Potentials of the Dry Granulation by Roller Compaction

Yujie Zhang

University of Edinburgh, Scotland, U.K.

Keywords: Roller Compaction, Dry Granulation, Agglomeration, Pharmaceutic Engineering, Drug Production.

Abstract: The latest trends in the field of pharmaceutical engineering are regarding roller compaction. Roller

compaction technology is a well-established strategy particularly involved in the medical industry. This

developing process has a great impact on the manufacturing of oral solid dosage forms while containing high-

quality active pharmaceutical ingredients (API). When the medical industry tends to develop a tablet, there

are three basic processing routes that have been considered: direct compression, dry granulation, and wet

granulation. Among these three high-efficiency productive ways, dry granulation is a process that compresses

powdery ingredients into tablets without adding any liquid solution. Dry granulation is carried out using either

slugging or roller compaction techniques. This pharmaceutic process has potentials for drug development as

it has been proved to continuously manufacture tablets by working with compaction machines. Roller

compaction employed to dry granulation can provide more advantages compared with other processing

methods. However, there are still have some challenges that this technology and researchers need to face.

Improvements on the dry granulation by roller compaction technology would give a great contribution to drug

development and goods production.

1 INTRODUCTION

The manufacture of processing solids into

pharmaceutical tablets is a multi-stages assembly line

whereby scientist has used this process for hundreds

of years. Most compressed tablets are required to go

through several procedures started from ingredient

dispensing. The ingredients will be divided by

accuracy, mixed with excipients through blenders,

and powders aggregated into granules. The dry

granulation is then compressed and coated into tablets

by using compaction techniques. Nowadays, there are

typically three similar routes for solid dosage

processing, including direct compression, dry

granulation, and wet granulation. Three alternative

procedures share similarities and differences. Among

these routes, direct compression is the simplest

process by bleeding the powder of API with excipient

particles and then compressing them directly into a

tablet machine. Although direct compression is the

most economical way in the manufacturing industry,

it cannot apply in many cases due to the segregation

of particles during routine processing. Most

manufacturing industries prefer granulation instead of

direct compression.

Granulation is a process which helps to avoid

segregation within particles. It is carried out in order

to let powder particles adhere to each other, resulting

in a high density of products which is known as

granules. Dry granulation is processed with no aid of

liquid blenders whereas wet granulation is required.

In the dry granulation process, powder particles

compacted by a force, causing adhesion. The powder

would be dried and physically milled to form granules

(Stutzman, 2020). Dry granulation is suitable in the

case of APIs that are hydrophilic and sensitive to heat,

which wet granulation cannot approach. Granulation

is a more challenging process than direct compression

because it requires higher techniques and more

complex steps. Researchers need to consider the

impact of high pressure from compaction machines

whether it would induce physical or chemical change

on APIs. However, the advantages of dry granulation

cannot be ignored, especially involved roller

compaction technology.

Zhang, Y.

Potentials of the Dry Granulation by Roller Compaction.

DOI: 10.5220/0011202700003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 303-307

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

303

2 DRY GRANULATION BY

ROLLER COMPACTION

Roller compaction technology is considered a well-

known and economic granulation method for drug

development. Dry granulation is a continuous method

with a low amount of energy required and suitable for

compounds that are sensitive to heat (Peter et al.

2010). During the process of dry granulation,

intragranular excipients would be compacted through

a roller compaction machine and result in granules.

Dry granulation has the same prior procedures with

direct compression, but the resulting powder would

continue to go through additional compaction and

sequentially form dried granules. The most important

parameters involved in this process are powder

feeding, pressure control, roll surface, and gap region,

which take place in the machine of roller compaction.

The common way for manufacturing granulation is

roller compaction, where the powder is compressed

into a ribbon before segregation happens. The powder

is fed into a feed hopper first and then passes through

a tube named screw feeder. After that, particles with

a bleed of the API and the excipients would load

through two counter-rotating rollers within the

compactor machine (Stutzman, 2020). Two rollers

keep rotating in order to squeeze the powders within

a small gap between rollers, generating a dried, solid

ribbon. The solid ribbon is then milled into small

fragments by crusher, blended with extragranular

excipients, and given an end product of tablets by

compressing the mixture, the process can be seen in

Figure 1, raw material is fed into the machine with a

final product of tablet (Hudon et al. 2019).

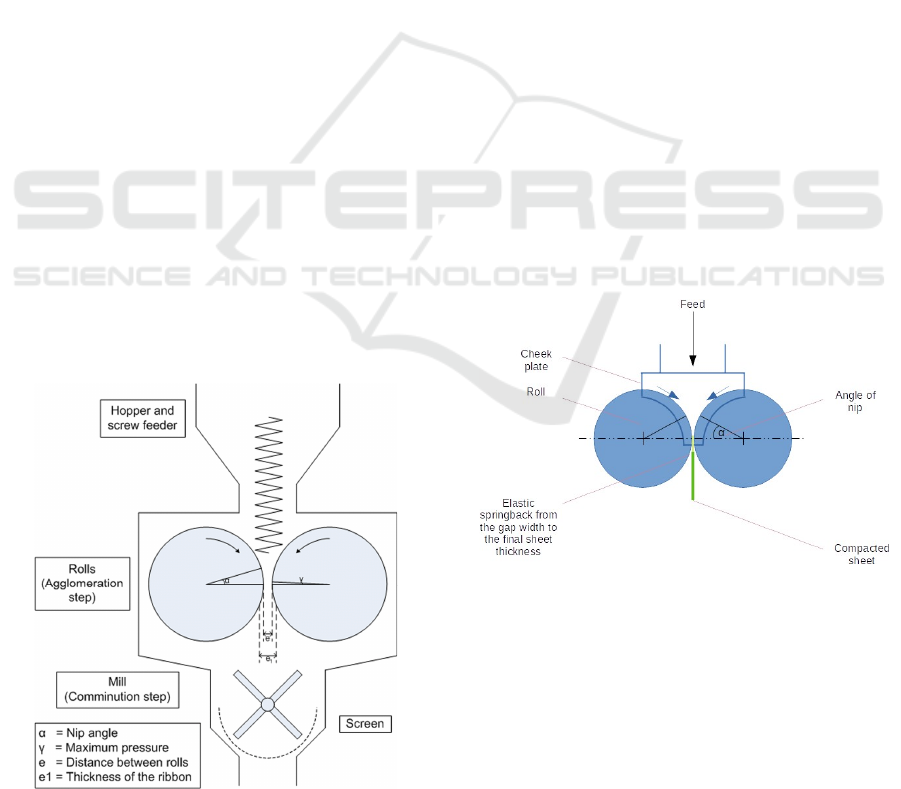

Figure 1: Process of roller compaction within the compactor.

Dry granulation by roller compaction is separated

into two alternative steps. The first step is

agglomeration started from putting the raw material

into the machine. The flowing powder is passed

through the feed hopper by using a feed screw to

transport it into the rollers, result in a solid form of a

ribbon. The second step is called the size reduction

step which compresses the ribbon into granules (Teng

et al. 2009). Each step plays an important role in the

granulation process. Variation happens during the dry

granulation that would affect the final quality of

tablets. Granulator speed is a possible variable that

would decrease the production of fine materials (Rana

et al. 2011). By understanding the principles of

compaction roller press, different zones are shown

within the compactor, as can be seen from Figure 2.

Two rotating rollers are the key point by applying a

force to compact powder into the solid ribbon. Unique

angle and specific shape of rollers that would allow

producing the amount of solid product. During the

agglomeration step, powder pass through the

compaction zone starts at the first zone, the nip

region. Particles within the power would break down

under the force of two plates. Then, powders would

be squeezed into small pieces of fragments under the

pressure of two rolls. Fragmentation takes place in the

roll gap and releases ribbon that bonds by dried

particles into the next stage (Rana et al. 2011). In this

whole process, the main compaction force is carried

out by the two rollers as it solves the big problem

about adhesion between particles.

Figure 2: Compaction zone of two rollers within the

compaction machine.

Instead of using liquid binders to stick each

particle, dry granulation depends on the compound

itself. During the compaction process, the power

suffered from great pressure would become easier to

be broken down. It has been indicated that materials

pass through the two rolls which give a very high

pressure, allowing to completely compact powder and

result in dried flakes. Also, the smooth surface of

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

304

rollers is beneficial for particles sticking and reduced

the use of lubricant. The different surfaces of rolls

would have more or less gripping force for the

compaction (Pietsch, 2002). The technology of

manufacturing granules from raw material has been

adapted to many industries since it was considered as

an economic way. Researchers need to control

parameters in roller compaction so that the machine

would effectively produce tablets. The density of the

ribbons is a relative parameter that has the ability to

control the flowability of granules and the

compactibility of final products (Peter et al. 2010).

Many results show that a large density of the ribbon

would manufacture a small number of fine granules

after granulation, thus there would have a better

flowability but a low rate of compactibility.

Comparing the quality of granules with the products

obtained from direct compression, there would be a

reduction in tablet strength due to the loss of

compactibility.

3 ADVANTAGES OF DRY

GRANULATION

The most obvious difference between dry granulation

and wet granulation is that dry granulation is not

required for liquid content. The major advantage of

dry granulation is that the process is suitable for the

API or excipients which are sensitive to heat and

moisture. This dry formulation of the drug satisfies

the compound which has a low melting point or

contains hydrophilic contents. Dry granulation is the

benefit to the manufacturing industry which

progresses a more economic and less equipment way

compared with wet granulation. Another advantage of

roller compaction is that the technique improves the

flow properties of powders. Throughout many

pharmaceutical applications, the main goal is to

increase the flowability of medical powder to achieve

a fast compressing of tablets. Researchers usually use

the compressibility index to calculate the flowability

of granules, with a method named The United State

Pharmacopeia (USP) (Anshul et al. 2017). Results

and data would then be collected from the

compressibility index calculation by using the

equation in Figure 3.

Figure 3: An equation used to calculate compressibility

index (CI).

The equation shows that bulk and trapped

densities can be determined per the procedure within

the USP. By calculating the compressibility index

(CI) in a different situation, results indicate that the

roller speed has an impact on CI. Variables include

roller forces that would change the flowability,

suggesting stronger ribbons produce by the strong

roller forces (Anshul et al. 2017). Furthermore, roller

compaction prevents particle segregation during the

granulation. The process of granulation forces the

powder to pass through two rotating rollers. By

squeezing and milling the mixtures, the density of

granules would increase so that each particle would

stick to the other tightly (Rana et al. 2011).

4 DISADVANTAGES AND

CHALLENGES

Roller compaction becomes a new trend in the drug

manufacturing industry. Although dry granulation by

roller compaction presents many benefits to the

economy and productivity, there are still have some

challenges that researchers need to overcome. One of

the major challenges during dry granulation is the loss

of compactibility in the double compaction (Heiman

et al. 2017). Researchers found the details of the loss

of tabletability by using microcrystalline cellulose

(Sun et al. 2007). Granules size enlargement on

tabletability would change the bonding within the

tablets. In the paper of Sun and Changquan Calvin

(2008), phenomenon of larger particles perform a

lower tabletability after the granulation process has

been addressed. To verify the phenomenon of loss of

compactibility, Sieve analysis has been introduced

which is a common method that used to detect the

powder particle size. Levels of different variables in

the designed experiments are showed in Table 1

(Herting et al. 2007). Experiments used fraction of

Theo and porosity of the ribbons to obtain the levels

of Microcrystalline cellulose (MCC) and theophylline

(Theo) since MCCs affect the flowability of granules

and Theo is another API ingredient used in particle

size (Herting et al. 2007). Sieve method can divide

granules in order to make a comparison between

variables in the granules of roller compaction. The

results of sieve analysis are usually presented in

median diameter of particles (μm). Based on the

results in Table 1, there was a relationship between

Fraction of Theo and MCC, with an increasing

percentage of fraction of Theo, the change on

granules size enlargement influenced by MCC is less

but significant (Herting et al. 2007). Subsequently,

Potentials of the Dry Granulation by Roller Compaction

305

the results shown that enlargement of granules also

reduced the tabletability after the granulation process

(Sun et al.2006). Therefore, granules size

enlargement plays an important role in causing the

reduced tabletability and this become one of the major

disadvantages of roller compaction through dry

granulation.

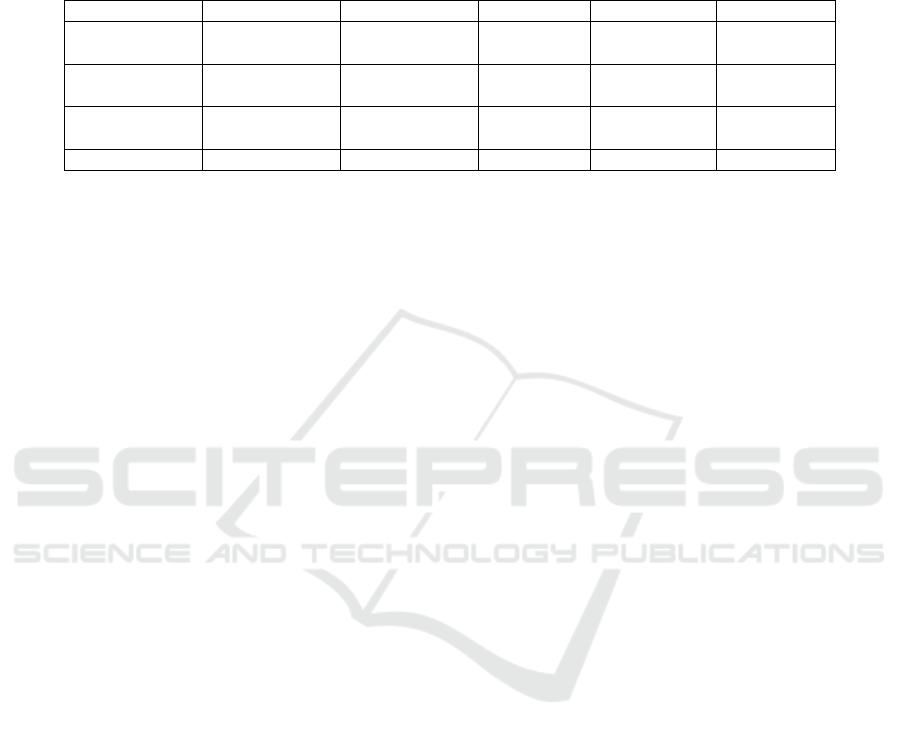

Table 1: Levels of variables for measuring the influence of particle size in the designed experiments.

Level -1 -0.33 0 +0.33 +1

MCC (μm)

21 - 56 - 106

Theo (μm)

7 - - - 110

Fraction (%)

25 41.67 50 58.33 75

Porosity (%) 20 26.67 30 33.33 40

Other disadvantages including the process is too

slow compare with direct compression. Direct

compression has the same characteristic as an absence

of liquid binder within the process. However, dry

granulation has additional steps of transforming the

raw materials into granules by go through the

compactor. The machine would cost more money and

time which is a burden for some drug industries.

5 CONCLUSIONS

In conclusion, the dry granulation technique has

drawn the attention of many pharmaceutical

industries because of the advantages of dry

granulation by roller compaction compared with other

compaction technology. The agglomeration step of

drug formulation briefly illustrates how powder of

APIs and excipients pass through the compactor and

result in dried granules. During the dry granulation,

the absence of liquid content gives a major advantage

to this process which becomes suitable for heat and

moisture products. Dry granulation also prevents

particle segregation and contributes to flowability.

Although the dry granulation process may lose

tabletability, researchers still believe the process has

the potentials to overcome the disadvantages.

ACKNOWLEDGEMENTS

I am very grateful to the Prof. Axel for his enormous

contribution towards the project. Professor Axel

provided me with encouragement and patience

throughout the duration of this research project.

Thanks to the teacher assistant Ben Wei who always

solve my question in patience.

REFERENCES

Anshul Gupte, et al. Comparative binder efficiency

modeling of dry granulation binders using roller

compaction. Drug Development and Industrial

Pharmacy, vol 43, no. 4, pp. 574-583, 2017.

Heiman, Johanna, et al. Roller Compaction of Hydrophilic

Extended Release Tablets—Combined Effects of

Processing Variables and Drug/Matrix Former Particle

Size. AAPS PharmSciTech, vol. 16, no. 2, pp. 267–77,

2015.

Hudon, Sophie, et al. Evaluation of a Dry Coating

Technology as a Substitute for Roller Compaction for

Dry Agglomeration Applications in the Pharmaceutical

Industry. Journal of Pharmaceutical Innovation, vol. 14,

no. 3, pp. 286–303, 2019.

Michael G. Herting, Peter Kleinebudde. Roll

compaction/dry granulation: Effect of raw material

particle size on granule and tablet properties.

International Journal of Pharmaceutics, vol. 338, pp.

110-108, 2007.

Peter, Stefanie, et al. Roller compaction/Dry Granulation:

Use of the Thin Layer Model for Predicting Densities

and Forces During Roller Compaction. Powder

Technology, vol. 199, no. 2, pp. 165–75, April 2010.

Pietsch, Wolfgang. Agglomeration Processes: Phenomena,

Technologies, Equipment / Wolfgang Pietsch.

Weinheim: Wiley-VCH, 2002.

Rana, Khokra, et al. Overview on roll compaction/dry

granulation process. Pharmacologyonline, vol. 3, pp.

286-298, November 2011.

Teng, Yue, et al. Systematical Approach of Formulation

and Process Development Using Roller Compaction.

European Journal of Pharmaceutics and

Biopharmaceutics, vol. 73, no. 2, pp. 219–29, 2009.

Sun C., Calvin. On the Mechanism of Reduced

Tabletability of Granules Prepared by Roller

Compaction. International Journal of Pharmaceutics,

vol. 347, no. 1, pp. 171–72, 2008.

Stutzman, Todd., Roller Compaction: New Trends,

Challenges and Solutions: When Developing a Tablet

or Capsule, Three Widely Used Technologies Are

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

306

Often Considered to Produce Solid Dosage Forms:

Direct Compression, Wet Granulation and Dry

Granulation. Manufacturing Chemist (London: 1981),

vol. 91, no. 11, pp.34, November 2020.

Sun C. Calvin, Micah W. Himmelspach. Reduced

tabletability of roller compacted granules as a result of

granule size enlargement. Journal of Pharmaceutical

Sciences, vol. 95, pp. 200-206, 2006.

Potentials of the Dry Granulation by Roller Compaction

307