Research Progress of Influencing Factors of Biological Contact

Oxidation Method

Leixiang Wu

*

, Zhuowei Wang, Ronghao Guan and Xingchen Liu

State Key Laboratory of Simulation and Regulation of Water Cycle in River Basin, China Institute of Water Resources and

Hydropower Research, Beijing, 100038, China

Keywords: Surface Water Pollution, Sewage Treatment, Biological Contact Oxidation Method.

Abstract: The biological contact oxidation method has the advantages of low operating cost, stable treatment effect,

and good effluent quality, and is widely used to treat domestic and industrial sewage. Based on a large

amount of literature, this research expounds the origin, development, and decontamination mechanism of

the biological contact oxidation method. The main factors affecting the biological contact oxidation method

and its research progress were systematically analysed to provide a reference basis for the further

development of this technology.

1 INTRODUCTION

In recent years, with the acceleration of

urbanization, the contradiction between the rapid

development of agriculture and water pollution has

intensified, and it is urgent to solve the problem of

rural water pollution (Ma, 2021). Traditional water

treatment technology has not adapted to the current

requirements of rural sewage treatment. As a new

and high-efficiency water treatment process, the

biological contact oxidation method has the

characteristics of activated sludge method and

biofilm method and the advantages of stable

treatment effect, impact load resistance and simple

management (Hu, 2015). Since the late 1970s, the

biological contact oxidation method has been widely

used in China, and many scholars have studied the

biological contact oxidation method and made

certain achievements (Jiang, 2013).

2 THE ORIGIN AND

DEVELOPMENT OF

BIOLOGICAL CONTACT

OXIDATION

Biological contact oxidation method is a kind of

biofilm method, which is developed on the basis of

biological filter. At the end of the 19th century,

Blaring first proposed the concept of biological

contact oxidation, and Closs applied for a related

patent in Germany in 1912. Before the 1950s, due to

the small specific surface area of the filter material,

low filter load, large floor space, high cost of

spraying water, and high energy consumption, the

practical application of this method was limited, and

it was not a mainstream water treatment technology

[4]. By the 1960s, with the development of plastic

technology, the filler of the biofilm method was

made into honeycomb or foam, which has the

advantages of light weight, easy processing and

molding, and large specific surface area. It has been

widely used in the contact oxidation process. In the

1970s, Japanese scholars studied the biological

contact oxidation method in depth, further improved

the contact filler, and promoted the engineering

application of the process. At present, the biological

contact oxidation method is widely used in sewage,

water supply purification treatment and river

ecological restoration (Li, 2008).

3 POLLUTANT REMOVAL

MECHANISM

Biological contact oxidation method is an efficient

biological treatment technology that organically

combines activated sludge method and biological

filter technology. It is composed of tank body, filler,

Wu, L., Wang, Z., Guan, R. and Liu, X.

Research Progress of Influencing Factors of Biological Contact Oxidation Method.

DOI: 10.5220/0011186300003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 95-99

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

95

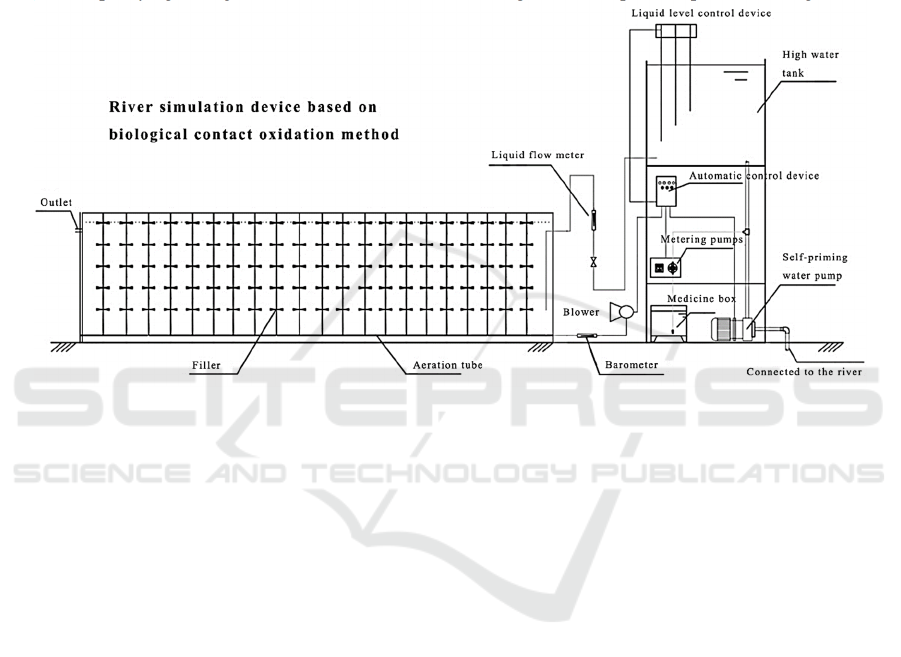

water distribution system and aeration system

(Figure 1). Biological contact oxidation method is

also called submerged biological filter, which

evolved from biological filter and contact aeration

oxidation. The biological contact oxidation method

is to fill the pond with a certain density of fillers and

aerate through the air from the bottom of the pond.

The sewage immerses all the fillers and extensively

contacts with the biofilm on the fillers to achieve the

purpose of purifying sewage under the function of

microbial metabolism. Following the law of

microbial growth cycle, the biofilm purification

effect is not good during the decay period. At this

time, under the impact of wastewater and gas, the

biofilm on the filler falls off quickly and is

discharged from the reactor with the water flow. At

the same time, the biofilm is replenished and

updated in time. As a result, the system can stably

and efficiently remove pollutants in the water body

during the entire operation process (Zhang, 2012).

Figure 1: River simulation device based on biological contact oxidation method.

4 FACTORS AFFECTING THE

REMOVAL OF POLLUTANTS

The pollutant removal effect of biological contact

oxidation method depends on the biological quantity

and activity of the biofilm. The factors affecting the

treatment effect of biological contact oxidation

method mainly include water temperature, pH value,

DO, filler properties, gas-water ratio, organic matter

load, and hydraulic load.

4.1 Water Temperature

Water temperature mainly affects biological

reactions in two aspects: on the one hand, it affects

the rate of enzyme-catalysed reactions; on the other

hand, it affects the rate of matrix diffusion into cells.

In the process of nitrification, the suitable growth

temperature of nitrate bacteria is 35~42℃, and that

of nitrite bacteria is 35℃. Temperature affects the

effect and rate of nitrification reaction of nitrifying

bacteria. The suitable temperature range for the

nitrification reaction is 15~35℃. When the

temperature is lower than 10℃, the nitrification will

be significantly inhibited. The influence of

temperature on nitrogen removal is significantly

higher than that on phosphorus removal, but the

decrease of temperature will change the phosphorus

release and absorption rate of phosphorus

accumulating bacteria (Helmer, 1998).

4.2 pH Value

The pH value is of great significance to the growth

of microorganisms. For most bacteria, the optimal

pH range is 4~7. The pH value is too high or too

low, not only restricts the osmotic function of the

microbial cell surface, but also inhibits the

enzymatic reaction inside the cell. Biological contact

oxidation method has good adaptability to pH.

According to the research results of Villaverde S.,

the suitable pH range for the growth of

microorganisms in the biological contact oxidation

method is 5~9. When the pH=8.2, the

microorganisms grow in the best condition, and the

maximum amount of biofilm will be obtained in this

case (Villaverde, 1997). In the actual operation of

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

96

sewage treatment, if the pH value is not in the range

of 5~9, the pH should be adjusted first.

4.3 Dissolved Oxygen

The biological contact oxidation method uses an

aeration device to aerate the water body of the

reactor, which has three main functions: 1) Provide

oxygen for the oxidation of microorganisms and

synthesize endogenous respiration; 2) Stirring to

maximize water turbulence and improve the mass

transfer effect between biofilm, pollutants, and

oxygen; 3) Promote the renewal of biofilm, improve

biological activity, prevent filler blockage, and

improve treatment effect. Therefore, to improve the

ability of the biological contact oxidation reactor to

remove pollutants, it is necessary to ensure that the

dissolved oxygen concentration in the system is

maintained above the minimum concentration level

required for bacterial metabolism. With the increase

of dissolved oxygen concentration, the ability of

nitrification reaction to remove NH

3

-N increases

significantly, and tends to a stable level when the

dissolved oxygen concentration is 7 mg/L. When the

dissolved oxygen concentration in the system is

lower than 0.5 mg/L, the nitrification reaction

basically stops.

4.4 Filler Properties

Filler is one of the important design parameters of

the biological contact oxidation method. The

performance, quantity, and layout of the filler not

only directly affect the effect of the contact

oxidation method in treating sewage, but also affect

the economic cost of the project. The filling rate of

the filler is between 30% and 70% of the effective

volume of the filter. Insufficient fillers will affect the

removal of pollutants. Too much filler will not only

increase the construction cost, but also hinder the

oxygen transfer rate. The physical and chemical

characteristics of common biological contact

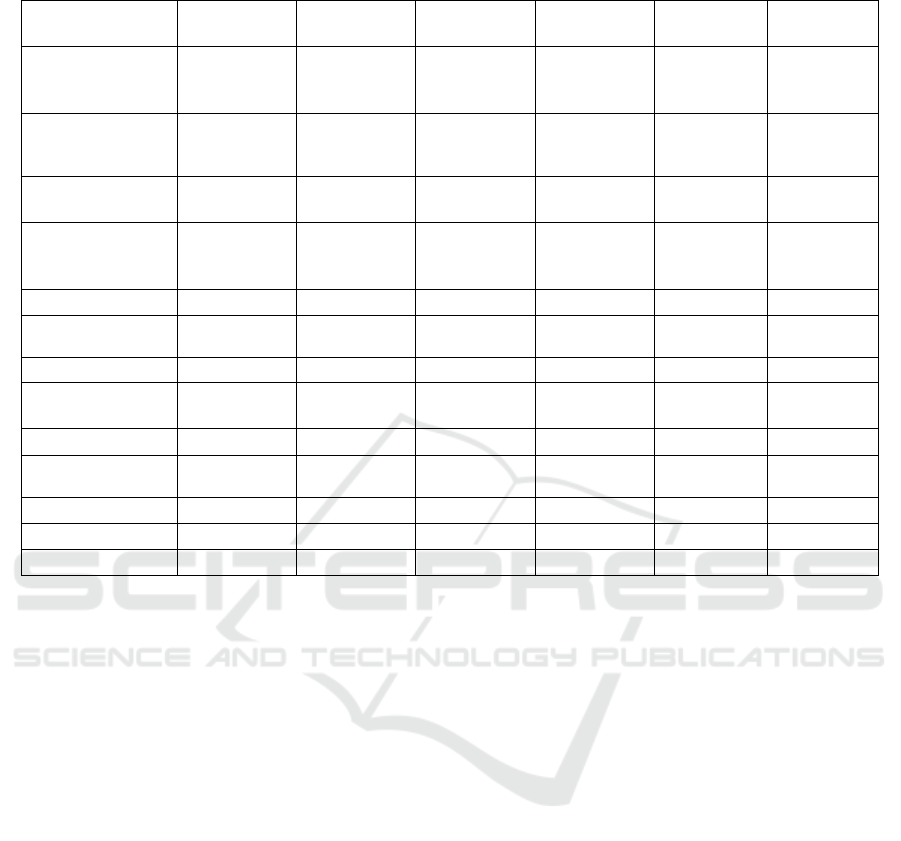

oxidation fillers are shown in Table 1 (Zhang, 2015).

4.5 Gas-Water Ratio

The gas-water ratio is the key to the design of the

application of biological contact oxidation

technology, and it plays a decisive role in the

treatment effect, the project investment, and the

operating cost. The gas-water ratio must be

maintained in a reasonable range, too high or too

low, it will have an adverse effect on the system.

When the air-to-water ratio exceeds a certain

threshold, long-term high-intensity aeration will

cause turbulence in water flow, produce a large

shear force to act on the biofilm, cause the biofilm to

fall off more seriously, and increase system

operating costs. When the air-to-water ratio is too

low, the DO content and mass transfer power in the

system will be insufficient, which will adversely

affect the metabolic activity of the aerobic

community and cause the system effluent water

quality to not meet the standard. The death of

aerobic microbes and the proliferation of anaerobic

microbes caused by insufficient aeration will

produce metabolic gas (H

2

S, NH

3

, etc.), resulting in

more voids in the biofilm, significantly weakened

biofilm adhesion, and even large areas of biofilm

shedding, which will eventually lead to the quality

of treated water deteriorated. Nitrogen and

phosphorus removal in bioreactors is a continuous

and complex reaction mechanism (Liu, 2003).

Existing research results show that, during the

intermittent aeration operation of the biological

contact oxidation system, the gas-water ratio is

preferably in the range of 5:1 to 10:1.

4.6 Volume Load of Influent Pollutants

The volume load of influent pollutants is one of the

important parameters that affect the design and

operation of the contact oxidation process. In the

biological treatment process, it comprehensively

reflects the concentration of organic matter in the

influent water and the hydraulic retention time.

There will be an optimal balance between influent

load, pollutant treatment effects and economic

benefits. When the volume load increases within a

certain range, the concentration of organic matter in

the sewage is relatively high, and the advantage of

easy cultivating bacteria has a strong metabolic

effect, thereby promoting the biodegradation of

pollutants (Ge, 2015). The small-scale trial study of

Zhang et al. with Xiaosha River sewage as the

treatment object in Shandong Province has similar

results (Zhang, 2012). When the volumetric load of

COD

Cr

increases to a certain range, it may change

the dominant bacteria in the reactor to heterotrophic

bacteria, inhibit the nitrification reaction, and

ultimately affect the removal effect of NH

3

-N (Lin,

2015).

Research Progress of Influencing Factors of Biological Contact Oxidation Method

97

Table 1. Physical and chemical properties of various fillers.

Compare items Honeycomb

packing

Soft filler Semi-soft

material

Combination

packing

Elastic filler Suspended

packing

Factory-supplied

specific surface

area (m

2

/m

3

)

150~200 500~700 150~200 200~300 200~300 150~250

Use specific

surface area

(m

2

/m

3

)

SAB

a

SAC

b

SS

c

SS SL

d

SL

Increase

oxygenation rate

-5% -10% 30%~40% 25%~35% 70%~100% 1%~30%

Water and air

distribution

performance

Poor Poor General Better Good Better

Film performance General Good General General Good General

Drag film

p

erformance

Poor Poor General General Good General

Blockage More serious No No General No No

Clumping and

broken wire

No More serious General No No No

Service life 4~6 years 1~2 years 5~8 years 5~8 years 7~10 years 5~8 years

Replacement of

filling

INC

e

INC INC INC INC CON

f

Support CON CON CON CON CON INC

Transport INC CON CON CON CON INC

Price (Yuan/m

3

) 700 100 220 200 250 1000

a

SAB: Small after blockage

b

SAC: Small after clumping

c

SS: Slightly smaller

d

SL: Slightly larger

e

INC: Inconvenient

f

CON: Convenience

4.7 Hydraulic Load

Hydraulic load is the amount of wastewater treated

per unit volume of filter media per day and is an

important parameter for the design and operation of

sedimentation tanks and biological filters. Studies

have shown that for treatment systems of different

sizes, when the hydraulic load increases within a

certain range, it has little effect on the performance

of the biological contact oxidation system COD

Cr

and NH

3

-N. As the hydraulic load further increased,

the removal rate of COD

Cr

and NH

3

-N decreased

significantly. This also shows that the biological

contact oxidation method has better resistance to

hydraulic load impact.

5 CONCLUSION

At present, surface water sources are generally

polluted, which has become a major factor

threatening the quality of water supply. The

improvement of the traditional treatment process and

the introduction of biological contact oxidation

treatment technology into the water treatment

process has gradually become an effective means to

treat micro-polluted source water and improve the

quality of drinking water. This research expounds

the origin, development, and decontamination

mechanism of biological contact oxidation method

by consulting many literature, and systematically

analyses the main factors affecting biological

contact oxidation method, including water

temperature, pH value, DO, filler properties, gas-

water ratio, organic matter load, and hydraulic load.

Biological contact oxidation method has become one

of the main technologies for wastewater treatment in

China. This study provides a reference for the

further development of this technology.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

98

ACKNOWLEDGEMENTS

This work was supported by the National key

research and development plan special (No.

2018YFC0407702), the National Natural Science

Foundation of China (No. 51879279, 51879278) and

the Ministry of Water Resources Department Project

(No. 12630100100020J002).

REFERENCES

Ge J., Hu X., Pang Y., Huang T., Teng Q. (2015).

Research on Purifying Lightly Contaminated Water in

Baihe River by Gravel Contact Oxidization Process.

Research of Environmental Sciences. 28, 816–22.

Helmer C. and Kunst S. (1998). Low temperature effects

on phosphorus release and uptake by microorganisms

in ebpr plants. Wat. Sci. Tech.. 37.

Hu P. (2015). Experimental research on fine bubble

aeration and biofilm treatment of rural sewage. Master

Thesis. China Institute of Water Resources and

Hydropower Research.

Jiang R., Yu Z., Li J., Pan B., Sun W., Wang F. (2013).

Research Situation of Bio-contact Oxidation Process.

Environmental Science and Management. 38, 61-

63+93.

Li L., Wen D., Zhang H., Xie S. (2008). Pilot Experiment

on the Treatment of the River Wastewater by a Step-

Feed Biological Contact Process. Environmental

Science. 29, 2227–2234.

Li L., Zhang H., Xie S., Wen Donghui. (2008).

Experimental Study on Treatment of River

Wastewater by Biological Contact Oxidation Process.

China Water & Wastewater. 24, 25-28+33.

Lin J. L., Tu Y. T., Chiang P. C., Chen S. H., Kao C. M.

(2015). Using aerated gravel-packed contact bed and

constructed wetland system for polluted river water

purification, A case study in Taiwan. J. Hydrol.. 525,

400–8.

Liu J., Wang B., Pan D., Li S., Wang P. (2003). Study on

the denitrification route in aerobic denitrification

process. Industrial Water Treatment. 23, 53–56.

Ma B., Guan R., Liu L., Huang Z., Qi S., Xi Z., Zhao Y.,

Song S., Yang H. (2021). Nitrogen Loss in Vegetable

Field under the Simulated Rainfall Experiments in

Hebei, China. Water. 13, 552.

Villaverde S. (1997). Influence of pH over nitrifying

biofilm activity in submerged biofilters. Water

Research. 31, 1180–1186.

Zhang X. (2015). Experimental Study on Small Integrated

Biological Contact Oxidation Device for Processing

University Campus Sewage. Master Thesis. Xinjiang

Agricultural University.

Zhang Y., Xie B., Zhang Z., Wang H. (2012). Feasibility

Study on Treatment of River wastewater by Biological

Contact Oxidation Process. Technology of Water

Treatment. 38, 51–54.

Research Progress of Influencing Factors of Biological Contact Oxidation Method

99