The Potential Application in Medical Biomimetic Materials

Wangcheng Zhu

a

Shanghai Pinghe, Bilingual School, Shanghai, China

Keywords: Biomimetic Material, Spider Silk, Nacre, Bone, Nanomaterials.

Abstract: The "biomimetic materials science" formed by the intersection of life science and material science has

excellent theoretical and practical significance. Biomimetic materials science takes material formation and

structure as the target, considers artificial material at the view of biomaterial, exploring the manufacture and

design of material from the angle of biological function. With unique formation methods, structural

characteristics, and biomechanical properties, biomimetic materials are becoming a new field of materials

science. Based on a lot of research work, this article reviews and summarizes the work done by predecessors

in medical bionic materials. The review focuses on the research progress of biomimetic materials science

includes silk protein, nacre, bone, nanomaterials. Numerous studies have shown that these biomimetic

materials have a potential application in medicine. Finally, the development prospects of medical

biomimetic materials are forecasted.

1 INTRODUCTION

1

In recent years, with the development of related

disciplines and the progress of modern technology,

bionic materials have been developed rapidly. The

results were widely used in aviation materials,

biomedical materials, textile materials and so on.

Biomimetic materials science aims to clarify

biological materials' structure and formation process,

with biological materials to consider the idea of

artificial materials, from the perspective of

biological function to consider the material design

and production.

Biomimetic material science is an essential

branch of bionics, which refers to study the

structural characteristics, structure, and activity of

biological materials from the molecular level. It

aims to find the new science similar or better than

the original biological materials, chemistry, material

science, biology, physics, and other disciplines

cross. Medical bionic materials are an important

application field of bionic materials.

Bionic materials, such as artificial tooth enamel,

artificial bone materials, and bionic artificial fibers,

through the design of structures and materials, are

expected to achieve high efficiency, low energy

consumption, and environmental harmony

a

https://orcid.org/0000-0002-7040-353X

(Arcidiacono, 2002). Imitation of natural animal and

plant-specific function and intelligent response, the

development of and biological similarity or beyond

the existing biological function of artificial

materials, such as lotus leaf self-cleaning materials,

like the shark's self-lubricating material, in the gene

transformation of the cells in the efficient synthesis

of chiral molecules and macromolecules (Tabata,

2001). Imitate the structure and performance of

biological tissues and organs, study the structure and

properties of natural biological materials from the

perspective of materials science, and develop bionic

materials. This review will shed light on the research

and development of high-performance biomedical

materials. This review mainly introduces the

biomimetic materials of silk protein, bone, nacre,

and cells, summarizes the current development of

biomimetic materials, and hopes to inspire other

researchers.

780

Zhu, W.

The Potential Application in Medical Biomimetic Materials.

DOI: 10.5220/0011295100003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 780-784

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 MECHANISM AND

APPLICATION OF

BIOMIMETIC MATERIALS

2.1 Biomimetic Materials of Silk

Protein

Silk protein can be used to prepare excellent

biomaterials due to its good biocompatibility, low

immunogenicity, processability, and degradability.

In recent years, based on the basic principles of

tissue engineering, through material processing

technology, various forms of silk protein scaffolds

(including three-dimensional porous scaffolds,

nanofibers, hydrogels, two-dimensional membranes,

etc.) (Applegate, 2016) and silk protein drug carriers

(Microspheres, nanoparticles, etc.) have been used in

the repair of hard bones, ligaments, skin,

cardiovascular, cartilage, cornea, nerves and other

organs and tissues and anti-cancer therapy (Melke,

2016).

According to different technologies for obtaining

silk protein, the source of silk protein can be divided

into natural silk protein, recombinant silk protein,

and genetically modified silk protein. At present,

natural silks that are used and studied more include

spider silk protein and fibroin. In spider silk protein,

major ampullate silk has the advantages of high

strength, good tensile strength, and large breaking

energy, so it is currently the most studied kind of

spider silk (Hinman, 2000). The silk fibroin in the

silkworm silk fiber is coated inside the sericin, with

a diameter of about 10 μm. Studies have found that

the secondary structure of silk protein includes four

types: β-sheet, random coil, α-helix, and β-turn

(Gray, 2016).

Silk protein biomaterials prepared by different

processing technologies have different application

forms in the field of biomedicine. Silk fibers were

originally used as surgical sutures due to their

biodegradability and good biocompatibility.

Effective weaving of silk fibers can produce

"artificial ligaments" that can be used to repair or

replace broken ligaments (Altman, 2002). XU et al.

combined silk fibroin and chitosan to prepare a

composite membrane and obtained an excellent

healing effect after covering the membrane on the

wounded part of the rat (Xu,2015). YODMUANG et

al. found that silk protein gel can effectively

promote the growth of chondrocytes and the

secretion of related collagen. The formation of the

internal network of silk protein gel is conducive to

the loading of drugs or foreign genes (Yodmuang,

2015). In addition, the most studied silk protein

scaffold is used for bone tissue repair. A study

showed that adding growth factors to the scaffold

can better repair defective tissues (Meinel,2005).

Recently, Shi et al. 3D printed silk protein and

gelatin to obtain a composite scaffold that can repair

damaged cartilage in rabbit knee joints (Shi, 2017).

2.2 Biomimetic Materials of Nacre

In order to protect molluscs from water-carried

debris and predators, the shells of organisms like

abalone have evolved into a stiff and impact-

resistant material named shell. Shells are composite

materials made by mollusks that combine inorganic

minerals (CaCO3) in the surrounding environment

with organic matter generated by themselves under

ambient temperature and pressure. The formation

process of shells is a biological mineralization

process.

The shell structure is divided into 3 layers, from

the outside to inside are stratum corneum, prismatic

layer, and nacre layer. The organic layer and the

mineral layer in the nacre are arranged alternately

under appropriate magnification. The so-called

"brick and mortar" structure can be easily observed.

Its comprehensive mechanical properties, especially

fracture toughness can be rasied by 2 to 3 orders of

magnitude than that of single-phase calcium

carbonate ceramics. The alternate laminated

arrangement of nacre aragonite crystals and an

organic matrix is the key to its high toughness.

Based on this principle, material scientists have

developed the development of imitation pearl

laminated composite materials. Based on this

principle of biomineralization, Yoo et al. prepared a

boron nitride nanosheet (BNNS)/gelatin

nanocomposite. In this study, hyperbranched

polyglycerol was used to functionalize BNNS to

enhance the bonding strength between entities. By

changing the composition and arrangement degree

of BNNSs and gelatin in the nanocomposite, the

mechanical properties of the nanocomposite can be

controlled. This adjustment of mechanical properties

can produce a material with properties similar to

human cortical bone. In vitro cell experiments show

that this artificial nacre can support the adhesion and

proliferation of adipose-derived stem cells,

indicating that it can be used in biomedicine (Yoo,

2018).

Fabrication techniques such as hot-press assisted

slip casting, freeze casting, extrusion and roll

compaction, paper-making method, and layer-by-

layer self-assembly have successfully yielded

The Potential Application in Medical Biomimetic Materials

781

materials that mimic the mechanical properties of

nacre. Yongli Zhang made SiC/AL toughening

composites with AL as soft phase and SiC as the

ceramic base (Heuer,1992). And his fracture

toughness is 2 - 5 times compared to the original

one. Yang hui made A1203 toughening composites

with carbon fiber as soft phase and A1202 as a

ceramic base, increasing its fracture toughness by

1.5 -2 times (Qian,2004).

2.3 Biomimetic Materials of Bone

The mimicking of the porous and branched structure

of bone is general in the work of some architects,

originating structures that are tough and lightweight.

Bone has evolved to protect their vital organs and

provide efficient structural support to vertebrates.

Bone structure is ideal for optimal solid structure

(Almqvist, 1999)—the shape of the long bones of

the animals at both ends of the thick, elongated

intermediate. The dumbbell head in the ends of the

long bone can increase the tensile strength and

fracture toughness. Inspired by this, people design

short fiber into a "dumbbell", improving the

composite strength and elongation. It is conducive to

the coordinated movement of the material in the

fiber and the bonding materials, greatly improving

the service life.

Hu et al. developed the absorbable

chitosan/hydroxyapatite composite bionic bone

structure of fracture fixation material by situ

precipitation method and shaping not only is a

dumbbell-shaped structure but easy degradation and

absorption, with releasing orthophosphate and

calcium ion. At the same time, mechanical

properties of the biomimetic composites, such as

bending strength, bending modulus, shear strength,

compression strength, are 2 to 3 times higher than

the natural bone. It is expected to replace the metal

and become the internal fixation of bone fracture,

avoiding suffering second surgery for patients

(Qiao,2003).

2.4 Nano Biomimetic Materials

After the advent of nanomaterials, biomimetic

materials research has begun to shift to nano

biomimetic materials. This is because the nature of

the animal's tendons, teeth, cartilage, skin, bones,

insects, etc., are nanocomposite materials (Lazaris,

2002). Mimic is the design of nature's biological

structure and the development of artificial bone,

joints, and blood vessels. Many nanomaterials such

as nanoparticles, nanotubes, nucleic acids, and

nanomaterials have great potential in clinical

applications. The main problem is that these

materials can be accepted by the host immune

system. As more and more nanodevices are

manufactured, it is reported that the biological

membranes with 18 nm diameter holes can protect

the encapsulated cells or tissues to avoid the immune

response (Wang,2020).

Biological cells have always been considered to

be a complex microenvironment. In order to be able

to develop more biochemical drugs, biodiagnostic

technologies, and bio-smart materials, many

investigators have shown strong interest in using

biomimetic nanotechnology to simulate and study

the regulation mechanism of enzymes separated in

cells. Balasubramanian et al. used undecylenic acid-

modified thermally hydrocarbonized porous silicon

(UnPSi) nanoparticles to "capture" horseradish

peroxidase (HRP) enzyme as a model and

demonstrated a design as a biomimetic cell

nanoreactor (Balasubramanian, 2017). Yuan Jinying

et al. used block copolymers containing amidine

groups to construct CO2-responsive macromolecular

vesicles and developed a new type of biomimetic

macromolecular nanodevices. The permeability of

vesicles can be controlled by adjusting the

concentration of CO2 gas. It can be used as a nano-

separator to selectively distinguish functional

molecules of different scales to achieve the

directional control of vesicles to different reactions

in the space and time range and achieve the function

of cell regionalized reaction (Yan, 2013).

3 DEVELOPMENT PROSPECTS

OF BIOMIMETIC MATERIALS

Bionic technology has been applied to military,

medical, industrial manufacturing, construction, and

other popular industries and fields. In the medical

field, bionic technology has just emerged. It is still

in the preliminary exploration and development

stage. Development of biomimetic materials is

growing exponentially, they can be well applies in

tissue engineering and regenera-tive medicine,

biosensors, drug/protein delivery, stem cell research,

3D bioprinting and soon (Das,2018). These

biological materials are inspired and manufactured

from existing designs and procedures in nature, as

well as understanding the chemistry and

mechanisms of cell biology, the nature of diseases,

modes of action, and biomolecular mechanisms.

Still, it has played an important role in medical

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

782

rehabilitation and the reconstruction of human

organs and tissues. It has been widely used in

diagnosing, preventing, and treating major human

diseases and rehabilitation. Biomedical materials

science has demonstrated the potential of the future.

The ultimate goal of this field is to produce natural

functional biomaterials, which can better understand

the basic principle of the cross-field of life science

and materials science.

Biomimetic technology is used for human bionic

materials. The difference in essence in biomimetic

materials and industrial materials is whether to use

in the physiological environment and conditions.

Bionic materials can be applied to human medical

research at the medical level by transplanting some

recognizable characteristics in the body and being

compatible with human organs, such as human skin

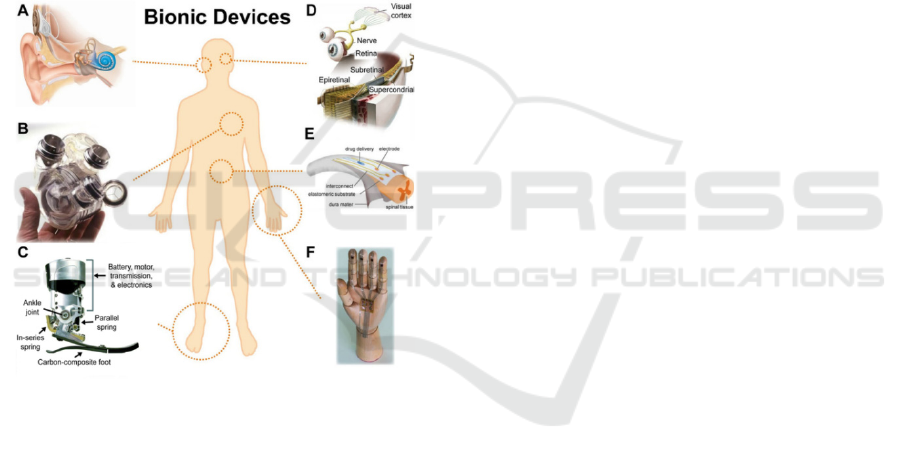

materials, blood, heart, etc (figure 1).

Figure 1: Bionic technologies for restorative medicine.

(A) Cochlear implant. (B) AbioCor self-

contained replacement heart. (C) Powered ankle-foot

prosthetic controlled by a neuromuscular model. (D)

Epiretinal, subretinal, and suprachoroidal implants.

(E) Electronic dura mater, ''e-dura,'' tailored for the

spinal cord. (F) A skin-inspired digital

mechanoreceptor, where the image shows a model

hand with DiTact sensors on the fingertips

connected with stretchable interconnects (Kong,

2016).

The development trend of materials is complex,

intelligent, dynamic, environmental, and bionic

materials have these aspects. The development and

achievements of bionic materials will affect all

aspects of society. It will bring about changes to the

human organs and biological systems and make the

materials and applications.

In short, the biomimetic medical materials

developed should have biocompatibility and

flexibility. They should contain cellular and

molecular induction and adhesion sites, sufficient

mechanical strength, and biodegradable and tissue

remodeling properties. To become a suitable

material for model biomedicine, the first

requirement is the ideal effect that is effective in the

body. The combination of biomaterials, technology,

software and equipment and interdisciplinary can

provide a systematic approach for medical

applications.

4 CONCLUSIONS

Four types of biomimetic medical materials with

different research have been discussed such as 1)

biomimetic materials of silk protein, 2) biomimetic

materials of nacre, 3) biomimetic materials of bone,

and 4) nano biomimetic materials. And these

materials can be applied to human medical research

at the medical level by transplanting some

recognizable characteristics in the body such as

cochlear implant, mechanical heart and so forth,

which is a boon for the disabled or the patient.

The development of this material involves many

cutting-edge disciplines and high-tech fields, such as

material science, medicine, cytology, engineering,

bionics, biotechnology, etc. If biomimetic medical

materials can get substantial and stable development,

they will have significant application prospects and

social effects. In the future, better biocompatibility,

biodegradability, good mechanical strength and

biological stability, and clinical applicability will

still require extensive and in-depth research.

REFERENCES

Almqvist, N., et al. (1999) Methods for fabricating and

characterizing a new generation of biomimetic

materials. Materials Science and Engineering: C. 7(1):

p. 37-43.

Altman, G.H., et al. (2002). Silk matrix for tissue

engineered anterior cruciate ligaments. Biomaterials.

23 (20): p. 4131-4141.

Applegate, M.B., et al. (2016). Photocrosslinking of silk

fibroin using riboflavin for ocular prostheses.

Advanced materials.28(12): p. 2417-2420.

Arcidiacono, S., et al.. (2002). Aqueous processing and

fiber spinning of recombinant spider silks.

Macromolecules. 35(4): p. 1262-1266.

Balasubramanian, V., et al. (2017). Biomimetic

Engineering Using Cancer Cell Membranes for

The Potential Application in Medical Biomimetic Materials

783

Designing Compartmentalized Nanoreactors with

Organelle-Like Functions. Advanced Materials.29(11):

p. 1605375.

Das, D. and I. Noh. (2018). Overviews of Biomimetic

Medical Materials, in Biomimetic Medical Materials:

From Nanotechnology to 3D Bioprinting, I. Noh,

Editor. Springer Singapore: Singapore. p. 3-24.

Gray, G.M., et al. (2016). Secondary Structure Adopted by

the Gly-Gly-X Repetitive Regions of Dragline Spider

Silk. International journal of molecular

sciences.17(12): p. 2023.

Heuer, A.H., et al. (1992). Innovative materials processing

strategies: a biomimetic approach. Science.255(5048):

p. 1098-1105.

Hinman, M.B., J.A. Jones, and R.V. Lewis. (2000).

Synthetic spider silk: a modular fiber. Trends in

biotechnology. 18(9): p. 374-379.

Kong, Y., et al. (2016). 3D Printed Bionic Nanodevices.

Nano Today. 11.

Lazaris, A., et al. (2002) Spider silk fibers spun from

soluble recombinant silk produced in mammalian cells.

science. 295(5554): p. 472-476.

Meinel, L., et al. (2005). Silk implants for the healing of

critical size bone defects. Bone.37(5): p. 688-698.

Melke, J., et al. (2016). Silk fibroin as biomaterial for

bone tissue engineering. Acta biomaterialia. 31: p. 1-

16.

Qian, C., et al. (2004). Super-hydrophobic characteristics

of butterfly wing surface. Journal of Bionic

Engineering.1(4): p. 249-255.

Qiaoling, H., et al. (2003) Studies on chitosan rods

prepared by in situ precipitation method. Chemical

Journal of Chinese Universities. 24(3): p. 528-531.

Shi, W., et al. (2017) Structurally and functionally

optimized silk-fibroin-gelatin scaffold using 3D

printing to repair cartilage injury in vitro and in vivo.

Advanced materials. 29(29): p. 1701089.

Tabata, Y.(2001). Recent progress in tissue engineering.

Drug discovery today. 6(9): p. 483-487.

Wang, Y. and X. Zhu.(2020).Nanofabrication within

unimolecular nanoreactors. Nanoscale. 12(24): p.

12698-12711.

Xu, Z., et al. (2015). Fabrication of a novel blended

membrane with chitosan and silk microfibers for

wound healing: characterization, in vitro and in vivo

studies. Journal of Materials Chemistry B. 3(17): p.

3634-3642.

Yan, Q., et al. (2013). Breathing Polymersomes: CO2-

Tuning Membrane Permeability for Size-Selective

Release, Separation, and Reaction. Angewandte

Chemie International Edition. 52(19): p. 5070-5073.

Yodmuang, S., et al. (2015). Silk microfiber-reinforced

silk hydrogel composites for functional cartilage tissue

repair. Acta biomaterialia.11: p. 27-36.

Yoo, S.C., et al. (2018). Biomimetic Artificial Nacre:

Boron Nitride Nanosheets/Gelatin Nanocomposites for

Biomedical Applications. Advanced Functional

Materials. 28 (51): p. 1805948.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

784