Mechanical Design of an Assistive Robotic System for Bilateral Elbow

Tendinopathy Rehabilitation

Andres Guatibonza

a

, Carlos Zabala, Leonardo Solaque

b

, Alexandra Velasco

c

and Lina Pe

˜

nuela

d

Militar Nueva Granada University, Bogot

´

a, Colombia

Keywords:

Rehabilitation Robotics, Upper Limb, Mechanical Design, Design Criteria.

Abstract:

Diseases related to upper limb mobility are increasingly common among the actual population. For this reason,

robotic physical assistive systems have been proposed to support therapy processes and improve the functional

capabilities of people. However, there are still open issues related to mechanical design, such as joint coupling

and bidirectional configurations. In this work, we present a novel design of a 7 DoF robotic assistive system

with anthropometric adjustment, arm change configuration for elbow tendinopathies rehabilitation to use it

in both arms. The design is supported by the analysis of the upper limb pathophysiology and the exercises

required to treat elbow tendinopathies.

1 INTRODUCTION

Currently, physical disabilities are a public health

problem, affecting people’s quality of life and lim-

iting the development of physical activities (Jabeen

et al., 2016). According to the World Health Organi-

zation (WHO), more than one billion people world-

wide have a disability, of which 16.5% suffer from

mobility-related impairments (WHO, 2011). Some

of the causes of this kind of impairments are injuries

related with neurological, vascular, infectious or de-

generative agents. Moreover the impairments can be

caused by high level of demand in the performance

of repetitive activities, occupational or domestic ac-

cidents, etc. (Jabeen et al., 2016; Dick et al., 2010;

Fagher and Lexell, 2014). These injuries usually oc-

cur in the tendon structures of the upper limb, espe-

cially in the shoulder and elbow becoming into ten-

dinitis or tendinopathies (Occhionero et al., 2014;

Costa et al., 2015), which consequently results in

pain, difficulty in the mobility and low strength. In

these cases, a physical rehabilitation process is re-

quired to restore the functionality of the affected joint

(Ritchie, 2003; Hillman, 2012; Kessler, 1950; ACP,

1932). Patients undergo treatments that include ex-

a

https://orcid.org/0000-0001-6102-563X

b

https://orcid.org/0000-0002-2773-1028

c

https://orcid.org/0000-0001-7786-880X

d

https://orcid.org/0000-0002-1925-9296

posing muscle tissues to progressive stress, increas-

ing range of motion and muscle strength, and prevent-

ing the onset of chronic pain (Ritchie, 2003; McHugh

et al., 2013; Wattchow et al., 2018; Bruder et al.,

2017; Milicin and S

ˆ

ırbu, 2018; Contributors, 2003;

Gates et al., 2015). As part of the rehabilitation pro-

cess, assistive robotics can be used to support phys-

iotherapy, providing technological tools to assist an

appropriate intervention depending on the level of

impairment (Linda et al., 2018; Olanrewaju et al.,

2015). The use of these technologies has increased

due to the ease of quantifying assessment variables

such as range of motion, velocities, muscle activity

and strength (Ballantyne and Rea, 2019). However,

the development of robotic devices naturally involves

mechanical design to a large extent, which is the focus

of our work.

Assistive systems are designed according to the

biomechanical characteristics of the required joint.

From the anatomical viewpoint, in exoeskeletons it

is complex to design a system that shares perfect

coupling with the joint preserving the range of mo-

tion. The limitation remains in the loss of mobility

ranges, usually to avoid the collision of the robotic

system with the patient; for example, when shoul-

der adduction-abduction exercises are performed (Is-

lam et al., 2020; Zimmermann et al., 2019).. In

the literature, there are some works that seek to im-

prove the conditions of mechanical coupling, such as

(Lessard et al., 2018) where tensegrity is proposed

320

Guatibonza, A., Zabala, C., Solaque, L., Velasco, A. and Peñuela, L.

Mechanical Design of an Assistive Robotic System for Bilateral Elbow Tendinopathy Rehabilitation.

DOI: 10.5220/0011289800003271

In Proceedings of the 19th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2022), pages 320-329

ISBN: 978-989-758-585-2; ISSN: 2184-2809

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

to approximate real movements more accurately, or

in (Liu et al., 2018) where mechanical postural syn-

ergies are developed to reduce complexity of trans-

mission mechanisms. In addition, in (Zimmermann

et al., 2019) the exoskeleton ANYexo has been devel-

oped, where the range of motion (ROM) is optimized

to mimic the interaction of the specialist. Another

example is the system TTI-Exo designed by (Ugurlu

et al., 2015), which has adjustable link lengths to par-

tially align the human and exoskeletal joints to avoid

uncontrolled forces caused by hyperstaticity.

On the other hand, systems have been designed

bilaterally or with an option to switch arms. For end-

effector based systems, bilateral design and imple-

mentation is much simpler because the anchor point

between the system and the upper limb is usually

through the hand grip. Work such as (Miao et al.,

2018; Miao et al., 2020a; Miao et al., 2020b; Sheng

et al., 2019; Zhang et al., 2020; Sun et al., 2021) have

implemented bilateral training in end-effector based

systems. For the case of exoskeletons the design is

more complex, and some authors opt to duplicate the

robotic system by adapting it for the opposing limb

as (Ugurlu et al., 2015; Kumar et al., 2019). Alterna-

tively, the same system for one limb can be adapted

for the opposite limb by means of an arm-switching

configuration. However, it reduces costs and adds at-

tributes in terms of adaptability, especially if used in

physical rehabilitation applications. The best known

system with this configuration is the Armeo Power

system by Hocoma (HOCOMA, ; Wu et al., 2018).

Nevertheless, to the best of our knowledge, in the lit-

erature there are no designs with this quality apart

from the Armeo Power.

In this paper we propose a mechanical design of

an assistive robotic system of 7 degrees of freedom

to support the therapy of elbow tendinopathies. The

criteria of a medical specialist has been considered as

part of the formulation and the development of the

mechanical design, as suggested by (Cruz Mart

´

ınez

et al., 2020). We present a novel design of anthropo-

metric adjustment and arm change, avoiding the need

to duplicate the arm. For this, initially we perform

an analysis of the physiopathology of the upper limb,

from this, qualitative and quantitative design criteria

are defined, determining the degrees of freedom and

torques required according to specifications obtained

from these criteria. Subsequently, we develop the me-

chanical design, showing the preliminary version to-

gether with the arm-switching configuration; then, we

present some conclusions of this work.

2 PHYSIOLOGY,

BIOMECHANICS AND

PATHOLOGIES OF THE UPPER

LIMB

In this section, we analyze concepts related to the

anatomy, physiology, pathologies and physiotherapy

of the upper limb. It is mandatory to know how the

articular system of the upper limb works in order to

understand the biomechanics and subsequently de-

velop a mechanical analogy that will allow us to es-

tablish design criteria according to the problem to be

addressed.

The upper limb is composed of three parts: the

arm, the forearm and the hand. In the proximal part

of the arm is the joint complex called the shoulder

(Fierro, 2015), which is the most mobile joint in the

entire human body since it allows the orientation of

the upper limb in the three anatomical planes (sagit-

tal, frontal and transverse), which allows flexion-

extension, adduction-abduction, internal-external ro-

tation, horizontal flexion-extension and complemen-

tary movements such as protraction-retraction (Keith

L. Moore and Agur, 2013; Knudson, 2007). The

elbow is located in the distal part of the arm and

proximal part of the forearm (Palacios, 2015). This

joint allows flexion and extension movements, as

well as distributing the load bearing forces and trans-

mitting pronation and supination movements to the

wrist. In the proximal part of the hand we find the

wrist joint, which allows movements of pronation-

supination, flexion-extension and radial-ulnar devia-

tion (Fierro, 2015; Keith L. Moore and Agur, 2013).

Note that in the schemes of elbow therapy exercises,

it also involves the mobility of the other joints of the

upper limb. (Knudson, 2007; Taboadela, 2007; Chau-

rand et al., 2007)

The normal joint ranges are shown in the Table

1, where the measurement methods of the AAOS

(American Academy of Orthopaedic Surgeons) of the

United States are used.

2.1 Tendinopathies and Physiotherapy

The elbow joint is frequently exposed to different con-

ditions or pathologies. Among the most common are

traumas such as fractures, dislocations, simple contu-

sions, sprains and strains (Med, ). There are also el-

bow tendinopathies produced mainly by activities or

work that require constant and repetitive use of the el-

bow (Ruiz, 2011). The tendinopathies of the elbow

are divided into lateral epicondylitis (tennis elbow)

(Sanchez, ), and medial epicondylitis (golfer’s elbow)

Mechanical Design of an Assistive Robotic System for Bilateral Elbow Tendinopathy Rehabilitation

321

Table 1: Joints and ranges of mobility. AAOS: American

Academy of Orthopaedic Surgeons.

Joint Movement Angles

Shoulder

girdle

Protraction -

Retraction

Protraction:

0° − 25°/30°, Re-

traction: 0° − 25°/30°

Shoulder

(gleno-

humeral)

Abduction -

Adduction

Abduction: 0° − 180°,

Adduction: 0°

Flexion -

Extension

Flexion: 0° − 180°, Ex-

tension: 0° − 60°

Internal -

External

rotation

Internal: 0° − 70°, Exter-

nal: 0° − 90°

Horizontal

Flexion -

Extension

Flexion: 0° − 135°, Ex-

tension: 0° − 40°/50°

Elbow Flexion -

Extension

Flexion: 0° − 150°, Ex-

tension: 0°

Wrist Pronation -

Supination

Supination: 0° − 80°,

Pronation: 0° − 80°

Flexion -

Extension

Flexion: 0° − 80°, Exten-

sion: 0° − 70°

(Grupo, 2011; SportMe, ). In these cases of trauma,

a physical rehabilitation process is necessary to re-

store the person physically, socially and occupation-

ally (ACP, 1932; Kessler, 1950; Ritchie, 2003; Hill-

man, 2012).

The main goal of physical rehabilitation is the

prevention of stiffness and restoration of the joint.

Once mobility, stability and pain are controlled, speed

and strength are restored later, essentially to prevent

chronic pain (Vulliet et al., 2017). Within physi-

cal therapy, the specialist uses some tests to validate

the diagnosis of tendinopathy as Maudsley, Mills,

Cozen, inverted cozen, golfer’s elbow sign, etc. And

then uses other exercises for rehabilitation as stretch-

ing, mobility and isometric exercises (Kessler, 1950;

ACP, 1932; Henning, 2010). As mentioned before,

the exercise schemes used in the diagnosis and re-

habilitation of tendinopathies require the use of the

elbow joint, and also the shoulder and wrist joints

(Cort

´

es Rojas and Ramos Moreno, 2017). Therefore,

the mechanical design must respond to the minimum

specifications of movement of the joints included in

the different diagnostic and rehabilitation protocols.

This leads to the selection of joints, ranges of mobil-

ity and degrees of freedom in the design of the robotic

system.

3 DESIGN CRITERIA

Based on the anatomy, physiology, and biomechanics

of the upper limb, and considering the diagnostic and

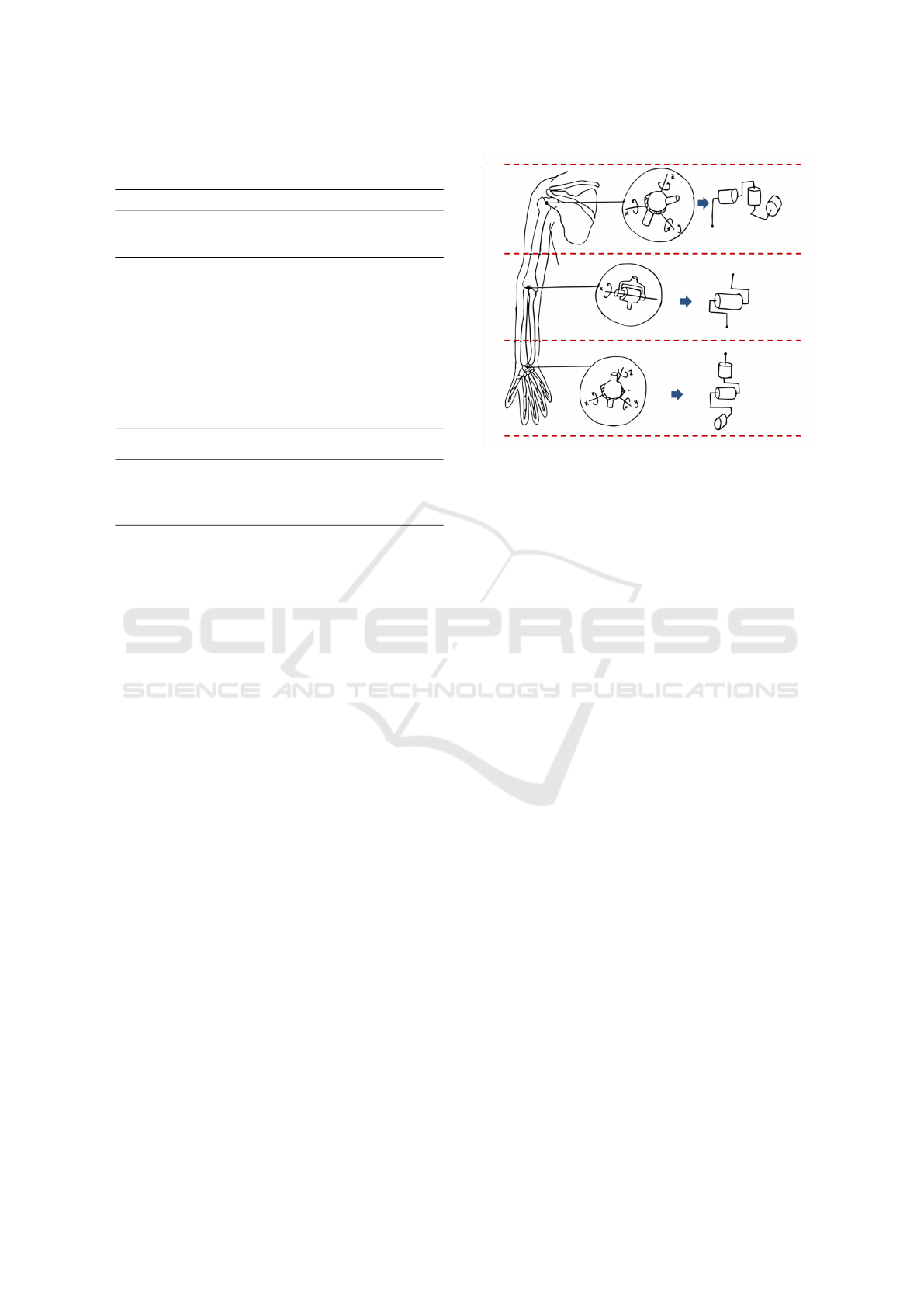

Figure 1: Anatomical-Mechanical analogy.

rehabilitation exercises for elbow tendinopathies, the

anatomical-mechanical model and the design specifi-

cations of the assistive system are determined. The

starting point is an anatomical and functional para-

metric definition of the upper limb. Then, a first

approach is made to design the device based on the

biomechanics of the upper limb. In Fig. 1 an analogy

of the mechanical model approach is presented.

Anatomically, it is complex to design an active

system that shares a perfect coupling with the joint

and preserves maximum working space, and the sys-

tem design must guarantee a perfect coupling between

the robotic system and the human limbs in order to

avoid discomfort or collisions (Islam et al., 2020;

Zimmermann et al., 2019), but preserving to a greater

extent the ranges of mobility.

3.1 Qualitative and Quantitative

Criteria

An qualitative and quantitative criteria are established

by analyzing the advantages and disadvantages of pa-

rameters such as the type of device (exoskeleton, end-

effector), type of chain (open, closed), type of trans-

mission (rigid, elastic), and above all, to seek the

greatest inclusion of the population through a para-

metric analysis of anthropometry based on anthro-

pometric indices of the Latino and U.S. population

(Avila-Chaurand et al., 2007; Gordon et al., 1989).

In Table 2 the criteria considered in the design of the

robotic assistive system are shown where qualitative

criteria as type of device, type of chain, type of trans-

mission, and quantitative criteria as dimensional pa-

rameters and functional parameters are considered.

The first three aspects listed in Table 2 (type of

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

322

Table 2: Qualitative and quantitative design criteria.

Advantages Disadvantages

Type of device

Final effector

Does not depend on the length of

the human arm, more people inclu-

sion

Limited movement according to di-

mensions

Easy to manufacture Cannot move each joint independently

Joint position estimation needed, can

not be directly measured

Exoskeleton

The movement occurs directly in

the patient’s joints.

Depends on anatomical lengths of pa-

tients, exclusion criteria

Independent movement for each

joint

Increased manufacturing complexity

Independent control of each junc-

tion, independent measurements

Type of chain

Open Wide movement regardless of de-

vice dimensions

Increased susceptibility to external

forces and inertia

Closed Major stability against external

forces

Movement limited by the dimensions

of the device

Type of transmission

Rigid

Direct connection with drive shaft,

avoids losses for friction or elastic-

ity.

Possible fractures in the structure due

to unforeseen shocks

Space optimization

Elastic

Quieter movements Possible sliding under forces greater

than supported

Absorbs shocks in the transmission Large dimensions

Easy disengagement and mainte-

nance

Min Max

Dimensional parameters

Height 1.47 m 1.93 m

Body mass 46.7 Kg 124.7 Kg

Upper limb

weight

2.335 Kg 6.235 Kg

Arm length 0.27 m 0.41 m

Arm perimeter 0.23 m 0.34 m

Forearm length 0.21 m 0.33 m

Forearm

perimeter

0.21 m

Side arm length 0.65 m 0.82 m

Elbow width 0.055 m 0.074 m

Elbow to elbow

width

0.34 m 0.7 m

Hand length 0.15 m 0.19 m

Wrist width 0.045 m 0.06 m

Hand width 0.069 m 0.091 m

Joint and

movement

Approx. torque + standard devi-

ation (N) in women

Approx. torque + standard devia-

tion (N) in male

Functional parameters

Shoulder ad-

duction

28.4 ± 7.5 51.3 ± 17.7

Shoulder flex-

ion

30.4 ± 8.7 55.0 ± 17.6

Shoulder exten-

sion

34.3 ± 11.2 73.5 ± 27.9

Shoulder inter-

nal rotation

19.4 ± 4.6 41.1 ± 10.1

Shoulder exter-

nal rotation

20.7 ± 5.2 38.3 ± 9.1

Elbow flexion 39.4 ± 7.7 70.9 ± 15.9

Elbow exten-

sion

22.0 ± 4.7 44.3 ± 9.8

Hand grip 250.4 ± 54.8 411.3 ± 73.5

Mechanical Design of an Assistive Robotic System for Bilateral Elbow Tendinopathy Rehabilitation

323

device, type of chain and type of transmission) are

based on the number of advantages versus the num-

ber of disadvantages. The other criteria are delimited

specifications according to the application. First, for

the type of device an exoskeleton is more appropriate,

the most important reason is that the motion is applied

directly at the joint and reduces the need to estimate

positions and velocities. Second, for the type of chain

is indifferent if design specifications and workspaces

are retained. In our case, an open chain configuration

was chosen because of the design complexity of the

whole upper limb, and also, the selection of a closed

chain limits the range of joint amplitude and singu-

larities may appear (Romero-Acevedo et al., 2018;

Guatibonza et al., 2018). Third, the type of transmis-

sion also depends on the application and the amount

of stress that will be applied to the actuator and to the

mechanical structure. In our case, the motion stud-

ies and the technical characteristics of the actuators

define the necessary load to satisfy the requirement

torque. Finally, the dimensional parameters define to

a large extent the design specifications of the robotic

system, since they are based on anthropometric stud-

ies of the target population. These dimensional cri-

teria have maximum and minimum values that the

robotic system must achieve. This is an aspect of

adaptability and generalization within the framework

of the target population. Similarly, the functional pa-

rameters define the specifications in terms of maxi-

mum torques and the need of transmission systems.

Whether using them or not depends on the technical

characteristics of the motors and the effort require-

ments.

In this work, the option of bilateral handling with-

out the need to duplicate the robotic system for the

opposite arm is proposed. This is possible through

an arm switching configuration. This feature reduces

costs and adds attributes in adaptability, especially if

it is used in physical rehabilitation applications (HO-

COMA, ; Wu et al., 2018).

3.2 Degrees of Freedom

Based on the mobility ranges defined in Table 1, the

workspace of the entire upper limb is defined by iden-

tifying the maximum lenghts that the upper limb can

achieve in the frontal, transverse and sagittal planes.

The design of the robotic system must then be ad-

justed to the defined workspace. The challenge now

is to define a design that preserves spatial specifi-

cations, adaptability to people with different anthro-

pometric proportions, collision avoidance with the

robotic system and configuration for arm-switching.

The following aspects play a very important role in

the design to guarantee the working space: 1. Num-

ber of degrees of freedom, 2. Optimization of the

space in the design constrained by the type of ac-

tuator used, and 3. The order in the location of

each of the actuation axes. The validation of points

1 and 3 requires heuristic strategies that can be ob-

tained by means of physical scale models or simu-

lation models. In our case, we verified this strategy

using both methods, focused mainly on the elbow

joint, because it is a compound joint where several

movements are generated on the same point (flexion-

extension, adduction-abduction, flexion-horizontal

extension, internal-external rotation and protraction-

retraction (scapulohumeral)) (Keith L. Moore and

Agur, 2013; Knudson, 2007).

The design of the system suggests a minimum

of 6 degrees of freedom (DoF), since the exercise

schemes defined in both diagnosis and rehabilitation

of tendinopathies indicate not only the use of the el-

bow joint, but also the other joints of the upper limb.

In our case, we consider the protraction-retraction

movements as a complement of the flexion-extension

horizontal shoulder movements to reach the full range

of amplitude in the transverse plane. Consequently,

the design is oriented to a redundant 7 DoF robotic

system. The procedure is as follows: We start from

a conceptual design where an initial order of the axes

of actuation is defined. Subsequently, we transfer the

concept to a physical scale model so that the options

of the order and alignment of the axes with the shoul-

der can be visually analyzed. Finally, the configu-

ration on the scale model suggests an organization

of the axes of action as defined here: 1. protraction

- retraction (scapulo-humeral), 2. flexion - horizon-

tal extension (gleno-humeral), 3. flexion - extension

(gleno-humeral), 4. adduction - abduction (gleno-

humeral), 5. elbow flexion - extension, 6. wrist prona-

tion - supination, and 7. wrist flexion - extension.

With these configurations, a simple CAD model is

constructed to confirm the range of the system in the

previously described workspace.

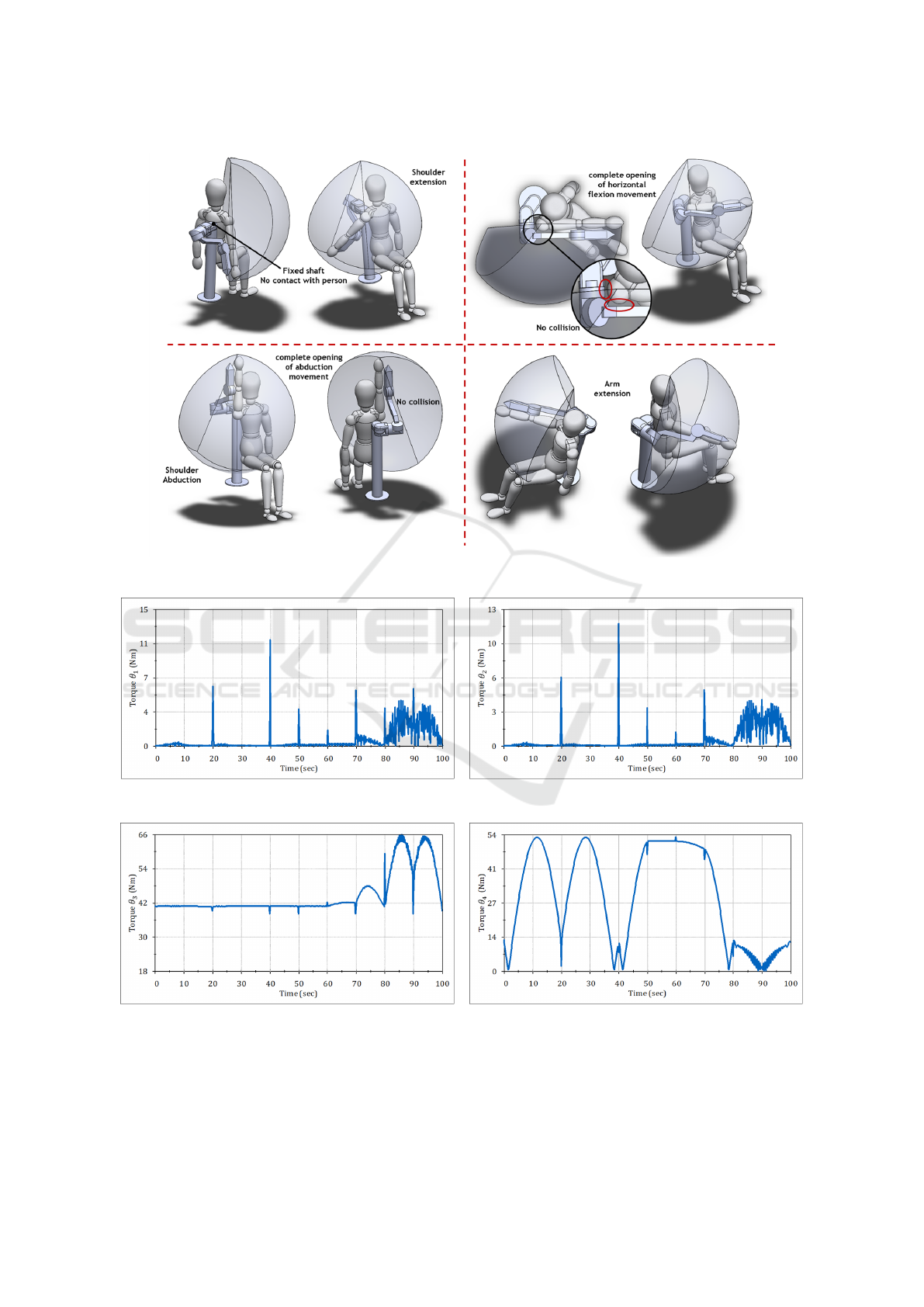

In Fig. 2 a simple conceptual design of the 7

DoF system is shown in the limit positions of the

workspace. The proposed configuration satisfies the

workspace of the upper limb and no collisions are

generated in maximum amplitudes of the movements

such as abduction, extension and horizontal flexion of

the shoulder.

3.3 Motion Analysis

The motion analysis allow to determine the maximum

torque required for each joint. In shoulder joint, ac-

tuators must provide necessary torque to move both

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

324

Figure 2: Composition of upper limb workspace based in AAOS.

(a) Torque acquisition from pronation-supination move-

ments.

(b) Torque acquisition from horizontal flexion-extension

movements

(c) Torque acquisition from flexion-extension movements (d) Torque acquisition from abduction-adduction move-

ments

Figure 3: Theoretical torques from motion analysis.

Mechanical Design of an Assistive Robotic System for Bilateral Elbow Tendinopathy Rehabilitation

325

robotic and human arm. Therefore, an analysis is car-

ried out to determine the last design criteria: choice of

the actuator and type of transmission (elastic, rigid).

To perform the simulation, an initial weight is as-

signed to the links of the CAD model using an aver-

age weight per link of 1.5Kg taken from Table 2. The

weights are then oversized by at least an additional 40

% or 50 %. Additionally, the weight of the human arm

is incorporated taking as a reference the maximum di-

mensional parameters of Table 2. Flexion-extension,

abduction-adduction and horizontal shoulder flexion-

extension movements are considered for the simula-

tion. From the motion studies an approximation of the

maximum torques is obtained. These values are used

as a reference for the choice of the actuators and di-

mensional design of the assistive robotic system. The

results obtained are shown in Fig. 3a-3d

Notice that the θ

1

Protraction - retraction (scapu-

lohumeral) and θ

2

Flexion - horizontal extension

(glenohumeral) joints reach maximum values of

12Nm. While θ

3

Flexion - extension (glenohumeral)

and θ

4

Adduction - abduction (gleno-humeral) joints,

the required torques reach values of 66Nm and 54Nm,

respectively. This implies that the actuators cho-

sen must satisfy these torques or, alternatively, use

torque multiplication drives if they are not commer-

cially available.

The torques obtained are purely theoretical and

will involve a reduction of the design dimensions of

the robotic system to reduce the demand of the mo-

tors on the physical therapy routines, the weight of

the patient’s arm, and the weight of the robotic as-

sistive system itself. With the results obtained from

Figs. 3a-3d we analyzed commercial aspects of the

actuators such as weight, continuous and maximum

torques, controller card included, transmission box in-

cluded and prices. Finally, we are using the RMD-X8

pro brushless actuators for their weight-quality-price

ratio. The actuators will be for the shoulder and elbow

joints, and following the same line the RMD L-5015

actuators are intended for the wrist joint. These actu-

ators are equipped with a transmission box. However,

the theoretical torque results obtained in Figs. 3a-3d

suggest adding an additional transmission stage that

can either be elastic or rigid. The choice does not

imply any advantage or disadvantage of one over the

other, as long as the same dimensional design con-

ditions and torque multiplication factor are preserved.

With these considerations, we proceed to the mechan-

ical design of the upper limb assistive robotic system.

4 MECHANICAL DESIGN OF

THE ROBOTIC ASSISTIVE

SYSTEM

For the design of the assistive robotic system, we start

by placing in the design software all the commercial

components required. In the structural development

of the arm, the actuators are the main components

since from there, we start to design drawers, housings,

supports, bases.

We start designing from the distal to the proxi-

mal part of the upper limb. The actuator is placed in

the same orientation of the movement to be executed.

Considering the design criteria in Table 2, we design

the wrist joint starting with the grip, subsequently,

the first joint movement (wrist flexion-extension), and

then, the second joint movement (wrist pronation-

supination). We implement handgrip adjustable to

different hand sizes, using a manual gear. To perform

the wrist flexion-extension movements, the axis of

movement between the robotic system and the wrist

are aligned.

Subsequently, the forearm section and the second

wrist movement are designed. The forearm has two

support points. One is located in the proximal part of

the forearm, and the other in the distal part. The actu-

ator for the wrist protraction-retraction movements is

located on the distal part of the forearm. The designed

system has a semicircular rail propelled by a belt. A

carriage is connected to the rail, which slides and ro-

tates concentrically with the midpoint of the semicir-

cle of the rail. This connection aligns it with the axis

of movement of wrist pronation-supination.

The proximal part of the forearm has two support

rods for length adjustment. These rods work as a lin-

ear rail by means of a worm screw. This mechanism

allows the operator to set up the length of the robotic

forearm according to the length of the patient’s fore-

arm. Finally, a setup gear is designed to make the

arm change. This allows the operator to rotate the

forearm-wrist-grip complement in 180° around the el-

bow joint. This option is similar to the Hocoma’s

Armeo Power system (HOCOMA, ), but it reduces

weight and size, without decreasing robustness.

The next joint (elbow flexion-extension) is then

designed. In the same way, the actuator is po-

sitioned to align the movement of the motor with

the elbow. Next to the output shaft, the support

is connected to other linear guide to correct the

length of the robotic arm according to the length

of the patient’s arm. We then proceed to design

the joints associated with the gleno-humeral shoulder

joint (flexion-extension, horizontal flexion-extension

and abduction-adduction). There are three actuators

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

326

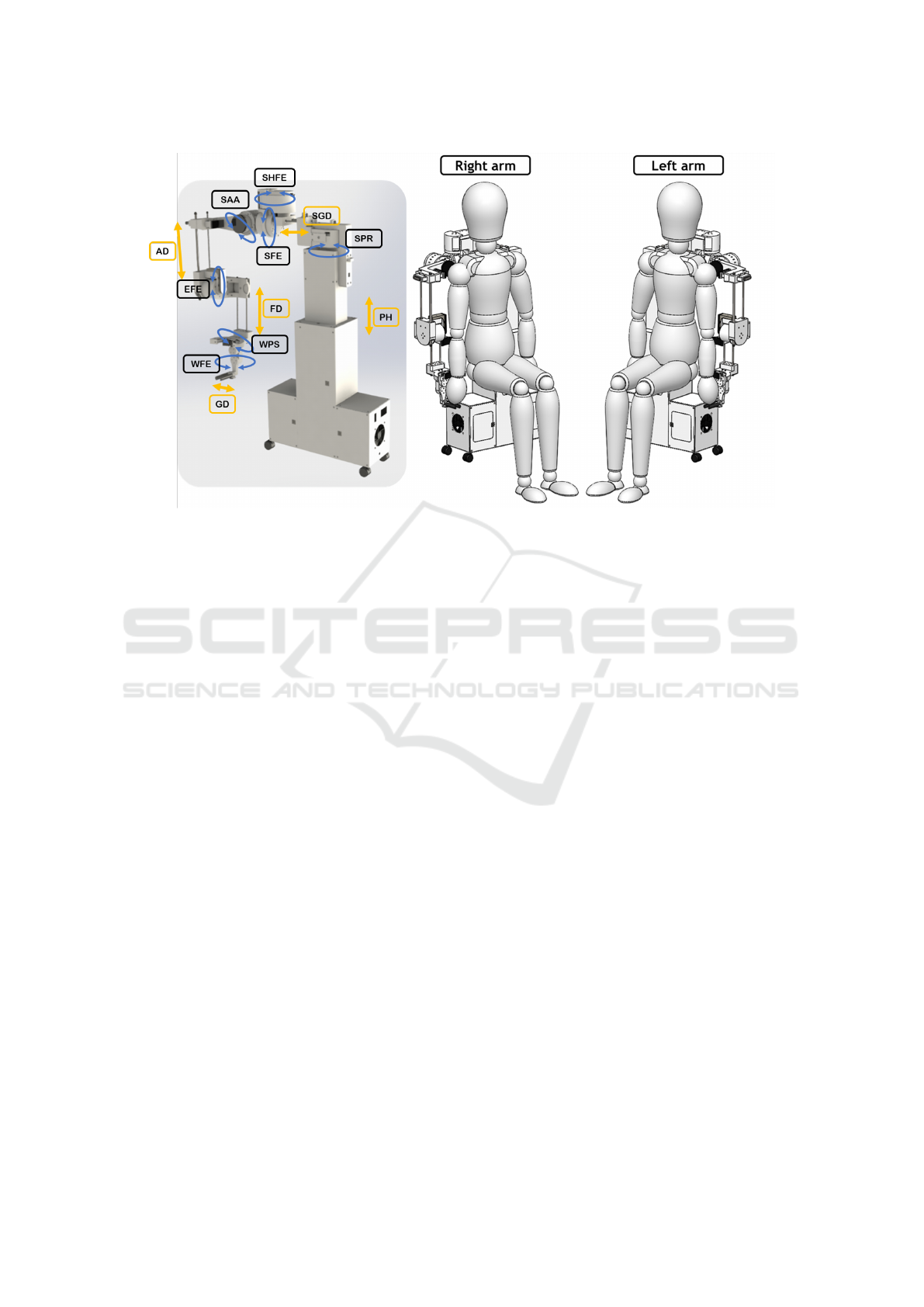

Figure 4: complete robotic assistive system design and arm switch configuration. SPR: shoulder protraction-retraction,

SHFE: shoulder flexion-extension, SFE: shoulder flexion-extension, SAA: shoulder adduction-abduction, EFE: elbow flexion-

extension, WPS: wrist pronation-supination, WFE: wrist flexion-extension, PH: patient height, SGD: scapulo-humeral to

gleno-humeral distance, AD: arm distance, FD: forearm distance and GD: grip distance

share the same frontal plane, and a locking mecha-

nism to execute the arm change configuration. This

mechanism allows to release the shoulder arm on an

axis to rotate it 180°. The actuators associated to

the flexion-extension and abduction-adduction move-

ments require planetary transmission. This is because

with this configuration a higher torque multiplica-

tion factor is obtained than with a belt transmission

(see the results in Figs. 3c and 3d). The planetary

transmission has a 1:8 ratio, which means a signif-

icant increase of the joints torque. As it is a rigid

transmission, helical gears are used to reduce noise

compared to spur gears. On the other hand, the ac-

tuator that performs the horizontal flexion-extension

movements does not require a substantial increase in

torque. Therefore, a belt drive is enough, since this

movement is performed in the horizontal plane, so

gravity does not affect.

Finally, the shoulder motion in the scapulo-

humeral part (pronation-supination) is an extension

of the horizontal flexion-extension movements of the

shoulder. So, in a similar way we have a belt transmis-

sion, which is enough because the movement is also

performed in the horizontal plane. This joint is impor-

tant as it supports the weight of the whole robotic arm

and the human arm. A reinforcement support is di-

rectly connected to the main base of the assistive sys-

tem. The base is composed of a structural system of

beams in the shape of an inverted T where the robotic

arm is housed in the upper part and this base functions

as a rail to correct the alignment height with respect

to the height of the patient. Rail guides are driven

by linear bearings and the movement is driven by lin-

ear actuators. The electronics, power supplies, control

systems and ventilation are located in the lower part,

to give more stability and robustness to the base of

the system. Finally, beaver-type wheels are included

to move the robotic system as needed. We present the

complete assistive robotic system in configuration for

left arm and right arm, and a render in Fig. 4.

5 CONCLUSIONS

This paper presents the procedure for the mechani-

cal design of a robotic assistive system for the reha-

bilitation of elbow tendinopathies. We present a se-

ries of guidelines for the design of this type of sys-

tems starting from an analysis of the physiological,

biomechanical and technological components associ-

ated with the pathology, supported also by motion

simulation studies where we consider joint mobility

ranges. Subsequently, we identified some qualitative

and quantitative design criteria that are of great im-

portance in the design of systems for physical rehabil-

itation, and we determined the complete workspace of

the upper limb, built the conceptual and mathematical

models of the system. We consider practical aspects

Mechanical Design of an Assistive Robotic System for Bilateral Elbow Tendinopathy Rehabilitation

327

of performance selection, and in addition, we propose

a never-before-seen arm switching configuration.

These criteria are a starting point in the systemati-

zation of the mechanical design processes of robotic

systems for physical assistance or rehabilitation. Fu-

ture work will be oriented to the construction of the

robotic assistive system, and the improvement of the

system as observed in practice.

FUNDING

This work is funded by Universidad Militar Nueva

Granada- Vicerrector

´

ıa de Investigaciones, under re-

search grant for project IMP-ING-3127, entitled

’Dise

˜

no e implementaci

´

on de un sistema rob

´

otico

asistencial para apoyo al diagn

´

ostico y rehabilitaci

´

on

de tendinopat

´

ıas del codo’.

REFERENCES

U.s. national library of medicine. el-

bow injuries and disorders.

https://medlineplus.gov/elbowinjuriesanddisorders.ht

ml. [Online; accessed March-2022].

ACP (1932). Physiotherapy: Its principles and practice. An-

nals of Internal Medicine, 6(2):298.

Avila-Chaurand, R., Prado-Le

´

on, L., and Gonz

´

alez-Mu

˜

noz,

E. (2007). Dimensiones antropom

´

etricas de la

poblaci

´

on latinoamericana : M

´

exico, Cuba, Colom-

bia, Chile / R. Avila Chaurand, L.R. Prado Le

´

on, E.L.

Gonz

´

alez Mu

˜

noz.

Ballantyne, R. and Rea, P. M. (2019). A game changer: ‘the

use of digital technologies in the management of up-

per limb rehabilitation’. In Advances in Experimental

Medicine and Biology, pages 117–147. Springer Inter-

national Publishing.

Bruder, A. M., Shields, N., Dodd, K. J., and Taylor, N. F.

(2017). Prescribed exercise programs may not be ef-

fective in reducing impairments and improving activ-

ity during upper limb fracture rehabilitation: a system-

atic review. Journal of Physiotherapy, 63(4):205–220.

Chaurand, R.

´

A., Le

´

on, L. R. P., and Mu

˜

noz, E.

L. G. (2007). Dimensiones antropom

´

etricas de

poblaci

´

on latinoamericana. Universidad de Guadala-

jara, CUAAD.

Contributors (2003). Rehabilitation of the hand & upper

limb. In Prosser, R. and Conolly, W. B., editors, Re-

habilitation of the Hand & Upper Limb, pages vii –

viii. Butterworth-Heinemann, Oxford.

Cort

´

es Rojas, M. F. and Ramos Moreno, I. R. (2017).

Revisi

´

on documental de los m

´

etodos diagn

´

osticos

y de tamizaje en des

´

ordenes m

´

usculo esquel

´

eticos

en miembros superiores de etiolog

´

ıa laboral.

http://hdl.handle.net/10554/39988.

Costa, J. T. D., Baptista, J. S., and Vaz, M. (2015). Inci-

dence and prevalence of upper-limb work related mus-

culoskeletal disorders: A systematic review. Work,

51(4):635–644.

Cruz Mart

´

ınez, G. M., Z-Avil

´

es, L., et al. (2020). Design

methodology for rehabilitation robots: Application in

an exoskeleton for upper limb rehabilitation. Applied

Sciences, 10(16):5459.

Dick, F. D., Graveling, R. A., Munro, W., and and, K. W.-B.

(2010). Workplace management of upper limb disor-

ders: a systematic review. Occupational Medicine,

61(1):19–25.

Fagher, K. and Lexell, J. (2014). Sports-related injuries

in athletes with disabilities. Scandinavian Journal of

Medicine & Science in Sports, 24(5):e320–e331.

Fierro, G. (2015). “anatom

´

ıa del hombro,” guido fierro

ortopedia y traumatolog

´

ıa - cirug

´

ıa de hombro y

codo. https://www.guidofierro.com/diagnostico-y-

tratamiento.

Gates, D. H., Walters, L. S., Cowley, J., Wilken, J. M., and

Resnik, L. (2015). Range of motion requirements for

upper-limb activities of daily living. American Jour-

nal of Occupational Therapy, 70(1):7001350010p1.

Gordon, C. C., Blackwell, C. L., Bradtmiller, B., Parham,

J. L., Barrientos, P., Paquette, S. P., Corner, B., Car-

son, J., Venezia, J. C., Rockwell, B. M., Mucher, M.,

and Kristensen, S. (1989). 2012 anthropometric sur-

vey of u.s. army personnel: Methods and summary

statistics.

Grupo, d. t. d. o. d. c. o. d. B. (2011). Epicondilitis y epitro-

cle

´

ıtis. revisi

´

on. Farmacia Profesional, 25(6):49–51.

Guatibonza, A. F., Solaque, L., and Velasco, A. (2018).

Kinematic and dynamic modeling of a 5-bar assistive

device for knee rehabilitation. In 2018 IEEE Third

Ecuador Technical Chapters Meeting (ETCM). IEEE.

Henning, T. (2010). Clinical tests for the musculoskele-

tal system: Examinations-signs-phenomena. JAMA,

303(15):1541.

Hillman, S. K. (2012). Core concepts in athletic training

and therapy with web resource. Annals of Internal

Medicine.

HOCOMA (-). Hocoma products overview. Online, ac-

cessed August-2020.

Islam, M. R., Brahmi, B., Ahmed, T., Assad-Uz-Zaman,

M., and Rahman, M. H. (2020). Exoskeletons in upper

limb rehabilitation: A review to find key challenges to

improve functionality. Control Theory in Biomedical

Engineering, pages 235–265.

Jabeen, T., Kazmi, S., Rehman, A., and Ahmed, S. (2016).

Upper and lower limbs disability and personality

traits. Journal of Ayub Medical College, Abbottabad:

JAMC, 28:348–52.

Keith L. Moore, A. F. D. and Agur, A. M. R. (2013). Moore,

anatom

´

ıa con orientaci

´

on cl

´

ınica. Wolters Kluwer

Health, S.A., Lippincott Williams & Wilkins.

Kessler, H. H. (1950). The principles and practices of reha-

bilitation. Physical Therapy, 30(3):126–127.

Knudson, D. (2007). Fundamentals of Biomechanics, Sec-

ond edition. Springer US.

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

328

Kumar, S., W

¨

ohrle, H., Trampler, M., Simnofske, M., Pe-

ters, H., Mallwitz, M., Kirchner, E. A., and Kirchner,

F. (2019). Modular design and decentralized control

of the RECUPERA exoskeleton for stroke rehabilita-

tion. Applied Sciences (Switzerland), 9(4).

Lessard, S., Pansodtee, P., Robbins, A., Trombadore, J. M.,

Kurniawan, S., and Teodorescu, M. (2018). A Soft

Exosuit for Flexible Upper-Extremity Rehabilitation.

IEEE Transactions on Neural Systems and Rehabili-

tation Engineering, 26(8):1604–1617.

Linda, N., Maia, M., Hennen, L., Wolbring, G., Bratan, T.,

Kukk, P., Cas, J., Capari, L., Krieger-Lamina, J., and

Mordini, E. (2018). Assistive technologies for people

with disabilities - part ii: Current and emerging tech-

nologies.

Liu, K., Xiong, C. H., He, L., Chen, W. B., and Huang, X. L.

(2018). Postural synergy based design of exoskele-

ton robot replicating human arm reaching movements.

Robotics and Autonomous Systems, 99:84–96.

McHugh, G., Swain, I. D., and Jenkinson, D. (2013). Treat-

ment components for upper limb rehabilitation after

stroke: a survey of UK national practice. Disability

and Rehabilitation, 36(11):925–931.

Miao, Q., McDaid, A., Zhang, M., Kebria, P., and Li, H.

(2018). A three-stage trajectory generation method

for robot-assisted bilateral upper limb training with

subject-specific adaptation. Robotics and Autonomous

Systems, 105:38–46.

Miao, Q., Peng, Y., Liu, L., McDaid, A., and Zhang, M.

(2020a). Subject-specific compliance control of an

upper-limb bilateral robotic system. Robotics and Au-

tonomous Systems, 126:103478.

Miao, Q., Zhang, M., McDaid, A., Peng, Y., and Xie,

S. Q. (2020b). A robot-assisted bilateral upper limb

training strategy with subject-specific workspace: A

pilot study. Robotics and Autonomous Systems,

124:103334.

Milicin, C. and S

ˆ

ırbu, E. (2018). A comparative study of re-

habilitation therapy in traumatic upper limb peripheral

nerve injuries. NeuroRehabilitation, 42(1):113–119.

Occhionero, V., Korpinen, L., and Gobba, F. (2014). Upper

limb musculoskeletal disorders in healthcare person-

nel. Ergonomics, 57(8):1166–1191.

Olanrewaju, O. A., Faieza, A. A., and Syakirah, K. (2015).

Application of robotics in medical fields: Rehabili-

tation and surgery. Int. J. Comput. Appl. Technol.,

52(4):251–256.

Palacios, J. R. (2015). Sistema lo-

comotor extremidad superior.

https://www.infermeravirtual.com/esp/actividades de

la vida diaria/ficha/extremidad superior/sistema loc

omotor.

Ritchie, P. (2003). Sports injuries: Mechanisms, prevention,

treatment. second edition. Arthroscopy: The Journal

of Arthroscopic & Related Surgery, 19(4):448.

Romero-Acevedo, M., Guatibonza, A., and Velasco-Vivas,

A. (2018). Modular knee-rehabilitation device: Con-

figuration and workspace of assisted physical therapy

routines. In 2018 IEEE 2nd Colombian Conference

on Robotics and Automation (CCRA). IEEE.

Ruiz, D. M. C. (2011). Epicondilitis lateral: conceptos de

actualidad. revisi

´

on de tema. Revista Med de la Fac-

ultad de Medicina, 19(1):9.

Sanchez, D. M. Epicondylitis, arthroscopic surgery unit.

https://www.ucaorthopedics.com/patologias/codo/epi

condilitis/. [Online; accessed March-2022].

Sheng, B., Xie, S., Tang, L., Deng, C., and Zhang,

Y. (2019). An Industrial Robot-Based Rehabilita-

tion System for Bilateral Exercises. IEEE Access,

7:151282–151294.

SportMe. “las tendinitis del codo. epicondili-

tis y epitrocleitis” medical center sportme.

https://clinicabernaldez.com/tendinitis-del-codo-

dolor-de-codo-epicondilitis-epitrocleitis/. [Online;

accessed March-2020].

Sun, J., Shen, Y., and Rosen, J. (2021). Sensor reduction,

estimation, and control of an upper-limb exoskeleton.

IEEE Robotics and Automation Letters, 6(2):1012–

1019.

Taboadela, C. H. (2007). Goniometria una herramienta para

la evaluacion de las incapacidades. Medicine. ASO-

CIART SA ART, pages 1–130.

Ugurlu, B., Nishimura, M., Hyodo, K., Kawanishi, M., and

Narikiyo, T. (2015). Proof of Concept for Robot-

Aided Upper Limb Rehabilitation Using Disturbance

Observers. IEEE Transactions on Human-Machine

Systems, 45(1):110–118.

Vulliet, P., Chervin, J., Pierrart, J., Bourdillon, E., and

Masmejean, E. (2017). Patolog

´

ıas del codo y reha-

bilitaci

´

on. EMC - Kinesiterapia - Medicina F

´

ısica,

38(2):1 – 18.

Wattchow, K. A., McDonnell, M. N., and Hillier, S. L.

(2018). Rehabilitation interventions for upper limb

function in the first four weeks following stroke: A

systematic review and meta-analysis of the evidence.

Archives of Physical Medicine and Rehabilitation,

99(2):367–382.

WHO (2011). World report on disability. Technical report,

World Health Organization.

Wu, W., Fong, J., Crocher, V., Lee, P. V., Oetomo, D., Tan,

Y., and Ackland, D. C. (2018). Modulation of shoul-

der muscle and joint function using a powered upper-

limb exoskeleton. Journal of Biomechanics, 72:7–16.

Zhang, L., Guo, S., and Sun, Q. (2020). Development and

assist-as-needed control of an end-effector upper limb

rehabilitation robot. Applied Sciences, 10(19):6684.

Zimmermann, Y., Forino, A., Riener, R., and Hutter, M.

(2019). ANYexo: A Versatile and Dynamic Upper-

Limb Rehabilitation Robot. IEEE Robotics and Au-

tomation Letters, 4(4):3649–3656.

Mechanical Design of an Assistive Robotic System for Bilateral Elbow Tendinopathy Rehabilitation

329