Research and Application of Microbial Enhanced Oil Recovery

Technology in High Waxy Oil Reservoirs

Rui Wang

1a

, Guan Wang

1

, Pei Wang

2

, Shasha Liu

1

, Chao Wang

1

, Jizhe Jing

1

, Ying Liu

1

,

Yajuan Tang

1

, Jinxiu Du

1

and Dong Xuan

3

1

Engineering Technology Research Institute, Huabei Oilfield Company of PetroChina, Renqiu, Hebei, China

2

The Forth Exploitation, Huabei Oilfield Company of PetroChina, Lang Fang, Hebei, China

3

Production Management Department, Huabei Oilfield Company of PetroChina, Renqiu, Hebei, China

Keywords: High Waxy Oil Reservoir, Microbial Oil Recovery, Compound Bacteria, Nutrition System.

Abstract: To solve the problems of high wax content and high freezing point in block Q, the compound strain which

could reduce wax content by 40% was selected through laboratory experiment and performance evaluation.

The nutrition system formula suitable for the target reservoir was obtained. After the formulation system

was applied to block Q, the colloid asphaltene and wax content of crude oil decreased, which was directly

reflected in the decrease of viscosity and solidifying point of crude oil. The solidifying point decreased by

12℃. The oil well fluid production increased and watercut decreased, achieving oil-increasing effect.

1 INTRODUCTION

1

The average porosity of block Q is 28.8% and

average permeability is 197.1mD, which is a high

porosity and medium permeability reservoir. The

high waxy content (32.1%) and high solidifying

point (40.1℃) leaded to poor liquidity and serious

paraffin precipitation in wellbore. After water

flooding development, the temperature of

near-well-bore area decreased. The precipitation and

deposition of wax blocked near-well-bore area and

reduced the permeability. The wax precipitation in

well shaft, string and borehole is serious. It seriously

affected the normal production and restricted the

efficient development of oil fields.

In order to solve the problems of high wax

content and poor fluidity of block Q, the degradation

of paraffin in crude oil by microorganisms and the

improvement of rheological properties by

metabolites were studied. The microorganisms for

wax removal generally use wax, colloid and

asphaltene as carbon sources (Qin 2015, Chen 2004,

Yi 2009), which can actively degrade the heavy

components, thus reducing the viscosity and

improving the fluidity of crude oil (Wang 2017,

Wang 2017). Microbial oil recovery technology is

a

https://orcid.org/0000-0001-7876-3954

simple in construction and has a long validity

period. It can avoid damage to oil layer caused by

hot washing with non-toxic and odor-free. It is safe

and environmentally friendly, and has good

economic, social and environmental benefits.

2 BACTERIA SCREENING

Experimental conditions: Crude oil, produced water

and injected water from block Q, temperature of

52℃.

Experimental methods: 100ml of produced water

was taken by 2% of the bacteria solution. 10g of oil

sample was added. After mixing, the sample was put

into a constant temperature shaker and cultured at

52℃. A blank test was conducted at the same time.

After 72 hours, the change of crude oil performance

was evaluated (Liu 2001, Shi 2008).

2.1

Adaptability Evaluation of Strain

Species and Reservoir

Environment

The strains were inoculated into the produced and

injected water for fermentation and culture, and then

the concentration of bacteria was observed with a

counter. The results showed that 11 selected strains

Wang, R., Wang, G., Wang, P., Liu, S., Wang, C., Jing, J., Liu, Y., Tang, Y., Du, J. and Xuan, D.

Research and Application of Microbial Enhanced Oil Recovery Technology in High Waxy Oil Reservoirs.

DOI: 10.5220/0011190200003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 127-131

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

127

grew well in formation and injection water. The

bacteria concentration was from 2.1×10

8

to 5.4×10

8

/mL, showing perfect adaptability.

Table 1: Comparison of bacterial concentration in different

production environments (10

8

/ml).

Bacterial Produced wate

r

Injected wate

r

1903 3.00 3.12

HB3 5.28 5.07

BB2 2.96 3.45

1906 2.52 2.67

DM-2 3.43 3.12

1665 3.54 3.77

5S 5.44 5.37

5BQ 3.47 3.62

6H 2.89 3.37

6B 3.22 3.47

5BZ 2.14 2.66

2.2 Emulsification Effect Evaluation

The selected strains had different degrees of

emulsification effect after acting with crude oil,

among which 6H, 6B, 5S, 5BQ and 5BZ had the best

emulsification effect, and oil and water were

completely mixed without obvious stratification.

Table 2: Oil emulsification comparison.

Bacterial Emulsification level

1903 4

HB3 3

BB2 4

1906 4

DM-2 4

1665 4

5S 5

5BQ 5

6H 5

6B 5

5BZ 5

The level is based on < Q/SY HB 0209-2016>.

2.3 Viscosity Reduction Evaluation

According to the experimental results, 5S, 6H and

6B had better viscosity reduction effect.

Table 3: Comparison of viscosity reduction effects of

different strains.

Bacterial Viscosity, mPa.s Reduction rate, %

Blan

k

39.8

/

1903 29.1

26.85

HB3 35.6

10.58

BB2 42.1

-5.80

1906 32.1

19.34

DM-2 43.2

-8.57

1665 33.5

15.65

5S 25.4

36.02

5BQ 30.2

24.10

6H 25.8

35.17

6B 27.4

31.02

5BZ 32.3

18.76

3 NUTRITIONAL SYSTEM

SCREENING AND

EVALUATION

3.1 Nutritional System Screening

The selection of nutrients follows these principles:

(1) Five nutrient elements for strain growth are

basic. (2) The cost is low. (3) A good effect of strain

proliferation and viscosity reduction is needed. (4)

The compatibility with reservoir formation water is

well with no precipitation reaction.

Crude oil is the main carbon source, and glucose

and sucrose are added as supplements. Nitrogen

sources are mainly nitrate, ammonium salt, urea, etc.

Inorganic salts are phosphate, sulfate and

compounds containing sodium, potassium and other

metallic elements. Growth factors are mainly

vitamin, amino acid, purine and pyrimidine. Yeast

extract and peptone contain production factors.

Based on the above principles, six formulas in Table

4 are formed.

Table 4: Six different microbial formulations (unit: %).

Component F-1 F-2 F-3 F-4 F-5 F-6

Nitrogen source a 0.25 0.20 * * * *

Nitrogen source

b

* * * 0.45 0.45 0.45

Sodium 0.10 0.10 0.10 * * *

Growth factors 0.20 0.20 0.20 0.10 0.15 *

Inorganic salt a * 0.35 0.35 0.01 0.01 *

Inorganic salt

b

0.35 0.35 * * 0.35 0.35

Inorganic salt c 0.35 * 0.50 0.40 * 0.35

Nitrogen source c * * 0.45 0.45 0.45 0.45

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

128

Inorganic salt

d

0.03 0.03 0.03 * * *

Microelement 0.17 0.17 0.17 * * *

Carbon source 0.10 0.10 0.10 * * *

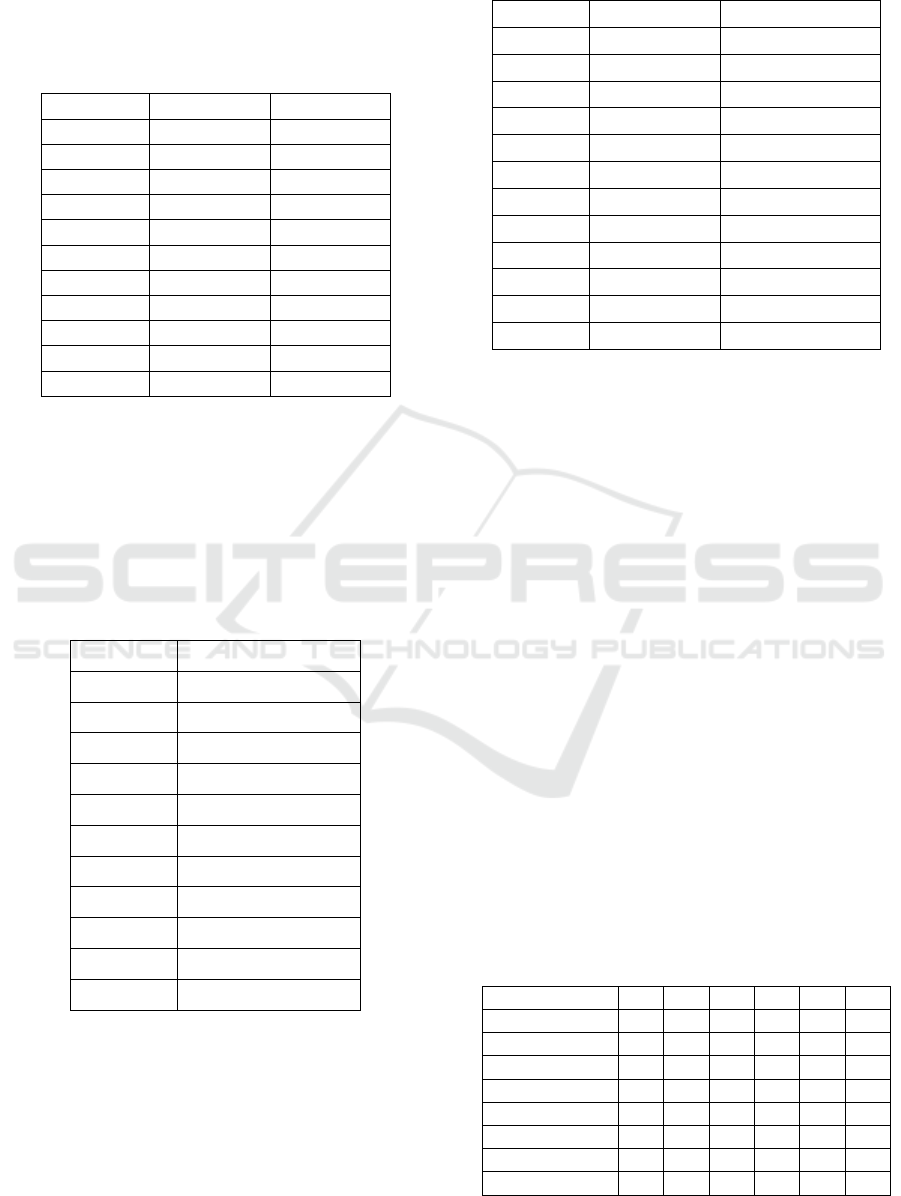

3.1.1 Emulsifying and Dispersing Effect

After being activated for 24 hours, 2% of selected

strains were transferred to the corresponding

nutritional formula added with 10% of crude oil. The

culture medium was carried out on a 150rpm shaker

at 52℃ for 5 days. Then the dispersion performance

was evaluated by using NIR Turbiscan with the

instability coefficient. The higher the instability

coefficient was, the better the dispersion

performance was. The results showed that 6H, 6B

and 5S of the selected strains had strong emulsifying

and dispersing effect in two different formulations.

But the emulsifying and dispersing effect was better

when the three strains were mixed in equal

proportion.

(a) F-3

(b) F-6

Figure 1: Dispersion effects comparison of different

strains.

3.1.2 Surface Activity of Microbial

Fermentation Broth

The culture solution was centrifuged (at 5000rpm for

20min), and the residual crude oil and cells were

removed by extraction and filtration to obtain a clear

liquid sample. The surface tension was measured

after standing at 25℃ for 1 hour. The results showed

that the combination strain could better reduce the

surface tension.

Figure2: Comparison of surface activities of different

strains.

3.1.3 Viscosity Reduction Effect

The strains were inoculated into a mixture of crude

oil sample and nutrient solution at a ratio of 3:7, and

cultured on a shaker for 5 days. Then the samples

were dehydrated to test the crude oil viscosity. The

experimental results were shown in Figure 3. The

results showed that the compound formula had

better viscosity reduction effect.

Figure 3: Comparison of viscosity reduction effects of

different formulas.

The wax content and freezing point of crude oil

were measured after dehydration. The experimental

result showed that F-3 had better effect.

Table 5: Comparison of wax content and freezing point of

different strains.

Wax

content

%

Decline rate

%

Freezing

point

℃

Blan

k

30.84

/

41.3

F-3 18.47 40.1 28.2

F-6 24.27 21.3 32.5

Research and Application of Microbial Enhanced Oil Recovery Technology in High Waxy Oil Reservoirs

129

3.2

Evaluation of Formula

Optimization

In order to further reduce the field injection cost, the

formulation 3 and 6H, 6B and 5S were selected for

further optimization. By comparing the properties of

different formulas, N-2 had better effect of

emulsifying, reducing wax content reducing and

crude oil viscosity decline.

Table 6: Optimized system formula (unit: %).

Component F-3 N-1 N-2 N-3

Microorganism 2.00 2.00 2.00 2.00

Sodium 0.10 0.08 0.05 0.03

Growth factors 0.20 0.15 0.10 0.05

Inorganic salt a 0.35 0.30 0.25 0.20

Inorganic salt c 0.50 0.35 0.25 0.20

Nitrogen source c 0.45 0.35 0.20 0.10

Inorganic salt d 0.03 0.02 0.01 0.01

Microelement 0.17 0.10 * *

Carbon source 0.10 0.10 0.10 0.10

Table 7: Performance parameters comparison of optimized

systems.

Formula Blank F-3 N-1 N-2 N-3

Viscosity

mPa.s

39.8 17.2 17.5 17.9 18.9

Surface tension

mN/m

56.50 38.15 40.12 40.65 42.31

Wax content

%

30.84 18.47 18.67 17.95 19.34

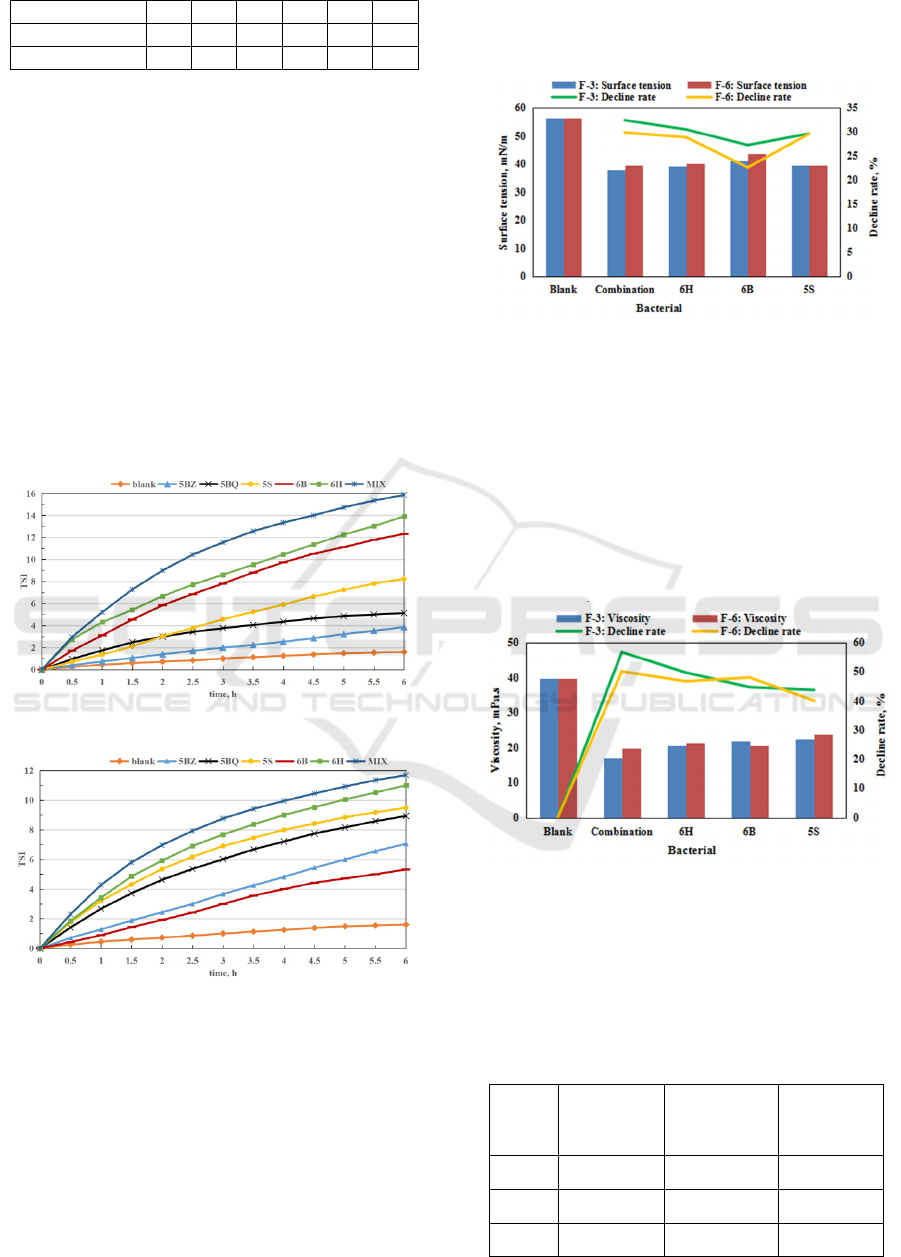

4 FIELD APPLICATION EFFECT

From 2019 to 2020, microbial oil recovery was

carried out in 2 well groups in block Q. After the

measures, the total bacterial concentration was

effectively increased from 10

4

/mL to 10

7

/mL. The

surfactant content was increased from 12.1mg/L to

60.4mg/L, which was conducive to crude oil

recovery. After microbial action, the gelatinous

asphaltene content and wax content decreased,

which was directly reflected in the decrease of the

viscosity and freezing point of crude oil. The

freezing point decreased by 12℃. The ascending

current of oil well decreased significantly and the

load was reduced.

Figure 4: Changes of microbial concentration of well Q53.

Table 8: Changes of crude oil properties before and after

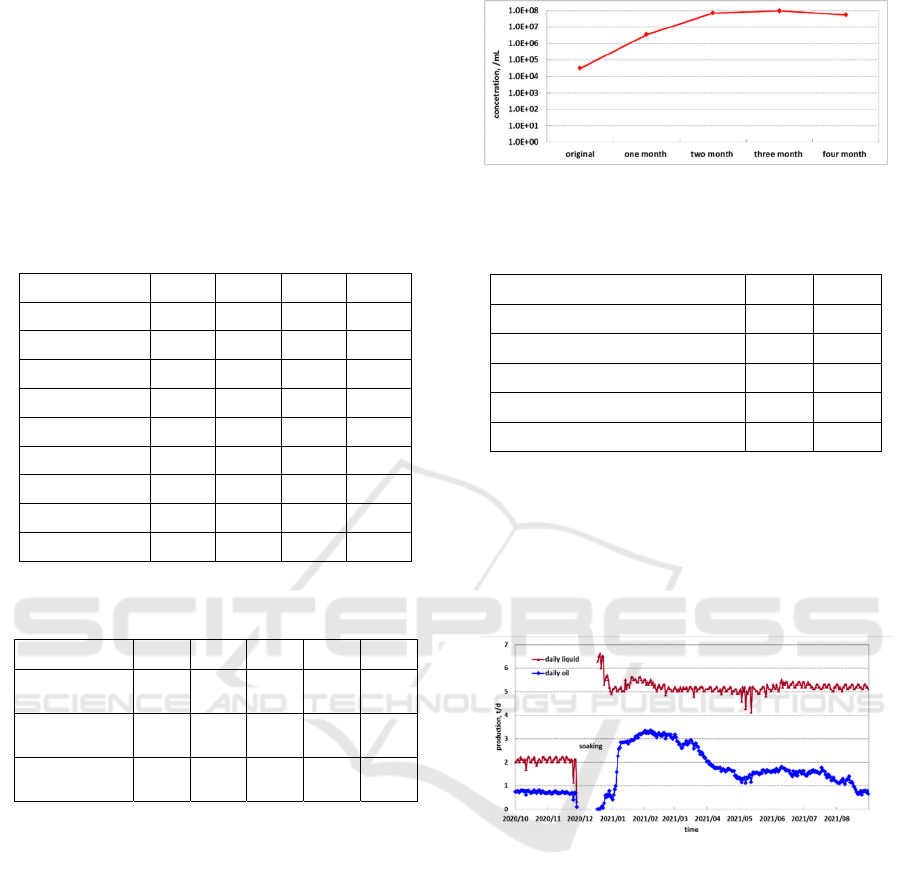

the microbial measures of Q53.

Time

Before Afte

r

Viscosity, mPa.s 16.1 9.8

Wax content, % 40.3 30.1

Freezing point, ℃ 40.0 28.0

Colloid asphaltene content, % 8.6 8.3

Saturated hydrocarbon content, % 62.2 54.2

After the implementation of huff and puff, the

liquid production of well Q53 increased and

watercut decreased. The daily production of liquid

increased from 2.1t/d to 5.3t/d. The daily production

of oil increased from 0.8t/d to 3.2t/d, watercut

reduced by 22.3%. The accumulative oil was 266t.

Figure 5: Production curve of well Q53.

5 CONCLUSION

1. Aiming at high waxy oil reservoirs, the selected

strains have good compatibility with the target

reservoir. After the compound strains act with crude

oil, miscible emulsification can occur in oil and

water. The surface tension is reduced by 32.47%, the

wax content is reduced by 40.1%, the viscosity of

crude oil is reduced by 56.7%, and the fluidity of

crude oil is improved.

2. The microbial recovery measures in block Q

take effect significantly, which suggest that MEOR

can improve oil displacement efficiency. This

technology provides the theoretical and practical

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

130

support for MEOR of high waxy reservoir and can

become one of the effective means to increase

production in the late waterflood development.

REFERENCES

Cheng A.H., YU J., FANG X.X. (2004). Improvement of

Qil Recovering Rate by Microbial Clearing and

Preventing Was and Its Application in Field Test. J.

Xinjiang Agricultural Sciences. 41: 70-72.

Liu W.G., Zhao B., Zhang H. (2001). Screening,

Performance Evaluation And Site Application of

Paraffin Thirsty Bacteria in Low Permeability

Reservoir. J. Special Oil & Gas Reservoirs. 8: 52-92.

Qin F.L., Ke C.Y., Sun F.L., 2015, Principles and Applied

Techniques of Microbiology in Oil&gas Field. Science

Press Publishing.

Shi Y., Ji R.L., Wang S.J. (2008). Screening and

Evaluation of Bacterial Species Using Petroleum

Hydrocarbon as the Sole Carbon Source for Oil

Recovery. J. Oilfield Chemistry. 25: 366-368.

Wang W.Q. Liu Y., Wang G.F. (2017). The Effect of a

Wax Strain on the Wax-removal and

Viscosity-reduction in Waxy Crude Oil. J. Journal of

Engineering Thermophysics. 38: 1906-1910.

Wang W.Q., Li J., Wang G.F. (2017). The Selection of

Paraffin-degrading Bacteria and Their Effects upon

the Rheological Characteristics of Heavy Crude Oil. J.

Journal of Southwest Petroleum University (Science

& Technology Edition). 39: 176-181.

Yi S.J., Hu K., Li B. (2009). Field Application of the

Technology of Microbial Paraffin Cleaning and

Preventing in Well of High Temperature and

Hyperhaline of Jianghan Oilfield. J. Journal of Oil and

Gas Technology. 31: 146-148.

Research and Application of Microbial Enhanced Oil Recovery Technology in High Waxy Oil Reservoirs

131