Study of the Treatment of Oily Sludge by Bio-slurry Method

Jing Wang

a

, Yue Ma

b

and Changtao Yue

*c

China University of Petroleum, Beijing, China

Keywords: Bio-slurry, Bacillus, Oily Sludge, Four-Component Analysis.

Abstract: In this manuscript, the bio-slurry method was used to treat oily sludge. Four strains of bacillus were selected

in the laboratory to biodegrade the crude oil in oily sludge. During the reaction, the residual oil rate was

measured regularly, and after the reaction, the degraded crude oil was separated into four components. The

results showed that JZ-2 and JZ-3 were effective in biodegradation. The crude oil degradation rate was 72.5%

and 74.3%, respectively, and the residual oil rate was decreased from 12.55% to below 2%, among which the

degradation rate of saturates was the fastest. It is concluded that the biological treatment of oily sludge can

achieve great results and has the potential of field application.

1 INTRODUCTION

1

The quantity of oily sludge in China is large, the

pollutant composition is complex, and the treatment

is difficult. If it is not handled properly, a large

amount of harmful substances will enter the soil and

groundwater, causing serious environmental

pollution. Oily sludge treatment technology mainly

includes physical method, chemical method and

biological method, among which biological method

is an environmentally friendly and low-cost method

(Gao, 2017;

Wael, 2013). Bio-slurry reactor is a

typical biological treatment technology, which uses

hydrocarbon degrading bacteria to treat oil pollutants

in oily sludge. By controlling various reaction

parameters, it provides the best conditions for the

growth of microorganisms, reduces the reaction time

and improves the reaction efficiency (Giulio, 2010;

Sunita J., 2017; FM, 2004).

In this study, the basic properties of oily sludge

samples were determined first, and then the bio-

slurry method was used to evaluate the crude oil

biodegradability of four strains of Bacillus, seeking

an economical and feasible method for the harmless

treatment of oily sludge.

2 MATERIALS AND

EXPERIMENTAL METHODS

In this study, four strains were screened from the

laboratory, all of which were Bacillus (Kishore,

2007). The strains were numbered JZ-1, JZ-2, JZ-3

and JZ-4 respectively. The oily sludge was collected

from Xinjiang oilfield. The moisture content, pH

value and oil content were measured, and the results

are shown in Table 1.

Table 1: Moisture content, pH value and oil content of oily sludge.

Num-ber

Moist-ure

conte-nt (%)

Aver-age

value (%)

pH value

Aver-age

valu-e

(

%

)

Dry base

oil cont-

ent

(

%

)

Aver-age

valu-e (%)

1 8.68 6.43 7.08

2 8.53 8.64 6.25 6.40 7.29 7.24

3 8.72 6.51 7.34

a

https://orcid.org/0000-0001-8029-7745

b

https://orcid.org/0000-0002-1724-9924

c

https://orcid.org/0000-0001-8438-3878

Wang, J., Ma, Y. and Yue, C.

Study of the Treatment of Oily Sludge by Bio-slurry Method.

DOI: 10.5220/0011218800003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 501-504

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

501

The experimental device of the bio-slurry reactor

is shown in Figure 1, which is composed of a constant

temperature water bath, a mechanical stirrer, and a

beaker. The experimental steps are as follows: ○,

1

200 g of dried sludge samples were added into 5 1L

beakers, and then adding 400 mL of inorganic salt

medium and the prepared bacterial liquid. ○,

2

T h e

beakers were placed in water baths at a temperature

of 45°C and stir with a stirrer at a speed of 250 rpm.

○,

3

Plastic films were covered on the beakers to

reduce water loss. Distilled water was added to the

beakers and water baths regularly to keep the liquid

level in the beakers basically unchanged. ○,

4

A n

appropriate amount of slurry was taken out every 7

days to measure their oil contents.

Figure 1: Bio-slurry reactor.

The content and composition of residual

petroleum pollutants in the oily sludge after

biodegradation are the main indicators for evaluating

the effect of the bio-slurry method in the treatment of

oily sludge. In this experiment, the gravimetric

method was used to determine the total extracted

organic (TEO) matter of the oily sludge.

Dichloromethane was used as the extraction agent to

carry out soxhlet extraction experiment. According to

the quality reduction of the sample after extraction,

the oil content could be obtained, and then the residual

oil rate of oily sludge could be calculated (Firouz,

2015;

Apourv, 2018; Douglas O., 2017). The

extracted solvent was dried, and then the biodegraded

crude oil was separated into four components to

characterize the biodegradation effect.

3 RESULTS AND DISCUSSION

After 35 days of biological treatment, the oil content

of oily sludge decreased significantly. Figure 2 to

figure 6 show the residual oil rates and degradation

rates of adding JZ-1, JZ-2, JZ-3, JZ-4 and blank

samples of the initial, 7 d, 14 d, 21 d, 28 d and 35 d.

It can be seen from the figures that the residual oil rate

of each sample has been reduced. Among them, JZ-3

had the highest degradation rate and the lowest

residual oil rate, followed by JZ-2 and JZ-1, and JZ-4

had the worst degradation effect, and the blank

sample also has a certain degree of degradation.

0 7 14 21 28 35

0

2

4

6

8

Residual oil rate

Degradation rate

Time /d

Residual oil rate /%

0

10

20

30

40

50

60

70

Degradation rate /%

Figure 2: Residual oil rate and degradation rate of sample

JZ-1.

0 7 14 21 28 35

0

2

4

6

8

Residual oil rate

degradation rate

Time /d

Residual oil rate /%

0

15

30

45

60

75

Degradation rate /%

Figure 3: Residual oil rate and degradation rate of sample

JZ-2.

0 7 14 21 28 35

0

2

4

6

8

Residual oil rate

degradation rate

Time /d

Residual oil rate /%

0

15

30

45

60

75

Degradation rate /%

Figure 4: Residual oil rate and degradation rate of sample

JZ-3.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

502

0 7 14 21 28 35

0

2

4

6

8

Residual oil rate

Degradation rate

Time /d

Residual oil rate /%

0

10

20

30

40

Degradation rate /%

Figure 5: Residual oil rate and degradation rate of sample

JZ-4.

0 7 14 21 28 35

0

2

4

6

8

Residual oil rate

degradation rate

Time /d

Residual oil rate /%

-5

0

5

10

15

20

25

30

Degradation rate /%

Figure 6: Residual oil rate and degradation rate of blank

sample.

It can be seen from Figures 2, 3, and 4 that, the oil

content of samples JZ-1, JZ-2 and JZ-3 have been

greatly reduced in the first 7 days. The oil was

observed, which may have been stripped from the

surface of sediment particles by microorganisms. At

this time, the degradation rates reached 34.7%,

40.3%, and 36.9%, respectively. The oil content also

decreased to a certain extent in the next 14 days, but

the oil content changed less at 21-35 days. This may

be because the oily sludge contained a large amount

of easily degradable organics in the initial stage of

treatment. Under this condition, microorganisms

could quickly use this part of the organics to grow and

reproduce. As time goes by, the content of easy-to-use

nutrients decreased, and a large amount of difficult-

to-degrade organic matter remained, so the

degradation rate slowed down, and the bacterial

concentration also decreased.

The device was operated continuously for 35 days,

and the residual oil rates of the three sludge samples

were reduced to about 2%, which were 2.4%, 1.9%

and 1.8%, respectively. The three bacteria had a good

effect on the degradation of oily sludge, the

degradation rates were 67.4 %, 72.5 % and 74.3 %,

respectively. The results indicated that JZ-3 had the

best effect, the effect of JZ-2 was not much different

from that of JZ-3, and the effect of JZ-1 was relatively

poor.

As can be seen from Figure 6, the residual oil rate

of blank sample also decreases during the reaction

time, which may be that part of the organics in the

slurry is volatile, but it is more likely that the oily

sludge sample contains hydrocarbon-degrading

indigenous microorganisms, which use the residual

oil in the slurry to grow, leading to the reduction of

residual oil rate. The treatment effect of JZ-4 was

better than that of blank sample, and the removal rates

of the two sample were 38.1% and 28.3%

respectively, but the removal rate of JZ-4 was lower

than that of other samples.

saturates

Aromatics Resin

asphaltene

0

15

30

45

60

75

Relative content /%

Crude oil components

initial blank

JZ-1 JZ-2

JZ-3 JZ-4

Figure 7: Changes of crude oil components in oily sludge

before and after biodegradation.

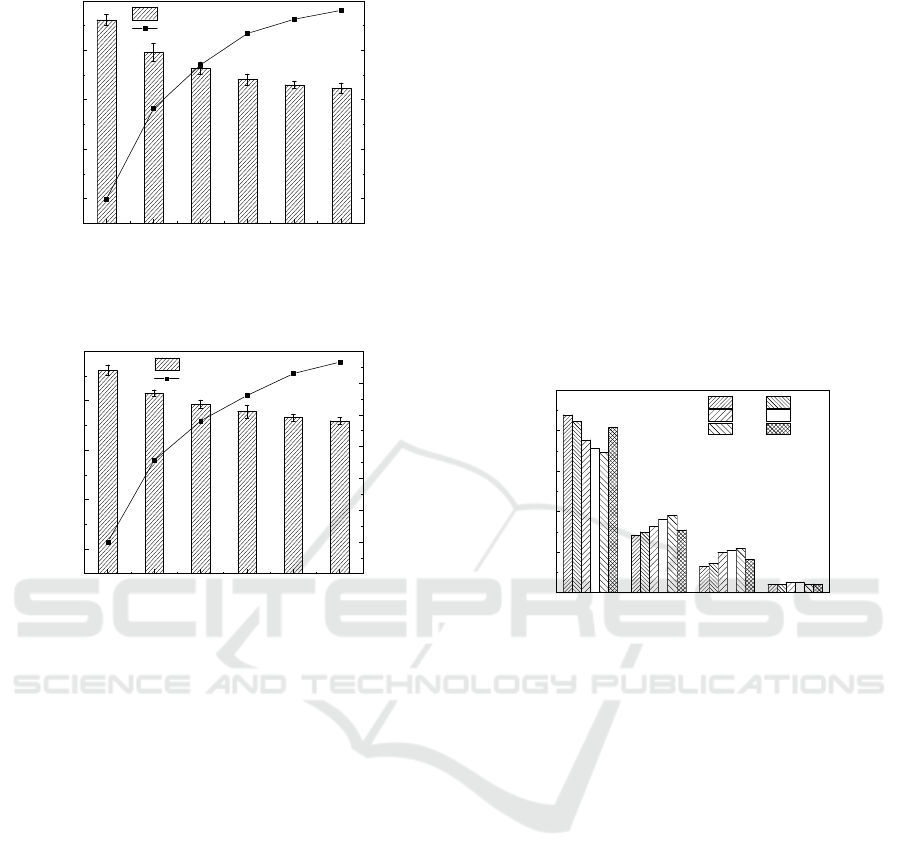

After 35 days of treatment, crude oil components

in all oily sludge samples were separated, and the

results are shown in Figure 7. Comparing with the

initial sample, the relative contents of saturates in

other samples decreased, among which JZ-1, JZ-2 and

JZ-3 samples decreased significantly, reaching 9.3%,

12.5% and 14.0%, respectively. The relative contents

of aromatics and resin increased, which was

equivalent to the changes of saturates in each sample.

This is because the saturates is more easily used by

microorganisms, so the content change is more

obvious compared with other components. However,

due to the relatively low content of asphalt, its content

does not change significantly.

The content changes of each component in oily

sludge are shown in Table 2. After 35 days of

biodegradation, the content of four components in

each sample decreased compared with the four

components in the initial oil sludge, among which the

saturates changed most obviously, and the other three

components also decreased significantly. Among the

samples, JZ-3 had the best biodegradation effect. The

degradation rate of saturates reached 79.8%; the

Study of the Treatment of Oily Sludge by Bio-slurry Method

503

degradation rate of aromatics was 65.5%; the

degradation rate of resin was 57.35%; the degradation

rate of asphalt reached 72.9%. The degradation rates

of JZ-2 were 77.7%, 64.9%, 56.3% and 65.3%,

respectively. The degradation rates of JZ-1 were

71.0 %, 62.3 %, 50.6 % and 58.0 %, respectively. The

degradation rates of JZ-4 were 42.5 %, 32.2 %,

22.7 % and 34.0 %, respectively.

Table 2 SARA analysis results of oil in different sludge samples

Numb-er

Saturate

(g/kg oily

slud

g

e

)

Aromatic

(g/kg oily sludge)

Resin

(g/kg oily

slud

g

e

)

Aspha-ltene

(g/kg oily

slud

g

e

)

Initial 47.70 15.40 7.12 2.18

Blank 32.97 11.70 5.62 1.62

JZ-1 13.36 5.80 3.52 0.92

JZ-2 10.62 5.41 3.11 0.76

JZ-3 9.65 5.31 3.04 0.59

JZ-4 27.41 10.45 5.50 1.44

4 CONCLUSIONS

In this study, four strains of Bacillus were used to

biodegrade oily sludge by the bio-slurry method. The

residual oil rate decreased significantly within the

first 7 days of biodegradation. After 35 days of

biodegradation, the content of the four components of

crude oil in each sample was lower than those in the

initial oily sludge, and the saturates had the most

obvious change. Among them, JZ-2 and JZ-3 had

better effects on crude oil degradation.

The application of biotechnology to the research

of oily sludge treatment will play a positive role in

promoting safe production and sustainable

development of the petroleum industry, creating and

maintaining a healthy ecological environment, which

has important theoretical and practical significance.

ACKNOWLEDGMENTS

This work was financially supported by the high value

utilization technology and demonstration of urban

organic solid waste (SQ2019YFC190052).

REFERENCES

ABBASIAN F, LOCKINGTON R, MALLAVARAPU M, et

al. A Comprehensive Review of Aliphatic Hydrocarbon

Biodegradation by Bacteria [J]. Applied Biochemistry

and Biotechnology, 2015, 176(3): 670-699.

DAS K, MUKHERJEE A K. Crude petroleum-oil

biodegradation efficiency of Bacillus subtilis and

Pseudomonas aeruginosa strains isolated from a

petroleum-oil contaminated soil from North-East India

[J]. Bioresource Technology, 2007, 98(7): 1339-1345.

GAO H, ZHANG J, LAI H, et al. Degradation of

asphaltenes by two Pseudomonas aeruginosa strains and

their effects on physicochemical properties of crude oil

[J]. International Biodeterioration & Biodegradation,

2017, 122: 12-22.

GHAZALI F M, RAHMAN R N Z A, SALLEH A B, et al.

Biodegradation of hydrocarbons in soil by microbial

consortium [J]. International Biodeterioration &

Biodegradation, 2004, 54(1): 61-67.

ISMAIL W, AL-ROWAIHI I S, AL-HUMAM A A, et al.

Characterization of a lipopeptide biosurfactant

produced by a crude-oil-emulsifying Bacillus sp. I-15

[J]. International Biodeterioration & Biodegradation,

2013, 84: 168-178.

PANT A, RAI J P N. Bioremediation of chlorpyrifos

contaminated soil by two phase bioslurry reactor:

Processes evaluation and optimization by Taguchi's

design of experimental (DOE) methodology [J].

Ecotoxicology Environmental Safety, 2018, 150: 305-

311.

PINO-HERRERA D O, PECHAUD Y, HUGUENOT D, et

al. Removal mechanisms in aerobic slurry bioreactors

for remediation of soils and sediments polluted with

hydrophobic organic compounds: An overview [J].

Journal of Hazardous Materials, 2017, 339: 427-449.

VARJANI S J, UPASANI V N. A new look on factors

affecting microbial degradation of petroleum

hydrocarbon pollutants [J]. International

Biodeterioration & Biodegradation, 2017, 120:71-83.

ZANAROLI G, TORO S D, TODARO D, et al.

Characterization of two diesel fuel degrading microbial

consortia enriched from a non acclimated, complex

source of microorganisms [J]. Microbial Cell Factories,

2010, 9: 13-20.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

504