuration. Springer, 783-793.

Statista (2018). Internet of Things (IoT) connected devices

installed base worldwide from 2015 to 2025 (in

billions). Retrieved on November 20, 2021, from

https://www.statista.com/statistics/471264/iot-number-

of-connected- devices-worldwide/.

vom Brocke, J., Hevner, A., Maedche, A. (2020).

Introduction to Design Science Research. In: Design

Science Research, Springer, Cham.

Wang, Z., Broccardo, M., Song, J. (2019). Hamiltonian

Monte Carlo methods for Subset Simulation in

reliability analysis. Structural Safety, Volume 76, 51-

67.

Wong, W., Zavodovski, A., Corneo, L., Mohan, N.,

Kangasharju, J. (2021). SPA: Harnessing Availability

in the AWS Spot Market. Conference on Computer

Communications Workshops.

Yuan, R., Tang, M., Wang, H., Li, H. (2019). A Reliability

Analysis Method of Accelerated Performance

Degradation Based on Bayesian Strategy. IEEE

Access, vol. 7, 169047-169054.

Zhou, J., Zonghuan, W., Zhonghua, Y. (2021). Research on

the Reliability Allocation Method of Smart Meters

Based on DEA and DBN. Applied Sciences 11, no. 15:

6901.

IoTBDS 2022 - 7th International Conference on Internet of Things, Big Data and Security

54