Towards Unlocking the Potential of the Internet of Things for the Skilled

Crafts

Andr

´

e Pomp, Andreas Burgdorf, Alexander Paulus and Tobias Meisen

Chair of Technologies and Management of Digital Transformation,

University of Wuppertal, Wuppertal, Germany

Keywords:

Internet of Things, Semantic Systems Engineering, Usability, Skilled Crafts.

Abstract:

The Internet of Things (IoT) enables companies to develop new digital business models or optimize existing

processes through digitalization. Since value creation in the skilled crafts is determined by the manufacturing

of material products and the provision of associated services, it is predestined for the use of IoT technologies.

While these services are increasingly finding their way into the consumer market via industrial providers, the

local skilled crafts with its small and medium-sized businesses lacks the knowledge to assess the potential and

to adequately develop and operate IoT solutions. Our aim is to develop a manufacturer-independent platform

that enables those businesses to implement IoT solutions independently. The platform is intended to support

craftsmen in identifying suitable IoT use cases and resulting business models for their trades, products or

services. For that, it will provide an overview of the components (e.g., sensors) required for the respective

use cases. Based on this, the use cases can be set up without special know-how with the help of the platform,

which also collects and manages the accruing data. Each craft business can identify new use cases and make

them available to the other users of the platform, thus creating a cross-trade solution from the skilled crafts

for the skilled crafts. Potential IoT use cases and their technical requirements were already identified in a

pre-study in collaborative hackathons and will be evaluated during the development of the IoT Crafts Portal.

The results are intended to assist craft businesses from a wide range of trades to identify and implement new

business models in such a way that they can be integrated into the existing processes of the businesses. At the

same time, there will be a transfer of knowledge between the craft businesses themselves, since each can use

the experience of the other business or offer its own insights.

1 INTRODUCTION

Dealing with digitalization is both an opportunity and

a challenge for a wide variety of industries. Mod-

ern agriculture, industrial production, and the trans-

portation and logistics sector are examples of how

the potential of advanced digitalization can be ex-

ploited. Numerous enterprises in these industries

have already been able to gain extensive experience

with digital and digitized products as well as services,

from which a wealth of novel business models have

emerged. At the same time, experience has shown

that digital transformation cannot be taken for granted

and poses a multitude of challenges. The Internet of

Things (IoT) (Ashton et al., 2009) plays a key role

here and it is rising in different domains, such as smart

cities (Gyrard and Serrano, 2015) or the smart home

(Zsch

¨

ornig et al., 2017). The underlying technolo-

gies focus in particular on mapping and describing the

physical, real world in a digital image by generating

digital shadows or even digital twins (Atzori et al.,

2010). The basic step in this process is the integra-

tion of sensors into products, machines and systems

in order to determine a digital image from the col-

lected data by means of various analysis and learning

processes. The digital image obtained in this way in

turn creates the basis for optimizing existing business

processes, services and products, and in many cases

also for generating new digital or digitalized business

models. The skilled crafts, where value creation is

determined by the manufacture of material products

or the provision of services on demand for the mate-

rial product, are therefore predestined for the intro-

duction of IoT technologies into everyday working

life. The mapping of the physical world in a digital

representation opens up numerous areas of applica-

tion (Sisinni et al., 2018). It is therefore all the more

surprising that although IoT technologies are increas-

ingly finding their way into the consumer market, the

focus of developments is completely bypassing the

Pomp, A., Burgdorf, A., Paulus, A. and Meisen, T.

Towards Unlocking the Potential of the Internet of Things for the Skilled Crafts.

DOI: 10.5220/0011066100003179

In Proceedings of the 24th International Conference on Enterprise Information Systems (ICEIS 2022) - Volume 1, pages 203-210

ISBN: 978-989-758-569-2; ISSN: 2184-4992

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

203

skilled crafts. As a result, the potential of the IoT

has so far been little or not at all widespread among

traditional small and medium-sized craft businesses

- despite the fact that the technologies are there and

the craft businesses are demonstrating their interest in

using the IoT, for example, in public workshops and

hackathons.

Large industrial companies, on the other hand,

which as representatives of industrial mass production

are often in direct competition with the skilled crafts,

are increasingly equipping their products with IoT-

capable sensor and communication technology and

providing associated applications for end customers.

In doing so, these companies focus on their area of ap-

plication, which prevents a comprehensive view and

correspondingly advanced overarching digitalization.

For example, customers can check the operating sta-

tus of their heating system and contact the manufac-

turer directly in the event of potential faults, but this

does not include regional craftsmen. The resulting

fragmented IoT platform landscape of individual in-

dustrial providers does not provide a breeding ground

from which regional craft businesses can benefit or,

due to the lack of access to data, participate. Other

key challenges for these craft businesses result, for

example, from difficult access to the topic and the

great uncertainties associated with it. Accordingly,

for regional craft businesses, i) assessing the potential

of IoT solutions and their impact on their operations,

and ii) acquiring the knowledge and skills to develop

and operate adequate IoT solutions are key obstacle

factors.

To address these challenges, our goal is to de-

sign and implement a vendor-independent end-to-end

IoT Crafts Portal, which will be developed from the

skilled crafts for the skilled crafts. This portal should

enable German craft businesses to i) identify suitable

IoT use cases and resulting business models for their

trade as well as their products or services and share

them with other businesses, ii) get an overview of the

required components (e.g. sensors) needed to imple-

ment the use cases, iii) set up the identified use cases

in a simple and user-friendly way via the portal, and

iv) collect, manage and use the resulting data for their

own business purposes.

The two most important aspects for the develop-

ment of the IoT Crafts Portal deal with the identifica-

tion of suitable IoT use cases and the creation of a cor-

responding crafts-friendly IoT portal as a prototype,

which can be used by the craft businesses for the im-

plementation of their IoT use cases. A large number

of different IoT sensors will be used to implement the

use cases. The resulting data will be stored in a cen-

tral data lake and managed via it. The main research

focus is on developing ways how the accessibility of

IoT technology can be enabled for the craftsmen. In

particular, the development of recommendation and

search systems based on machine learning methods

as well as the design of corresponding visual user in-

terfaces are in focus. Another important aspect is the

investigation of approaches on how the IoT technol-

ogy and its application potential can be didactically

prepared for the craft businesses and communicated

to them in a target group-oriented or -adaptive way.

Based on the IoT Crafts Portal, different participat-

ing craft businesses from a wide variety of trades aim

to identify and develop IoT-based use cases and pro-

totypes, which either optimize an internal process or

enable the implementation of an additional (digital)

business model specific to their trade and business.

In this way, craft businesses improve their work

organization and design with Digital Transformation

technologies. The fact that the data generated on the

developed IoT Crafts Portal belongs to the craft busi-

nesses itself ensures that they can use it profitably.

At the same time, craft businesses can already ben-

efit from implemented IoT use cases of other (craft)

businesses. If a new use case is identified and im-

plemented using the developed IoT portal, it also be-

comes available to other businesses. This enables

knowledge transfer both within and across trades, so

that the full potential of IoT use cases for the skilled

crafts is exploited. In summary, the developed IoT

portal enables the strengthening of craft services in

Germany by enabling the development of modern

IoT-based business models, which is reflected, for ex-

ample, in new services for the end customer of the

respective craft businesses.

The rest of the paper is organized as follows: Sec-

tion 2 will show related work and discuss the issues

of current IoT platforms for technical inexperienced

users. Afterwards, we show and discuss in Section 3

potential use cases that we already identified in two

different pre-studies using a hackathon concept be-

fore we present the methodology and the approach

that we follow in order to develop the IoT Crafts Por-

tal in Section 4. Finally, we give a short conclusion in

Section 5.

2 RELATED WORK

The related work can essentially be divided into i) the

area of technical implementation (IoT platforms and

existing IoT solutions) and ii) the area of existing plat-

forms in the Skilled Craft Sector that push the issue of

digitalization.

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

204

2.1 Technical Implementation and

Existing IoT Solutions

Today, IoT platforms are ubiquitous. Well-known

technology companies such as Amazon

1

, Microsoft

2

,

Google

3

or Deutsche Telekom

4

already offer scalable

IoT platforms that enable the implementation of any

IoT use cases - provided the technical programming

skills are available and the user already knows ex-

actly which use case might fit his business. In ad-

dition, there are a number of other platforms (Bosch

5

,

Upswift

6

, Influxdata

7

or Device Insight

8

) which also

offer IoT platforms for customers. The focus of these

platforms is on the collection and evaluation of the

raw data generated in the IoT. However, these plat-

forms address either users with advanced technical

skills or large enterprises with their own IT depart-

ments. IoT use cases that produce the required IoT

raw data have to be identified and implemented by the

users themselves - knowledge transfer between users

does not take place and is not focused on by these

platforms. In reverse, this means that every craft busi-

ness itself must acquire the necessary skills, identify

its use cases and then either also implement them via

an IoT platform in a time-intensive manner or com-

mission IT experts to do so - without knowing a pri-

ori the economic benefits. Moreover, there exist also

concepts for semantic IoT and data platforms, such as

(Palavalli et al., 2016), (Dorsch, 2016), (Cambridge

Semantics, 2016) or (Pomp et al., 2021). However,

they only deal with semantically describing sensor

data and do not focus on IoT use cases.

In addition to the existing IoT platforms, which

are mainly aimed at companies from the Industry

4.0 sector, there are already various IoT-based solu-

tions that have been developed for the skilled crafts.

Hilti (Hilti, 2020) and Bosch (Bosch, 2020), for ex-

ample, offer IoT-based solutions that enable crafts-

men to track the tools in use. The company Doka

(Doka, 2020) offers sensor technology and the as-

sociated software to measure and predict the drying

time of cement. In the context of monitoring moisture

damage in roofs, Saint Gobain has developed Isover

GuardSystem (Saint Gobain, 2020), a solution that al-

lows flat roofs to be monitored in real time and alerts

the owner in the event of moisture damage. While on

1

https://aws.amazon.com/de/iot/

2

https://azure.microsoft.com/en-us/overview/iot/

3

https://cloud.google.com/iot-core

4

https://iot.telekom.com/en

5

https://developer.bosch-iot-suite.com/

6

https://www.upswift.io/

7

https://www.influxdata.com/influxdb-cloud-iot

8

https://www.device-insight.com/

the one hand these examples show the potential al-

ready inherent in IoT solutions for the skilled crafts,

on the other hand, it becomes clear that all these so-

lutions are isolated applications which are offered by

one manufacturer and can only be used in this context.

So if a craft business now wants to use all these dif-

ferent solutions, it must first learn of their existence

(for example, via trade fairs, representatives of the

companies or via other craft businesses) and then buy

these solutions from the various large companies in

each case. At the same time, the craft business loses

control over its data, because it usually becomes the

property of the large company. On the one hand, this

prevents reuse for other IoT use cases. On the other

hand, it shows that there is not yet a solution tailored

to the needs of the skilled crafts that enables them to

have an overview and all-encompassing use of the In-

ternet of Things. There are craft businesses that try

out IoT solutions in hackathons or even implement

them on their own initiative (e.g. Holzgesp

¨

ur

9

) and

offer them to their customers - but this remains more

the exception than the rule - even though the IoT of-

fers numerous possibilities.

2.2 Digital Platforms for the Skilled

Crafts

In the course of the last few years, numerous

platform-based business models have emerged in the

digital skilled crafts, which have greatly changed

communication between customers, crafts, trade and

industry. The current study by the Ludwig Fr

¨

ohler

Institute for Skilled Crafts Sciences (LFI) (Ludwig-

Fr

¨

ohler-Institut f

¨

ur Handwerkswissenschaften, 2019)

shows that more than 100 transaction-oriented plat-

forms are active in the craft value chain in Germany.

Here, previous platforms can be divided into the cate-

gories of partner brokers, franchisers, infrastructure

providers, advertising platforms and online stores.

Partner mediators, like MyHammer

10

or Blauarbeit

11

,

focus thereby on the switching of craft businesses for

services desired by the final customer. Businesses,

which do not co-operate with the respective plat-

forms, remain thereby outside. Franchiser, like Mys-

ter

12

or Banovo

13

, even go one step further. Here,

the local craftsman’s business is only used as an exe-

cuting instance - all offers and contract arrangements

run via the respective platform. The consequence

of this is, of course, that the local craft business no

9

https://www.holzgespuer.de/

10

https://www.my-hammer.de/

11

https://www.blauarbeit.de/

12

http://myster.de/

13

https://www.banovo.de/

Towards Unlocking the Potential of the Internet of Things for the Skilled Crafts

205

longer has the business in its own hands and must

therefore submit to the rules of the platform oper-

ators. Infrastructure providers, such as Helpling

14

or Caroobi

15

, on the other hand, give craft busi-

nesses more freedom. Advertising platforms and on-

line stores then already try to win customers via new

channels. The LFI study shows that platforms have

become an important tool in the skilled crafts for

building new business models and simplifying inter-

action with customers. However, the study only looks

at transaction-oriented platforms. Data-centric plat-

forms, which essentially include all Infrastructure-

as-a-Service (IAAS), Software-as-a-Service (SAAS),

Platform-as-a-Service (PAAS) and other specialized

platforms, such as IoT platforms, were not consid-

ered. It has already been shown in the previous sec-

tion that although technical solutions do exist, they

are not tailored to the skilled crafts and their needs.

In summary, it can be said that there is no existing

IoT platform that enables craft businesses to i) find

out about the IoT, ii) identify relevant use cases and

associated sensor technology, and iii) subsequently

implement and operate the use cases relevant to their

own business themselves.

3 POTENTIAL OF THE IoT FOR

THE SKILLED CRAFTS

Over the last three years, we conducted together

with our partners Kreishandwerkerschaft Rhein-

Erft, Handwerkskammer D

¨

usseldorf, Kompe-

tenzzentrum Digitales Handwerk Koblenz and

Wirtschaftsf

¨

orderung Rhein-Erft GmbH two

hackathons with altogether 20 different craft busi-

nesses from different trades in which we explored

potential use cases for either improving processes

within the own business or setting up new IoT-based

business models. Each hackathon was organized in a

two-day workshop format where the craft businesses

identified IoT-based use cases on the first day and

implemented them as prototypes in conjunction with

scientists and developers from our institute on the

second day.

The aim of implementing the prototypes together

with the craftsmen was to show them, using concrete

examples that are relevant to them and that were iden-

tified by themselves, (i) which sensors are available,

(ii) what they can measure and how they record data,

(iii) how the data can then be sent to a backend and

can be stored and processed accordingly. For that,

14

https://www.helpling.de/

15

https://caroobi.com/

Figure 1: Selection of sensors for the craftsmen.

Figure 2: Developed dashboard for one of the IoT use cases.

we provided a large set of different sensors to the

craftsmen (cf. Figure 1). After selecting the relevant

sensors for their use cases, the craftsmen had to con-

nect the sensors to a Raspberry Pi and the data were

recorded using NodeRED

16

. From there, the data was

transmitted via an MQTT Broker to a cloud instance

on which we then developed visualizations and busi-

ness logic for the identified use cases (cf. Figure 2).

In this way, the craftsmen were able to understand ex-

actly what was happening, how the data was trans-

mitted and how it could then be processed. However,

it would not have been possible for the craftsmen to

implement the prototypes without the help of the ad-

visors.

A central result of the two hackathons conducted

is the large number of different IoT use cases iden-

tified by the participants from the various craft busi-

nesses from different trades that were assessed as rel-

evant for their business. Altogether, 52 different IoT

use cases were identified in various domains. In addi-

tion to obvious use cases that are already covered by

the state of the art but were not known to the crafts-

men (e.g. tracking of tools or moisture penetration on

the roof), many interesting new use cases were also

identified. For instance, two businesses from the con-

struction trades identified a use case for monitoring

the tightness of cellars during and after the construc-

tion phase. Trades from the glazing or metal craft

came up with use cases for equipping their products

with additional sensor technology to, for example,

track the use of these products - and thus being able

to optimize their products in the future. Businesses

16

https://nodered.org/

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

206

from the electrical, sanitary-heating-air-conditioning

or roofer sectors had ideas to offer new services to

their customers in the form of ”predictive mainte-

nance” through the use of IoT technology. A roof-

ing company, for example, would like to equip gutters

with water flow sensors. Based on the amount of rain

that has fallen and the flow rate within the gutter, it

is possible to calculate whether the gutter is clogged

and whether maintenance is required, which can then

be offered in advance.

The hackathons have proven to be a useful tool

for introducing craftsmen to IoT topics. In particular,

the great potential of IoT for the skilled crafts could

be experienced by the participants, but it also became

obvious that the implementation of own IoT use cases

cannot be achieved by the craftsmen themselves. The

support of developers and scientists has always been

needed.

4 METHODOLOGY AND

APPROACH

Figure 3: Adding IoT Platforms as missing Platform for the

Skilled Crafts.

As outlined in Section 2, there is, to the best of our

knowledge, no platform that focuses on enabling craft

businesses to implement IoT use cases (cf. Figure 3),

as these i) only add value for technically skilled indi-

viduals, ii) do not provide an overview of which IoT

use cases are implementable, relevant or already exist,

iii) do not enable knowledge transfer between users,

and iv) are usually only in English. These disadvan-

tages are flanked by the fact that small and medium-

sized craft businesses - in contrast to large enterprises

- often do not have the financial means to build up

the corresponding required technical staff to identify,

set up and manage IoT use cases. This means that

relevant IoT use cases, such as, Monitoring the de-

gree of drying of screed, cannot be efficiently imple-

mented with the existing solutions on the market, as

these solutions do not address the explicit needs of

craft businesses. At the same time, however, the ex-

perience gained in our conducted pre-studies (cf. Sec-

tion 3), shows, among other things, that these are pre-

cisely the kind of use cases that support craft busi-

nesses in their day-to-day work, or in which potential

for the digitalization of craft businesses is seen. Ac-

cordingly, the goal for the developed IoT Crafts Por-

tal is to show businesses similar scenarios from IoT

projects that have already been carried out by other

craft businesses and to provide information on sensor

technology and information processing. For the above

example, the portal could display, for example, Mois-

ture sensors that can be installed in the screed. After

the required sensors have been acquired by the crafts-

man’s company, they can be directly integrated into

the portal and the corresponding analyses or moni-

toring solutions can be carried out. In the example

mentioned, a craftsman’s company would be notified

when the desired degree of drying has been reached,

so that the connection work can be carried out earlier

than expected, if necessary.

Compared to the current state of the art, the IoT

Crafts Portal presented here fills an important gap.

It represents an end-to-end solution that is explicitly

adapted and optimized for the skilled crafts and can be

used in a wide variety of trades. Through an explicit

focus in development of the IoT Crafts Portal on intu-

itive usability (queries using natural language, simple

plug-and-play connection of sensors, automatic rec-

ommendation of useful use cases), a complexity of

the solution is achieved that is suitable for craftsmen

without appropriate technical training and is missing

in the current market. Through a continuous expan-

sion of use cases, it should also be ensured that all

businesses always have the opportunity to move at

the current state of the art. If new use cases arise in

a trade, they can be implemented via the IoT Crafts

Portal and also made directly available to other craft

businesses (knowledge transfer). If a business identi-

fies and implements a new use case, such as the de-

tection of leaking roofs via the IoT Crafts Portal, it

is possible to make this use case available to other

businesses. This means that other businesses can see

which sensor technology is needed and get access to

the implemented use case. This mechanism allows

other businesses to see use cases that have already

been successfully implemented. On the one hand, this

mechanism thus strengthens confidence in the use of

IoT technology. On the other hand, it enables indi-

vidual craft businesses to independently develop new

business models for their own operations. At the same

time, the business that provides a use case can also

benefit.

Towards Unlocking the Potential of the Internet of Things for the Skilled Crafts

207

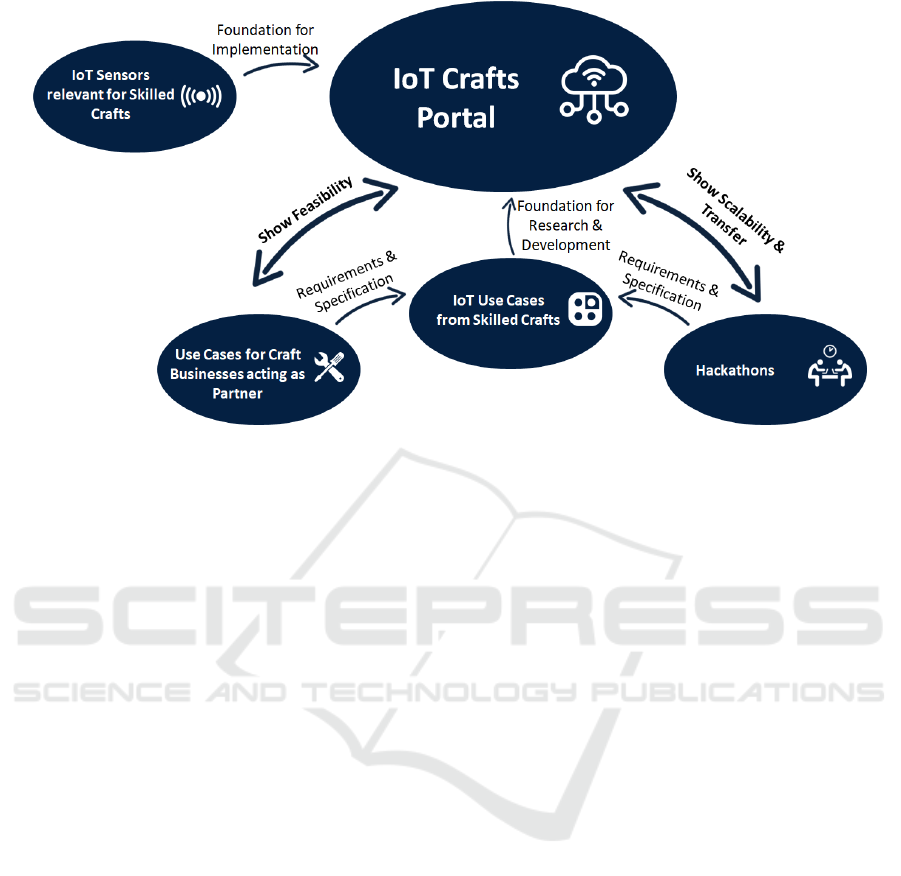

Figure 4: Main Aspects for the development of the IoT Crafts Portal.

4.1 Approach

Figure 4 shows the main aspects for the development

of the IoT Crafts Portal and how they are related to

each other. All in all, we follow an agile approach for

developing the IoT Crafts Portal. This first requires

the identification of potential use cases in the skilled

crafts that can be implemented with the help of cur-

rent IoT technology. In order to create a broad cover-

age of use cases for different trades, the IoT Crafts

Portal will be developed in close cooperation with

seven application partners from seven different trades.

Together we define IoT-based use cases at the begin-

ning of the development phase that are to be imple-

mented with the help of the IoT Crafts Portal. On the

one hand, these use cases serve to derive requirements

for the technical development of the platform and, on

the other hand, they serve as initial use cases that can

be used by other crafts businesses. By conducting six

different hackathons with a large number of craft busi-

nesses that are not involved in the development, it will

be evaluated, on the one hand, that already defined

use cases are transferable to other businesses and/or

trades, and on the other hand, the agility of the fur-

ther development will be demonstrated, as further use

cases will be identified and added to the IoT Crafts

Portal. In this context, we also explore in particu-

lar which didactic concepts are suitable to bring craft

businesses closer to IoT technology. Both the exe-

cution of hackathons and the implemented use cases

(lighthouse projects) can then be used specifically to

promote the dissemination of the IoT Crafts Portal

to transfer it to the broad public. In the implemen-

tation of the IoT Crafts Portal, technical research is

needed in particular on how data processing pipelines

for heterogeneous data streams can be implemented

for a wide variety of IoT use cases by people who do

not deal with IoT solutions in detail in everyday life.

For this purpose, setting up IoT use cases by means

of intuitive user interfaces is seen as a central build-

ing block. In the following, we will elaborate these

important aspects in more detail.

4.2 Identification and Evaluation of IoT

Use Cases

At the beginning, two hackathons will be conducted

with the aim of identifying a broad mass of poten-

tially relevant IoT use cases and establishing an un-

derstanding of the necessity as well as the potential of

using IoT in the skilled crafts. In doing so, the par-

ticipants of the hackathons will be supported and ac-

companied by experienced scientists and developers.

In order to ensure target group-adaptive communica-

tion, a didactic concept will be developed that will

enable craft businesses to gain added value from and

access to IoT technology. In addition to the use cases

that arise during the hackathons, each craft business

of the seven application partners from seven different

trades will define at least one further use case relevant

to this enterprise in a workshop.

The evaluation of the IoT Crafts Portal is based

on four further hackathons. In contrast to the first

two hackathons, which serve to identify user cases,

these evaluation hackathons will be conducted with

less assistance. This will show whether the skilled

craftsmen are able to implement their use cases inde-

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

208

pendently using the IoT Crafts Portal. At the same

time, this will iteratively identify additional require-

ments and use cases. In this way, the development of

the portal will be continuously guided in the right di-

rection and its usability will also be ensured by craft

businesses not involved in the development of the IoT

Crafts Portal. Based on the experience of hackathons

already held (cf. Section 3), it can be assumed that

three to four additional previously unknown use cases

will be identified in each hackathon.

4.3 IoT-sensor Screening

Based on the identified IoT use cases, an overview

will be created of which IoT sensors are relevant for

the identified use cases, how they function and to what

extent they already have industry approval. In addi-

tion, all further sensor technology that might be rele-

vant to the skilled crafts will be identified in a further

search and included in the sensor technology catalog

so that it can later be included in the IoT Crafts Por-

tal. This systematic approach will ensure that a wide

range of use cases for the skilled crafts can be covered

by the IoT Crafts Portal. This screening will be con-

tinuously updated. The results will be made available

to the public in a separate database.

4.4 IoT Crafts Portal

Based on the identified use cases and an overview of

relevant sensors, technical requirements for the IoT

Crafts Portal are formulated and a technical architec-

ture is designed. This includes the definition of inter-

faces for data acquisition, decisions on technologies

to be used, and the identification of suitable data anal-

ysis and AI-based learning methods needed to imple-

ment the use cases.

Next, procedures will be developed to connect the

identified sensors to the IoT Crafts Portal via plug-

and-play solutions. For this purpose, modules are

needed that record and read out the data from the sen-

sors and forward it to the IoT Crafts Portal. To solve

the problems of heterogeneity in terms of data format

and meaning (semantics), the data added to the portal

will be annotated with semantics based on a craft IoT

ontology that is to be defined before. Based on the

semantic annotation, the data will be converted into a

syntactically uniform data format and will be stored

in a data lake.

In order to be able to flexibly implement the differ-

ent use cases of the craft businesses on the basis of the

data to be collected, modular data processing is im-

plemented. This is based on the semantic information

defined when adding the sensors. In addition, generic

data processing building blocks are implemented that

allow different processing steps, such as converting

units or merging data streams. In this way, flexible

data processing is created that enables the fusion of

different sensor data streams and thus provides a ba-

sis to adequately implement a wide range of different

IoT crafts use cases.

One of the most important building blocks of the

IoT crafts portal will be a recommendation and search

engine. This engine is being designed and imple-

mented to enable knowledge transfer between the

craft businesses and to encourage them to implement

further IoT use cases or identify them for themselves.

The search engine provides an efficient way to iden-

tify use cases that have already been implemented by

other businesses based on a natural query language.

The recommendation system, on the other hand, sug-

gests further useful use cases to businesses based on

their profile and trade as well as the use cases im-

plemented so far, which have been implemented by

other businesses with similar profiles. This ensures

that businesses are always kept up to date and are no-

tified when new IoT use cases emerge that are of in-

terest to them. State of the art machine learning tech-

niques will be used to develop the recommendation

and search engine.

In order to enable a simple and intuitive opera-

tion for the craft businesses, a user interface is imple-

mented that allows to realize own use cases even with-

out technical training. This interface should create the

possibility to identify, implement and monitor desired

use cases. In addition to the findings from the first two

hackathons, the requirements and wishes of the craft

businesses for the user interface will be recorded in a

workshop. On this basis, a user interface will be de-

veloped, which will be continuously adapted with the

crafts businesses in an agile approach.

5 CONCLUSION

In this paper, we presented our concept for develop-

ing a manufacturer-independent IoT portal that en-

ables small and medium-sized craft businesses from

the skilled crafts to implement IoT solutions inde-

pendently. Through preliminary studies, we showed

how craftsmen can be introduced to the topic of IoT

and how great the potential of IoT is for the skilled

crafts. Subsequently, we presented a concept for the

implementation of the IoT Crafts Portal, which should

enable craftsmen to implement IoT use cases them-

selves. The next steps now include conducting fur-

ther hackathons, identifying more IoT use cases and

implementing the IoT Crafts Portal.

Towards Unlocking the Potential of the Internet of Things for the Skilled Crafts

209

REFERENCES

Ashton, K. et al. (2009). That ‘internet of things’ thing.

RFID journal, 22(7):97–114.

Atzori, L., Iera, A., and Morabito, G. (2010). The internet of

things: A survey. Computer networks, 54(15):2787–

2805.

Bosch (2020). Track My Tools. http://bosch-

trackmytools.com.

Cambridge Semantics (2016). Anzo Smart Data Discovery.

http://www.cambridgesemantics.com/.

Doka (2020). Smart Tools for Construction.

https://www.doka.com/en/news/press/in-the-digital-

fast-lane.

Dorsch, L. (2016). How to bridge the interoper-

ability gap in a smart city. http://blog.bosch-

si.com/categories/projects/2016/12/bridge-

interoperability-gap-smart-city-big-iot/.

Gyrard, A. and Serrano, M. (2015). A unified semantic

engine for internet of things and smart cities: from

sensor data to end-users applications. In 2015 IEEE

International Conference on Data Science and Data

Intensive Systems, pages 718–725. IEEE.

Hilti (2020). on!Track. https://ontrack.hilti.com.

Ludwig-Fr

¨

ohler-Institut f

¨

ur Handwerkswis-

senschaften (2019). Plattformen im Handwerk.

https://bit.ly/3ruEbeI.

Palavalli, A., Karri, D., and Pasupuleti, S. (2016). Se-

mantic internet of things. In 2016 IEEE Tenth Inter-

national Conference on Semantic Computing (ICSC),

pages 91–95.

Pomp, A., Paulus, A., Burgdorf, A., and Meisen, T. (2021).

A semantic data marketplace for easy data sharing

within a smart city. In Proceedings of the 30th ACM

International Conference on Information & Knowl-

edge Management, pages 4774–4778.

Saint Gobain (2020). ISOVER GuardSystem.

https://www.isover.de/guardsystem.

Sisinni, E., Saifullah, A., Han, S., Jennehag, U., and Gid-

lund, M. (2018). Industrial internet of things: Chal-

lenges, opportunities, and directions. IEEE transac-

tions on industrial informatics, 14(11):4724–4734.

Zsch

¨

ornig, T., Wehlitz, R., and Franczyk, B. (2017). A

personal analytics platform for the internet of things-

implementing kappa architecture with microservice-

based stream processing. In International Conference

on Enterprise Information Systems, volume 2.

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

210