Influences of Injection Positions of Pyrolytic Wastewater on No

x

Emission of Semi-coke

Xueting Yang

1,2

, Guoliang Song

1,2,3,*

, Yuan Xiao

1,2

, Zengcai Ji

1,2

and Chao Wang

1,4

1

Institute of Engineering Thermalphysics, Chinese Academy of Sciences, Beijing 100190, China

2

University of Chinese Academy of Sciences, Beijing 100049, China

3

Dalian National Laboratory for Clean Energy, Dalian 116023, China

4

University of Science & Technology of China, Hefei 230026, China

*Corresponding author

Keywords:

Pyrolytic Wastewater, Semi-Coke, No

x

Emission, CFB.

Abstract:

The amount of pyrolytic wastewater produced by coking plant was huge and it was difficult to deal with,

there were many defects in conventional pyrolytic wastewater treatment methods. Incineration method

could remove most of the organics and harmful substances in pyrolytic wastewater, and generate CO

2

and

H

2

O, it truly realized zero discharge of pyrolytic wastewater, but its effects on the combustion and pollutant

emissions of semi-coke was not clear, so experiments were carried out in a 0.1 MW circulating fluidized

bed test platform to investigate the influences of injection positions of pyrolytic wastewater on the

combustion temperature and NO

x

emission of semi-coke. The results showed that the NO

x

emission was cut

down by 13.81 %and 22.58 % when pyrolytic wastewater was injected into furnace and tail flue,

respectively. It indicated that pyrolytic wastewater realized zero discharge when burning with semi-coke,

the NO

x

emission of semi-coke was cut down as well, and it was more appropriate for pyrolytic wastewater

to reduce NO

x

emission in tail flue compared to the furnace.

1 INTRODUCTION

A large amount of pyrolytic wastewater is produced

every year in the coking plants, the composition of

pyrolytic wastewater is complex, containing

aromatic and long-chain hydrocarbon organic

matters, benzene, volatile phenol, ammonia nitrogen

and oil (Ji, 2016, Wang, 2017), so it has

characteristics such as high chemical oxygen

demand (COD), high chromaticity and poor

biodegradability, it is difficult to degrade and

recycle (Li, 2017, Wang 2014). The conventional

methods are to degrade or flocculate pyrolytic

wastewater by microorganism, chemical reagent and

physical methods. The processes of conventional

methods are complex, which are greatly affected by

temperature and the composition of pyrolytic

wastewater, so that the treatment capacity of

conventional methods is limited. An easy, clean and

efficient treatment method desperately needs to be

found out. Incineration method is not affected by the

temperature and quality of wastewater, and can

destroy the molecular structure of harmful

substances through controllable high-temperature

chemical reaction. It can remove most of the

organics and harmful substances in pyrolytic

wastewater and generate CO

2

and H

2

O, truly

realizing zero discharge of pyrolytic wastewater

(Xiao, 2012).

Literatures about the incineration of coal

pyrolytic wastewater are few, Li XF et al. (Li, 2018)

found through simulation that the temperature of the

furnace reduced when the pyrolytic wastewater

enters the circulating fluidized bed furnace for

incineration, and the power generation was cut down

by about 1.5 % when the coal supply of the system

kept stable.

Alar Konist et al. (Konist, 2018) incinerated

pyrolytic wastewater from shale oil plants in a 60

kW

th

circulating fluidized bed combustor, the NO

x

emission was increased by up to 1.8 times when the

flow rate of pyrolytic wastewater was 4.6 kg/h. Alar

Konist et al.( Konist, 2019) also carried out

experiments in an oil shale fired 250 MW

th

circulating fluidized bed boiler, and found that the

incineration of pyrolytic wastewater increased the

48

Yang, X., Song, G., Xiao, Y., Ji, Z. and Wang, C.

Influences of Injection Positions of Pyrolytic Wastewater on Nox Emission of Semi-coke.

DOI: 10.5220/0011179400003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 48-52

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

NO

x

emission by 27 % and increased oil shale

consumption by up to 6 % when the flow rate of

pyrolytic wastewater was 13 t/h.

To deal with pyrolytic wastewater in CFB

boilers, the appropriate position for incineration and

its influences on the operation and pollutant

emission of CFB boilers should be investigated. In

the experiments of literature (Konist, 2018), the

pyrolytic wastewater was incinerated in the lower

part of furnace which near the feed position of oil

shale, the pyrolytic wastewater was sent to the

furnace together with oil shale in literature (Konist,

2019). To figure out the influences of injection

positions of coal pyrolytic wastewater on NO

x

emissions of semi-coke, some experiments were

carried out in this paper, the injection positions

included furnace and tail flue, and it was vital for the

clean and efficient treatment of coal pyrolytic

wastewater.

2 EXPERIMENTAL SECTION

2.1 Fuel Characteristics

The proximate and ultimate analysis of semi-coke

used during experiments were shown in Table 1,

subscript “ar” represents the as received basis. The

particle diameter of semi-coke was 0-1 mm. The

pyrolytic wastewater used in experiments came from

a coking plant in Shanxi Province, China, and its

components were shown in Table 2.

Table 1: Proximate and ultimate analysis of semi-coke.

Proximate Analysis (wt%) Ultimate Analysis (wt%, ar)

Lower calorific value

M

ar

A

ar

V

ar

FC

ar

C

ar

H

ar

O

ar

N

ar

S

ar

Q

ar,net

(MJ/kg)

4.78 7.06 6.2 81.96 82.54 0.84 3.59 0.82 0.37 28.62

Table 2: Components of pyrolytic wastewater (mg/L).

PH Volatile phenol

Ammonia

nitrogen

COD Oils Salts sulfide

9.02 2.84×10

3

37.2 3.08×10

4

203 6.99×10

4

<0.005

2.2 Test Platform

Experiments were carried out in a 0.1 MW CFB test

platform to investigate the effects of pyrolytic

wastewater on the combustion and emission

characteristics of semi-coke when pyrolytic

wastewater was injected from different positions. As

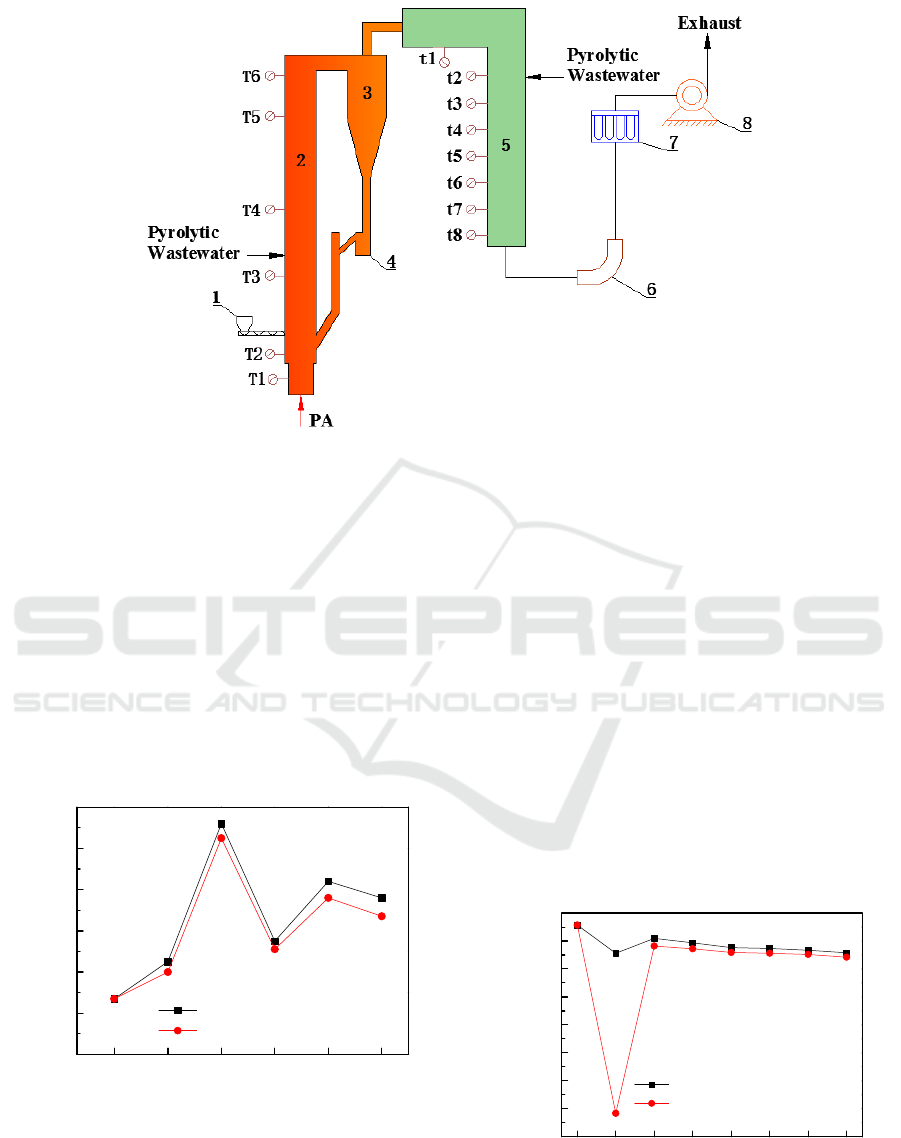

shown in Fig.1, the 0.1 MW CFB test platform was

consist of furnace, cyclone, loop seal, tail flue, flue

gas cooler, bag filters and induced draft fan. The

inner diameter of furnace was 150 mm, there were

six thermal couples along the axis of furnace, the

inner diameter of tail flue was 150 mm, along which

there were eight thermal couples as shown in Fig.1.

Pyrolytic wastewater was injected into the furnace

and tail flue from the positions near T3 and t2,

respectively, the mass of injected wastewater was

about 10 % of semi-coke.

The excess air ratio was controlled around 1.15,

the temperature in furnace was around 935℃,

pyrolytic wastewater was injected into the furnace in

the position near T3, and was injected into tail flue

in the position near t2 when the temperature was

appropriate. The flue gas was filtered, dried then

analyzed by Testo 350 measuring system. In the

following discussion, the NO

x

emission had

normalized to dry flue gas with an oxygen

concentration of 6 %.

Influences of Injection Positions of Pyrolytic Wastewater on Nox Emission of Semi-coke

49

1- Screw feeder; 2- CFB furnace; 3- Cyclone; 4- Loop seal; 5- Post-combustion chamber; 6- Flue gas cooler; 7- Bag filters;

8- Induced draft fan

Figure 1: Schematic diagram of 0.1MW CFB test platform.

3 RESULTS AND DISCUSSIONS

Compared to the temperature distributions without

pyrolytic wastewater, the temperature of tail flue

was stable when pyrolytic wastewater was injected

into furnace, and the temperature of furnace was

stable when pyrolytic wastewater was injected into

the tail flue. Fig.2 and Fig.3 showed the temperature

distributions of furnace and tail flue in different

conditions, respectively.

T1 T2 T3 T4 T5 T6

820

840

860

880

900

920

940

847

865

932

875

904

896

847

860

925

871

896

887

Combustion without PW

PW was injected into furnace

Temperature (℃)

Sample point in furnace

Figure 2: Temperature distribution of furnace.

“PW” represented pyrolytic wastewater. The

temperature in furnace decreased slightly when

pyrolytic wastewater was injected into T3, the

temperature of T2, T3, T4, T5 and T6 dropped 5 to 9

degrees, while the temperature of T1 did not change

due to the heat storage of bed material. It indicated

that there was little effect on the temperature of

furnace when deal with pyrolytic wastewater in the

furnace.

As shown in Fig.3, the temperature of t2

decreased sharply when pyrolytic wastewater was

injected into the tail flue, the temperature of t3, t4,

t5, t6, t7 and t8 all decreased in varying degrees, and

all above 15℃. It could indicate that the temperature

change of tail flue was more obvious than that of the

furnace when the same percentage of pyrolytic

wastewater was injected into furnace and tail flue,

respectively.

t1 t2 t3 t4 t5 t6 t7 t8

100

200

300

400

500

600

700

800

900

857

756

809

793

776

773

767

758

857

184

782

772

759

756

752

742

Combustion without PW

PW was injected into tail flue

Temperature (℃)

Sample point in tail flue

Figure 3: Temperature distribution of tail flue.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

50

There were lots of semi-coke and bed material

particles circulating through the furnace, cyclone

and loop seal, the heat loss caused by pyrolytic

wastewater was soon supplemented, while there

were few combustible particles in the tail flue, so

that the injection of pyrolytic wastewater led to

larger decrease of temperature. Sample point t2 was

the nearest point from where pyrolytic wastewater

was injected into, much heat was absorbed to

evaporate the water when flue gas and fly ash flow

by the injection position.

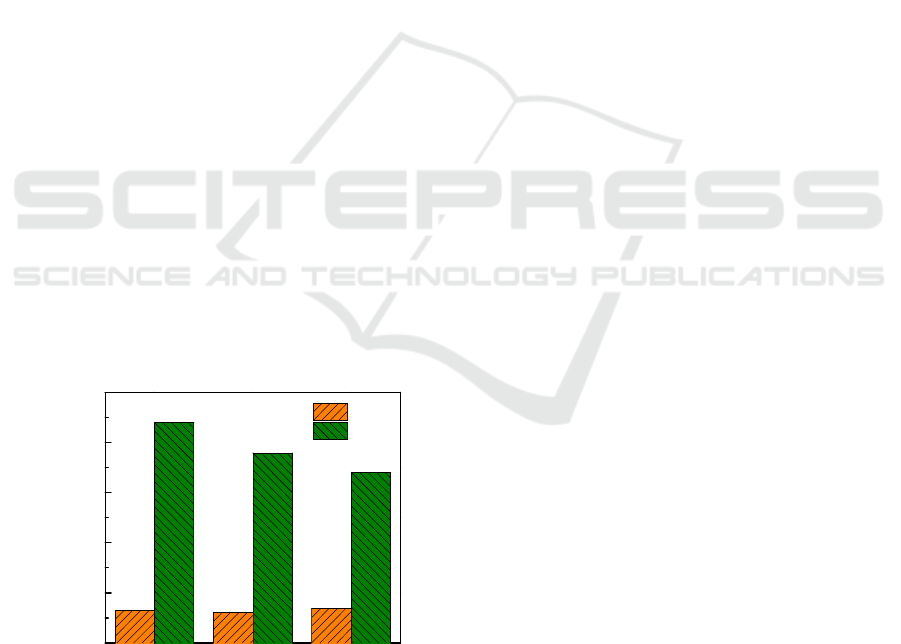

Fig.4 showed the pollutant concentration in flue

gas of three cases, respectively, “None” represented

no pyrolytic wastewater was injected, and its NO

x

emission concentration was 439.67 mg/m

3

. It was

obviously that the NO

x

emission decreased when

pyrolytic wastewater was injected into furnace or

tail flue, the NO

x

emission were cut down by

13.81 %and 22.58 % when pyrolytic wastewater was

injected into furnace and tail flue, respectively.

Compared to being injected into the furnace, the

NO

x

emission was lower when pyrolytic wastewater

was injected into tail flue. It indicated that it was

more appropriate for pyrolytic wastewater to reduce

NO

x

emission in tail flue.

When pyrolytic wastewater was injected into

furnace, the semi-coke particles were in the state of

incomplete combustion in the position where

pyrolytic wastewater was injected into, part of

nitrogen in semi-coke was released, and NH

3

in

pyrolytic wastewater reacted with NO

x

through the

following reaction (R1), and the organic matters and

residual NH

3

(if there was) in pyrolytic wastewater

would be oxidized by air.

4NH

3

+6NO→5N

2

+6H

2

O (R1)

None Furnace Tail flue

0

100

200

300

400

500

Injection position

CO

NO

x

CO(ppm)

NO

x

(

mg/m

3

)

Figure 4: Pollutant concentration in flue gas.

The particles in flue tail were almost burned out,

and the NO

x

concentration in the flue gas was high,

the organic matters in pyrolytic wastewater such as

hydrocarbons would not be oxidized due to low

temperature in the position of t2 when pyrolytic

wastewater was injected into tail flue, the CO

emission increased as well due to the drop of

temperature. Hydrocarbons and NH

3

reacted with

NO

x

, so the NO

x

emission was the lowest when

pyrolytic wastewater was injected into tail flue.

The incineration of pyrolytic wastewater

together with semi-coke could not only realize zero

discharge of pyrolytic wastewater, the NO

x

emission

of semi-coke was reduced as well. However, the

residence time of pyrolytic wastewater was short

when it was injected into tail flue, so there was no

guarantee of sufficient residence time for the organic

matters to decompose.

4 CONCLUSIONS

Experiments were carried out to explore the effects

of injection positions of pyrolytic wastewater on

combustion temperature and pollutant emissions of

semi-coke. The main conclusions were as follows:

(1) The temperature change of tail flue was more

obvious than furnace when the same percentage of

pyrolytic wastewater was injected into furnace and

tail flue, respectively.

(2) The NO

x

emission was cut down by

13.81 %and 22.58 % when pyrolytic wastewater was

injected into furnace and tail flue, respectively.

(3) It was more appropriate for pyrolytic

wastewater to reduce NO

x

emission in tail flue

compared to the furnace, but there was no guarantee

of sufficient residence time for organic matters to

decompose.

ACKNOWLEDGEMENTS

This work was financially supported by the National

Key Research & Development Program of China,

grant NO. 2018YFB0605002.

REFERENCES

Konist Alar, Oliver Järvik, Tonu Pihu, Dmitri

Neshumayev, (2018). Chemical Engineering

Transactions, 70: 859-864.

Konist Alar, Oliver Järvik, Heliis Pikkor, Dmitri

Neshumayev, Tõnu Pihu, (2019). Journal of Cleaner

Production, 234: 487- 493.

Influences of Injection Positions of Pyrolytic Wastewater on Nox Emission of Semi-coke

51

Ji QH, Salma Tabassum, Sufia Hena, Cláudia G.Silva, Yu

GX, Zhang ZJ, (2016). Journal of Cleaner Production,

126: 38- 55.

Wang W, Ren XS, Yang K, Hu ZH, Yuan SJ, (2017).

Journal of Hazardous Materials, 340: 152– 159.

Li M, Liu XM, (2017). Technology of Water Treatment,

11: 57- 61.

Li XF, Zhang CQ, Li WH, Guo YH, Kang ZZ, (2018).

Modern Chemical Industry, 9: 209- 214.

Wang XH, Men ZW, Xu M, Wong L, Liu K, (2014).

Clean Coal Technology, 6: 36- 41.

Xiao SQ, Ma JL, Li XJ, Chen XP, (2012). Industrial

Water Treatment, 6: 16- 19.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

52