Collaboration of Semantically Enriched Digital Twins based on a

Marketplace Approach

Joel Lehmann

1 a

, Andreas Lober

2 b

, Alessa Rache

1 c

,

Hartwig Baumg

¨

artel

2 d

and Julian Reichwald

1 e

1

Mannheim University of Applied Sciences, Paul-Wittsack-Str. 10, 68163 Mannheim, Germany

2

Ulm University of Applied Sciences, Prittwitzstraße 10, 89075 Ulm, Germany

Keywords:

Digital Twins, Cyber-physical System, Marketplace, Ontology, SPARQL, Manufacturing.

Abstract:

Digital Twins are a key concept and an enabling technology within the digital transformation. They can com-

municate bilaterally with their physical counterpart. Thus the twins are reflecting each other’s properties and

state changes. Digital Twins add value to many use case domains, e. g., smart manufacturing. Nevertheless,

today’s implementations are mostly data and state representations of their physical counterparts, tying the

digital twin to a passive and reactive role. The authors argue that semantically enhanced digital twins that

autonomously perform actions and interactions on digital market spaces can add substantial value to various

use cases. An architectural approach is proposed, and an implemented proof of concept shows the feasibility.

1 INTRODUCTION

Digital Twins (DTs) are a key concept within digital

transformation. The concept asserts that all systems

are dual in nature and have a digital representation

besides their physical one (Grieves, 2019). Thus, a

DT bridges the gap between the physical and digi-

tal space: data and state changes of the physical as-

set are reflected by the DT and vice versa. By de-

sign, DTs fit into highly distributed, heterogeneous

environments. Since the digital representation may

– in contrast to its physical counterpart – easily be

extended by adding functionalities like, e.g., simu-

lation systems or machine learning algorithms, such

extended DTs can add substantial value to use cases

from scenarios like, e.g., smart manufacturing, smart

health, or smart cities. Nevertheless, current DT im-

plementations are mainly based on simple data and

state representations of the physical asset; hence they

are tied to a passive role inside the system.

The authors argue that a more active role of a

DT in communicating with other DTs, negotiating

with them, and autonomously executing their deci-

sions (which are by definition also executed in the

physical space) can bring crucial benefits to the manu-

a

https://orcid.org/0000-0001-8261-8362

b

https://orcid.org/0000-0003-3513-6103

c

https://orcid.org/0000-0001-7598-8672

d

https://orcid.org/0000-0002-6251-8898

e

https://orcid.org/0000-0002-4809-5710

facturing domain. DTs of products or services would

be able to interact with DTs of consumers on digital

marketplaces and automatically negotiate on pricing,

delivery times, or other product or service properties.

They could also assemble themselves into complex

products or modules if this is beneficial after negotiat-

ing. A system like this can leverage substantial value

to specific use cases and scenarios. The authors pro-

pose a system where DTs represent data and state in-

formation of a physical asset. Moreover, they will – in

a first step – be enhanced by semantic functionalities,

which can be seen as an essential condition for any

cross-domain negotiation and communication. The

DTs will be implemented using a decentralized run-

time environment, an essential element for executing

autonomous actions in a second step.

After discussing the motivation and the related

work in this field in section 2, the authors present their

proposed architecture of the aforementioned system

in section 3. After the description of the implemen-

tation, a demonstration use case is shown as a proof

of concept in section 4. The work is concluded with a

discussion and prospects our future work in section 5.

2 MOTIVATION & RELATED

WORK

Production machines cannot easily be integrated into

complex negotiation scenarios. Due to their limited

Lehmann, J., Lober, A., Rache, A., Baumgärtel, H. and Reichwald, J.

Collaboration of Semantically Enriched Digital Twins based on a Marketplace Approach.

DOI: 10.5220/0011141200003286

In Proceedings of the 19th International Conference on Wireless Networks and Mobile Systems (WINSYS 2022), pages 35-45

ISBN: 978-989-758-592-0; ISSN: 2184-948X

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

35

extensibility, these physical assets are unable to in-

teract proactively. In contrast, the DT of a physical

asset can be easily extended. However, DTs are of-

ten used as pure data and state representations with

at most reactive behavior. With this contribution, the

authors go beyond this by giving the DTs their own

framework, paving the way for collaborative interac-

tion between DTs within a marketplace scenario. Se-

mantic technologies are a cornerstone of increased au-

tonomy. Therefore, the authors will discuss both fo-

cal points of DTs and semantic representation of pro-

duction skills to synthesize our architectural concept

later.

2.1 Digital Twins

Digital Twins are a key concept and an enabling tech-

nology within the digital transformation. Michael

Grieves first introduced the concept of DTs when

he created and evolved an entirely new paradigm

for Product Lifecycle Management and engineering

methodologies commencing in 2003 (Grieves, 2019).

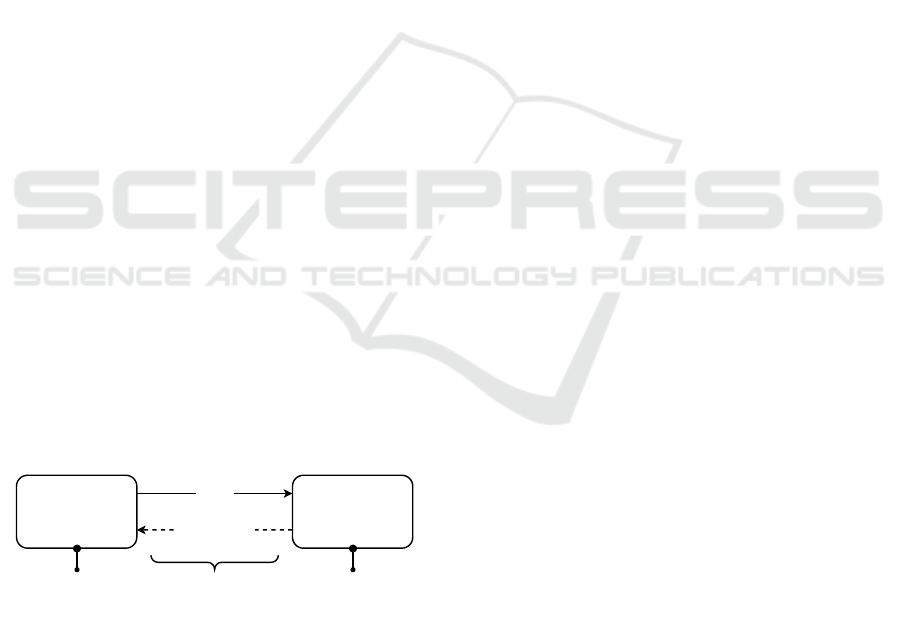

Grieves’ approach is based on the duality between

physical and digital spaces, as depicted by figure 1.

While on the one side, an instance of a real-life en-

tity exists in the physical space, on the other side,

its virtual representation coexists in the digital space.

Both spaces are linked by a digital thread, consist-

ing of a bidirectional stream of data and information.

While the solid arrow shows the data obtained from

the physical space, the dashed arrow represents the

feedback information provided by the DT. Each DT

is unambiguously related to his physical twin in a 1:1

relation. DTs are highly use-case driven. Depending

on its specific application, the twin can be a complex

representation of a physical entity with high-fidelity

modeling or an abstracted minimalistic data construct

(Grieves, 2021).

Data

Physical Space

Information

Digital Space

Digital Thread Digital TwinPhysical Twin

Figure 1: Concept of a Digital Twin According to Grieves.

(van der Valk et al., 2021) subdivide DTs into

specific archetypes, which were subsequently vali-

dated through interviews with industry experts. Five

archetypes are distinguished starting from a basic DT,

only providing mandatory characteristics, extending

to a fully autonomously interacting exhaustive Twin.

They classify the twins into the following:

1. Basic Digital Twin

2. Enriched Digital Twin

3. Autonomous Control Twin

4. Enhanced Autonomous Control Twin

5. Exhausive Twin

The expert interviews revealed that the autonomously

interacting archetypes 3 - 5 have not yet been im-

plemented apart from individually designed solutions.

Regarding the more advanced archetypes 4 and 5,

the research only provides conceptual approaches and

pilot studies. Their conclusions are consistent with

other studies addressing definitions and characteris-

tics, stating that DTs are mostly still at an early stage

of development. Only a few domains are already

using specific implementations with maximum value

exploitation. The concept and its potential are yet

transferable to many other areas (Negri et al., 2017;

Kritzinger et al., 2018; Barricelli et al., 2019; Fuller

et al., 2020).

Extended DTs going beyond simple data represen-

tation are just emerging, with much elaboration still to

be done (Saracco, 2019). Continuous cross-domain

linking of DTs in the production process is neces-

sary for a steady increase in competitiveness (Wag-

ner et al., 2019). DTs are complex systems that inte-

grate several technical disciplines. Choosing a univer-

sal development platform remains challenging due to

various formats, protocols, and standards. Therefore,

industrial practices require reliable infrastructures (Qi

et al., 2021).

The German Industrie 4.0 initiative, as an affilia-

tion of industrial companies and associations, drives

the concept of DTs through the Asset Administration

Shell (AAS). Standard IEC TS 62443-1-1:2009 de-

fines an asset as a physical or logical object owned

by or under the custodial duties of an organization.

This asset has either a perceived or actual value to

the organization. The AAS provides multi-vendor in-

teroperability and consistent value chains throughout

their lifecycle to fully exploit an asset’s potential (P.

I. 4.0, 2020).

Most recent publications focus on the implemen-

tation of passive AAS without autonomous capa-

bilities. Consequently, reactive as well as proac-

tive AAS implementations with intelligent decision-

making and interaction with other AAS are still in

their infancy (Sakurada et al., 2021). According to

(Ocker et al., 2021), a suitable framework for provi-

sioning proactive DTs by using AAS does not yet ex-

ist. Creating DTs via AAS is a challenge that requires

a significant amount of manual effort because of its

complex heterogeneous raw information.

WINSYS 2022 - 19th International Conference on Wireless Networks and Mobile Systems

36

(Vogel-Heuser et al., 2021) use DTs provided by

the AAS to create a Multi-Agent System (MAS) and

its required knowledge base. The respective agents

of products and resources are intended to improve

production processes in a decentralized approach. In

their alike test case, (Rocha et al., 2019) demonstrated

a MAS-based architecture representing a manufactur-

ing system. The MAS is used to control the hard-

ware of a production system and work orders through

different agents. The approach shows a distributed

agent-based control system demonstrating a modular

design of a production system. MAS and DTs are

conceptually and functionally very close. With the

growing emergence of Industrial Cyber-Physical Sys-

tems (ICPS), new opportunities for MAS will also

arise (Karnouskos et al., 2020). However, the MAS

approaches are limited to the domain of one company,

and it is not clear how this MAS would play out in a

cross-company open marketplace scenario. Further-

more, MAS operate in a decentralized manner close to

the edge based on traditional agent frameworks with

several issues, whereas DTs primarily run centrally,

for instance, within a cloud environment.

This work is based on Grieves’ conceptual frame-

work. His idea of a DT is entirely domain-indepen-

dent and can easily be transferred to many other use

cases. Hence, it is also feasible to add intelligent fea-

tures to the DT. The subsequent elaboration should

thus be as open as possible. However, a later eval-

uation of the implementation based on the AAS and

MAS will not be ruled out but investigated in further

publications.

2.2 Semantical Representation of

Production Skills

Digital Twins are designed to realize the interaction

of cyber and physical entities, causing the overall

complexity of these systems to increase along with

accelerating requirements regarding design, devel-

opment, and testing. Several concepts built on a

Service-oriented Architecture (SOA) have shown to

be promising for representing knowledge and capa-

bilities of production systems (Leitao, 2016). In con-

trast to the traditional component-based hierarchical

approach, the SOA-concept is more complex but of-

fers greater flexibility (Dorofeev and Wenger, 2019).

These approaches for complex design processes can

be classified as Model-Driven Engineering (MDE).

Focusing on reducing the overall emerging complex-

ity, MDE has emerged as a promising approach within

process automation to serve a semantic representation

provided by the underlying capabilities of the compo-

nents, resources, and production systems.

For the support of MDE of software projects for

manufacturing automation, a SysML-based approach

is presented in (Vogel-Heuser et al., 2014), in which

functional as well as non-functional requirements can

be covered using a language profile. An ontology-

based approach is presented in (Ameri and Dutta,

2006) and introduces the Manufacturing Service De-

scription Language (MSDL). Thereby, core concepts

and relations for the description of manufacturing

processes are combined in an upper ontology. An

opposing design has been presented in (C

ˆ

andido and

Barata, 2007) and provides a generic approach to-

wards an ontology for describing entities in a man-

ufacturing system based on a multi-agent system.

The IDEAS project introduces a configuration

method for describing executable skills for evolvable

assembly systems using a process-oriented semantic

model. In this approach, object-oriented skills are

defined using an assembly process type as well as

a granularity level (Ferreira and Lohse, 2012). The

capability and skill model of machines presented in

(K

¨

ocher et al., 2020) is based on distinct ontology

design patterns which are based on common indus-

try standards for the direct description of executable

skills and further provide an approach to enable the

plug-and-produce principle. A semantic model in Au-

tomationML is proposed in (Anandan et al., 2017) for

representing skills in a computer-interpretable format

to support high-performance plug-and-produce sys-

tems. Building on the automation of different ma-

chines by plug-and-produce, an approach by Pfrom-

mer et al. is presented in (Pfrommer et al., 2015),

in which the skill is defined as the capability of a re-

source using AutomationML and OPC UA to model

and execute the skills. Another approach presented

in (Backhaus and Reinhart, 2015) defines a skill as

a vendor-neutral description of the functionality of a

machine, where skills perform specific processes re-

quired to manufacture certain products.

(J

¨

arvenp

¨

a

¨

a et al., 2016) provide a capability model

approach by describing the skills by parameters and

names. Taxonomies such as DIN 8580 are used by

a process taxonomy to align capabilities and prod-

uct requirements. Within the BaSys 4.0 project, skills

are defined as a set of properties and made available

via semantic annotations, thus providing another ap-

proach to modeling skills on a semantic basis (Perzylo

et al., 2019).

A graph-based skill metamodel for CPS is pre-

sented in (Brovkina and Riedel, 2019), in which skills

are specified as a composition of atomic and essen-

tial operations put independently to other operations.

In (Bauernhansl et al., 2020), the semantic represen-

tation of different elements and capabilities of pro-

Collaboration of Semantically Enriched Digital Twins based on a Marketplace Approach

37

duction systems and the resulting representation and

grouping of information for a highly flexible recon-

figuration of the system has been structured in an in-

formation model.

The overall objective of the presented approaches

is to build a semantic representation based on the

given information of an existing production system.

However, the consistency of the engineering data is

not or only partially ensured in these approaches. Fur-

thermore, frameworks for marketplace scenarios are

not considered in any cases.

3 ARCHITECTURE

Based on the authors’ motivation to raise DTs to a

higher level of collaboration and interaction and the

fact, which emerged from the discussion of the re-

lated work, that there are no adequate frameworks for

proactive DTs as well as collaborative marketplace

approaches, the authors are subsequently introducing

the general structure of their framework. The subsec-

tions distinguish between different types of DTs and

elaborate the collaborative approach between them.

Based on Grieves’ concept, as shown in figure 1, the

DTs will be further refined. The introduced digital

spaces are depicted as two entities to distinguish the

unique types, which will be renamed later.

3.1 Asset Digital Twin

To efficiently interact with an asset settled in the op-

erational technology (OT), the asset has to be provi-

sioned as DT, enabling full access to be processed by

information technology (IT). OT in this context refers

to the isolated combination of hardware and software

within an automated production facility. Due to still

much-used encapsulated fieldbus systems or propri-

etary automation protocols, an OT/IT gateway is re-

quired in most cases. An asset interface can be estab-

lished using standard IT protocols, such as Message

Queuing Telemetry Transport (MQTT), to overcome

this issue.

In order to give DTs room to negotiate, they need

their habitat within IT. This environment is realized

through a centralized approach in the digital space.

It could also be transposed through a decentralized

concept as a multi-agent system (MAS), addressed in

further planned publications.

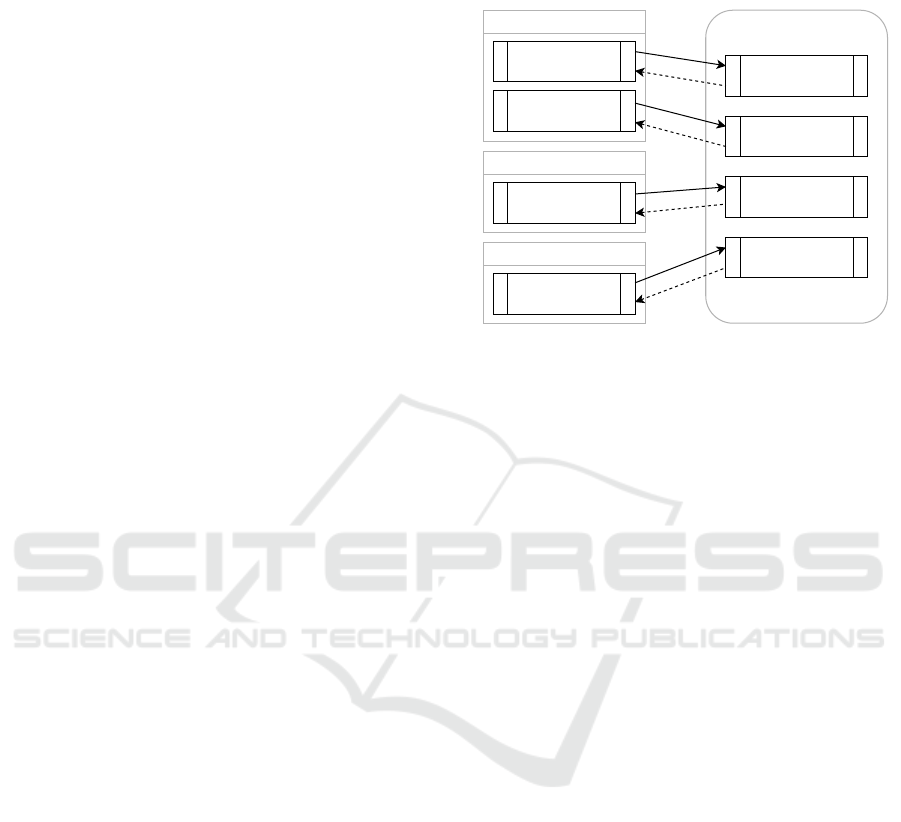

Figure 2 depicts the coherence with various com-

panies participating in the digital space. Each com-

pany offers services through the DTs of its assets.

Hence, the DTs are accumulated across company

boundaries. Those lead away from traditional isolated

market spaces and market strategies towards central-

ized skill and capability trading open marketplaces.

Digital Space

Asset 3

DT

Asset 1

DT

Asset 2

DT

Asset n

DT

Company A

Asset 1

Asset 2

Company B

Asset 3

Company C

Asset n

Figure 2: Interconnection of Production Assets and Their

Digital Twins within the Digital Space.

A semantic description within each DT is neces-

sary for implementing a proactive negotiation behav-

ior between the twins. Particular attention is paid to

the description of the skills and capabilities of an as-

set, as this forms the basis for reasoning required later.

In addition to the unique semantic self-description,

the assets need to continuously reconcile relevant op-

erational parameters in their DTs, represented by the

solid arrows. These DTs can be used to derive bene-

fits through data analytics during the operation of the

architecture, thereby increasing the efficiency and uti-

lization of companies’ operating resources. The nego-

tiations between the DTs allow conclusions about on-

going operations and the execution of production pro-

cesses triggered by the other type of DT introduced

in the following subsection. The dashed arrows rep-

resent this fed-back information.

3.2 Complex Product Demand Digital

Twin

The second part of the authors’ architecture consists

of specific customer-centered, complex product de-

mands. According to (Pfisterer et al., 2016), a com-

plex product consists of a combination of products

and services that can be tailored to fit the customer’s

individual needs and contextual requirements. In or-

der to make this demand to the architecture accessi-

ble, it must be composed into a Complex Product De-

mand Digital Twin (CPDDT). Thus, customers also

participate directly in the digital space through their

CPDDT.

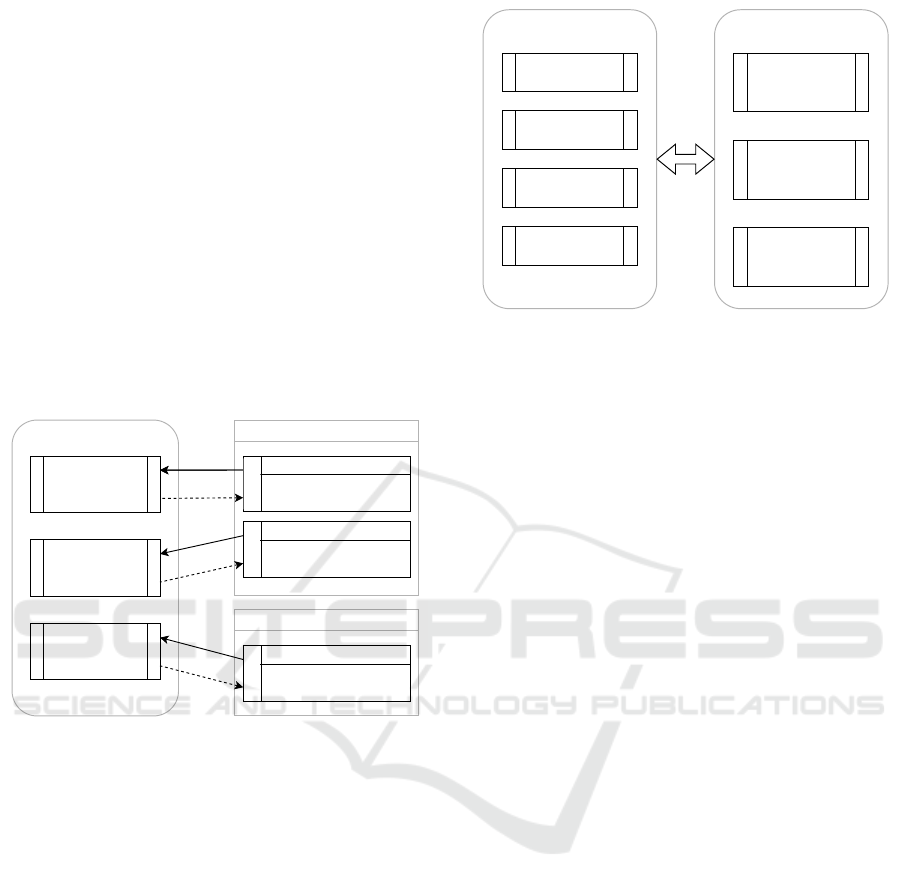

Figure 3 depicts various customers who provide

their specific complex product demands through their

WINSYS 2022 - 19th International Conference on Wireless Networks and Mobile Systems

38

CPDDT in the Digital Space. The complex product

demands are created via an intuitive interface to make

the customer’s provisioning process as easy as possi-

ble. A composing service then transforms the com-

plex product demand and finally provisions a seman-

tically enriched CPDDT to the digital space, repre-

sented by the solid arrows. This digital space offers

the possibility of contacting other DTs and establish-

ing an interactive collaboration between them. The

CPDDTs feedback, represented by the dashed arrow,

requests missing descriptive data, final approval, or

rejection from the customer. Similar to the provi-

sioning process, the composing service converts the

CPDDT information back into a human-readable for-

mat for the customer interface. Subsequently, this al-

lows the production process to be triggered by the As-

set DTs to satisfy the complex product demand.

Digital Space

Complex Product

Demand DT

Complex Product 1

Customer A

Complex Product Demand

Complex Product 1

Complex Product Demand

Complex Product 2

Composer

Complex Product

Demand DT

Complex Product 2

Customer B

Complex Product Demand

Complex Product n

Complex Product

Demand DT

Complex Product n

Composer

Composer

Figure 3: Interconnection of Complex Product Demands

and Their Digital Twins.

3.3 Collaboration of Digital Twins

After the types of DTs have been introduced, collab-

orative interaction can be further discussed. The re-

spective digital spaces have been renamed for sim-

plicity to differentiate the various DT types. All en-

tities are nonetheless located within a shared frame-

work. Since the marketplace-oriented interaction

mechanisms take place exclusively at the twin level,

the link to the physical space, i.e., the assets on the

one hand and the customer demands on the other, is

neglected.

According to (Einav et al., 2016), peer-to-peer

(P2P) market principles establish trade between frag-

mented buyers and sellers. These buyers and sellers

are transposed into DTs located in supply- and de-

mand space in the shown case. DTs can therefore be

considered as peers within a marketplace of twins de-

picted by figure 4. The bidirectional arrow linking

supply and demand space is intended to abstract the

Supply Space

Asset 3

DT

Asset 1

DT

Asset 2

DT

Asset n

DT

Demand Space

Complex Product

Demand DT

Complex Product 1

Complex Product

Demand DT

Complex Product 2

Complex Product

Demand DT

Complex Product n

Figure 4: Digital Twins of Assets and Complex Product De-

mands.

P2P connection between each DT.

There are several challenges in designing market-

places. The primary goal is to effectively match Asset

DTs and CPDDTs while keeping matching problems

at a minimum. Furthermore, there are general prob-

lems regarding pricing and trust, which will not be

focused on further here (Pfisterer et al., 2016).

In order to satisfy complex product demands via

its CPDDT, the semantic description is utilized. The

CPDDT triggers queries on the underlying ontology

of the framework to match asset DTs, which can

meet with the specified sub-components or services.

Thus, the CPDDT successfully combines the sub-

components and services required to fulfill its demand

with the other DTs. The following section discusses

the required procedures in more detail.

4 IMPLEMENTATION

After showing the architectural overview, this section

paves the way for proactive interaction between DTs

and reinforces the authors’ concept by implement-

ing a simplified use case in the manufacturing do-

main. This demonstrator use case illustrates the col-

laboration more comprehensibly. Based on the moti-

vation to create a marketplace-based interaction con-

cept, the main foundation of semantic technologies

comes into action here, which is essential for collab-

oration among DTs.

According to figure 5, the authors have instanti-

ated different entities of DTs in supply- and demand

space. On the left side, various kinds of asset DTs

are shown, such as a Storage, a Punching Machine, a

Drilling Machine, and a Laser Cutting Machine. This

accumulation of production assets offers a bandwidth

of skills and capabilities facing the needs of CPDDTs.

Located on the right side is the CPDDT of sheet metal

Collaboration of Semantically Enriched Digital Twins based on a Marketplace Approach

39

Supply Space

Drilling Machine

DT

Storage

DT

Punching Machine

DT

Laser Cutting

Machine DT

Demand Space

Complex Product

Demand DT

Sheet Metal with hole

Figure 5: Demonstration Use Case.

with a hole. In order to satisfy this complex product

demand, it first needs the specified sheet metal. Then

it has to find an asset DT that can make the speci-

fied hole into the sheet metal. A functional ontol-

ogy is built and service queries are implemented via

SPARQL query. Not part of the implementation is

the complete description of a DT since the focus of

this paper is on the realization of the logical query of

services based on an ontology. By Using this log-

ical query, a reasoning mechanism to the DTs can

be provided to search for the appropriate service on

their own and form a collaborative partnership. In the

demo showcase, the digital space is considered. This

digital space is independent of the physical twin ini-

tially neglected in this example. The integration of the

physical twin into the demo use case is planned and

will be realized later.

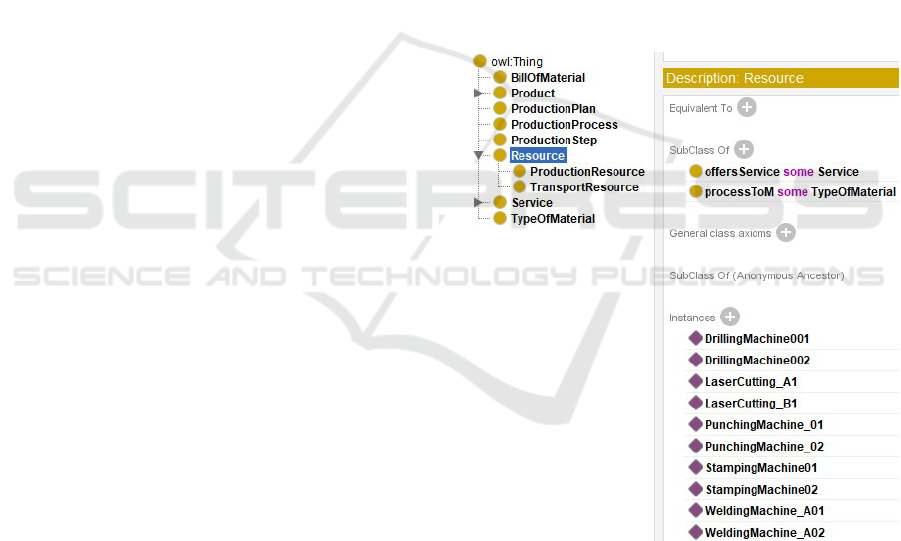

In order to implement the previously presented use

case, the authors have built an ontology that describes

eight classes on the top-level hierarchy consisting

of BillOfMaterial, Product, ProductionPlan, Produc-

tionProcess, ProductionStep, Resource, Service, and

TypeOfMaterial. The basic structure of the ontology

is based on Pfrommer et al., who divided a system into

products, processes, and resources (Pfrommer et al.,

2013), within this work the ontology was extended by

the classes ProductionPlan, ProductionStep, BillOf-

Material, and TypeOfMaterial. This extension of the

basic ontology allows being more precise by mod-

eling the digital marketplace scenario. The logic of

the SPARQL query is based on Lober et al., who

demonstrated a SPARQL query for transport services

as well as semantic-based service discovery (Lober

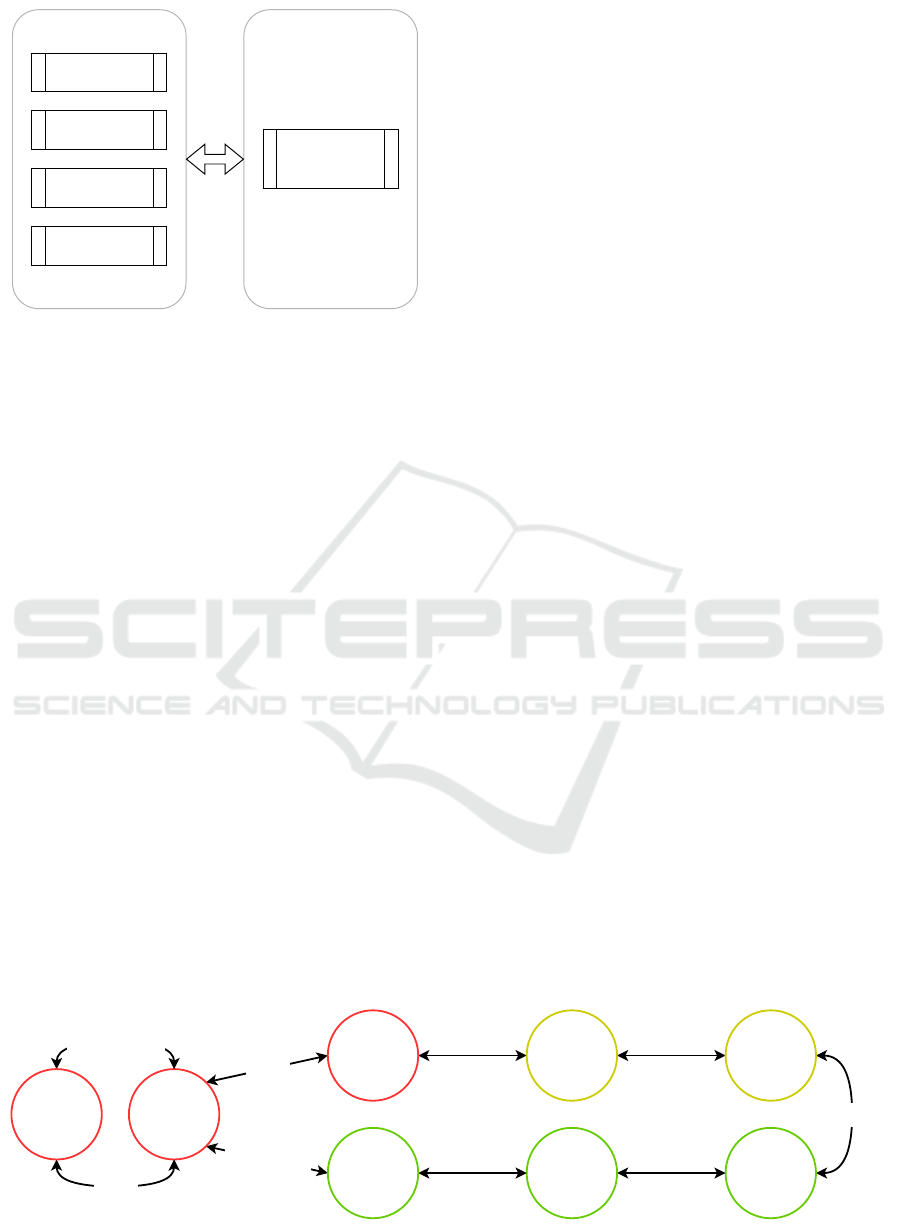

et al., 2020). Figure 6 shows the high-level structure

of the ontology. The eight classes contain all the nec-

essary information for the marketplace scenario by re-

lating the basic classes Services, Resources, Produc-

tionProcesses, and Products. The necessary capabil-

ities are inferred from the production process via the

production plan and the necessary production steps.

The classes BillOfMaterial and TypeOfMaterial de-

fine the necessary information about raw materials

and products relating to the production process. The

CPDDT should find and connect to the relevant Asset

DTs using the ontology.

The classes are divided into logical areas to de-

scribe the ontology more precisely. The first area

(red) handles the product and the information that di-

rectly deals with the product (e.g., type of material

and bill of material). The second area (green) deals

with the production plan, the production process that

can be defined, and the production steps it contains.

The last section (yellow) describes the resources and

the class of services offered by the resources required

to produce the product.

The first area framed in red contains the classes

Product, BillOfMaterial, and TypeOfMaterial. The

class Product represents all types of products in this

simple example. It has RawMaterial, SemiFinished-

Product, and FinishedProduct as sub-classes. Hence,

some products can be raw material or semi-finished

products as well as finished products depending on

the level of the supply chain; all product individu-

als are linked directly to the main class via an in-

stanceOf property. A product is assigned to RawMa-

terial, SemiFinishedProduct, or FinishedProduct by

using various object properties to subclass via a rea-

soning mechanism, depending on its relationship to

the product to be manufactured. This variability in

the structure of the product class allows the dynamic

isToM

isToMOf

hasProductionPlan

isProductionPlanOf

Product

isProcessedToMOf

processToM

TypeOfMaterial

isOfferedServiceOf

offersService

Resource

isNeededServiceOf

needsService

Service

ProductionStep

hasProductionStep

isProductionStepOf

ProductionProcess

definesProductionProcess

isDefinedProductionProcessOf

ProductionPlan

containsMaterial

isContainedMaterialOf

hasBoM

isBoMOf

BillOfMaterial

Figure 6: Top-Level Ontology Classes.

WINSYS 2022 - 19th International Conference on Wireless Networks and Mobile Systems

40

representation of the digital marketplace to be real-

ized. The instances of the class FinishedProduct can

have varying complexity, expressed in the depth of its

partial structure, consisting of various semi-finished

products and raw materials. In order to describe the

product in its entire variability, various data properties

such as thickness and holeDiameter are used to de-

scribe the properties of the product. In the shown use

case, the product needs a resource capable of making

a sheet with a thickness of 5mm and a hole diameter

of 1.5mm. The CPDDT can be associated with the

production process by logically linking the required

production steps (e.g., ability to drill holes) through a

given Production Plan using reasoning. These steps

are necessary to create the product from raw material

resources or components.

In order to describe the product more precisely,

the class BillOfMaterial is used. The class defines

the exact number of necessary raw material and semi-

finished products to manufacture the product via its

instances linked to the production steps. Furthermore,

this class is used to assign an instance of the Product

class to its subclass RawMaterial or SemiFinished-

Product. This assignment is realized via a combina-

tion of several object properties.

While the class BillOfMaterial establishes a link

to the production steps, the class TypeOfMaterial is

used to describe the product’s type of material. The

class is also directly linked to the resources via an ob-

ject property (isProcessedToMOf ).

The second area (outlined in yellow) deals with

the production plan and its production process that

can be derived from it, which contains individual pro-

duction steps. The class ProductionPlan defines a

production plan for a specific product and is linked

to the class Product via the object property isPro-

ductionPlanOf. It defines the flow within the pro-

duction process by specifying the required services.

These services are fulfilled in the individual produc-

tion steps.

While the production plan defines which services

are required, the class ProductionProcess describes

which production steps run within the process. The

production process is assigned to precisely one pro-

duction plan of a specific product.

The instances of the class ProductionStep repre-

sent several specific production steps related to the

production service needed to produce a product (ob-

ject property: needProductionService). Furthermore,

the production step defines the input and output mate-

rials of the step via the object properties needsInput-

Material and createOutputMaterial. Via a Data prop-

erty (PositionInProcess), the process sequence is ex-

plicitly defined, which is implicitly described by the

input and output materials. The output material of the

last production step is the finished product.

The last area (framed in yellow) shows the classes

Resource and Service. Both classes describe essential

information for the supply space in the digital market-

place. Within the class Resource, possible physical

devices are included, such as production machines,

which log into the digital marketplace with specific

capabilities (ProductionServices). Each resource of-

fers one or more services and can use these services

to serve specific production steps required to manu-

facture or transport a product. The object property

offersService describes the resource assignment. The

class has two sub-classes that can be extended de-

pending on the use case. The sub-classes are shown

in figure 7, including all instances of the top-level re-

source class. If a production step is defined as a pro-

duction service or a transport service, these instances

are assigned to the corresponding sub-classes via rea-

soning.

Figure 7: Subclasses of the Ontology.

All logistics or production services relevant to the

use case, subdivided into sub-classes, are included in

the classService. A resource always offers service and

at the same time fulfills a production step, which is

assigned to a production process in the class Produc-

tionProcess. Via the inverse object property offered-

ServiceBy and object property isNeededServiceOf, the

logical connections are described.

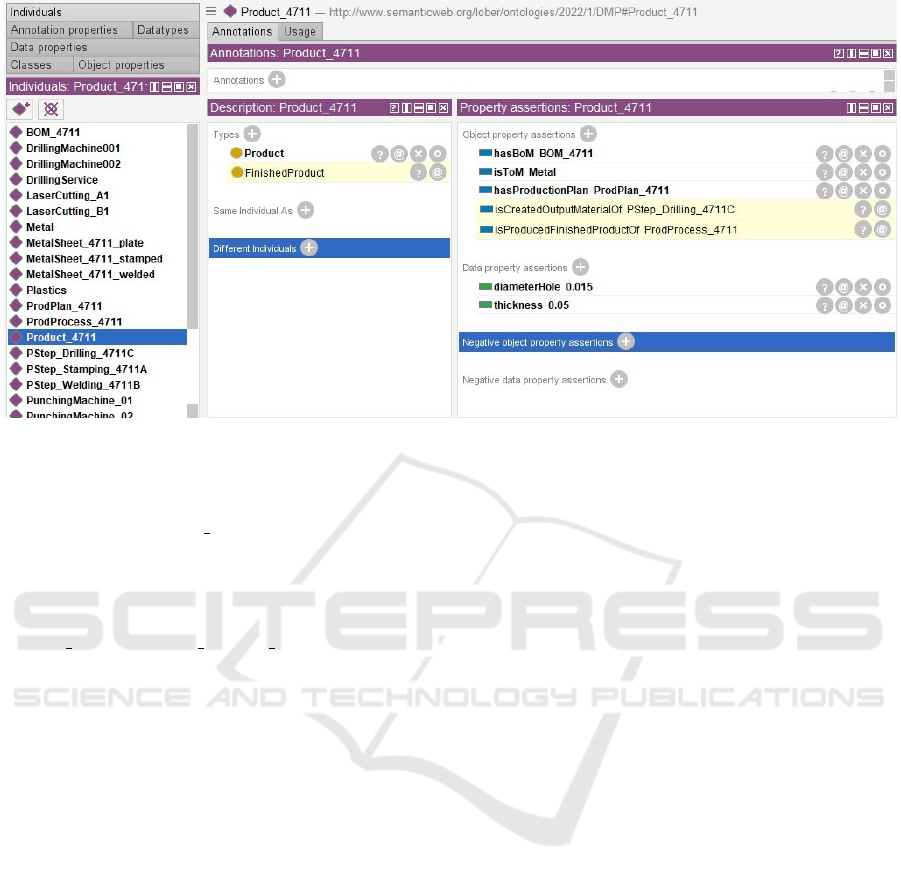

Figure 8 shows an example of the reasoning mech-

anism within the ontology. The logic structures the

Collaboration of Semantically Enriched Digital Twins based on a Marketplace Approach

41

Figure 8: Example of Reasoning.

class Product to assign instances to the sub-class Fin-

ishedProduct. In the example, a reasoner instanti-

ates the product Product 4711 as an instance of the

subclass FinishedProduct. This logic is made ac-

cessible implicit via the inverse object properties is-

ProducedFinishedProductOf and the corresponding

ProductionProcess and ProductionStep (e.g., Prod-

Process 4711 and PStep Drilling 4711C). Explicitly,

this connection is specified via the inverse object

property isCreatedOutputMaterialOf. The decisive

point here is the manufacturing process of the prod-

uct. It determines the processing steps via the routing,

for example, and thus defines whether a resource or a

process (process step) covers the product side or the

side of the producing system.

In the shown use case, a sheet with a thickness

of 5mm and a hole diameter of 1.5mm is produced

in three production steps. It is intended that only the

drilling service can fulfill the desired depth and width.

This is due to the fact that the machines entered (in-

stances of the resources) have specific capabilities and

cannot, for example, cut, drill, or punch through sheet

metal. Using a SPARQL query on the created ontol-

ogy will show that semantic filtering based on specific

requirements of a complex product is one way to en-

able collaborative negotiation of DTs based on this.

According to the presented architecture, the re-

spective classes establish a logical relation via spe-

cific object properties. The instances of the class Pro-

ductionStep are only assigned to different resources

via their relationship to their products and services.

This logic ensures that individual processes and steps

can be easily added to the ontology without being lim-

ited to a subclass. This easy adding becomes essen-

tial as soon as a production process also contains a

transportation process of a more complex product (as-

semblies and modules). Resources represent a more

explicit example. A resource can be a production

resource and a transport resource, which carries out

work steps or a logistical process during manufactur-

ing. Like the processes, the resources are assigned to

the sub-classes of the resource class. This mapping

is done via reasoning in the ontology, ensuring a flat

class hierarchy. This flat class hierarchy is necessary

to ensure a high degree of flexibility within the ontol-

ogy.

If the use case has to be executed, a SPARQL

query must be performed on the ontology, shown in

the appendix. The SPARQL query filters the repre-

sented information on the ontology by specifying re-

strictions in the lower area of the query (WHERE)

for identifying appropriate production resources. This

query first filters on all described products and queries

the corresponding necessary production plan, produc-

tion processes, and corresponding production steps.

The subsequent rows query the matching information,

which production resource can fulfill the production

steps and fulfill the specific variable properties of the

product requirements. The variables’ product proper-

ties are represented as data properties within the on-

tology and represent the variable information about

the thickness and hole diameter of the product. Many

production resources can be filtered out by specify-

ing minimum and maximum hole depths that the ma-

chines can meet. The last filter represents the machin-

able material that the machines can process.

Table 1 shows that five production resources are

sorted out of six possible resources due to non-

WINSYS 2022 - 19th International Conference on Wireless Networks and Mobile Systems

42

Table 1: Results of SPARQL Query for Suitable Production Resources.

Product

Product

Process

Production

Resource

Material

Minimum

Thickness

Maximum

Thickness

Product

Thickness

Diameter

hole Res.

Diameter

hole Prod.

Possible

Resource

Product 4711 ProdProcess 4711

DrillingMachine001 Sheet Metal 0.05 0.025

0.05

0.015

0.015

Yes

DrillingMachine002 Sheet Metal 0.01 0.05 0.020 No

LaserCutting A1 Wood 0.02 0.06 0.015 No

LaserCutting B1 Wood 0.06 0.1 0.010 No

PunchingMachine 01 Plastic 0.01 0.05 0.020 No

PunchingMachine 02 Sheet Metal 0.1 0.15 0.1 No

matching properties. In the application example,

the data properties filter for appropriate resources

to perform the correct production process (ProdPro-

cess 4711). From the table, it can be seen that some

resources are filtered as they are capable of process-

ing inappropriate material. Other resources cannot

serve the necessary thickness or diameter hole for the

required product. Thus, only DrillingMachine001 is

output as a possible resource at the end of the query.

This use case is intended to illustrate that complex fil-

tering is possible in a production step which can pro-

vide the starting point for intelligent collaborative ne-

gotiation of DTs based on the semantic description of

the capabilities of a production system.

5 CONCLUSIONS & FUTURE

WORK

This paper presents a novel concept of leveraging DTs

to a collaborative level based on a marketplace ap-

proach. The intention was to break through the lim-

ited extensibility of physical production machines by

twinning them and empowering the DTs to negotiate

proactively with others. After discussing our motiva-

tion and the related work in this field, we presented a

high-level overview of our aforementioned architec-

ture. Subsequently, a proof of concept was imple-

mented using a simplified demonstration use case.

Combining the DT concept and semantic tech-

nologies enables contextualization and thus opens up

entirely new possibilities. With this contribution, the

authors go beyond DTs as pure data and state rep-

resentations with at most reactive behavior by giving

the DTs their own framework, paving the way for col-

laborative interaction within a marketplace scenario.

For instance, the virtual representations of product de-

mands and production machines can efficiently inter-

operate in the manufacturing domain. This combi-

nation facilitates cross-company interlinking through

different industry sectors to the customer. Likewise,

the customer experience for complex products in-

creases due to the optimization of production time and

speed and convenient participation in the marketplace

and usability. At the same time, higher utilization of

production resources on the supply side is effectively

possible by providing non-operational production re-

sources on the marketplace. The maximum potential

of a marketplace of twins arises with the increasing

heterogeneity of the market participants.

As the architecture is still at an early stage, sev-

eral limitations need to be addressed in the future. On

the practical side, in an increasingly growing mar-

ketplace, flooding scenarios between the DTs need

to be addressed, optimization approaches for recom-

mendation and ranking must be considered. In addi-

tion, the BillOfMaterial and TypeOfMaterial classes

of the ontology must be specified more granularly, en-

abling different Bill of Material types to be integrated

as subclasses. The operational side raises problems

concerning the transport and logistics of products be-

tween individual manufacturing steps, which must be

investigated.

The research and development of the presented

work form the basis for future research areas. In ad-

dition to the limitations described above, our future

work will focus on the following three main areas.

The initial research area intended to further expand

on this work will be the specific structure and con-

text of semantically enriched DTs, particularly asset

DTs and CPDDTs. In addition, the detailed elabo-

ration of negotiation mechanisms within the market-

place will be elaborated. Furthermore, agent-based

methods constitute an important field of research that

needs to be evaluated.

ACKNOWLEDGEMENTS

This work is supported by a grant of the Karl V

¨

olker-

Foundation.

REFERENCES

Ameri, F. and Dutta, D. (2006). An upper ontology for man-

ufacturing service description. volume 2006.

Collaboration of Semantically Enriched Digital Twins based on a Marketplace Approach

43

Anandan, P., Ferreira, P., Lohse, N., and Guedes, M. (2017).

An automationml model for plug-and-produce assem-

bly systems. pages 849–854.

Backhaus, J. and Reinhart, G. (2015). Digital description

of products, processes and resources for task-oriented

programming of assembly systems. Journal of Intelli-

gent Manufacturing, 28.

Barricelli, B. R., Casiraghi, E., and Fogli, D. (2019). A sur-

vey on digital twin: Definitions, characteristics, appli-

cations, and design implications. 7:167653–167671.

Bauernhansl, T., Weyrich, M., Zarco, L., M

¨

uller, T., Marks,

P., Schlegel, T., and Siegert, J. (2020). Semantic struc-

turing of elements and capabilities in ultra-flexible

factories. Procedia CIRP, 93:335–340.

Brovkina, D. and Riedel, O. (2019). Skill-based metamodel

for sustaining the process-oriented cyber-physical sys-

tem description. pages 1–6.

C

ˆ

andido, G. and Barata, J. (2007). A multiagent control

system for shop floor assembly. pages 293–302.

Dorofeev, K. and Wenger, M. (2019). Evaluating skill-

based control architecture for flexible automation sys-

tems. In 2019 24th IEEE International Conference

on Emerging Technologies and Factory Automation

(ETFA), page 1077–1084. IEEE Press.

Einav, L., Farronato, C., and Levin, J. (2016). Peer-to-peer

markets. Annual Review of Economics, 8:615–635.

Ferreira, P. and Lohse, N. (2012). Configuration model for

evolvable assembly systems.

Fuller, A., Fan, Z., Day, C., and Barlow, C. (2020). Digi-

tal twin: Enabling technologies, challenges and open

research. IEEE Access, 8:108952–108971.

Grieves, M. (2019). Virtually Intelligent Product Systems:

Digital and Physical Twins, pages 175–200.

Grieves, M. (2021). Intelligent digital twins: The role of AI

and ML in the future of digital twins chief scientist of

advanced manufacturing florida institute of technol-

ogy.

J

¨

arvenp

¨

a

¨

a, E., Siltala, N., and Lanz, M. (2016). Formal

resource and capability descriptions supporting rapid

reconfiguration of assembly systems. pages 120–125.

Karnouskos, S., Leitao, P., Ribeiro, L., and Colombo, A. W.

(2020). Industrial agents as a key enabler for realiz-

ing industrial cyber-physical systems: Multiagent sys-

tems entering industry 4.0. IEEE Industrial Electron-

ics Magazine, 14(3):18–32.

K

¨

ocher, A., Hildebrandt, C., Fay, A., and Vieira da Silva,

L. M. (2020). A formal capability and skill model for

use in plug and produce scenarios.

Kritzinger, W., Karner, M., Traar, G., Henjes, J., and Sihn,

W. (2018). Digital twin in manufacturing: A cat-

egorical literature review and classification. IFAC-

PapersOnLine, 51(11):1016–1022. 16th IFAC Sym-

posium on Information Control Problems in Manufac-

turing INCOM 2018.

Leitao, Colombo, K. (2016). Industrial automation based on

cyber-physical systems technologies: Prototype im-

plementations and challenges. Computers in Industry,

81:11–25. Emerging ICT concepts for smart, safe and

sustainable industrial systems.

Lober, A., Baumg

¨

artel, H., and Verbeet, R. (2020). Seman-

tic service discovery in heterogeneous cyber-physical

systems.

Negri, E., Fumagalli, L., and Macchi, M. (2017). A re-

view of the roles of digital twin in cps-based produc-

tion systems. Procedia Manufacturing, 11:939–948.

27th International Conference on Flexible Automa-

tion and Intelligent Manufacturing, FAIM2017, 27-30

June 2017, Modena, Italy.

Ocker, F., Urban, C., Vogel-Heuser, B., and Diedrich,

C. (2021). Leveraging the asset administration

shell for agent-based production systems. IFAC-

PapersOnLine, 54(1):837–844. 17th IFAC Sympo-

sium on Information Control Problems in Manufac-

turing INCOM 2021.

P. I. 4.0 (2020). Details of the asset administration shell part

1. Plattform Industrie 4.0, Federal Ministry for Eco-

nomic Affairs and Energy (BMWi), Berlin, Germany.

Perzylo, A., Grothoff, J., Lucio, L., Weser, M., Malakuti,

S., Venet, P., Aravantinos, V., and Deppe, T. (2019).

Capability-based semantic interoperability of manu-

facturing resources: A basys 4.0 perspective. IFAC-

PapersOnLine, 52(13):1590–1596. 9th IFAC Confer-

ence on Manufacturing Modelling, Management and

Control MIM 2019.

Pfisterer, D., Radonjic-Simic, M., and Reichwald, J. (2016).

Business model design and architecture for the inter-

net of everything. Journal of Sensor and Actuator Net-

works, 5(2).

Pfrommer, J., Schleipen, M., and Beyerer, J. (2013).

Pprs: Production skills and their relation to prod-

uct, process, and resource. In IEEE 18th Confer-

ence on Emerging Technologies & Factory Automa-

tion (ETFA), 2013, pages 1–4, Piscataway, NJ. IEEE.

Pfrommer, J.,

ˇ

Stogl, D., Aleksandrov, K., Navarro, S., Hein,

B., and Beyerer, J. (2015). Plug & produce by mod-

elling skills and service-oriented orchestration of re-

configurable manufacturing systems. at - Automa-

tisierungstechnik, 63:790–800.

Qi, Q., Tao, F., Hu, T., Anwer, N., Liu, A., Wei, Y., Wang,

L., and Nee, A. (2021). Enabling technologies and

tools for digital twin. Journal of Manufacturing Sys-

tems, 58:3–21. Digital Twin towards Smart Manufac-

turing and Industry 4.0.

Rocha, A. D., Tripa, J., Alem

˜

ao, D., Peres, R. S., and

Barata, J. (2019). Agent-based plug and produce

cyber-physical production system – test case. In 2019

IEEE 17th International Conference on Industrial In-

formatics (INDIN), volume 1, pages 1545–1551.

Sakurada, L., Leitao, P., and De la Prieta, F. (2021).

Towards the digitization using asset administration

shells. In IECON 2021 – 47th Annual Conference of

the IEEE Industrial Electronics Society, pages 1–6.

Saracco, R. (2019). Digital twins: Bridging physical space

and cyberspace. Computer, IEEE Computer Society,

52(12):58–64.

van der Valk, H., Haße, H., M

¨

oller, F., and Otto, B. (2021).

Archetypes of digital twins.

Vogel-Heuser, B., Ocker, F., and Scheuer, T. (2021). An

approach for leveraging digital twins in agent-based

WINSYS 2022 - 19th International Conference on Wireless Networks and Mobile Systems

44

production systems. at - Automatisierungstechnik,

69(12):1026–1039.

Vogel-Heuser, B., Sch

¨

utz, D., Frank, T., and Legat, C.

(2014). Model-driven engineering of manufactur-

ing automation software projects – a sysml-based ap-

proach. Mechatronics, 24(7):883–897. 1. Model-

Based Mechatronic System Design 2. Model Based

Engineering.

Wagner, R., Schleich, B., Haefner, B., Kuhnle, A.,

Wartzack, S., and Lanza, G. (2019). Challenges and

potentials of digital twins and industry 4.0 in product

design and production for high performance products.

Procedia CIRP, 84:88–93. 29th CIRP Design Confer-

ence 2019, 08-10 May 2019, P

´

ovoa de Varzim, Port-

gal.

APPENDIX

The following SPARQL query, as introduced in the

implementation section, filters the represented infor-

mation on the ontology by specifying restrictions in

the WHERE-Statement to identity appropriate pro-

duction resources:

PREFIX DMP: <http://www.semanticweb.org/lober/ontologies/2022/1/DMP#>

SELECT ?Product ?ProductionProcess ?Resource ?ProductionService

WHERE {?Product DMP:hasProductionPlan ?ProductionPlan.

?Product DMP:thickness ?ProductThickness.

?Product DMP:diameterHole ?DiameterHole.

?Product DMP:hasToM ?TypeOfMaterial.

?ProductionPlan DMP:definesProductionProcess ?ProductionProcess.

?ProductionProcess DMP:hasProductionStep ?ProductionStep.

?ProductionStep DMP:needsProductionService ?ProductionService.

?ProductionResource DMP:offersProductionService ?ProductionService.

?ProductionResource DMP:processToM ?ProcessableToM.

Filter (?ProcessableToM = ?TypeOfMaterial).

?ProductionResource DMP:minThickness ?MinThickness.

Filter (?MinThickness <= ?ProductThickness).

?ProductionResource DMP:maxThickness ?MaxThickness.

Filter (?MaxThickness >= ?ProductThickness).

?ProductionResource DMP:diameterHoleResource ?DiameterHoleRes.

Filter (?DiameterHoleRes = ?DiameterHole).}

Collaboration of Semantically Enriched Digital Twins based on a Marketplace Approach

45