Bioremediation of Antimony and Arsenic Co-contamination from

Antimony Mining Area with Sulfate-reducing Bacteria

Juan Zhong

1,2,3,4 a

, Xiaokui Che

1,2,3 b

, Xinglan Cui

1,2,* c

, Hongxia Li

1,2 d

, Qidong Zhang

1,2 e

,

Lei Wang

1,2 f

, Qi Zheng

1,2 g

and Xuewu Hu

1,2,5 h

1

GRINM Resources and Environment Tech. Co., Ltd., Beijing, 101407, China

2

National Engineering Laboratory of Biohydrometallurgy, GRINM Group Co., Ltd., Beijing, 100088, China

3

GRINM Group Corporation Limited, Beijing 100088, China

4

GRIMAT Engineering Institute Co., Ltd., Beijing, 101407, China

5

School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing,

Beijing, 100083, China

Keywords: Antimony Mining Area, Bioremediation, Sulfate-Reducing Bacteria, Arsenic.

Abstract: The contamination of antimony (Sb) and arsenic (As) in the soil of antimony mining area is the most

common pollutant. Metal sulfide precipitation by sulfate-reducing bacteria (SRB) is considered to be a

promising method. In this work, antimony and arsenic contaminated soil from an antimony mining area was

treated by the application of a mixed culture of SRB. The soil samples initially contained the concentration

of 17550 mg/kg Sb and 3231 mg/kg As, and the leaching concentration exceeds the groundwater IV

standard. Changes of Eh, pH, aqueous Sb and as were monitored over 50 days in this experiment. The

results indicated that SRB was able to increase the pH value and decrease the redox potential of the solution.

When the SRB was growing well in the system, the high concentration of Sb in the solution was reduced

from 7.8 mg/L to less than 0.5 mg/L. However, As showed a completely opposite trend to antimony. The

presence of SRB can promote the release of as from contaminated soil, and the concentration of As will

gradually decrease when the activity of SRB decreased. This work demonstrates that SRB can trigger the

release of Sb, while as caused the opposite effect.

1 INTRODUCTION

1

Antimony (Sb) and Arsenic (As) are toxic and

carcinogenic metalloids of global concern and listed

as priority control pollutants by the European Union

and the United States Environmental Protection

Agency (Fu, et al., 2016). As the largest antimony

producer in the world, China risks more severe of

antimony pollution far than other countries. In

addition to high concentration of antimony pollution,

high arsenic pollution usually accompanies in

a

https://orcid.org/0000-0001-6436-9518

b

https://orcid.org/0000-0003-4913-9700

c

https://orcid.org/0000-0002-9972-9015

d

https://orcid.org/0000-0003-0654-0115

e

https://orcid.org/0000-0003-1843-6809

f

https://orcid.org/0000-0002-4476-0496

g

https://orcid.org/0000-0002-9708-660X

h

https://orcid.org/0000-0001-6643-749X

antimony mining area and surrounding environment

due to the mineral oxidation and arsenic alkali slag

leaching. Antimony and arsenic are non-essential

toxic elements for human body, which could be

absorbed and accumulated by plants when they

existed in dissolved state, and potentially entered the

human body and caused various diseases such as

cardiovascular diseases, skin lesion, reproductive

disorders, diabetes, and even cancer in the skin,

bladder, kidney, and lung (Alam, McPhedran, 2019;

Singh, et al., 2015).

In the past 20 years, significant progress has

been made in the treatment of antimony/arsenic

pollution. These technologies fall into two main

categories, directly remove antimony and arsenic

from contaminated media and reduce its biotoxicity

in the environment, both of which can reduce the

health risks of antimony and arsenic to human body

(Feng, et al., 2017). At present, remediation

technologies are mainly including biological

1174

Zhong, J., Che, X., Cui, X., Li, H., Zhang, Q., Wang, L., Zheng, Q. and Hu, X.

Bioremediation of Antimony and Arsenic Co-contamination from Antimony Mining Area with Sulfate-reducing Bacteria.

DOI: 10.5220/0011381600003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 1174-1178

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

oxidation/reduction, electrokinetics,

phytoremediation, coagulation–flocculation, ion

exchange, and solidification/stabilization (Wan, et

al., 2019). Biological methods have been widely

used in the treatment of heavy metal pollution due to

their advantages of low remediation cost,

environmental friendliness and simple operation. In

particular, sulfide precipitation generated by sulfate

reducing bacteria (SRB) is considered to be an

effective method for the removal of heavy metal

pollution. Under anaerobic conditions, SRB can

reduce sulfate to sulfide, which is able to precipitate

metals and metalloids, decreasing its solubility and

pervasiveness (Zacarias-Estrada, et al., 2020).

Microbial redox reactions can significantly affect

the conversion of valence states between Sb (III) and

Sb (V). Although there are relatively few studies on

bioreduction of Sb (V), it has been shown that

microorganisms have the ability to reduce Sb(V). Sb

is a strong chalcophile element, thus it can be easily

reacted with the dissolved sulfide produced by SRB

to form antimony sulfide. Sb (V) usually exists as Sb

(OH)

6-

and can be reduced to HSb

2

S

4−

, Sb

2

S

4

2−

,

Sb

2

S

3

, and Sb (III)-sulfide complexes by the

dissolved sulfide under anoxic conditions (Xi et al.,

2020). Sb and As belong to the same main group and

their properties are similar. As(V) usually exists in

the form of H

2

AsO

4−

and HAsO

4

2−

and the sulfide

produced by SRB can potentially precipitate As(V)

as arsenic sulfides (realgar (AsS) and orpiment

(As

2

S

3

)), or form soluble thio-As species when As

concentration reaches equilibrium, thus promoting

or reducing As migration and immobilization (Fan,

et al., 2018).

There are many reports of As remediation by

SRB, and the Sb biotransformation has also been

studied in recent years. However, few studies have

investigated the bioremediation of Sb and As co-

contamination by SRB. Therefore, this study

investigated the potential of As/Sb removal and

immobilization ability mediated by SRB in the soil

of antimony mining area. The objectives of this

study are (1) investigate the bioremoval efficiency of

As/Sb during the growth of a mixed culture of SRB,

and (2) evaluate the long-term stability of the

remediation process.

2 MATERIALS AND METHODS

2.1 Site Location and Soil Sampling

Soil samples were derived from an antimony mining

area located in Qinglong County, Guizhou Province,

Southwest China. The soil samples were collected

from the upper surface (5-15 cm) in April, 2021. The

collected samples were transferred with ice to the

laboratory within two days, and stored at 4℃ before

the incubation experiments. To determine the main

elemental compositions in the soil, samples were

freeze-dried, sieved through 100 mesh and then

measured using X-ray fluorescence (XRF,

PANalytical BV).

2.2 Bacterial Culture

The SRB consortium used in this study was

originated from National Engineering Laboratory of

Biohydrometallurgy. Prior to the experiments, the

bacteria were cultured in liquid medium containing

per liter: 0.01 g CaCl

2

·2H

2

O, 0.5 g MgSO

4

·7H

2

O, 1

mL sodium lactate, 1.0 g Yeast extract, 0.5 g KCl,

0.5 g K

2

HPO

4

. The SRB were incubated for 3 days

to a late exponential phase at 30°C in an anaerobic

reactor.

2.3 Bioreduction Experiment

The microcosm experimental system was performed

simultaneously in 500 mL serum bottles, containing

200 g contaminated soil, 375 mL of liquid medium,

with 10% v/v of SRB enriched anaerobic consortium

as inocula and nitrogen as gas headspace to impose

anaerobic condition. In the early stage of the

reaction, medium was not supplemented during the

culture process. After 35 days, the same volume of

medium solution was added after each sampling.

Control treatments without addition of SRB were

also set up for comparison. All the bottles were

anaerobic incubation at 25-30°C in static conditions.

Each experiment was carried out in triplicate. At

regular intervals, liquid supernatant samples (5.0

mL) were filtered through a sterile syringe to

analysis of aqueous Sb and As. The redox potential

(Eh) and pH were also monitored at each sample

internal.

2.4 Analytical Methods

Soil samples were heated at 105℃ for 2 h to

determine water content. The pH of soil samples was

measured at solid/water ratio of 1:2.5 with a pH

meter (Thermo Scientific Orion 3-Star, Germany).

To determine the leaching toxicity of heavy metals

in soil samples, sulfuric acid and nitric acid method

were applied.

The pH and Eh of water samples were

immediately measured after sample collection with

Bioremediation of Antimony and Arsenic Co-contamination from Antimony Mining Area with Sulfate-reducing Bacteria

1175

pH meter and redox potential meter (pH/ORP

controller PC-350, China), respectively. Total

dissolved Sb and As content were quantified using

Inductively Coupled Plasma Optical Emission

Spectroscopy (ICP-OES, Agilent 725, USA).

3 RESULTS AND DISCUSSION

3.1 Characterization of The Soil

The antimony mining area soil sampled at Qinglong

County were reddish brown in appearance. The

contaminated soil was almost neutral, and the

average pH values are 7-7.8. The soil moisture

content was 6.8%. The main element of the sample

as conducted by XRF analysis were summarized in

Table 1. Totally, Sb contents were several times

greater than that of As, and the concentration of Sb

and As was 17550 and 3231 mg/kg, respectively.

Besides, the soil also contained high concentrations

of Fe (18.74%), Ca (6.85%), S (6570 mg/kg), Ti

(4720 mg/kg). According to the Chinese national

standards for groundwater quality, the leaching

concentration of Sb and As exceeds the groundwater

Ⅳ standard, in which As exceeds 1.256 times and

Sb exceeds 728 times.

Table 1: The XRF results of the antimony mining area

soil.

Elements Con.

(mg/kg)

Elements Con.

(mg/kg)

Elements Con.

(mg/kg)

Fe 187400 Ti 4720 Sr 330

Ca 68500 As 3231 Ba 273

Sb 17550 Cl 1070 Cr 215

K 10610 Zn 861 Cu 115

S 6570 Mn 498 V 114

3.2 Variation of Physicochemical

Properties in the Soluble Medium

After 3 days of reaction, the solution in the

remediation group began to turn black and hydrogen

sulfide was produced (Figure 1), while there was no

significant change in the control group, indicating

that SRB in the remediation group could quickly

adapted to the high concentration of antimony and

arsenic pollution environment and played a

biological reduction function in this system.

Figure 1: Solution color changes during remedation.

ORP and pH are fundamental properties which

can reveal the activity of microorganism and the

process of mineral transformation (Gao, et al., 2021.

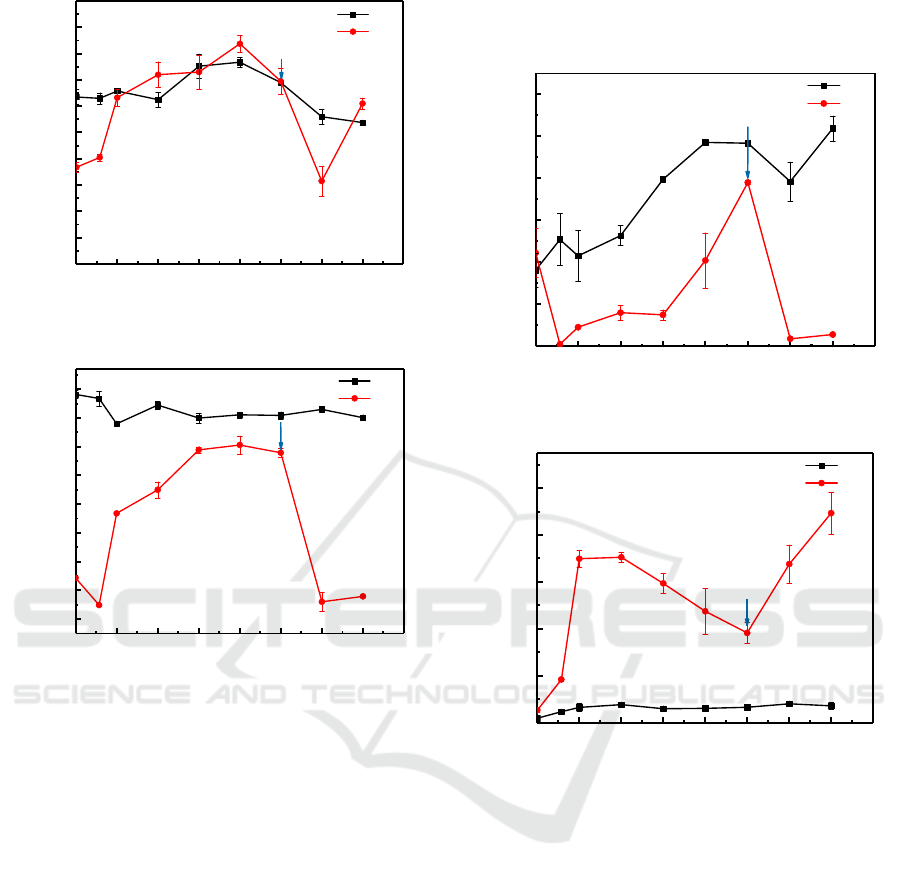

Changes of Eh and pH during the 50d reaction

period was shown in Figure 2. The pH in biotic

systems increased from the initial value of 7.2 to 8.3

within 28 d, which may be attributed to the

alkalinity (HCO

3

−

) generation and biogenic H

2

S

accumulation due to the sulfate reduction by SRB

(Fan, et al., 2018). Subsequently, pH decrease was

observed in the treatment may be relative to the

death of SRB in the system. Thus, when liquid

medium was supplemented to the system, the pH of

solution began to increase again. With the initiation

of the remediation treatment by SRB, the Eh was

decreased in the first 4 days, then increased

gradually and reached a peak to approximately 50

mV (Figure 3), reflecting the decrease of SRB

activity. After the addition of medium in 35d, the Eh

decreased markedly from 40 mV to -220 mV,

indicated that SRB was growing well and resulted in

a strong reducing condition in the culture. In the

abiotic control treatments, the pH presented an

upward trend first and then falling, and the Eh nearly

remain unchanged at ~100 mV throughout the entire

incubation period.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1176

Figure 2: pH changes during remedation.

Figure 3: ORP changes during remedation.

3.2 Concentration Changes of Sb and

As in Solution

The Sb concentration in the CK group increased

from 3.62 mg/L to 10.37 mg/L (Figure 4). While in

the SRB bioremediation group, the Sb concentration

decreased rapidly from 4.45 mg/L to 0.91 mg/L

within 7 days, after that, there was a slightly

increase, and then began to increase sharply,

reaching 7.80 mg/L on the 35 days. After

supplemented with the medium, Sb concentration

quickly decreased to 0.36 mg/L, and maintained a

low concentration during the whole experiment. The

change of As concentration was shown in Figure 5.

The As concentration in the CK group increased

from 0.37 mg/L to 1.30 mg/L from 0-7d, and then

remained relatively stable. The As concentration in

the SRB bioremediation group decreased from 1.05

mg/L to 13.97 mg/L from 0-7d, and it began to

decrease significantly on the 14 days, and the

concentration decreased to 7.64 mg/L on the 35

days. After supplemented with medium, As

concentration started to increase rapidly at the end of

this experments.

Figure 4: Sb concentration changes during remedation.

Figure 5: As concentration changes during remedation.

SRB mediated sulfate reduction to produce H

2

S,

and H

2

S reacted with Sb to produce insoluble

precipitate Sb

2

S

3

, which may be the reason for the

decrease in Sb concentration in the initial stage.

With the consumption of the substrate, we observed

that the ORP gradually increased, the activity of

SRB decreased and the production of H

2

S decreased,

and inability to precipitate the dissolved Sb

completely, resulting in an increase in the

concentration of Sb in the solution. In addition, the

medium was supplemented in the later stage, and

ORP and the concentration of Sb decreased rapidly,

confirming that the highly active SRB can

precipitate Sb by mediating sulfate reduction to

produce H

2

S. However, the change of As

concentration in solution was opposite to Sb, which

indicated that SRB may lead to the release of

arsenic. This may be because As (V) was reduced to

0 7 14 21 28 35 42 49 56

6.6

6.8

7.0

7.2

7.4

7.6

7.8

8.0

8.2

8.4

8.6

pH

Time (d)

CK

SRB

Addition of medium

0 7 14 21 28 35 42 49 56

-250

-200

-150

-100

-50

0

50

100

150

Eh (eV)

Time (d)

CK

SRB

Addition of medium

0 7 14 21 28 35 42 49 56

0

2

4

6

8

10

12

Sb (mg/L)

Time (d)

CK

SRB

Addition of medium

0 7 14 21 28 35 42 49 56

0

4

8

12

16

20

As (mg/L)

Time (d)

CK

SRB

Addition of medium

Bioremediation of Antimony and Arsenic Co-contamination from Antimony Mining Area with Sulfate-reducing Bacteria

1177

As (III) in the presence of SRB, while As (III) is

more unstable and easily released into the

environment. Although H

2

S can react with As to

form insoluble As

2

S

3

, this precipitate is not stable

(Matos et al., 2018). In the presence of high

concentrations of sulfide and at near-neutral pH, the

transformation of insoluble As

2

S

3

into soluble As

(OH)S

2

2-

could be observed in the system (Sun et al.,

2019). Therefore, it is difficult to remeditation of As

by SRB alone, which requires strict reaction

conditions.

4 CONCLUSIONS

During the reductive process of contaminated soil

from antimony mining area by SRB, the changing

trend of Sb and As were different. The change of

aqueous Sb concentration showed two stages, firstly,

when the activity of SRB decreased, the Sb

immobilization by SRB would be gradually released

in the early stage of the reaction. next, the released

Sb quickly removed from the solution when the

OPR value decreased to negative. However, SRB

caused a negative effect on As in this study. This

process verified a cost-effective biological process

to remove Sb from Sb-As contaminated soil, while

the remediation of As through SRB needs further

study.

ACKNOWLEDGEMENTS

The project was funded by the Youth Fund Project

of GRINM (No. 12120), the National Key Research

and Development Project (No. 2020YFC1807700),

the Open Foundation of State Key Laboratory of

Vanadium and Titanium Resources Comprehensive

Utilization (No. 2021P4FZG13A), and the National

Key Research and Development Project (No.

2019YFC1805900).

REFERENCES

Alam, R. & McPhedran, K. (2019). Applications of

biological sulfate reduction for remediation of arsenic

– A review. Chemosphere, 222, 932-944.

Fan, L., Zhao, F., Liu, J., & Frost, R. L. (2018). The As

behavior of natural arsenical-containing colloidal

ferric oxyhydroxide reacted with sulfate reducing

bacteria. Chemical Engineering Journal, 332, 183-191.

Feng, C., Aldrich, C., Eksteen, J. J., & Arrigan, D. W. M.

(2017). Removal of arsenic from alkaline process

waters of gold cyanidation by use of

Fe3O4@SiO2@TiO2 nanosorbents. Minerals

Engineering, 110, 40-46.

Fu, Z., Wu, F., Mo, C., Deng, Q., Meng, W., & Giesy, J.

P. (2016). Comparison of arsenic and antimony

biogeochemical behavior in water, soil and tailings

from Xikuangshan, China. Sci Total Environ, 539, 97-

104.

Matos, L. P. d., Costa, P. F., Moreira, M., Gomes, P. C. S.,

Silva, S. d. Q., Gurgel, L. V. A., & Teixeira, M. C.

(2018). Simultaneous removal of sulfate and arsenic

using immobilized nontraditional SRB mixed culture

and alternative low-cost carbon sources. Chemical

Engineering Journal, 334, 1630-1641.

Singh, R., Singh, S., Parihar, P., Singh, V. P., & Prasad, S.

M. (2015). Arsenic contamination, consequences and

remediation techniques: a review. Ecotoxicol Environ

Saf, 112, 247-270.

Sun, J., Hong, Y., Guo, J., Yang, J., Huang, D., Lin, Z.,

Jiang, F. (2019) Arsenite removal without thioarsenite

formation in a sulfidogenic system driven by sulfur

reducing bacteria under acidic conditions. Water Res,

151, 362-370.

Wan, X., Lei, M., & Chen, T. (2019). Review on

remediation technologies for arsenic-contaminated

soil. Frontiers of Environmental Science &

Engineering, 14(2).

Xi, Y., Lan, S., Li, X., Wu, Y., Yuan, X., Zhang, C., Yun,

G. L., Huang, Y. Quan, B., Wu, S. (2020).

Bioremediation of antimony from wastewater by

sulfate-reducing bacteria: Effect of the coexisting

ferrous ion. International Biodeterioration &

Biodegradation, 148.

Zacarias-Estrada, O. L., Ballinas-Casarrubias, L.,

Montero-Cabrera, M. E., Loredo-Portales, R.,

Orrantia-Borunda, E., & Luna-Velasco, A. (2020).

Arsenic removal and activity of a sulfate reducing

bacteria-enriched anaerobic sludge using zero valent

iron as electron donor. J Hazard Mater, 384, 121392.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

1178