Preparation and Adsorption Properties of Chemically Modified Isatis

Indigotica Fort Draff based Biosorbent

Xiaochun Yin

a

, Jie Li, Nadi Zhang, Hai Zhu, Ting Ke, Yonge Gu, Junliang Meng, Jianjun Wu

*

and Yongfeng Wang

*

School of Public Health, Gansu University of Chinese Medicine, Lanzhou 730000, Guansu Province, China

119261751@qq.com, 11704014@qq.com,

*

591806561@qq.com,

*

331220684@qq.com

Keywords:

Radix Isatidis Residue, Chemical Modification, Adsorbent, Heavy Metals, Removal.

Abstract:

Objective: to treat the Isatis Indigotica fort draff to enhance its adsorption capacity for heavy metals.

Methods: Isatis Indigotica fort draff was modified with NaOH, Na

2

CO

3

and citric acid to prepare Isatis

Indigotica fort draff based biosorbent; the structure was characterized by scanning electron microscopy and

Fourier transform infrared spectroscopy; then the effects of solution pH value, solution concentration,

adsorbent dosage, and adsorption time of copper ion solution on the adsorption performance of Isatis

Indigotica fort draff based adsorbent were studied by static adsorption experiments, so as to clarify the

adsorption mechanism; it provides a guide for the resource utilization of Isatis Indigotica fort draff and an

experimental basis for the preparation of new adsorbents. Results: The adsorption properties of RIR-NaOH,

RIR-Na

2

CO

3

, and RIR-CA were all better than RIR; the order of the maximum adsorption capacity of the

modified Isatis Indigotica fort draff based adsorbent for copper ions is: RIR-Na

2

CO

3

> RIR-NaOH > RIR-

CA > RIR. Conclusion: The Isatis Indigotica fort draff based adsorbent has the potential to remove heavy

metals from water, and is a new type of adsorbent.

1 INTRODUCTION

a

With the acceleration of urbanization and the

increase of industrialization, heavy metal pollution

in water has gradually become a serious problem

that plagues many countries around the world (Bai

2015, Broaga 2014). Heavy metals exist stably and

persistently in the environment and accumulate in

the human body through the food chain, causing

serious harm to human health and ecosystem (Cao

2016, Chen 2010). Therefore, the removal of heavy

metals from water is of great significance to both

human beings and ecosystems. At present, the main

methods to remove heavy metals from wastewater

are ion exchange, chemical precipitation, and

membrane filtration. However, the wide application

of these methods in commercial applications is

limited by high cost and low reusability. On the

contrary, biosorption has attracted more and more

attention in the removal of heavy metals because of

its operability and low cost. Biosorbent resources

are extensive and easy to obtain, such as algae

a

https://orcid.org/0000-0002-9749-2608

residue (Dai 2019), herb residue (Deng 2018), and

so on. As a Chinese herbal medicine with multiple

functions, Radix Isatidis can not only be used for the

treatment of some diseases such as influenza (Du

2019), but also for the prevention of diseases (Duan

2021, Huang 2015, Huang 2020, Jia 2016). Radix

Isatidis contains a variety of active substances (Jia

2010), which are currently being extensively

studied, developed and utilized. Through

processing, a variety of Radix Isatidis products can

be synthesized (Jiang 2020), such as Radix Isatidis

granules, Radix Isatidis injection, and so on.

However, if the Isatis Indigotica fort draff after

extraction is not treated in time, it will pollute the

environment to some extent. Therefore, how to treat

the waste Isatis Indigotica fort draff and reduce its

pollution to the environment has become an

important problem to be solved.

After the active substances are extracted from

Radix Isatidis, the drug residue still contains many

effective components such as lignocellulose (Kim

2003, Kommula 2013), so the preparation of Isatis

Indigotica fort draff into a cellulose based adsorbent

is a common treatment method (Pan 2018, Reddy

Yin, X., Li, J., Zhang, N., Zhu, H., Ke, T., Gu, Y., Meng, J., Wu, J. and Wang, Y.

Preparation and Adsorption Properties of Chemically Modified Isatis Indigotica Fort Draff based Biosorbent.

DOI: 10.5220/0011375600003443

In Proceedings of the 4th International Conference on Biomedical Engineer ing and Bioinformatics (ICBEB 2022), pages 1013-1021

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

1013

2019). Lignocellulose is composed of carbohydrates

(cellulose and hemicellulose), lignin, and other

components (protein, lipid and inorganics) (Tan

2019). It is a rich and renewable resource on earth

and a good source of heavy metal adsorbents (Tan

2020, Tian 2020, Ulfa 2019, Wang 2019, Wang

2019). However, due to the close connection among

the components of lignocellulose, the adsorption of

heavy metals by cellulose is hindered. Therefore, the

direct use of Isatis Indigotica fort draff for heavy

metal adsorption has the problem of low adsorption

capacity and adsorption rate. Reasonable

modification of Isatis Indigotica fort draff to remove

hemicellulose and lignin is very important to

increase its adsorption capacity.

In this work, chemical reagent was used to

modify Isatis Indigotica fort draff. The structure of

resulting absorbent was characterized by scanning

electron microscope (SEM) and Fourier transform

infrared spectroscopy (FTIR). The effects of

solution pH value, solution concentration, adsorbent

dosage, and adsorption time of copper ion solution

on the adsorption performance of Isatis Indigotica

fort draff based adsorbent were studied through

static adsorption experiment to clarify the

adsorption mechanism. It provides guidance for the

resource utilization of Isatis Indigotica fort draff and

experimental basis for the preparation of new

adsorbents.

2 EXPERIMENTAL METHODS

2.1 Materials

The Radix Isatidis used in the experiment came

from Huirentang Pharmacy in Lanzhou, and the

experimental water was deionized water.

2.2 Methods

2.2.1 Preparation of the Absorbent

(1) Decolorization: The purchased Radix Isatidis

was washed with deionized water for 1-2 times,

boiled for 3 times (30 min each time), dried at

65 °C, crushed and passed through a 40-mesh sieve.

The prepared drug residue and methanol were mixed

in a ratio of 1:5 and stirred to remove bioactive

components and pigments. The methanol is

constantly replaced during stirring until the

methanol is colorless after stirring. After washing

with distilled water and drying at 65 °C, the

prepared drug residue was named as decolorized

Isatis Indigotica fort draff and recorded as RIR.

(2) Modification:

1) NaOH modification: The RIR was added into

an aqueous solution of NaOH (1 mol/L) at a solid-

to-liquid ratio of 10:1 and stirred magnetically for 4

h (120 r/min). The resulting residue was washed

with deionized water to be neutral, filtered, and

dried, which was named as NaOH modified Isatis

Indigotica fort draff and denoted as RIR-NaOH.

2) Na2CO3 modification: The RIR was added

into an aqueous solution of Na

2

CO

3

(1 mol/L) at a

solid-to-liquid ratio of 10:1 and stirred magnetically

for 4 h (120 r/min). The resulting residue was

washed with deionized water to be neutral, filtered

with sand filter funnel, and dried, which was named

as Na

2

CO

3

modified Isatis Indigotica fort draff and

denoted as RIR-Na

2

CO

3

.

3) Citric acid modification: The RIR was firstly

treated with 0.1 mol/L NaOH for 30 min. The

resulting residue was then mixed with an aqueous

solution of citric acid (0.6 mol/L) at a solid-to-liquid

ratio of 10:1 and stirred magnetically for 4 h (120

r/min). The resulting residue was washed with

deionized water to be neutral, filtered, and dried,

which was named as citric acid modified Isatis

Indigotica fort draff and denoted as RIR-CA. All the

Isatis Indigotica fort draff based biosorbents were

named RIR-Ts.

2.2.2 Structural Characterization of RIR-Ts

(1) FTIR: Fourier transform infrared spectroscopy

(FTIR, Nicolet Nexus, USA) was used to study the

molecular structure and chemical bonds of RIR-Ts.

The samples for analysis were dried before use,

ground in a mortar, mixed with potassium bromide

powder and pressed into transparent sheets. The

experiment was carried out in the spectral range of

4000-400 cm-1.

(2) SEM: the morphology of lignocellulose

compounds was studied by SEM (JSM-6701F,

JEOL, Japan). The samples for analysis were stored

in an oven at 50 ℃ overnight.

(3) analyzer (Perkin-Elmer Cetus Instruments,

Norwalk, CT) was used to study the thermal

stability and composition of the adsorbent. About 10

mg of the sample was placed in the sample holder

and heated from room temperature to 800℃

(heating rate = 10 ℃/min). The purging gas was

nitrogen with a flow rate of 20 mL/min.

(4) XRD: the crystalline properties of cellulose

were studied by using X-ray diffractometer (JDX-

3530,2kw, Tokyo, Japan). Before analysis, the

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1014

sample was ground into fine and uniform powder

and stored in an oven at 50 °C overnight. Using Cu

pulsed radiation with a wavelength of 0.154 nm, the

crystallization of the compound was determined by

monitoring the position, shape, and intensity of the

reflection from the distribution structure substrate.

2.2.3 Adsorption Properties and Reusability

(1) Establishment of Standard Curve A series of

concentration gradient solutions were obtained by

step dilution method, and the absorbance of copper

ions with different concentrations were measured by

flame atomic absorption photometer. This step was

repeated for three times to obtain the standard curve.

(2) Influencing Factors of Adsorption

Performance A series of Cu(NO

3

)

2

solutions (250

mL) with different concentrations were prepared.

The pH value of the solution was adjusted by 0.1

mg/L NaOH and 0.1 mg/L HCl. Different amount

(0.01 g, 0.02 g, 0.04 g, 0.06 g, 0.08 g, 0.10 g) of

Isatis Indigotica fort draff was added into the

Cu(NO

3

)

2

solutions with different pH values

(1,2,3,4,5,6) and different concentrations of copper

ions (20 mg/L, 40 mg/L, 60 mg/L, 80 mg/L, 100

mg/L, 150 mg/L). The resulting mixtures were

oscillated on the oscillator at room temperature for a

certain period of time (10 min, 20 min, 30 min, 40

min, 60 min, 75 min, 120 min). 1 mL of supernatant

was taken and diluted with pure water in a 50 ml

volumetric flask, and then the absorbance of the

solution was measured on the flame atomic

absorption analyzer after fully oscillating. The

concentration value was obtained by automatic

conversion of the instrument, and then the original

solution concentration value is obtained by

multiplying the concentration value by 50. After

calculation, the experimental adsorption capacity,

adsorption kinetic model parameters, and adsorption

isotherm parameters can be obtained.

(3) Reusability After the adsorption process is

completed, the adsorbent was separated from the

copper ion solution. After being washed, the

adsorbent is desorbed with eluent. After desorption,

the adsorbent was separated, and the next

adsorption-desorption process is cycled for a total of

four adsorptions-desorption experiment. Two sets of

parallel experiments were carried out to calculate

the average value of desorption efficiency.

3 RESULTS AND DISCUSSION

3.1 Characterization of Chemically

Modified Isatis Indigotica Fort

Draff based Biosorbent

3.1.1 SEM Analysis

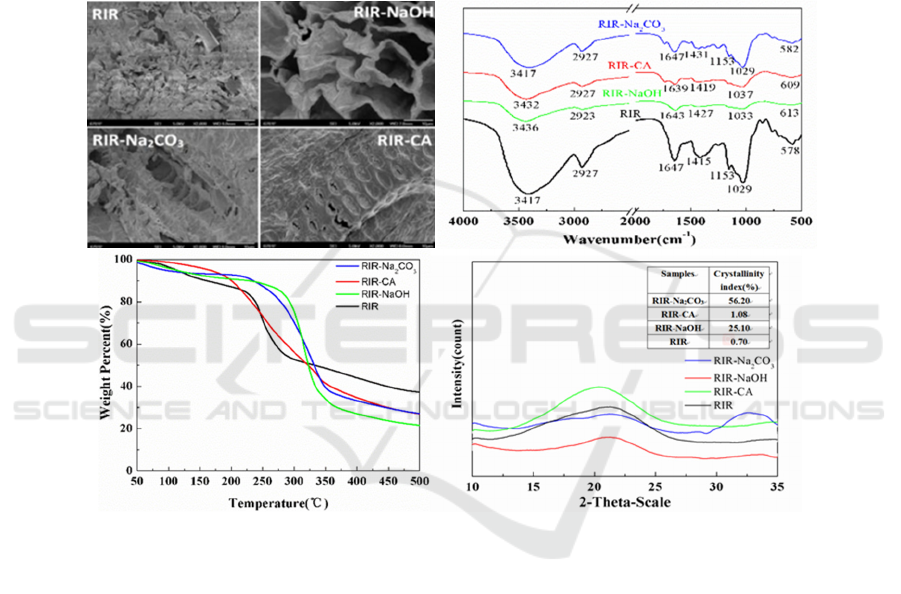

The SEM images of RIR, RIR-NaOH, RIR-Na

2

CO

3

,

and RIR-CA are shown in Figure1-(a). The results

show that the structure of RIR is relatively dense,

and the surface of RIR-NaOH, RIR-Na

2

CO

3

, and

RIR-CA show signs of fiber surface fracture and

fiber disintegration, and the surface pores increase.

The increase in pores is beneficial to increase the

contact area between heavy metal ions and the

surface area of cellulose, and to adsorb more heavy

metal ions.

3.1.2 FTIR Analysis

The IR spectra of RIR, RIR-NaOH, RIR-Na

2

CO

3

,

and RIR-CA are shown in Figure1-(b). In general,

before and after the modification, the peak shape of

the IR spectrum is roughly the same, and there is no

big shift. Before modification, the peak is broad and

strong near 3417 cm-1, indicating that there were

many stretching vibration absorption peaks of O-H

and N-H on the surface of the Isatis Indigotica fort

draff -based biosorbent; the absorption peak of 2927

cm-1 comes from the stretching vibration of

saturated C-H bonds, the absorption peak of 1647

cm-1 comes from the stretching vibration of C=O of

aliphatic aldehyde, the absorption peak of 1415cm-1

is from the deformation vibration of CH

3

- and -CH

2

-

, the absorption peak of 1153 cm-1 is from the

stretching vibration of ester bond, and the

absorption peak of 1029cm-1 is from the bending

vibration of -OH. After modification, the peak

intensity of Isatis Indigotica decreased, the

amplitude decreased, and the wave peaks became

wider, indicating that the content of various groups

on the surface of the modified Isatis Indigotica were

reduced (Wei 2003).

3.1.3 TG Analysis

The thermograms of RIR, RIR-NaOH, RIR-

Na2CO3, and RIR-CA are shown in Figure1-(c).

According to the thermal decomposition of each

component of lignocellulosic biomass, Reddy et al.

(Xu 2021), Chen et al. (Yang 2016), and Braga et al.

(Yang 2020) divided the TG curves of the

Lignocellulosic biomass into three stages, namely,

Preparation and Adsorption Properties of Chemically Modified Isatis Indigotica Fort Draff based Biosorbent

1015

the dehumidification stage, the decomposition of the

cellulose molecular skeleton and the loss of

hemicellulose, and the decomposition of solid

residues. In this experiment, according to the

thermogravimetric curve, when the temperature is

lower than 120-220 ℃, the weight loss of the

sample is between 5% and 8%, mainly due to the

evaporation of water in the sample. When the

temperature is between 220 and 350 ℃, the curve

drops faster, mainly due to the decomposition of

cellulose and hemicellulose. The order of the weight

loss rate of the four adsorbents is as follows: RIR-

NaOH > RIR-Na

2

CO

3

> RIR-CA > RIR, which

shows that the loss rate of cellulose and

hemicellulose of the modified adsorbent is higher.

When the temperature is higher than 350 ℃, the

weight of the sample changes slowly, which is

mainly related to the decomposition of lignin (Yi

2019). In addition, it can also be observed that the

thermal stability of the adsorbent after modification

is higher than that before modification.

(a) (b)

(c) (d)

Figure 1: Characterization of RIR, RIR-NaOH, RIR-Na2CO3, and RIR-CA.(a)SEM of RIR, RIR-NaOH, RIR-Na2CO3, and

RIR-CA. (b)FTIR spectra of RIR, RIR-NaOH, RIR-Na2CO3 and RIR-CA. (c) TG of RIR, RIR-NaOH, RIR-Na2CO3 and

RIR-CA. AR-Na2CO3 and AR-CA. (d)XRD profiles of RIR, RIR-NaOH, RIR-Na2CO3 and RIR-CA.

3.1.4 XRD Analysis

The XRD patterns of RIR, RIR-NaOH, RIR-

Na

2

CO

3

, and RIR-CA are shown in Figure1-(d). The

results show that the crystallinity indexes of RIR,

RIR-NaOH, RIR-Na

2

CO

3

, and RIR-CA are 0.7%,

25.10%, 56.20%, and 1.08% respectively. It was

found that the crystallinity of the modified adsorbent

was higher than that before modification, indicating

that the structure of lignin and hemicellulose was

destroyed after modification, making the overall

structure loose. Secondly, it is found that the

crystallinity index of RIR and RIR-CA is very low,

which may be due to the changes of Radix Isatidis

in the process of chemical treatment since its

composition is different from those of the other two

Chinese herbal medicines. We need to conduct in-

depth research in future.

3.2 Study on the Absorption Behavior

of Isatis Indigotica Fort Draff

based Biosorbent on Copper ions

3.2.1 The Influence of Solution pH on

Adsorption

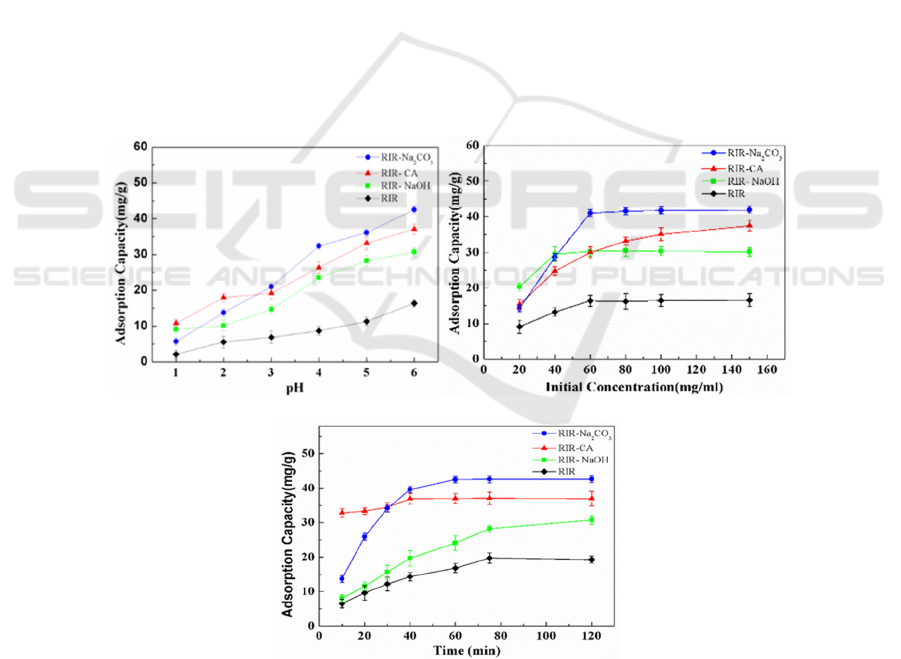

The effect of solution pH on the adsorption capacity

of copper ions is shown in Figure 2-(a). When the

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1016

pH is too high, copper ions will exist in the form of

precipitation, which is not conducive to adsorption.

Therefore, the maximum pH of the solution studied

in this experiment is about 6.0. It can be seen from

the figure that the adsorption capacity of RIR, RIR-

NaOH, RIR-Na

2

CO

3

, and RIR-CA for copper ions

all increases with the increase of pH value. This is

mainly due to the high concentration of H+ in the

solution at the beginning, which competes with

copper ions for the active sites of the adsorbent.

Therefore, the adsorption capacity is low. As the pH

value increases, the concentration of H+ decreases,

which weakens the competition gradually.

Therefore, the adsorption capacity is increased. In

addition, in the process of pH change, the adsorption

capacity of RIR-NaOH and RIR-CA is always

higher than that of RIR, and the adsorption capacity

of RIR-CA is always higher than RIR-NaOH.

3.2.2 The Effect of Initial Solution

Concentration on Adsorption

As shown in Figure 2-(b), the adsorption capacity of

RIR, RIR-NaOH, RIR-Na

2

CO

3

, and RIR-CA for

copper ions varies with the adsorption

concentration. It can be seen from the figure that

with the increase of the initial concentration of the

solution, the change trend of adsorption capacity

increases first and then remains basically

unchanged. The possible reason is that because the

dosage of the adsorbent is fixed, the number of

adsorption sites is fixed, and the maximum amount

of copper ions that can be adsorbed is also fixed.

When the concentration of copper ions in the

solution is low, the adsorption sites are unsaturated.

When the concentration of copper ions in the

solution increases to a certain extent, the adsorption

sites reach saturation, at which time the adsorption

capacity is the largest. Even the concentration of

copper ions further increases, the adsorption

capacity will no longer change. When RIR, RIR-

NaOH, RIR-Na

2

CO

3

, and RIR-CA reach adsorption

equilibrium, their optimal copper ion concentrations

in the solution that can be adsorbed are 60, 100, 60,

and 60 mg/L, respectively.

(a) (b)

(c)

Figure 2: Study on the adsorption effect of Isatis In digotica Fort Draff residue-based bio-adsorbent on Cu2+. (a) Effect of

solution pH on the adsorption capacity of Isatis Indigotica Fort Draff based biosorbent.. (b) Effect of initial concentration of

solution on the adsorption capacity of Isatis Indig otica Fort Draff based biosorbent. (c) Effect of adsorption time on the

adsorption capacity of Isatis Indigotica Fort Draff based biosorbent.

Preparation and Adsorption Properties of Chemically Modified Isatis Indigotica Fort Draff based Biosorbent

1017

3.2.3 The Effect of Adsorption Time on

Adsorption

Figure 2-(c) shows the change of adsorption

capacity of copper ions by RIR, RIR-NaOH, RIR-

Na2CO3, and RIR-CA with adsorption time. It can

be seen from the figure that with the increase of

adsorption time, the adsorption capacity increases

first and then remains basically unchanged. The

possible reason is that at the beginning of the

adsorption, there are many sites on the surface of the

adsorbent that can be used to adsorb copper ions and

there are more free copper ions in the solution.

However, as the reaction proceeds, these adsorption

sites gradually reach saturation, the copper ion in the

solution decreases, the adsorption tends to be

balanced, and the adsorption capacity reaches the

maximum. In the whole process of adsorption, the

adsorption capacity of RIR-NaOH, RIR-Na

2

CO

3

,

and RIR-CA are all higher than that of RIR, and the

adsorption capacity follows an order of RIR-

Na

2

CO

3

> RIR-NaOH > RIR-CA. Therefore, the

three modification methods can all increase the

adsorption capacity of RIR, and the modification

effect of Na

2

CO

3

is better than the other two. In

addition, in the whole adsorption process, the

adsorption time when RIR-CA, RIR-Na2CO3, RIR,

and RIR-NaOH reach equilibrium is 40, 60, 75, and

75 min respectively. Therefore, there is no

significant change in the adsorption time when RIR-

NaOH reaches adsorption equilibrium compared

with RIR. The adsorption time of RIR-CA and RIR-

Na

2

CO

3

is reduced compared with RIR when

reaching the adsorption equilibrium, that is, the

Na

2

CO

3

modification can shorten the adsorption

time of the adsorbent.

3.2.4 Adsorption Isotherm

The Langmiur isotherm model and the Freundlich

isotherm model were used to fit the adsorption data

of the Isatis Indigotica fort draff-based adsorbent,

and the formula is as follows:

Langmiur model:

(1)

Freundlich model:

(2)

It can be seen from Table 1 that the fitting

constant obtained by the Langmiur isotherm model

is closer to 1, so the Langmiur isotherm model can

better describe the adsorption data. It shows that the

adsorption of heavy metal ions by the adsorbent is

single-layer adsorption, and the adsorption process

is chemical adsorption. According to the Langmuir

adsorption isotherm, the saturated adsorption

capacities of RIR, RIR-NaOH, RIR-Na

2

CO

3

, and

RIR-CA for copper ions are 18.72, 31.91, 54.23, and

47.73 mg/g respectively. It can be seen that the

performance of Na

2

CO

3

modified Isatis Indigotica

fort draff based adsorbent is the best.

Table 1: Adsorption isotherm model and parameters of Isatis Indigotica Fort Draff based biosorbent.

Adsorbent

Langmuir Model

Freundlich Model

qmax(mg/g) K(L/mg) RL2 KF n RF2

RIR 18.72 6.50×10-2 0.987 4.10 3.30 0.769

RIR-NaOH 31.91 1.67×10-1 0.993 4.88 5.47 0.556

RIR-Na

2

CO

3

54.23 3.25×10-2 0.919 4.24 1.99 0.742

RIR-CA 47.73 2.63×10-2 0.995 1.91 5.13 0.920

3.2.5 Adsorption Kinetics

The first-order and second-order equations of

adsorption kinetics are respectively used to fit the

adsorption data of the adsorbent, and the formula is

as follows:

The first-order equation of adsorption kinetics:

(3)

The second-order equation of adsorption

kinetics:

(4)

The results are shown in Table 2. The linear

correlation coefficient R

1

2

obtained by quasi first-

Lmm

e

e

e

KQQ

C

q

C 1

+=

eFe C

n

Kq log

1

loglog ×+=

t

k

qqq ete )

303.2

()log()log(

1

−=−

e

e

t q

t

qkq

t

+=

2

2

1

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1018

order kinetic fitting of the three adsorbents is

relatively small, indicating that the reaction does not

accord with the relevant characteristics of the quasi

first-order reaction. The linear correlation

coefficient R

2

2

obtained by the quasi second-order

kinetics fitting is greater than that of the quasi first-

order kinetics, and the degree of fit is high,

indicating that the quasi second-order kinetics

model can describe the adsorption data of these

three adsorbents well. This also shows that the

adsorption process of heavy copper ions on the

surface of the Isatis Indigotica fort draff based

biosorbent is chemical adsorption.

Table 2: Adsorption kinetic model and parameters of Isatis Indigotica Fort Draff based biosorbent.

Adsorbent

qe,exp

(mg/g)

Quasi first order dynamics model Quasi second order dynamics model

qe,cal(mg/g) k1(min−1) R

1

2

qe,cal(mg/g) k

2

(g/mg·min-1) R

2

2

RIR 16.54 14.85 3.71×10-2 0.566 20.56 1.71×10-3 0.982

RIR-NaOH 31.00 49.18 4.05×10-2 0.527 44.68 4.36×10-4 0.992

RIR-Na

2

CO

3

42.65 42.67 7.03×10-2 0.862 51.15 1.09×10-3 0.971

RIR-CA 37.55 3.85 2.14×10-2 0.564 37.69 1.47×10-2 0.991

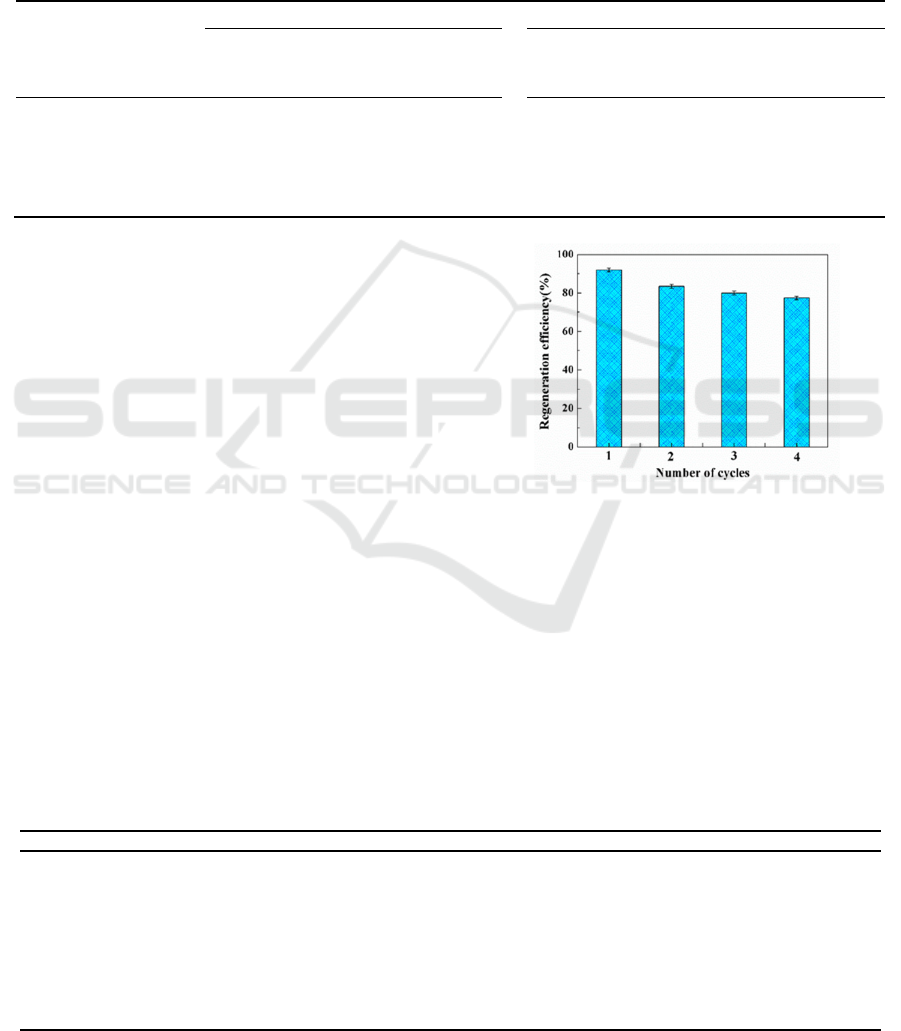

3.2.6 Reusability

LR-Na

2

CO

3

, the best bio-adsorbent for Cu

2+

in our

experiment, was selected to study the adsorption and

desorption conditions. The regeneration and

reusability of LR-Na

2

CO

3

for heavy metals Cu

2+

were evaluated by four consecutive adsorption–

desorption cycles (Figure 3). It showed that LR-

Na

2

CO

3

has good reusability for Cu

2+

, the

adsorbability remained higher than 74% after four

consecutive adsorption–desorption cycles,

consistent with other reports, which indicated that

the LR-Na

2

CO

3

is a suitable potential adsorbent for

the removal of the heavy metal ions Cu

2+

from

water.

Figure 3: Reusability of RIR-Na

2

CO

3

.

3.3 Comparison with Other

Adsorbents

The qmax value obtained in this study was

compared with various biosorbents reported in the

literature for removing

Cu2+

, as shown in Table3. The

results show that the adsorption capacity of RIR-CA

and RIR-Na2CO

3

are higher than that of other

biosorbents (such as activated carbon fiber,

modified sawdust cellulose, and so on).

Table 3: Comparison of Isatis Indigotica Fort Draff and other adsorbents.

Absorben

t

Metal Ion qmax(mg/g) Reference

RIR-CA

Cu

2+

47.73 this study

RIR-Na

2

CO

3

54.23 this study

Autotrophic nitrifying granular

sludge

15.02 Zhang et al. (Yu 2019)

Activated carbon fiber 25.51 Yu J, Chi C, Zhu B, Qiao K, Yan

S.(Yuan 2019)

Modified sawdust cellulose 4.33 Ulfa S M, Chamidah N, Kurniawan

A.(Zhang 2020)

Papermaking sludge 28.788 Dai C, Zhang Y. (Zhang 2020)

Preparation and Adsorption Properties of Chemically Modified Isatis Indigotica Fort Draff based Biosorbent

1019

4 SUMMARY

The Isatis Indigotica fort draff was used as raw

materials and modified with NaOH, Na

2

CO

3

, and

citric acid to prepare the Isatis Indigotica fort draff

based biosorbent, which was used in the study of the

adsorption of heavy metal copper in water. The

structure of the modified biosorbent was

characterized by FTIR, SEM, TG and XRD. It was

found that the structure of the modified biosorbent

was loose and the cellulose surface active groups

increased. The adsorption performance of RIR, RIR-

NaOH, RIR-Na

2

CO

3

, and RIR-CA is better than that

of RIR. The order of the maximum adsorption

capacity of the modified Isatis Indigotica fort draff

based adsorbent for copper ions is: RIR-Na

2

CO

3

>

RIR-NaOH > RIR-CA > RIR. The adsorption

process of copper ion conforms to the quasi first-

order kinetic model and Langmuir model, that is, the

adsorption of copper ion on its surface is chemical

adsorption. The adsorption capacity of Na

2

CO

3

modified Radix Isatidis for copper ions is the best,

and the maximum adsorption capacity after four

consecutive adsorption-desorption cycles is about

77% of that at the first adsorption. In conclusion, the

modification of NaOH, Na

2

CO

3

, and citric acid can

not only improve the adsorption performance of

Isatis Indigotica fort draff, but also reduce the

environmental pollution caused by the unreasonable

use of Isatis Indigotica fort draff and improve the

resource utilization rate of Isatis Indigotica fort

draff.

ACKNOWLEDGEMENT

This work was supported by NSFC (82160900),

Innovation Fund Project of Higher Education in

Gansu Province (2021B-159), Open Foundation of

Collaborative Innovation Center for Prevention and

Control by Chinese Medicine on Disease Related

Northwestern Environment and Nutrition

(998/99860202) , Open Foundation of Traditional

Chinese Medicine Research Center of Gansu

Province (ZYZX-2020-ZX16) and Research on

prevention and control of COVID-19 by integrated

Traditional Chinese and Western Medicine(2020C-

36).

REFERENCES

Bai L, Wu C, Gu F. The Adsorption of Lead-containing

Wastewater by Modified Isatis indigotica Fort

Draff[J]. Hubei Agricultural Sciences. 2015; 54(24):

6219-6222.

Braga R M, Costa T R, Freitas J C O, Barros M F, Melo D

M A, Melo M A F. Pyrolysis Kinetics of Elephant

Grass Pretreated Biomasses. J. Therm. Anal. Calorim.

2014; 117(3): 1341-1348.

Cao K. Correlation between Chemical Composition in

Process of Isatidis Radix Preparation and Its

Pharmacological Activity [J]. Journal of North

Pharmacy. 2016; 13(11): 119-120.

Chen W, Tu Y, Sheen H K. Impact of Dilute Acid

Pretreatment on the Structure of Bagasse for

Bioethanol Production. Int. J. Energy Res. 2010;

34(3):265-274.

Duan N, Fang L, Zhang X. Non-carcinogenic Health Risk

Assessment of Soil Heavy Metals Based on Target

Organ[J]. Safety and Environmental Engineering.

2021; 28(04): 207-212.

Du Z, Chen H, An Y, Guo X. Research Progress on

Preparation Techniques of Lignocellulose-based

Heavy Metal Adsorbents[J]. Journal of Agro-

Environment Science. 2019; 38(12): 2659-2671.

Deng C, Ma H, Wang Z, Zhou J. Characterization and

Pyrolysis of Apricot Shell Cellulose[J]. Journal of

Forestry Engineering. 2018; 3(6): 87-92.

Dai C, Zhang Y. Study on the Preparation of Functional

Adsorption Material from Paper Sludge and Its

Adsorption Properties for Cu2+[J]. Environmental

Pollution and Control. 2019; 41(6): 621-625+630.

Huang W, Chen H. Research Progress on Antiviral of

Active Components of Radix Isatidis[J]. Journal of

Mathematical Medicine. 2015; 28(1): 96.

Huang Y, Dong F, Li C. Research Progress on the

Determination Methods of Main Chemical

Components in Radix Isatidis[J]. China

Pharmaceuticals. 2020; 29(7): 150-156.

Jia J, Cao R, Du Y, Zhao Z, Li L. Review of the

Researches on Polysaccharides from Isatis Indigatica

Fort. Science and Technology of Food Industry. 2016;

37(18): 378-383.

Jia W, Qin K, Liu L. Research on the Components

Determination of Isatis Indigotica Fort Draff and Its

Application[J]. Journal of Taishan Medical College.

2010; 31(7): 520-521.

Jiang S, Zhou M, Deng W, Dai H, Fang G, Wu W. High-

wet-strength Paper-based Lignocellulosic Adsorbents

and Its Heavy Metal Ion Adsorption Properties[J].

Journal of Forestry Engineering. 2020; 5(3):101-107.

Kim T H, Kim J S, Sunwoo C, Lee Y Y. Pretreatment of

Corn Stover by Aqueous Ammonia. Bioresour.

Technol. 2003; 90(1): 39-47.

Kommula V P, Reddy K O, Shukla M, Marwala T, Rajulu

A. V. Physico-chemical, Tensile, and Thermal

Characterization of Napier Grass (Native African)

Fiber Strands. Int. J. Polym. Anal. Charact. 2013;

18(4): 303-314.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1020

Pan H, Zhu P, Wei X, Zhang Y. Research Progress of

Radix Isatidis [J]. Guide of China Medicine. 2018;

16(30): 30-32.

Reddy K O, Maheswari C U, Reddy D J P, Rajulu A V.

Thermal Properties of Napier Grass Fifibers. Mater.

Lett. 2009; 63(27): 2390-2392.

Tian Y, Zhao J, Feng B, Sun X. Research Progress in the

Removal of Heavy Metal by Algae[J]. Journal of

Kunming University of Science and Technology

(Natural Science). 2020; 45(05): 97-104.

Tan S, Bai X, Wang X, An Y, Ning G, Zhang X.

Adsorption of Pb (II) on Modified

Lignocellulose/Montmorillonite[J]. Journal of Inner

Mongolia Agricultural University (Natural Science

Edition). 2019; 154(4): 76-83.

Tan S, Bai X, Wang X, An Y, Shen Y, Zhang X. Study of

Adsorption Property of Lignocellulose-based

Nanocomposite towards Mn2+[J]. Journal of Inner

Mongolia Agricultural University (Natural Science

Edition). 2020; 159(3): 74-80.

Ulfa S M, Chamidah N, Kurniawan A. Adsorption of

Cu(II) in Aqueous Solution by Modified Sawdust

Cellulose[J]. IOP Conference Series Earth and

Environmental Science. 2019; 239: 012008.

Wang J, Li W. Determination of Effective Components in

Banlangen Granules and Research Progress of

Pharmacological Effects[J]. China Medical Herald.

2019; 16(18): 49-52.

Wang J, Li W. Determination of Effective Components in

Banlangen Granules and Research Progress of

Pharmacological Effects[J]. China Medical Herald.

2019; 16(18): 49-52.

Wei P, Wei D, Mo D. Biosorption of Lead by Isatis

Indigotica Fort Draff[J]. Ion Exchange and

Adsorption. 2003; 19(4): 351-356.

Xu S, Wang Y, Bi W, Zhou J, Chen W. Preparation of a

Modified Microbial Adsorbent and Its Adsorption

Characteristics for Cd[J]. Acta Scientiae

Circumstantiae. 2021; 41(04): 1342-1350.

Yang Y, Zhong Y, Li S, Deng M, Yang X, Yang Y, Yao

Y. Research Progress on the Harm of Heavy Metals to

Human Body in Aquatic Products[J]. Agricultural

Technology and Equipment. 2020; (10): 55-56. More

references

Yuan T, Hu S. Current Situation and Treatment Methods

of Heavy Metal Pollution in Water[J]. Construction

and Budget. 2019; (06): 75-78.

Yang C. Advances in Pharmacological Research of Radix

Isatidis[J]. Chinese Journal of Modern Drug

Application. 2016; 10(9): 282-283.

Yi J, Huo Z, Abdullah M A, Khalid A A, Li J. Application

of Agroforestry Waste Biomass Adsorption Materials

in Water Pollution Treatment[J]. Progress in

Chemistry. 2019; 31(5): 760-772.

Yu J, Chi C, Zhu B, Qiao K, Yan S. High Adsorptivity

and Recycling Performance Activated Carbon Fibers

for Cu(II) Adsorption. Sci. Total Environ. 2019; 700:

134412-134435.

Zhang B. Heavy Metal Pollution in Water and Its

Remediation Methods[J]. Chemical Enterprise

Management. 2020; (17): 63-64.

Zhang B, Zeng M, Zhang L, Wang H, Zeng Y, Huang S,

Wu J, Cheng Y, Long B. Adsorption of Cu2+ by

Autotrophic Nitrifying Granular Sludge and Its

Adsorption Isotherm[J]. Chemical Industry and

Engineering Progres. 2020; 39(4): 1583-1590.

Preparation and Adsorption Properties of Chemically Modified Isatis Indigotica Fort Draff based Biosorbent

1021