Numerical Study on Droplet Evaporation Simulation Scheme and

Evaporation Characteristics of Salt-containing Desulfurization

Wastewater

Guojun Yu

a

and Li Zhang

b

College of Energy and Mechanical Engineering, Shanghai University of Electric Power, China

Keywords: Desulfurization Wastewater, Salt-Containing Droplets, Evaporation Characteristics, Numerical Simulation.

Abstract:

In order to accurately simulate the evaporation characteristics of salt-containing desulfurization wastewater

in high temperature flue gas, five simulation schemes for droplet evaporation of desulfurization wastewater

were discussed based on DPM model of FLUENT platform and combined with the actual composition of

desulfurization wastewater. A simulation scheme for realizing the influence of soluble salts and suspended

solids on the evaporation of wastewater droplets was determined. The differences of evaporation characteristic

parameters such as evaporation time, evaporation distance, particle size change and mass change of

wastewater droplets obtained under different schemes were explored, and the evaporation characteristics of

wastewater with different salt content were studied. The results show that the evaporation characteristics of

different schemes are different. It is recommended to use the evaporation simulation scheme considering the

actual composition of desulfurized wastewater in the simulation; The greater the salt content, the shorter the

time and distance required for evaporation of waste water droplets. Under the research conditions in this paper,

when the salt content of wastewater is doubled, the particle size of remaining particles increases by 10.3%,

the relative mass of remaining particles increases by a percentage of 2.3, the total evaporation time and the

total evaporation distance decrease by 6% on average.

1

INTRODUCTION

1

Since 2015, the government has issued a series of pol-

lution control policies, which put forward the require-

ment of near zero discharge for desulfurization

wastewater from thermal power units. At the same

time, the increase in desulfurization wastewater from

large thermal power units increases the task of treat-

ment. Therefore, concentration and reduction become

necessary before the terminal treatment of desulfuri-

zation wastewater. Atomization evaporation is one of

the terminal treatment technologies of desulfurization

wastewater treatment process and has a certain appli-

cation in engineering. However, with the concentra-

tion and reduction of desulfurization wastewater, the

composition of wastewater changes. Correspond-

ingly, wastewater droplet evaporation characteristics

will also change. How to accurately master the evap-

oration characteristics of wastewater droplets is of

a

https://orcid.org/0000-0002-9039-1388

b

https://orcid.org/0000-0002-6203-6119

great engineering significance for better application

of atomization evaporation technology and improve-

ment of desulfurization wastewater treatment effect.

In previous studies, the treatment of wastewater

droplets was different. Ref. (Zhang 2011, Kang 2013,

Min 2019) considered that water accounted for the

majority of desulfurization wastewater, and treated

desulfurization wastewater as pure water which can

evaporate completely. Ref. (Chen 2016, Ran 2016,

Wang 2019) still thought that desulfurization

wastewater could be evaporated totally, the difference

was that they considered the physical property differ-

ence between waste water and pure-water. In fact,

desulfurization wastewater contains Ca, Ma, Cl and

SO

3

as well as suspended solids (Wu 2006). Espe-

cially after concentration and reduction, the propor-

tion of soluble salts in desulfurization wastewater be-

comes larger. Therefore, above research work has

shortcomings.

18

Yu, G. and Zhang, L.

Numerical Study on Droplet Evaporation Simulation Scheme and Evaporation Characteristics of Salt-containing Desulfurization Wastewater.

DOI: 10.5220/0011175800003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 18-25

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

In recent two years, researchers started paying at-

tention to the influence of soluble salts in desulfuriza-

tion wastewater on droplet evaporation. Ref. (Xiong

2020) researched the influence of soluble salts on

droplet evaporation characteristics by using a shell

formation model. Ref. (Yang 2020) regarded desulfu-

rization wastewater as homogeneous salt solution and

took into account the influence of salt crystallization

on droplet evaporation characteristics during the nu-

merical study. However, the research on atomization

evaporation of saline desulfurization wastewater is

not enough. How to consider the actual composition

of desulfurization wastewater and how to use the

droplet model provided by the numerical simulation

platform to simulate the evaporation process of desul-

furization wastewater more accurately? What are the

differences in evaporation characteristics between

different numerical simulation schemes for

wastewater droplet evaporation? These are all worthy

of in-depth study.

Based on the above analysis, combined with the

actual composition of desulfurization wastewater, this

paper discussed several research schemes on how to

simulate the droplet evaporation of desulfurization

wastewater on FLUENT platform. and obtained the

evaporation characteristics in several aspects under

different schemes. A simulation research scheme

which could realize the influence of soluble salts and

suspended solids on the droplet evaporation of

wastewater was determined. At last, the evaporation

characteristics of desulfurization wastewater with dif-

ferent salt content were studied

2 MATHEMATICAL MODEL OF

DESULFURIZATION

WASTEWATER

EVAPORATION

It is generally considered that the evaporation process

of desulfurization wastewater in flue gas is a dilute

two-phase flow.

2.1 Control Equation of Continuous

Phase

Continuous phase flue gas is considered as a mixture

of dry flue gas and water vapor. The flow and heat

exchange processes are described in a general form as

follows (Feng 2019):

𝜕

𝜌𝜙

𝜕𝑡

+𝑑𝑖𝑣𝜌𝐔

𝜙 = 𝑑𝑖𝑣𝛤

𝑔𝑟𝑎𝑑𝜙 + 𝑆

(1)

in equation: 𝜙 is a general variable for different

equations; 𝜌 is density of flue gas; 𝐔

is the veloc-

ity vector of flue gas; 𝛤

is a general diffusion coef-

ficient; 𝑆

is a general source term, which repre-

sents the droplet evaporation, the interaction force be-

tween flue gas and droplets, the heat required for

evaporation.

2.2 Trajectory Equation of Discrete

Phase

The trajectory equation of atomized droplets can be

obtained by integrating the particle forces in Laplace

coordinates (Jen 2005):

d𝐔

dt

=𝐹

𝐔

−𝐔

+

𝐠𝜌

−𝜌

𝜌

(2)

in equation: 𝐔

is the velocity of particle; 𝐹

𝐔

−

𝐔

is the drag force acting on unit mass particle.

2.3 Heat and Mass Transfer Equation

between Two Phases

During the process of evaporation, there is heat and

mass transfer phenomena between flue gas and drop-

lets. The droplets may have three different phenom-

ena: heating, evaporation and boiling. When the drop-

let temperature is lower than the "critical" evapora-

tion temperature, only heat transfer exists between the

droplet and the flue gas. When the droplet tempera-

ture is higher than the "critical" evaporation tempera-

ture and lower than the boiling point temperature, the

heat absorbed by the droplet is used for both temper-

ature rise and evaporation (i.e. unsteady evaporation)

and then enters the steady evaporation stage, the heat

is fully used for droplet evaporation. When the tem-

perature reaches the boiling point, the droplets absorb

heat and boil.

Generally, atomization evaporation of desulfuri-

zation wastewater is the above evaporation phenom-

ena. Without considering the influence of radiation,

the droplet temperature equation and the evaporation

rate formula determined by the convection mass are

as follows (Miura 1977):

𝑀

𝑐

𝑑𝑇

𝑑𝑡

=ℎ𝐴

𝑇

−𝑇

+

𝑑𝑀

𝑑𝑡

𝛾 (3)

𝑑𝑀

𝑑𝑡

=𝑘

𝐴

𝜌

𝑙𝑛

1+𝐵

(4)

in equation: 𝑀

is droplet mass; 𝑐

is the specific

heat capacity of the droplet; 𝐴

is the surface area of

the droplets; 𝑇

、

𝑇

is separately the temperature of

flue gas and the droplets. h is the convection heat co-

efficient of the droplet surface; 𝛾 is the latent heat of

vaporization; 𝑘

is the mass transfer coefficient;𝐵

Numerical Study on Droplet Evaporation Simulation Scheme and Evaporation Characteristics of Salt-containing Desulfurization Wastewater

19

is the Spalding mass transfer number.

If the droplet contains solids, the remaining parti-

cle will enter the heating process after all the evapo-

rable components evaporate. The temperature equa-

tion is as follows (Miura 1977):

𝑀

𝑐

𝑑𝑇

𝑑𝑡

=ℎ𝐴

𝑇

−𝑇

5

3 DISCUSSION ON SIMULATION

SCHEME OF DROPLET

EVAPORATION

The treatment scheme of wastewater droplet evapora-

tion simulation is related to the components of desul-

furization wastewater and the discrete phase model

provided by the numerical simulation platform.

3.1 Component Analysis of

Desulfurization Wastewater

Desulfurization wastewater is the most difficult ter-

minal wastewater in thermal power plant, in which

there are many kinds of pollutants such as suspended

solids, salt content, heavy metal, fluoride and so on.

Measurement results showed that desulfurization

wastewater after pretreatment still contains Cl

-

, SO

4

2-

,

Na

+

, K

+

, Mg

2+

, Ca

2+

and suspended solids. Therefore,

desulfurization wastewater is generally considered to

consist of pure water, soluble salts and suspended sol-

ids (Liang, 2019). Because the crystallization of salts

and existence of suspended solids would affect the

droplet evaporation characteristics, the simulation

scheme of wastewater droplet considering the exist-

ence of these substances is a more reasonable scheme.

3.2 Discussions on Discrete Phase

Model of FLUENT Simulation

Platform

FLUENT platform could simulate many physical

phenomena such as flow, heat transfer, mass transfer,

combustion, radiation and so on. The platform pro-

vides several particle models for discrete phase simu-

lation. Both droplet model and multicomponent

model are suitable for simulating droplet evaporation.

Droplet model is mainly used to simulate the evapo-

ration of homogeneous droplets which the physical

parameters doesn’t change during the simulation.

Therefore, droplet model can’t simulate the crystalli-

zation of soluble salts and the presence of suspen-

sions. The multicomponent model can define several

components of the droplet, and can define the physi-

cal properties and evaporation of each component

separately. With the evaporation or crystallization of

the droplet components, the composition and physical

properties of the droplet change during the simula-

tion. Therefore, the multicomponent model could

simulate the mixture with salt crystallization and sus-

pension, and realize different simulation schemes of

wastewater droplets by defining the composition and

content.

3.3 Discussion on Droplet Evaporation

Scheme of Desulfurization

Wastewater

Based on the above analysis, combining with the

DPM model provided by FLUENT simulation plat-

form, considering the actual composition of desulfu-

rization wastewater and the treatment scheme of

desulfurization wastewater droplets in previous liter-

atures, the following five schemes which may simu-

late the evaporation of wastewater droplets are deter-

mined:

(1) Scheme 1: Disregard soluble salts and sus-

pended solids, treat wastewater as pure water, select

droplet model.

(2) Scheme 2: Disregard suspended solids, treat

wastewater as a mixture of pure water and soluble

salt, select droplet model.

(3) Scheme 3: Treat wastewater as a mixture of

pure water, soluble salt and suspended solids, select

droplet model.

(4) Scheme 4: Disregard suspended solids, treat

wastewater as a mixture of pure water and soluble

salt, select multicomponent model, define the physi-

cal properties and proportion of pure water and solu-

ble salt respectively.

(5) Scheme 5: Treat wastewater as a mixture of

pure water, soluble salt and suspended solids, select

multicomponent model, define the physical proper-

ties and proportion of pure water, soluble salt and sus-

pension respectively.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

20

4 RESEARCH OBJECT AND

CALCULATION CONDITION

SETTING

4.1 Research Object

Taking the evaporation of desulfurization wastewater

in flue as an example, above five schemes of desulfu-

rized wastewater are compared. The flue between air

preheater and dust collector of one unit is chose. Fig.1

gives the size of the flue and the plan of the nozzle.

Tab.1 gives the relevant parameters of the flue gas and

atomized wastewater.

Figure 1: Flue structure and nozzle layout.

Table 1: Related parameters of flue gas and wastewater.

Paramete

r

Unit Value

Flue gas flow rate m/s 10

Flue

g

as tem

p

erature

K

433

Mass fraction ratio of water vapor

in flue

g

as

% 0.08

Waste water temperature

K

323

Waste water

q

uantit

y

t/h 4.2

Number of nozzles 6

Dro

p

let in

j

ection rate m/s 5

Droplet size μm 60

4.2 Composition of Desulfurization

Wastewater

The main content of desulfurization wastewater is

shown in Tab.2. Refer to Ref. (Liang, 2019), it is as-

sumed that the soluble salts containing in the

wastewater are CaCl

2

, MgCl

2

, NaCl, MgSO

4

and

KCl. The contents of the soluble salts are calculated.

It is assumed that the suspension in wastewater is

mainly calcium sulfate. The content is 70mg/L ac-

cording to the national standard. Tab.3 shows the

composition and physical properties of desulfuriza-

tion wastewater.

Table 2: Main ion content in wastewater.

Ions Ca

2+

Mg

2+

Na

+

K

+

Cl

-

SO

Content(mg/L) 500 3954 683.5 175.2 6594.5 9600.3

Table 3: Composition and physical parameters of wastewater.

Component Water

Soluble salts Suspended solids

CaCl

2

MgCl

2

NaCl MgSO

4

KCl

CaSO

4

Content (g/L) 978.32 1.388 6.151 1.738 12.00 0.335 0.07

Density (kg/m

3

) 1000 2152 2325 2165 2660 1984 2960

C

P

(J/kg·k) 4180 657.5 752.6 870.4 805.5 657.5 733.8

4.3 Calculation Condition Setting

Three sets of grids with total numbers of 1.17, 2.03

and 2.4 million are generated. After verification of

grid independence, the number of grids used for cal-

culation is 2.03 million.

In the simulation, it is considered that the contin-

uous phase is composed of dry flue gas and water va-

por. The component transport model is used to con-

sider the evaporative mass transfer of droplets. The

inlet of flue is set as the velocity inlet boundary, the

outlet is set as the pressure outlet boundary and the

wall is insulated without slip. Discrete phase droplets

are injected from nozzles with uniform particle

size(60μm). The droplet trajectory is calculated by

discrete random walk model. The wall collision

model adopts capture type and the flue outlet is es-

cape type. The discrete phase and the continuous

phase are coupled and the steady-state tracking

method is used with the maximum iteration step of

50000. SIMPLE algorithm is used for pressure-veloc-

ity calculation and second-order upwind mode is used

for equation discretization. The physical parameters

of waste water droplets in different schemes are set

according to Tab.3.

Numerical Study on Droplet Evaporation Simulation Scheme and Evaporation Characteristics of Salt-containing Desulfurization Wastewater

21

5 DISCUSSION OF SIMULATION

RESULTS OF DIFFERENT

DROPLET EVAPORATION

SCHEMES

5.1 Particle Motion Analysis

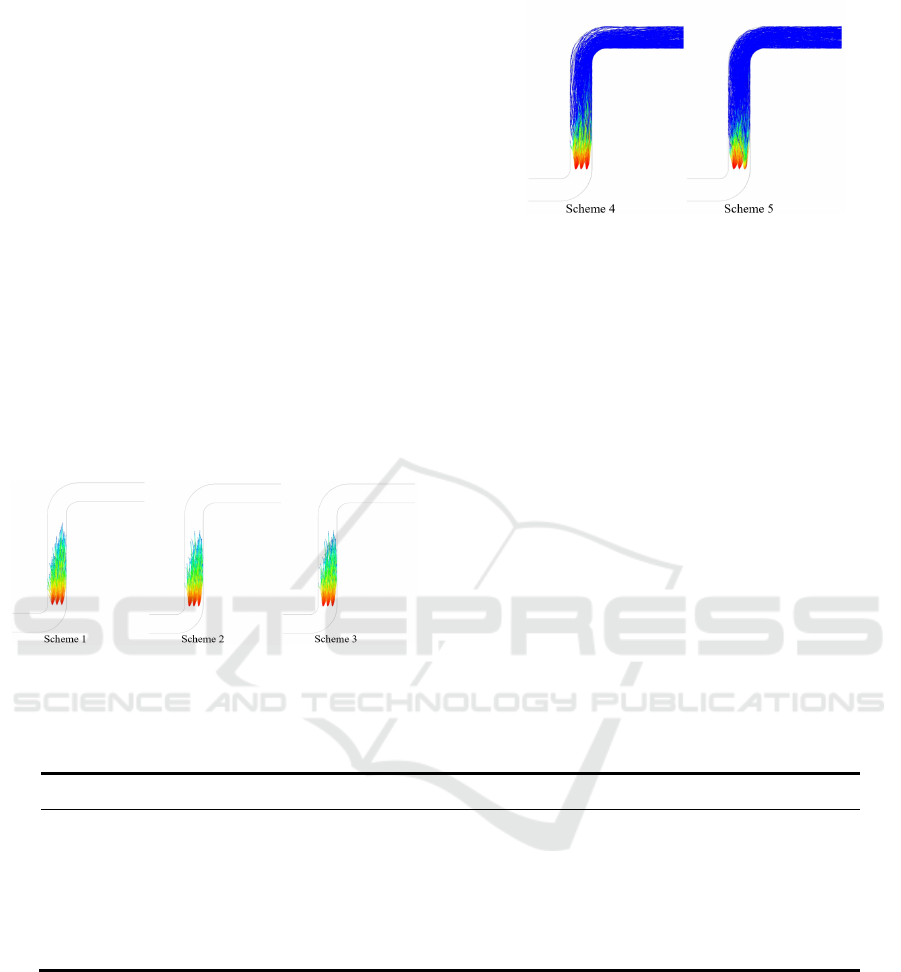

According to the above numerical methods, the sim-

ulation of five schemes for droplet evaporation of

wastewater was completed. The continuous phase

flow fields obtained have little difference, but the par-

ticle motion is different. Fig.2 shows the particle mo-

tion of five schemes. It can be seen qualitatively that

the wastewater droplets of Scheme1, 2 or 3 evaporate

completely in a vertical flue, only the evaporation

processes are slightly different. However, for Scheme

4 or 5, there are residual particle after wastewater

evaporation due to the salt or suspended solids. The

residual particles are discharged with the flue gas.

Figure 2: Droplet trajectory of each scheme.

5.2 Comparison of Evaporation

Characteristics

Table 4 shows the evaporation time and distance of

the wastewater droplets under each scheme. It can be

seen that the time and distance required for droplet

evaporation in Scheme 1, 2 or 3 are not significantly

different, and the minor differences are mainly caused

by the slight changes of physical parameters of

wastewater, such as density and specific heat capac-

ity. However, compared with the first three schemes,

the evaporation time and distance are longer in

Scheme 4 or 5 due to considering the presence of

crystalline salts and suspended solids, because these

have adverse effects on droplet evaporation. The re-

search object in this paper has a vertical flue of 12.5m.

The simulation results in Tab.4 shows that the drop-

lets have evaporated completely before leaving the

bend and do not impact on downstream equipment.

Table 4: Evaporation time and distance of each scheme.

Scheme 1 2 3 4 5

Average evaporation time (s) 0.603 0.586 0.586 0.621 0.624

Complete evaporation time

(

s

)

0.975 0.978 0.978 1.311 1.307

Average evaporation distance

(

m

)

5.900 5.680 5.680 5.930 5.993

Complete evaporation dis-

tance (m)

9.197 9.201 9.201 12.08 12.03

Fig.3 shows the variation of droplet temperature

with evaporation time. It can be seen that the evapo-

ration first experienced the unsteady stage since the

droplets of Scheme 1, 2 and 3 are all pure solutions.

Then the evaporation rapidly enters a steady stage

with a temperature of about 331.8K until the droplets

completely evaporate. For Schemes 4 and 5, the un-

steady evaporation stage is relatively slow, because of

the salt or suspended solids in Schemes 4 and 5,

which may need additional heat to rise temperature.

Then the evaporation also enters a steady stage with

almost the same evaporation temperature as the first

three schemes. After the steady evaporation lasts for

a short time, all the water evaporates, the remaining

crystalline salts or solids begin to absorb heat and rise

temperature. In addition, duo to discard the suspended

solids in Scheme 4, the temperature of wastewater

droplet is slightly different from that in Scheme 5.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

22

Figure 3: Variation of average temperature of droplet with

time of each scheme.

Fig.4 compares the change of droplet mean diam-

eter with evaporation time. It shows that the average

droplet size of the five schemes decreases rapidly

with evaporation time in the early stage of droplet

evaporation, and the change rate is basically the same.

However, during the later stage of evaporation, the

change of average droplet size is different. The results

of Scheme 1, 2 and 3 show that the droplets evaporate

completely and rapidly, while the average particle

size of Scheme 4 and 5 tend to a fixed value due to

the retention of crystalline salts and suspended solid.

Figure 4: Variation of average size of droplet with time of

each scheme.

Fig.5 is a graph of the change of the relative mass

of droplets with evaporation time. It can be seen from

the figure that the change trend of droplet mass ob-

tained by each scheme is basically the same. In the

early stage of evaporation, the droplets are evaporated

quickly by about 50% due to the large temperature

difference between droplets and flue gas. For the re-

maining 50% mass, the heat transfer between droplets

and flue gas is reduced due to the reduction of tem-

perature difference between droplets and flue gas and

the reduction of droplet surface area. Therefore, it

takes a long time to completely evaporate.

Figure 5: Variation of relative mass of droplet with evapo-

ration time of each scheme.

By comparing the simulation results of the above

five schemes, it is easy to find that the characteristics

of droplets simulated by the first three schemes using

droplet model have the same trend, and there are

slight differences among them, mainly due to the dif-

ferent settings of physical properties of wastewater

droplets. Similarly, the evaporation characteristics

obtained by the multicomponent model have the same

trend. The difference between Scheme 4 and Scheme

5 is mainly due to whether the presence of suspended

solids is considered and is especially in the later stage

of droplet evaporation. Due to better consideration of

the actual composition of wastewater, Scheme 5 is

recommended in this paper.

6 EVAPORATION

CHARACTERISTICS OF

WASTEWATER WITH

DIFFERENT SALT CONTENT

On the basis of the above wastewater components, it

is assumed that the wastewater is concentrated to dif-

ferent degrees. Using Scheme 5, the evaporation char-

acteristics of droplets with different salt content are

further studied.

Figure 6: Variation of average temperature of droplet with

different salt content with evaporation time.

0.00.20.40.60.81.01.21.4

320

330

340

350

360

370

380

390

400

Average temperature of waste water droplets/K

Evaporation time/s

Scheme1

Scheme2

Scheme3

Scheme4

Scheme5

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4

0

10

20

30

40

50

60

Average particle size of waste water droplets/μm

Evaporation time

/s

Scheme1

Scheme2

Scheme3

Scheme4

Scheme5

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4

0

20

40

60

80

100

Relative quality of waste water droplets/%

Evaporation time

/s

Scheme1

Scheme2

Scheme3

Scheme4

Scheme5

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4

320

330

340

350

360

370

380

390

400

Average temperature of waste water droplets/K

Evaporation time/s

Salt content 4.34%

Salt content 6.50%

Salt content 8.67%

Salt content 10.84%

Salt content 13.01%

Numerical Study on Droplet Evaporation Simulation Scheme and Evaporation Characteristics of Salt-containing Desulfurization Wastewater

23

Figure 7: Variation of average particle size of droplet with

different salt content with evaporation time.

Figure 8: Variation of relative mass of droplet with different

salt content with evaporation time.

Fig.6-8 show the variation of average tempera-

ture, average particle size and relative mass with

evaporation time when droplets of desulfurization

wastewater with different salt content evaporate.

Fig.6 shows that the less the salt content, the later the

wastewater droplets enter the steady evaporation, the

longer the steady evaporation duration, the lower the

steady evaporation temperature, and the lower the

temperature of the final particles. It can be seen from

Fig.7 and Fig.8 that with the increase of salt content,

the earlier the particles enter the stage of constant par-

ticle size and mass, indicating that the complete evap-

oration time of droplets becomes shorter. At the same

time, it can be seen that the larger the salt content, the

larger the diameter and mass of the final remaining

particle.

Finally, the evaporation time, distance and resid-

ual relative mass of wastewater with different salt

content are extracted from the simulation results as

shown in Tab.5. It can be seen that the relative mass

of the remaining particles obtained by the numerical

simulation is the same as the mass fraction of salt in

wastewater before evaporation, which also shows the

accuracy of the calculation to a certain extent. In ad-

dition, the table shows that the higher the salt content,

the shorter the time and distance required for the

evaporation of wastewater droplets, and the greater

the influence on the evaporation characteristics.

Therefore, for the atomization evaporation simulation

of desulfurization wastewater after concentration, it is

more necessary to adopt wastewater droplet simula-

tion scheme considering the existence of crystalline

salt precipitation and suspended solids.

Table 5: Evaporation time and distance of droplets of wastewater with different salt content.

Salt content (%) 4.336 6.505 8.673 10.841 13.009

Relative mass of remaining

p

articles

(

%

)

4.336 6.505 8.673 10.841 13.009

Residual

p

article size

(

μ

m

)

15.74 18.10 20.01 21.66 23.12

Average evaporation time

(

s

)

0.602 0.587 0.566 0.503 0.489

Maximum evaporation time

(

s

)

1.252 1.134 1.093 1.034 0.971

Average evaporation dis-

tance

(

m

)

5.820 5.717 5.400 4.907 4.744

Maximum evaporation

distance

(

m

)

11.71 10.23 10.48 9.25 9.25

7 CONCLUSION

The variation of evaporation characteristics of

wastewater droplets needs further consideration un-

der the background of concentration and reduction,

which needs comprehensive analysis combined with

wastewater composition and droplet treatment

scheme. By comparing evaporation simulation

schemes of wastewater droplet and exploring the in-

fluence of salt content on droplet evaporation charac-

teristics, the following conclusions are obtained:

(1) The evaporation characteristics of wastewater

droplets obtained by different simulation schemes are

different. For the simulation scheme considering salt

or suspended solids, the unsteady evaporation process

is slow, and the temperature rise of residual particle

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4

0

20

40

60

80

100

Relative quality of waste water droplets/%

Evaporation time/s

Salt content 4.34%

Salt content 6.50%

Salt content 8.67%

Salt content 10.84%

Salt content 13.01%

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4

10

20

30

40

50

60

Average particle size of waste water droplets/μm

Evaporation time

/s

Salt content 4.34%

Salt content 6.50%

Salt content 8.67%

Salt content 10.84%

Salt content 13.01%

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

24

after evaporation of wastewater droplets can be sim-

ulated, and the evaporation time and evaporation dis-

tance are longer.

(2) Scheme 5 takes into account the actual com-

position of desulfurization wastewater. The simula-

tion scheme is recommended when simulating atom-

ization evaporation of wastewater.

(3) Under the research conditions in this paper,

when the salt content of wastewater is doubled, the

particle size of remaining particles is increased by

10.3%, the residual relative mass is increased by a

percentage of 2.3, and the total evaporation time and

distance are reduced by 6% on average.

REFERENCES

B. Yang, L. Zhang, Bb. Zuo, et al.. Numerical Simulation

of Evaporation characteristics for Salt-containing

Desulfurization Wastewater Droplets in Low Tempera-

ture Flue [J]. Journal of Engineering Thermo-physics,

41(04): 925-932, 2020.

CHEN Q, THU K, BUI T D, et al. Development of a model

for spray evaporation based on droplet analysis[J]. De-

salination, 399: 69-77,2016.

Gl. Xiong, Hs. Wu, Sq. Li, et al. Numerical Simulation of

the Influence of Soluble Salt on Evaporation Character-

istics of Desulfurization Wastewater Droplet in High

Temperature Flue Gas [J]. Proceedings of the CSEE,

40(16): 5239-5247, 2020.

Gt. Wang. Numerical simulation of flue gas desulfurization

wastewater [D]. North China Electric Power Univer-

sity, 2019.

Hl. Min. Study on Evaporation Process of Droplet in Boiler

Tail gas [D]. Southeast University, 2019.

JEN T C, LI L, CUI W, et al. Numerical investigations on

cold gas dynamic spray process with nano- and micro-

size particles[J]. International Journal of Heat and Mass

Transfer,48(21-22): 4384-4396, 2005.

Jy. Ran, Zr. Zhang. Numerical Study on Evaporation Char-

acteristics of Different Substance Droplet in Low Tem-

perature Flue Gas [J]. Proceedings of the CSEE, 30(26):

62-68, 2016.

K. Miura, T. Miura, S. Ohtani. Heat and mass transfer to

and from droplets[J]. Chemical Engineering Progress

Symposium Series,163(73): 95-102, 1977.

Mq. Kang. Study on flue gas desulfurization wastewater

duct evaporation treatment system design and experi-

ment [D]. Chongqing University, 2013.

Sq, Feng. Numerical simulation on Desulfurization

Wastewater Evaporation Characteristics in Flue Gas

and Process Design of in thermal power plant [D].

North China Electric Power University (Beijing), 2019.

Yw. Wu. Study on the wastewater treatment in limestone-

gypsum wet FGD process [J]. Electric Power, 04: 75-

78, 2006.

Zr. Zhang. Study on Key Problems of the Thermal Power

Plant FGD Waste water with Evaporation treatment

[D]. Chongqing University, 2011.

Zx. Liang. Study on the Characteristics of the Spray Struc-

ture and the Unsteady Evaporation of the Droplets for

the Desulfurization Wastewater [D]. Chongqing Uni-

versity, 2019.

Numerical Study on Droplet Evaporation Simulation Scheme and Evaporation Characteristics of Salt-containing Desulfurization Wastewater

25