A Novel Approach to Functional Equivalence Testing

Ranjith Jayaram and Jetendra Kumar Borra

Mercedes-Benz Research and Development India, Bengaluru, India

Keywords: Model, Software, Functional Equivalence, Verification.

Abstract: In Model Based Software Development, sometimes it is required to transform the model and respective

software code from one platform to another platform that is having different tool setup. For example,

transforming a legacy model to the newly adapted architecture or transforming a model supplied from third

party to production model and so on. Once the model is adapted to the new platform, there will be changes in

the model, hence the code generated from the model can be different from that of legacy artifacts. After

transformation activity, developers have to be sure that the new model and code is functionally equivalent to

that of the old set. It is also important from quality standpoint that there are no deviations in the functionality

after migration. With most of the compilation toolchains being closed source it is difficult to identify the

issues during migration unlike in systems engineering. Achieving functional equivalence between the

production artifacts and the reference/legacy artifacts provide conformity to the engineer of successful

migration. In this paper, a methodology is proposed in which even with non-availability of few artifacts from

legacy setup, functional equivalence is achieved using Model in loop and software in loop simulation results

matchup. The method and the results are presented in the paper with two different use cases.

1 INTRODUCTION

The automotive industry is evolving very fast and

automotive engineering is becoming more software

driven. In software development, it is very common

that different components of software are developed

across different teams, different suppliers and

integrated into production code after rigorous testing.

Different strategies and tools are being followed in

different organizations while planning and carrying

out the software development. There are cases where

the documentation for the legacy artifacts such as

requirements, model, code are not available. One

such case is legacy models that are being improved

from time to time, grown big and not having enough

documentation for requirements. When there is no

stringent process for the software development, it is

common that sometimes documentation is not

available for the old models. In cases where proper

documentation is not available, the engineers working

on the respective functionality are the only source

with knowledge of the requirements. Another case is,

third party unit develop the model with the

requirements given in descriptive format or model

format, generate model based code and tested. After

testing is complete, the code is flashed in Electronic

Cntrol Unit (ECU) and only the ECU will be

delivered to the product owner from the supplier. In

all the above cases, when the software team plan to

transform the models and software to new platform,

with at least one of the information resources like

requirements, code and test specifications missing,

obtaining functional equivalence after migration

guarantees the engineer that there is no deviation

during migration from one platform to another

platform. Functional equivalence in this context

means the legacy code and the transformed code both

should work in the exact manner as a product without

deviation in the functionality.

2 PROBLEM

Two of the cases mentioned earlier are considered in

this paper to explain our methodology and the

application of the methodology is not limited to these

but can be used for multiple use cases. First case

considered in this paper is to adapt the legacy floating

point model to TargetLink based fixed point model.

The floating point model is not accompanied with

code, unit test specifications and the tool used for

generating code from floating point model is

244

Jayaram, R. and Borra, J.

A Novel Approach to Functional Equivalence Testing.

DOI: 10.5220/0011269900003274

In Proceedings of the 12th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2022), pages 244-251

ISBN: 978-989-758-578-4; ISSN: 2184-2841

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

unknown, which make the transformation and

obtaining functional equivalence difficult. Since the

idea is to transform the model from one set up to

another, it is important to make sure that there is no

deviation in the functionality after migration. Before

going forward, to avoid confusion and for easier

explanation here onwards consider the legacy floating

point model as reference model and the model

developed with latest architecture as production

model. In Model Based Development (MBD), across

projects different tools are used for validating and

verifying the code generated. Let us explore how

different verification methods were fared in the

current case. Model compare tools can be used to

compare the models to identify the differences. Both

the production and reference models are different in

nature of development i.e, floating point and fixed

point respectively. Since in production model fixed

scaling is given to each variable and parameter in the

model, there will be differences in the properties of

each model block hence making it difficult to confirm

from model comparison that code works as expected.

As the model grows bigger, the model comparison

activity becomes more laborious and less efficient.

Due to the reasons mentioned above, model

comparison do not fare well in ensuring the functional

equivalence.

In order to do code comparison between both

production and reference model based codes, there is

no code available with the reference model artifacts.

Automated code can be generated for reference model

using a relevant compiler and it can be compared with

the code of production model. The code from

production model is generated in TargetLink

platform. When auto generated reference model code

is compared with the implicit automatically

optimized, typecasted TargetLink based code

(production code), the number of differences found is

high due to inclusion of scaling and property

differences. It is a laborious task for the engineers to

identify the deviations among the differences. Even

with the sincere efforts of the engineers there are high

chances of inefficiencies, and makes the whole idea

resource heavy, time intensive and inefficient. If test

specification is available with the reference model,

same test matrix can be used on both the production

and reference artifacts for software in loop unit

testing and result matchup. With some extra test cases

for the fixed point data range, resolution testing and

comparing the results functional equivalence can be

achieved. Since the test matrix and reference model

code are not available, software in loop testing and

result matchup is not possible. Vehicle testing is

costly and the test engineer has to drive, test for all

the functionalities which is very costly and

inefficient. Some of the software level bugs related to

scaling and resolution of data variables can go

without being identified in vehicle testing. Direct

vehicle testing also contradicts with the whole idea of

making the software vehicle ready with minimum

issues and pre-validated sufficiently for vehicle

testing. One interesting idea would be to prepare the

test specification for the reference model and the

production code can be validated by the same test

specification. Since the requirements are embedded in

the form of reference model, writing test cases using

reference model sounds like a possible solution. But

even with this solution how to completely validate the

production code that has calculations with fixed point

scaling with less efforts of resource is unanswered.

The results on the production code has to be analysed

for resolving the failed cases, which is time intensive

for engineers. Since there is no reference code, it is

not possible to do software in loop simulation on

reference artifacts and there are no reference results

to compare with the production code testing results.

As driver drives the car with the code but not with the

model it is very important for the engineer to

completely validate the production code, hence this

idea can be ignored.

The second case considered in the paper is a set of

reference model which is Non-AUTOSAR

TargetLink fixed point scaling environment model,

code and test matrix for unit testing. Production

model is AUTOSAR platform based model

transformed from reference model and code. Starting

with similar analysis like the one in first case, model

comparison will not work, as there will be a change

in the model architecture. Due to difference in

platform setup, it is difficult to find the differences in

the code as there will be restructuring in the code.

Since the test matrix is available for the reference

model the same can be used on the production code,

by comparing the results, we can make sure that

software is equivalent and hence functional

equivalence can be achieved. However, for unit

testing done with various coverage metrics, for

example like C1 coverage there is a chance that some

branches in code could be missed in testing. The

functional equivalence process should be developed

such that if there is any minor issue underlying, it

should not go unreported without being registered

with the engineer. In both the cases, even though the

context and settings are different the target is to

achieve the functional equivalence of the production

code with that of reference. In search of solution for

this problem we researched the literature and our

A Novel Approach to Functional Equivalence Testing

245

findings from our literature survey are given in the

next section.

3 LITERATURE AND

MOTIVATION

In order to integrate the legacy systems into the

system, there are three methods mentioned in

literature (C. Chiang, 2007) wrapping, rewriting and

reengineering. Considering the cost for a short

duration project or project of small scale perspective

wrapping process will suffice but with a compromise

on quality of legacy code. For large scale projects

with use case for longer period of time, reengineering

option will work as good solution but consumes lot of

resources. In case of converting the legacy models to

a different platform rewriting helps in adopting the

characteristics of the new platform faster. While

integrating the legacy with new setup, or rewriting the

setup, stability of the software plays a significant role.

As mentioned in (P. Atcherley, 1994), testing the

replacement for a legacy system is not well explored

in literature. Once the legacy system is adopted to the

new desired platform, functional test cases prepared

from understanding of the requirements will give a

good understanding of what is the region that is being

covered and what is not. Adding new test cases can

cover the uncovered regions. In (P. Atcherley, 1994),

it was pointed that there must exist a platform to test

the cases on the legacy code for better results to run

both the legacy code and reengineered code on the

same platform to assure that the migration is defect

free. With reference to the experience report

(Antonini, Canfora, Cimitile, 1994), it points that

adequate setup to test the re-engineered work with

original work is marginally tackled. In (Hocking,

Knight, Aerllo and Shiraishi, 2014), one of the

common problems and similar to the current problem

is taken i.e, a 32 bit development model is tested for

equivalence with its corresponding 16 bit production

model using the novel concept constrained

equivalence. The concept of constrained equivalence

is analogical to the concept of a transfer function.

Given the valid inputs for the first model, second

model should have same results as first model,

obviously with in the acceptable tolerance limits. The

support tool that is being used in the work is

Prototype Verification system (PVS) along with

Simulink to simulate the models. Using constrained

equivalence concept model equivalence is achieved

but no details are mentioned regarding total system

validation i.e. model and code together. In the current

problem of interest, production model, which is

developed in TargetLink platform, is used for

generating optimized code and reference is floating

point Simulink model. Even though the method

mentioned is not appropriate for the current problem,

the idea is absorbed for structuring a possible

solution. For regression testing, Back to Back testing

is an interesting testing concept coined decades back

(MA Vouk, 1990). It is a concept that can be adapted

for wide range of cases. Using this concept with the

existing test matrix, we can test the new code and

compare with the previous version to find out the

latest changes in the code compared to its previous

version. This concept has to be adapted as per the

availability of the resources for the case. From the

literature it is evident that there is no clear existing

method to achieve functional equivalence.

With this knowledge from literature and the

motivation to resolve the current problem of interest

with a minimum effort solution, a novel methodology

have to be developed. The solution should be cost-

efficient such that there is no need for the newly

developed software to be tested rigorously in

expensive Vehicle/HIL (Hardware-in-the-Loop)

testing to achieve functional equivalence. Instead,

after passing functional equivalence test with the

proposed method, couple of regression tests on

Vehicle/HIL setup should prove the credibility of the

software.

4 BACKGROUND

For the first case as mentioned earlier (Section 2) MIL

(on reference model) – MIL (on production model)

comparison stands out as good option but the code

validation is still an open question and answering this

question closes the problem. Before going into the

methodology, brief information on BTC Embedded

tester, Back to Back testing and Wrapper is provided

in the following subsections for ease of understanding

of the method.

4.1 BTC Embedded Tester

There are multiple tools available with engineers for

testing activities, we chose BTC EmbeddedTester.

BTC is one of the tools which can offer back to back

testing. BTC Embedded Tester is a tool provided by

BTC Embedded systems AG. It provides an ISO

26262 certified and fully automated back-to-back test

between model and code. It can execute the same test

cases on multiple levels i.e., MIL (Model-in-the-

loop), SIL (Software-in-the-loop) and PIL

SIMULTECH 2022 - 12th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

246

(Processor-in-the-loop). Using this tool, engineers’

set of test cases for functional check can be uploaded

and evaluated. If the test cases are not giving full

coverage, there is a facility with the tool to

automatically generate the test cases for uncovered

parts of the code and missed unique test

combinations. With one click back to back testing

option and automated test matrix generation feature,

this tool is handy for the engineers.

4.2 Back to Back Testing

This is a popular and resource efficient testing

methodology. In this method, same set of test cases

are used for testing different variants of the software

or for testing functionally equivalent components. In

multiversion experiments, at first individual testing of

the software is completed and then the results are

compared with its previous version, we call it as back

to back testing. Based on the reliability target to be

achieved back to back testing strategy is modified

from case to case. The limitation of this testing is in

multiversion software cycles if the issue is missed in

MIL test, it will be missed in SIL testing as well. So,

issues in particular branch of code will go unnoticed,

i.e. if a functional aspect test is missed in MIL testing,

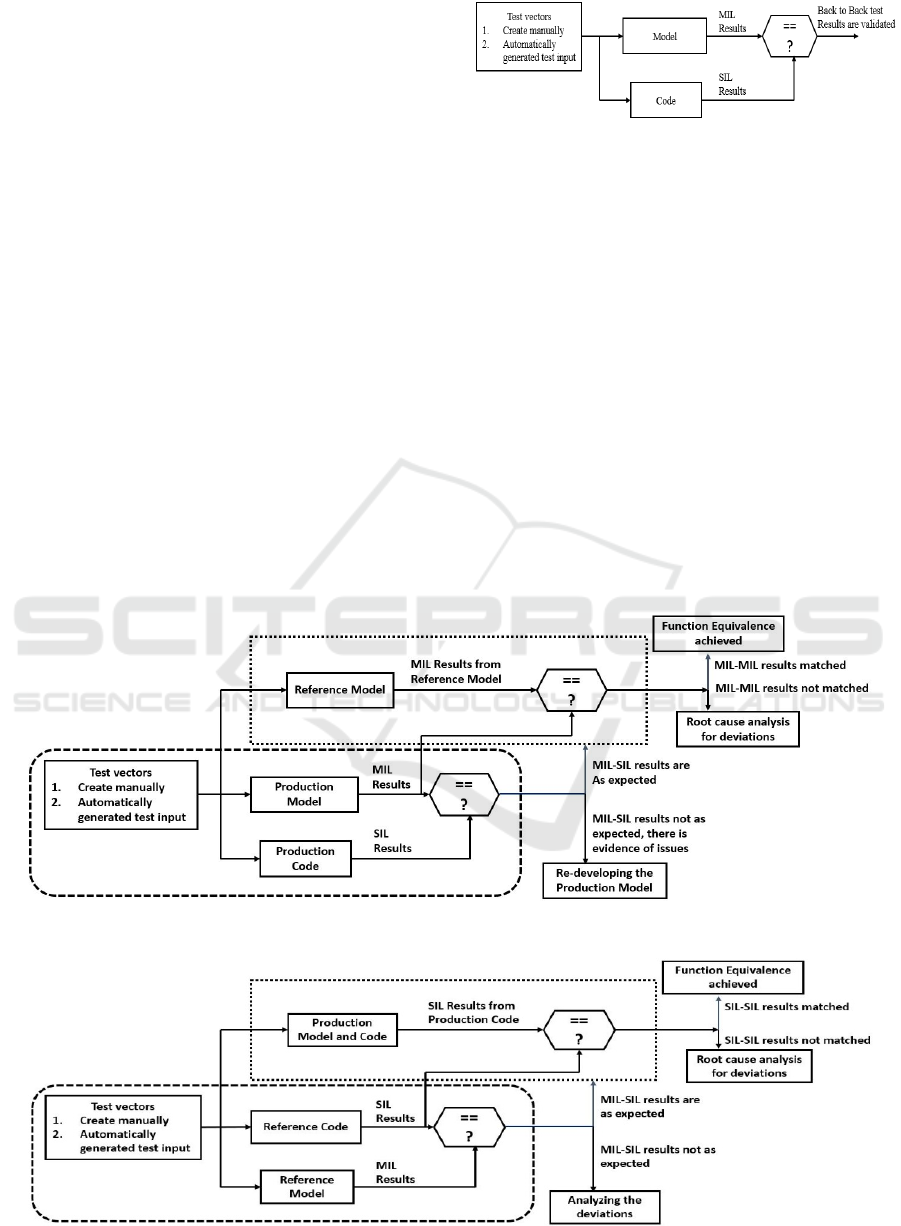

Figure 1: Back to Back testing.

it will be missed in SIL testing as well, because same

test matrix is used for MIL-SIL testing and result

comparison. To overcome this limitation, in our

method an extra step is added for maximum code

coverage. Back to back testing concept is given in

Figure 1. The use case of Back to Back testing for the

current problem of interest is comparison of results

from SIL, MIL of the same model and then

comparing xIL-xIL results of reference and

production model. More information on Back to Back

testing can be referred from (MA Vouk, 1990).

4.3 Wrapper

A wrapper is a function or script which helps in better

abstraction of data/signals of the core function by

means of signal routing. The core function and the

wrapper can be modified independently. In scenarios

Figure 2: Functional Equivalence methodology for Case 1.

Figure 3: Functional Equivalence methodology for Case 2.

A Novel Approach to Functional Equivalence Testing

247

when the interface changes or signal naming

replacements are needed, it can be achieved with

wrapper without modifying the function logic.

5 APPROACH

The approach is similar for both the cases but not the

same. The core idea of the approach is one set of input

matrix, the one that tests the functionality, coverage

and data range of signals in the model, is fed to the

available reference model package and to the available

production model package. We expect the output

values from both the sets to be matched. The first case

is reference model which is floating point model but

code, test specifications are not available with the

resource package. Production model is fixed-point

TargetLink based model and corresponding code is

TargetLink auto generated. The second case discussed

here is, the reference model is TargetLink based fixed

point scaled model with Code, test matix available in

the resource package and the production model is,

same model migrated to AUTOSAR platform with

new tool chain. The approach for both the sections is

explained in the subsequent sections.

5.1 Case 1

For the production model, test matrix is developed or

completely auto-generated from BTC Embedded

Tester and MIL-SIL results are compared. If there are

no major deviations in MIL-SIL result comparison

then we can proceed to next step. If there are

deviations in MIL-SIL result comparison they should

be addressed. Most of times by keeping one LSB

tolerance setting to the result analysis, issues of

considerable interest will be reported and minor

deviations due to one LSB, which are very common

can be avoided. With the production code tested test

matrix, reference model is tested and results are

compared. If the results are matching with justifiable

deviations, production model is passed, else root

cause analysis will be done for the failure as it points

a potential bug/deviation. The process is shown in

Figure 2. With the new methodology proposed

instead of going in forward direction that is

comparing the reference model results with

production model results, the functional equivalence

is done in reverse manner. First the production model

and code is tested back to back with MIL, SIL with

the proven test specification and MIL results,

reference model is tested and MIL results are

compared there by achieving functional equivalence.

Explaining the method in easy steps below:

(i) Generate test matrix for production code first

using reference model as requirement source.

(ii) Generate extra test cases for coverage and

unique test combinations automatically from

BTC.

(iii) Generate MIL-SIL results for production code.

(iv) If no deviations in MIL-SIL results, use the

same test matrix from step (i) and step (ii) for

MIL testing on reference model.

(v) Compare MIL results of reference model with

MIL results of production model.

(vi) Justify and resolve the deviations found if any.

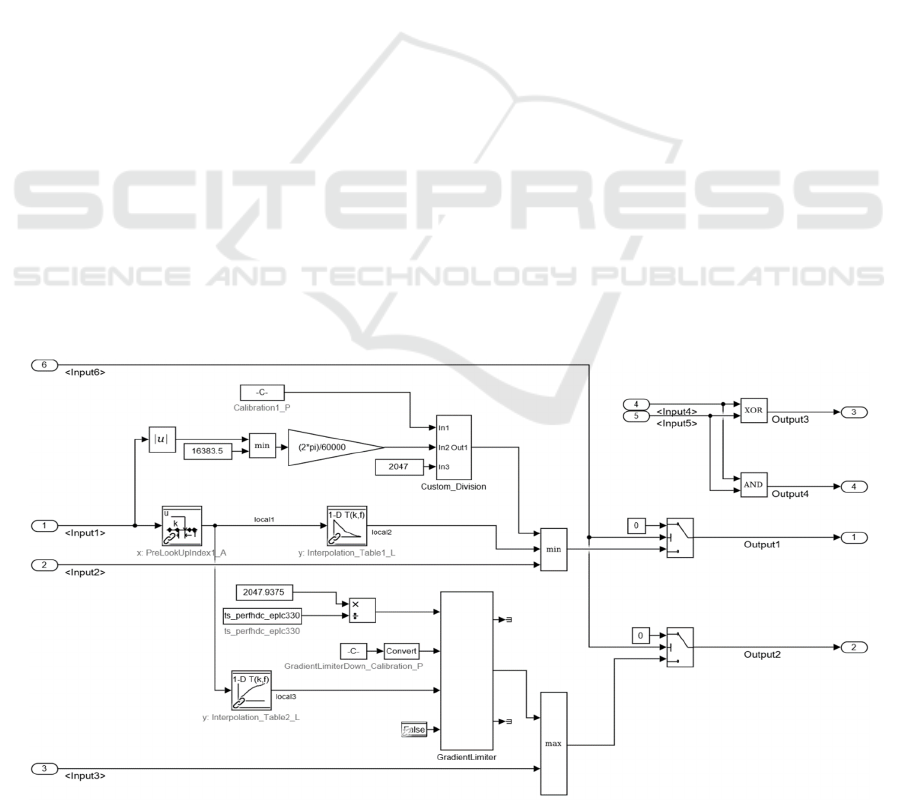

Figure 4: Floating point Model – Reference Model Case 1.

SIMULTECH 2022 - 12th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

248

Figure 5: Fixed point Model - Production Model Case 1.

Figure 6: MIL – MIL result for floating to fixed-point model adoption.

5.2 Case 2

In this case the platform to which the production

model is transformed is different to that of reference

model. During migration from one platform to another

there are chances that signal names might be

interchanged or properties will be changed by mistake

which might create a deviation in the functionality. If

the unit test matrix is available for the reference

model, it is used. In cases where function test matrix

is not available, test inputs can be automatically

generated from the unit testing tools. As code of the

reference model is available, SIL-SIL result

comparison will suffice for the functional

equivalence. In this case first the reference model is

taken and with the existing test matrix if the functional

test cases are not reaching 100% coverage, extra test

cases can be automatically generated. With the

enhanced test matrix, on the reference model the MIL-

SIL simulations are done and the results are compared.

Since the reference code is already tested one,

whenever it deemed not necessary SIL-MIL back-to-

back test can be skipped. Wherever there is a deviation

it will be analysed and justified. The enhanced test

matrix is given as test input to the AUTOSAR based

production model and the SIL results are compared. If

there is an unjustifiable deviation, root cause analysis

has to be done for finding the issue. The process is

given in Figure 3. With this approach, if there is any

issue/deviation that was not found earlier, it would not

go unnoticed by the engineer during this process. In

simple steps:

(i) Use the existing test matrix and generate extra test

cases from BTC tool based on the need or

generate full test matrix from tool.

(ii) Use the test matrix on reference model and

generate SIL results.

(iii) Use the same test matrix in step (ii) on production

model and generate MIL-SIL

(iv) Do MIL-SIL analysis and look for any deviations.

(v) Compare the SIL results of reference model and

SIL results of production model, if found any

deviations do root cause analysis

A Novel Approach to Functional Equivalence Testing

249

6 RESULTS AND DISCUSSION

For analysis of the above mentioned method, a demo

model is taken. The floating point model (the

reference model) is given in Figure 4. The model also

represents the functional requirements. As mentioned

in Section 5.1, the reference model is transformed to

fixed point model given in Figure 5, which is

production model. A deviation is introduced in the

production model intentionally at input4 and input5,

OR gate is used in place of XOR gate. This kind of

deviation can happen during migrating or during

fixing the scaling for the calculation of signal or

optimizing the model. In order to replicate similar

issues a deviation is purposefully introduced in the

model. As mentioned in the process, first functional

test cases for the production model are written,

enhanced the test matrix with the automatic unique

combination test cases from the testing tool and

production model is tested. With the same test matrix,

reference model is tested and as a purposeful issue is

introduced in the model, results show that there is a

deviation at Output3 signal. At the MIL-SIL back to

back testing of the production model, the deviation at

Output3 will not appear because the test cases are

written for production model. As same logic given in

model is replicated in the code, MIL-SIL results pass

the back-to-back test. Now the engineer can process

back to model development, the deviation can be

corrected. Once the deviation is corrected, the results

will be as expected. Sometimes the deviations can be

due to one LSB deviation of the signals, as per the

engineers decision and the product requirements

those can be justified and can be moved to next step

in the software development process. Given the

context, one point to note is, in most of the software

development processes unit testing is considered as a

necessary artifact before delivering the code for

software integration and code coverage percentage is

the quality metric. In coverage testing it is possible

that sometimes unique test combinations will be

missed while writing the test matrix. One such case is

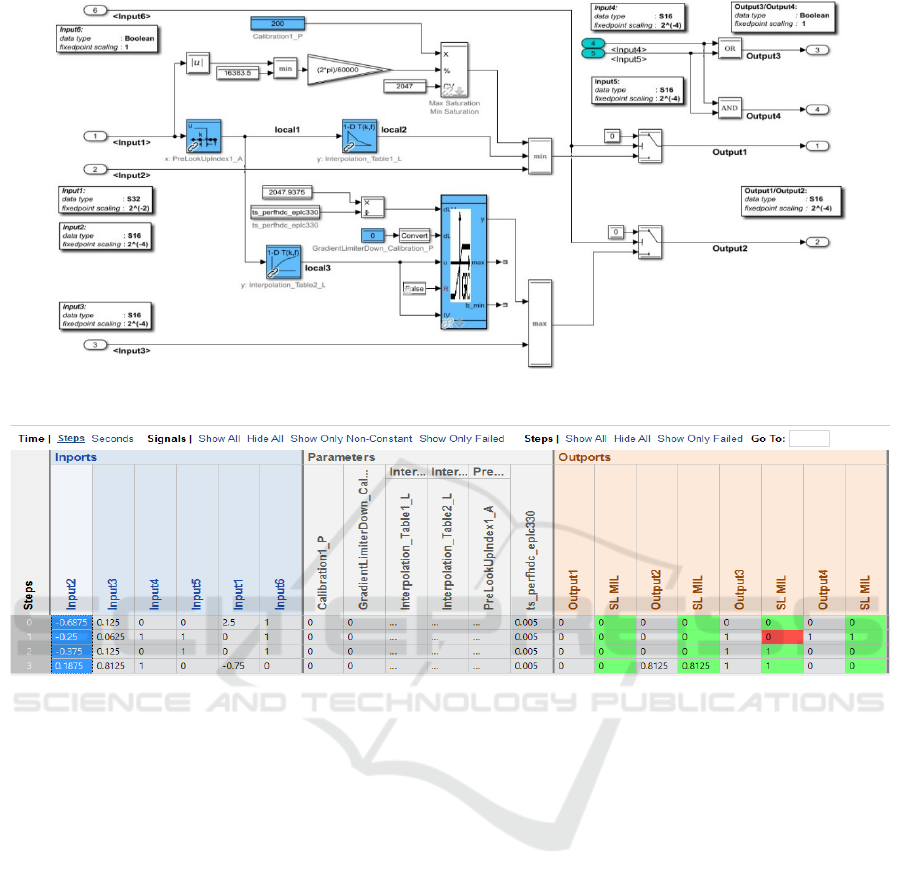

explained in the below in Table 1. From the first three

test cases in the table, it covers 100% coverage, when

the same test matrix is used on the production model,

the test passes inspite of having a deviation between

reference model and production model. Unique test

cases from the testing tool helps in adding extra test

cases, which were missed even with 100% coverage.

With the unique test combination, test case when

tested on both the models, it will show the difference

in results. If there is an issue which was hidden in the

earlier process during the functional equivalence

testing, these will pop-out. The MIL-MIL results for

case 1 are given in Figure 6.

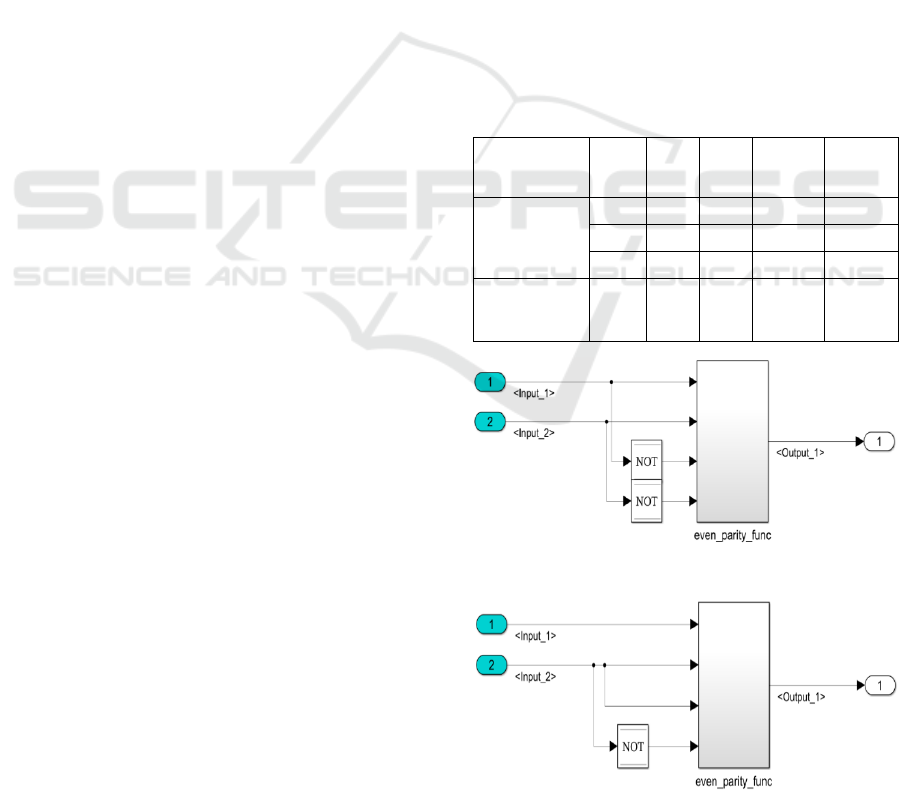

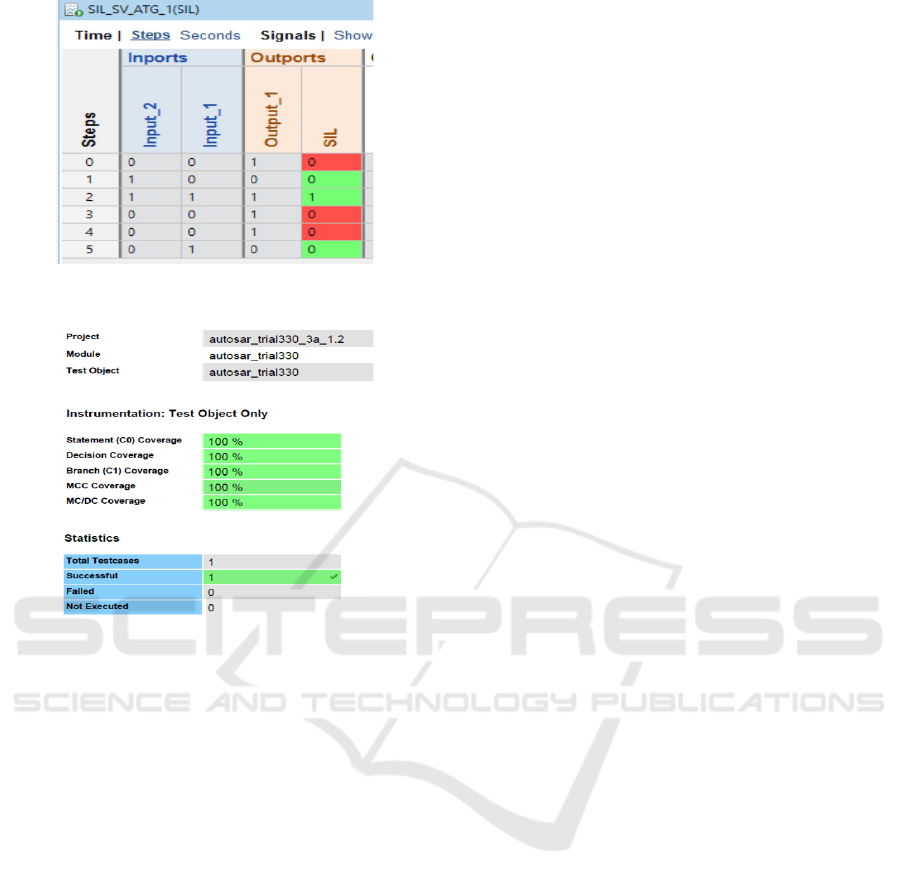

In order to explore case 2, an example model is

taken which has undergone signal routing changes to

provide better data abstraction of AUTOSAR model

migration. The reference model is Non-AUTOSAR

model as shown in Figure 7 and the production model

is AUTOSAR model as shown in Figure 8. In Figure

7, the function given is even parity function, whose

function is, if even number of inputs are true then

output is true, else false. With migration to

AUTOSAR architecture, new interface signals are

created to replace old interfaces to be compatible with

AUTOSAR architecture. Sometimes the properties,

scaling of the signals might change during the new

signal creation process or there arise scenarios where

the signal routing can go wrong with migration when

compared to the reference model. One more possible

case of deviation is when the model is migrated,

unnecessary or redundant signals and logics is

removed, in such cases the unit test results of both the

models will not match.

Table 1: Test cases for XOR logic.

Test scenario

Test

No.

Input

4

Input

5

Reference

model

Output 3

Production

model

Output 3

Manual test

cases

1 0 0 0 0

2 0 1 1 1

3 1 0 1 1

Unique test

combination

from BTC tool

4 1 1 1 0

Figure 7: Reference Non-AUTOSAR model.

Figure 8: Production AUTOSAR model.

SIMULTECH 2022 - 12th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

250

Figure 9: Functional Equivalence Test Results.

Figure 10: Conventional Test Results.

When tested this in the conventional method by

designing the test scenarios i.e. test step 1, step 2 and

step 5 shown in Figure 9 to cover the requirement and

code coverage, we can notice that some of these

deviations in functionality are not identified in the

results despite achieving 100% code coverage as

shown in Figure 10. Hence functional equivalence

test plays a crucial role in validating the migration of

model in an effective manner. Along with the existing

test cases of the reference model, automatically

generated unique test combinations from the testing

tool are tested on reference and production models.

Test scenarios in step 0,step 3 and step 4 in Figure 9

are the unique test combinations automatically

generated from the testing tool. When the results are

compared as there is a deviation introduced, fail cases

appeared in the results. This will go to the notice of

the engineer and necessary steps can be taken. In the

cases where due to redundancy or optimization if

some signals or any logics are removed, if the

engineer analyses and confirms that the test failures

are as expected due to modifications carried out, fail

cases can be justified and software module can be

moved to next level in the process.

7 CONCLUSION

In the literature, we did not find relevant methodology

to solve the issues during migration activities. We

initially started with an idea and evolved this

functional equivalence process after trialing on

different set of issues and software components. The

sequence of steps given in the process is novel and

carefully designed to identify issues, minimize the

efforts. Future scope of this work to automating this

function equivalence testing process and developing

a Continuous Integration and Continuous

Development (CI/CD) setup to make better use of

resources.

ACKNOWLEDGEMENTS

We thank Kaushik Raghunath and Samiya Behera for

supporting and guiding us in completing this idea.

REFERENCES

C. Chiang (2007). Software stability in software

Reengineering, IEEE International Conference on

Information Reuse and Integration.

P. Atcherley (1994). Reengineering legacy systems into

new environments, IEEE Colloquium on Reverse

Engineering for Software Based Systems.

Antonini, Canfora, Cimitile, (1994). Re-engineering legacy

systems to meet quality requirements: an experience

report, Proceedings 1994 International Conference on

Software Maintenance

A.B.Hocking, J.Knight, M.A.Aiello and S.Shiraishi,.

(2014). Proving Model Equivalence in Model Based

Design, IEEE International Symposium on Software

reliability Engineering Workshops.

MA Vouk (1990). Back-to-back Testing, Information and

Software Technology

BTC Embedded Systems AG, EmbeddedTester,

https://www.btc-es.de/en/products/btc-

embeddedtester.

A Novel Approach to Functional Equivalence Testing

251