Effects of Different Minimal Ventilation Modes on Environmental

Quality and Production Performance of Henhouse

Li Yang

1a

, Chaowu Yang

1,2,* b

, Longhuan Du

3c

, Chenming Hu

1d

, Chunlin Yu

1,2 e

,

Huarui Du

1f

, Qingyun Li

1g

, Mohan Qiu

1,2 h

, Zengrong Zhang

1,2 i

, Xaoyan Song

2j

,

Han Peng

2k

, Jialei Cheng

1,2 l

, Xia Xiong

1,2 m

, Bo Xia

2n

, Siyang Liu

2o

and Shiliang Zhu

1,2 p

1

Animal Breeding and Genetics Key Laboratory of Sichuan Province, Sichuan Animal Science Academy, Chengdu, China

2

Sichuan Animal Science Academy, Chengdu, China

3

College of Architecture and Environment, Sichuan University, Chengdu, China

liqingyun2008@163.com, mohan.qiu@163.com, zhangzengrong2004@163.com,

babalasxy@163.com,429441032@qq.com, 592271024@qq.com, xiongxia20120904@163.com, 12532976@qq.com,

uniyaliu@163.com, zhushiliang1994@163.com

*Corresponding author

Keywords: Minimal Ventilation, Environmental Quality, Production Performance, Henhouse.

Abstract: In order to study the effects of minimum ventilation on the environmental quality and production

performance of chicken coop in cold season, two different minimum ventilation risk control modes were

tested, namely intermittent minimum ventilation mode and continuous minimum ventilation rate mode, and

the changes of internal environmental quality and production performance of two kinds of chicken coop

were compared. The results showed that the environmental quality of the continuous ventilated chicken

house was better than that of the intermittent ventilated chicken house, and the temperature, relative

humidity, ammonia and carbon dioxide concentrations were significantly lower than those of the

intermittent ventilated chicken house (P < 0.05), and the environmental uniformity of the house was

significantly better than that of the intermittent ventilated chicken house. At the same time, the laying rate

and eggshell thickness of chickens were higher than intermittent ventilation chicken house. The results

showed that the continuous minimum ventilation method had better environmental quality in cold season,

and the performance and egg quality of chickens were significantly better than that of intermittent

ventilation method.

1 INTRODUCTION

1

With the development of modern chicken industry,

people pay more and more attention to chicken

a

https://orcid.org/0000-0002-9565-3148

b

https://orcid.org/0000-0001-6537-268X

c

https://orcid.org/0000-0001-7318-1250

d

https://orcid.org/0000-0001-6497-6713

e

https://orcid.org/0000-0001-5657-7886

f

https://orcid.org/0000-0002-0555-8279

g

https://orcid.org/0000-0002-9299-5265

h

https://orcid.org/0000-0002-3079-541X

i

https://orcid.org/0000-0003-0926-6270

j

https://orcid.org/0000-0002-6396-964X

k

https://orcid.org/0000-0002-1828-1782

l

https://orcid.org/0000-0001-7643-4778

m

https://orcid.org/0000-0003-0448-9491

n

https://orcid.org/0000-0003-1687-0337

o

https://orcid.org/0000-0001-8175-5103

p

https://orcid.org/0000-0002-0624-0123

house environment. In the production of laying hens,

feed, temperature, relative humidity, light,

immunization program and many other factors

jointly determine the performance and egg quality of

laying hens, among which temperature accounts for

30%-40%. Temperature is an important

environmental factor affecting the performance of

laying hens. When the breeding environment

temperature is higher or lower than the suitable

range of chickens, it will affect the normal body

metabolism, production performance continues to

decline, induce the occurrence of disease, even death

(Mueller 1959, Al-Saffar 2003, Zhao 2013).

Therefore, in order to maintain the best performance

and egg quality of laying hens, the ambient

temperature must be controlled in a suitable range.

But in winter, the chicken house warm and

ventilation is contradictory, if not properly

controlled, will seriously affect the production

performance of chickens, serious will suffer from a

Yang, L., Yang, C., Du, L., Hu, C., Yu, C., Du, H., Li, Q., Qiu, M., Zhang, Z., Song, X., Peng, H., Cheng, J., Xiong, X., Xia, B., Liu, S. and Zhu, S.

Effects of Different Minimal Ventilation Modes on Environmental Quality and Production Performance of Henhouse.

DOI: 10.5220/0011184900003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 89-94

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

89

variety of diseases, among which respiratory

diseases are the most common.

Winter laying hens ventilation rate affect the

inner temperature stability and air quality, which

affect health and production performance of laying

hens, in order to guarantee the henhouse

environment temperature, most of the henhouse

adopts the model of minimum ventilation rate, the

required ventilation rate, ventilation mode mainly

ruled out the foul air inside the henhouse, sufficient

oxygen supply flock. Its value is usually designed

and calculated based on the principle of carbon

dioxide balance. The value of carbon dioxide

determines the minimum ventilation volume and the

ventilation heat consumption of the chicken house.

In China, the minimum ventilation volume of laying

hens in winter is usually the traditional empirical

value and recommended value, and the minimum

ventilation volume of laying hens in winter is

relatively large. Intermittent ventilation is generally

used in winter to solve the contradiction between

ventilation and heat preservation, but intermittent

ventilation will cause large temperature difference

and temperature fluctuation in the house, which will

affect the performance and health of laying hens.

Wang Yang et al. summarized and analyzed the test

data of NH

3

and CO

2

concentration in laying hens

with different fecal cleaning methods by relevant

scholars at home and abroad, and put forward

suggestions on the value of CO

2

concentration in

laying hens with modern conveyor belt fecal

cleaning. Based on the balance principle of CO

2

concentration. In this paper, the minimum

ventilation rate of laying houses under the risk

control system of continuous ventilation in winter is

set at 0.4 ~ 0.5 m

3

/ (h•kg) (Wang 2017). Based on

this value, intermittent minimum ventilation and

continuous minimum ventilation tests were carried

out in two laying hens with the same space and

breeding scale, respectively, to compare the

environmental quality of the two houses and the

production performance during the test, so as to

provide a certain reference for the accurate risk

control system of chicken houses in cold season.

2 MATERIALS AND METHODS

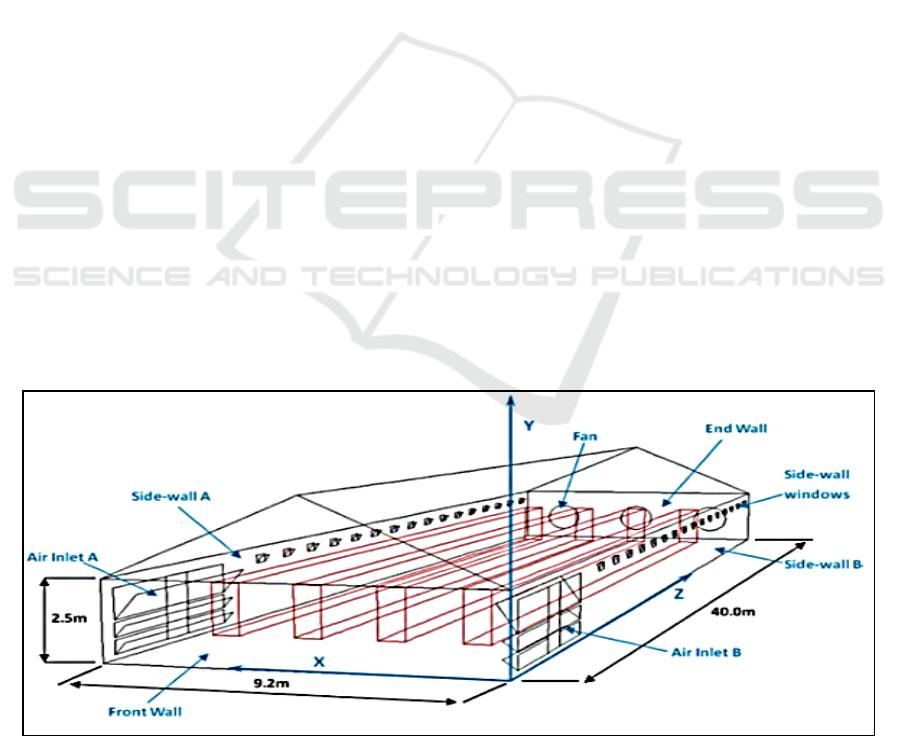

2.1 The Henhouse

Two experimental chicken houses were located in

Chengdu, Sichuan Province, China, and the test time

was January 5, 2021, solstice, February 5, as shown

in Figure 1. The size of the test hen house is 40m in

length, 9.2m in width and 2.5m in height (ceiling

height). the henhouse features two side-wall air

intakes (or air intakes) for cooling the wet curtain in

the summer, located at the front of the house. This

hen house was provided with 2 side-wall air inlets

(or referred as tunnel inlets) located at the front end

of the house. 3 fans were installed at the end wall of

the house, two are temperature control fans, and the

middle one is time control fan. there were in total 32

side-wall windows as shown in Fig. 1. For the 2 air

inlets and all side-wall windows, a bottom hinged

flap mechanism was used to control the opening

angle, enabling a control range from 0° (fully

closed) to 90° (fully open).

Figure 1: Schematic drawing of the henhouse.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

90

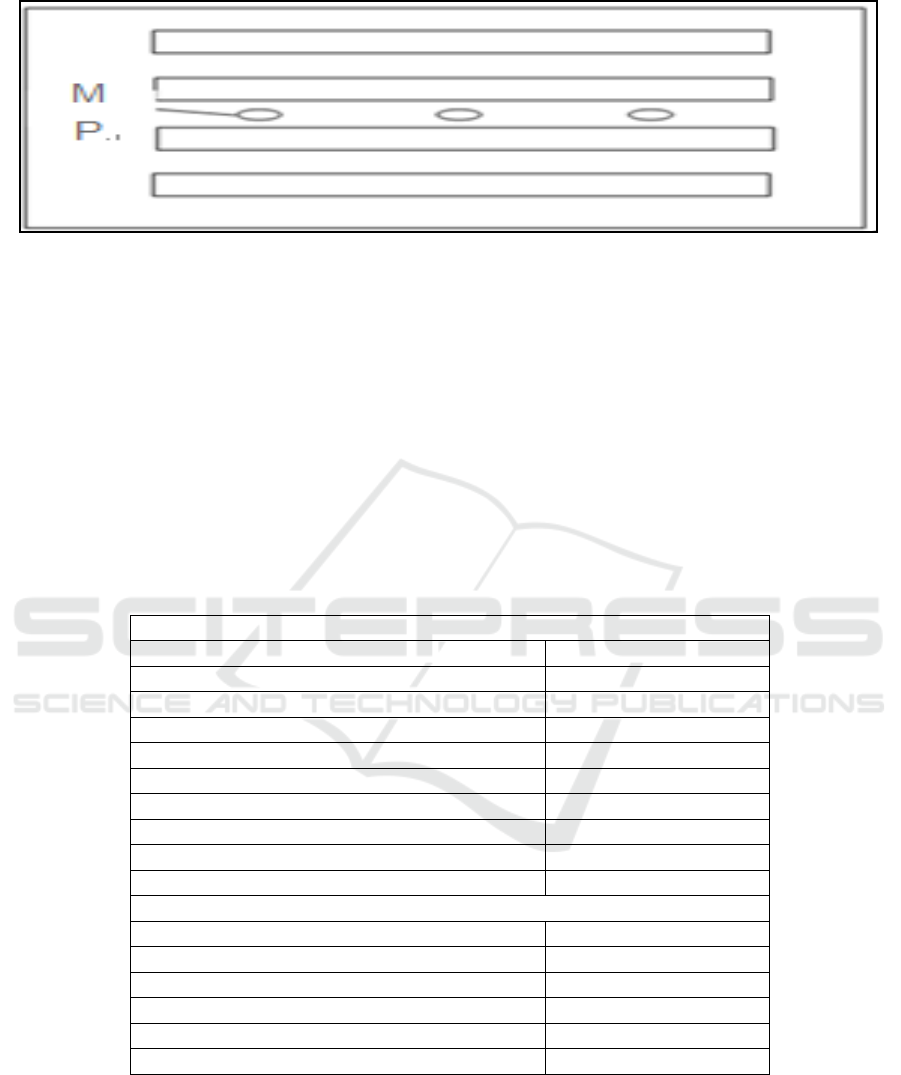

Figure 2: Schematic drawing of the measurement position.

The minimum ventilation volume was 0.5m

3

/

(h•kg) in. The air flow direction of the two

henhouses was air inlet through the side wall

window and air outlet from the rear end fan. One of

them adopts intermittent ventilation mode (IV).

When it is turned on, the ventilation volume of the

controlled frequency conversion fan is set to

150m

3

/min. The fan is set to 5 minutes for one cycle,

and the cycle mode is 2 minutes for opening and 3

minutes for closing. The other one uses a time-

controlled frequency conversion fan for continuous

ventilation (CV), and the ventilation volume of the

fan is set at 60m

3

/min.

2.2 Experiment Animal

During the experiment, 3000 broiler breeders with

an average weight of 2.4kg were bred in both

chicken houses. During the experiment, chickens

were fed and managed strictly in accordance with

the feeding management manual, and they were free

to drink water and eat. Dietary composition and

nutrient levels were shown in Table 1.

Table 1: Composition and nutrient levels of the basal diet (air-dry basis).

Ingredients (%)

Corn 64

Soybean meal 16

rapeseed meal 3

wheat bran 4

corn gluten meal 3.5

Limestone 7.5

CaHpO4 0.8

NaCl 0.3

Premix1) 0.9

Total 100.0

Nutrient levels2)

Metabolizable energy/(MJ/Kg) 11.33

Crude Protein 16

Calcium 3.1

Available Phosphorus 0.42

Lysine 0.84

Methionine 0.4

1) Premix Provided the following Per kg of diets: VA 12500 IU, VD 2500 IU, VE 30 IU, VK3 1.8 mg, VB12 12 ug, biotin 0.2mg, choline

600 mg, Fe 80 mg, Cu 8 mg, Mn 90 mg, Zn 72 mg, I 0.9 mg, Se 0.27 mg.

2) Calculated values.

2.3 Instrumentation

A portable multi-function high-resolution air

velocity meter (Model 9545, TSI, MN) was used to

measure the indoor air velocity, air temperature and

relative humidity. Meanwhile, a compound gas

detector (GT-2000) is used to measure CO2 and

NH3 concentrations in the chicken house. eggshell

Effects of Different Minimal Ventilation Modes on Environmental Quality and Production Performance of Henhouse

91

thickness, egg weight, albumen height, yolk color

and Haugh unit were measured using a thickness

gauge (PEACOCK P-1) and egg quality tester

(ORKA Egg Analyzer EA-01).

2.4 Measurements

Respectively using automatic detection equipment,

daily record two hen house within 24 hours of

temperature, relative humidity, concentration of

carbon dioxide and ammonia, the measurement

location is shown in Figure 2. At the same time, the

egg production rate of each chicken house was

recorded, and randomly selected 200 eggs do

experiments henhouse each egg quality, including

egg weight, eggshell thickness, albumen height, egg

yolk color and hartz units. EXCEL2010 software

was used to build a monitoring database, and the

data of environmental parameters, egg production

rate and egg quality were calculated as the daily

statistical mean, and the environmental parameters

and egg quality were expressed as the mean ±

standard deviation. SPSS 20 was used for one-way

ANOVA, LSD was used for multiple comparisons,

and pair correlation analysis.

3 RESULTS

3.1 Environmental Quality

Two henhouse environment quality parameter

statistics after the results are shown in Table 2, and

(IV) the temperature and relative humidity of hen

house (CV) is significantly higher than the

henhouse, evenness is 5.23 ℃ and 1.25 ℃

respectively, (IV) the henhouse evenness is poorer,

intermittent opening and closing, the main reason for

the henhouse fan fan opens, inner temperature to

produce, make the inner temperature difference,

Similarly, the relative humidity in the house will

also plummet; (IV) The concentration of carbon

dioxide and ammonia gas in the chicken house was

also significantly higher than that in the (CV)

chicken house, in which the concentration of carbon

dioxide was much higher than the standard

requirements and the uniformity was as high as

1058.57 mg/m3. Since carbon dioxide mainly came

from the respiration of the chickens, intermittent

ventilation would also cause the accumulation of

carbon dioxide in the house. Ammonia mainly

comes from the decomposition of excreta of

chickens, and ammonia will also accumulate in

intermittent ventilation mode.

3.2 Production Performance

According to Table 3, the laying rate in (CV) house

was significantly higher than that in (IV) house (P <

0.05), while in egg quality, the eggshell thickness in

(CV) house was significantly higher than that in (IV)

house (P < 0.05). Egg weight in (CV) house was

higher than that in (IV) house, but the difference was

not significant (P > 0.05), albumen height in (CV)

house was lower than that in (IV) house, but the

difference was not significant (P > 0.05), yolk color

and Haugh unit were also not significant (P > 0.05).

Table 2: Average value and average value of environmental quality parameters of two chicken houses.

Ventilation

form

Temperature

(℃)

Relative humidity

(%)

CO

2

(mg/m

3

)

NH

3

(mg/m

3

)

M±SD

UNIF

M±SD UNIF M±SD UNIF M±SD UNIF

IV

23.87

*

±2.

38

6.23 55.42

*

±5.18 5.29 2155.82

*

±568.45 1058.57 1.88

*

±0.39 2.18

CV

20.42±0.

98

2.25 50.60±3.52 4.66 1309.09±63.88 89.26 0.28±0.03 0.08

Note: 1. UNIF is the absolute value of the difference between the highest value and the lowest value at different time or at

different measurement points in the analysis of environmental parameters.2. The data with same or no superscript star(*)

indicates significance (p<0.05) in a list.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

92

Table 3: Laying rate and egg quality.

Ventilation

form

LR

(%)

ST

(μm)

EW

(g)

AH

(mm)

YC HU

IV 63.32 37.63±2.38 60.14±4.22 5.71±0.89 6.37±1.38 73.46±5.83

CV 68.11* 38. 20±3.22* 60.67±3.02 5.65±0.67 6.46±1.55 74.83±7.01

Note: 1.LR, laying rate; ST, shell thickness; EW, egg weight; AH, albumen height; YC, yolk color; HU, Haugh unit.2. The

data with same or no superscript star(*) indicates significance (p<0.05) in a list.

4 DISCUSSIONS

4.1 Environmental Quality Analysis of

Different Ventilation Modes

Among the environmental parameters of chicken

house, temperature is the most significant factor

affecting the health and production performance of

chickens. Compared with other animals, chicken has

a higher temperature, thicker feathers and no sweat

glands. Its body temperature can only be dissipated

by epidermal evaporation and respiration, and its

regulation ability is particularly weak. It is generally

believed that the appropriate temperature of laying

hens is 13-23℃, and the critical temperature is 0-

30 ℃ (Hu 2004). Generally, heavy varieties are cold

and heat tolerant, while light varieties are the

opposite (An 2004). Therefore, in the production of

laying hens, to maintain the best performance and

quality of laying hens, the environmental

temperature must be controlled within the

appropriate range. In winter, the insulation and

ventilation of chicken coop are contradictory to each

other. It is necessary not only to maintain the

appropriate temperature in winter, but also to control

the air quality in the coop. The minimum ventilation

mode is the best method to solve this problem at

present. In this experiment, two control modes of

intermittent ventilation and continuous ventilation

were compared, and the results showed that under

the two ventilation modes, except the carbon dioxide

concentration of intermittent ventilation, other

indoor environmental parameters were in a relatively

suitable range. But sheds (IV) temperature, relative

humidity, concentration of carbon dioxide and

ammonia concentration (CV) is significantly higher

than the henhouse, significant difference (p < 0.05),

continuous ventilation mode of environment

parameters is better than that of intermittent

ventilation mode, especially the uniformity is far

better than the intermittent ventilation mode, under

the condition of guarantee optimum temperature, the

inner environment to stability of the continuous

ventilation mode is stronger, Small fluctuation;

However, the intermittent ventilation mode has poor

uniformity, especially the temperature and carbon

dioxide concentration. When the fan is turned on,

the chickens will suffer a sudden drop in

temperature, which will produce certain stress effect

on the chickens.

4.2 Effects of Chicken House

Environment on Production

Performance and Egg Quality

Different environmental quality can affect the

performance and egg quality of laying hens. In this

experiment, the overall production performance and

egg quality of (CV) chicken house were better than

that of (IV) chicken house. Among them, the laying

rate of (CV) house was better than that of (IV)

house, and the difference was significant (P < 0.05).

In terms of egg quality, there was no significant

difference except eggshell thickness. Compared

with the environmental quality of the chicken house,

both temperature and relative humidity are within

the suitable range of laying hens. It can be seen that

temperature and relative humidity have little

influence on production performance and laying

performance. The main difference lies in the

uniformity of harmful gas concentration and

environmental quality. Research shows that in the

high concentration of ammonia environment,

chicken feed intake, reduce the egg production

performance, egg quality, rate is negatively related

to the inner ammonia concentration, at the same

time, when the inner elevated co2 concentration,

laying hens production performance degradation,

feed conversion rate is negatively related to the

concentration of carbon dioxide, ammonia, The

experimental results are consistent with those of

Reece et al (Reece 1980), When carbon dioxide

levels reach 2% to 3 %, eggshell thinning occurs in

flocks. Due to the intermittent ventilation conditions,

the chickens are intermittently affected by sudden

temperature changes, always under the cold and hot

Effects of Different Minimal Ventilation Modes on Environmental Quality and Production Performance of Henhouse

93

stress response, will cause the chicken immunity

decline, it is very likely to induce some

environmental bacteria disease outbreak.

5 CONCLUSIONS

In the present study, the minimum ventilation

volume designed with 0.5 m

3

/(h•kg) as the

calculation parameter in winter can not only ensure

the temperature requirements of the chicken coop,

but also better achieve the environmental quality

control target. However, this experiment showed

that adopting different risk control time model

would cause different environmental quality in the

barn, and also affect the production performance and

egg quality of the chickens. By comparing two

different control modes, we found that usually takes

5 minutes as a cycle of intermittent risk control

system mode, can cause environmental quality

variation within the hen house increased, especially

the concentration of harmful gases such as carbon

dioxide and ammonia is much higher than continue

with wind model, in terms of production

performance, rate and shell thickness were also

affected. And adopting continuous ventilation mode

of the henhouse, although slightly below intermittent

ventilation mode, but still control within the scope of

a more comfortable, more important is effectively

exhaust the harmful gas of inner, inner environment

parameter to less volatile, reduces the stress reaction

of chickens, significantly improve the rate and egg

quality, therefore, in the cold season, The minimum

ventilation mode with continuous ventilation is

better than the intermittent ventilation mode.

However, in this study, the comparison of energy

consumption and efficiency between the two control

modes was not made.

ACKNOWLEDGMENTS

This work was supported by Sichuan Province Basic

Scientific Research Project (SASA202002); China

Agriculture Research System of MOF and MARA

(CARS-41-04); Sichuan province key research and

development plan (2020YFN0065, 2019YFN0009,

2020YFN0146, 2021YFN0029, 2021YFYZ0031).

REFERENCES

Al-Saffar A A, Rose S P. (2002). World’s Poultry Science

Journal, 58, 317–331

An lilong.2004, Environmental Health of livestock, Higher

Education Press, Beijing, 1

nd

edition.

Hu jianhong, Chen xingping, Jiang jun, et al. (2002).

Livestock ecology,2,58-60.

Mueller W J. (1959). Poultry Science, 38,620-624.

Reece F N, Lott B D. (1980). Poultry Science, 59,2400-

2402.

Wang Yang, Caoyuan W,Baoming Li. (2017).

Transactions of the Chinese Society of Agricultural

Engineering, 33, 240-244.

Zhao Yang, Xin Hongwei, Shepherd Timothy A, et al.

(2013). Biosystems Engineering, 115, 311-323.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

94