Knowledge Sharing Model for Integrated Development of Products in

Machine-building (Results of the Exploratory Study)

Diana Antonova

a

, Svilen Kunev

b

and Irina Kostadinova

c

Department of Management and Social Activities, University of Ruse “Angel Kanchev”, 8 Studentska str., Ruse, Bulgaria

Keywords: Knowledge Creation, Exchange and Transfer, Shared Supplier Knowledge, Process Performance,

Core Competencies, NPD, Value for Consumers.

Abstract: Every industrial enterprise should apply effective knowledge creation and transfer as an instrument for

increasing its competitiveness in strategic, long-term horizon. It makes the research of different techniques

adopted by companies for turning knowledge into a competitive advantage extremely important both for

academics and practitioners. Research works that analyse the key characteristics of creation of new knowledge,

exchange and knowledge transfer put focus mainly on activities for research and development (R&D) in

knowledge intensive industrial sectors, such as biotechnologies and information and communication

technologies. In this paper, we explore the knowledge creation, exchange and transfer in the traditional

mechanical engineering in Bulgaria, Germany, Japan and the USA.

1 INTRODUCTION

The capabilities of the companies to develop products

stem from their skills to create, disseminate and

implement knowledge in the various phases of the

innovation process (Kunev et al., 2012).

The majority of studies is directed to the issues of

integration of activities (Griffin, 1997; Shah at al.,

2009; Kostadinova et al., 2019; Kunev, 2010;

Ruskova et al., 2018) and the phases in the

development of new products (Vitliemov et al., 2001;

Iliev et al., 2018; Zlatarov et al., 2018) as opposed to

the issues of integration of knowledge (sharing).

This paper is based on the integration (sharing) of

knowledge in the new product development –

IKNPD, (Orstavik, 2004). Empirical research of

IKNPD (Todorova et al., 2011; Stoycheva et al.,

2016; Antonova, Stoycheva, 2018) prove the

importance of organisational integration for the

competitive advantage of the industrial enterprise

through a correlation between the interaction patterns

and the opportunities for success. Such collaborative

efforts contribute to marked improvements in the

innovation activities of industrial enterprises and lead

to good market results (Stoycheva et al., 2018).

a

https://orcid.org/0000-0002-6060-6974

b

https://orcid.org/0000-0001-8726-935X

c

https://orcid.org/0000-0001-8845-7598

Although there is no doubt about the importance of

shared knowledge, concerning NPD, it is hard to

create such useful knowledge sharing spontaneously,

due to the different cognitive worlds of departments

and individuals and the „basic information", which

consists essentially of what must be separated from

the specific content, particularly in the thematic

setting of IKNPD. Among the seven phases of the

IKNPD process – idea, concept elaboration, design of

the system, testing and improvement, production,

commercialization – the first and the last phase

include concept development and precede the design

of the system (Antonova, et al, 2018). This is the

level, at which knowledge sharing should be executed

among the development teams (Ruskova, 2012). An

important aspect of knowledge access and exchange

are also the user requirements, supplier capacity and

core competences (Orstavik, 2004).

Multifunctional coordination is enhanced through

increasing the in-depth knowledge with every

function. In reality, there is no practical evidence that

knowledge integration improves IKNPD results. In

order to summarize the preliminary study on the

topic, this study analyses the content of knowledge

integration and the eventual reasons for correlation of

126

Antonova, D., Kunev, S. and Kostadinova, I.

Knowledge Sharing Model for Integrated Development of Products in Machine-building (Results of the Exploratory Study).

DOI: 10.5220/0010657900003064

In Proceedings of the 13th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2021) - Volume 3: KMIS, pages 126-132

ISBN: 978-989-758-533-3; ISSN: 2184-3228

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

performance in NPD. It proves the interdependence

between the three types of knowledge sharing: of the

consumers (users); the core (basic) competencies of

the organization; and the suppliers’ capacities.

2 RESEARCH METHOD

The goal of this research is to develop and test a

knowledge sharing model for integrated industrial

product development, using indexes for the level of

teamwork, which try to clarify the three categories of

shared knowledge (i.е. of the users, suppliers and core

company competences) and the product presentation

(i.e. time to commercialization and value to users).

The main task is to elaborate a valid and reliable scale

for measuring IKNPD by presenting the process and

the product, i.e. cause-and-effect links of the impact

of shared knowledge on the IKNPD process

execution (mostly evaluated by the degree of

teamworking and R&D productiveness), as well as

the links between the impact of process presentation

on the main strategic imperatives such as time to

commercialization and value to users. The research

includes hypotheses testing, empirically derived from

the model:

H1. The greater the extent of shared knowledge of

users, the higher the degree of teamwork and R&D

productiveness.

Н2. The greater the extent of shared knowledge of

suppliers, the higher the degree of teamwork and

R&D productiveness.

Н3. The greater the extent of shared knowledge of

core competences, the higher the degree of teamwork

and R&D productivity.

Н4. The higher the degree of teamwork and R&D

productivity, the shorter the time to commerciali-

zation is.

Н5. The higher the degree of teamwork and R&D

productiveness, the higher the value to the user is.

2.1 Pilot Study

The design of the research process is grounded on

generally accepted methods for amplification of

standardized tools. The pilot study was conducted by

on-line monitoring of machine-building enterprises

with similar profile in May 2018. The survey

questionnaire was revised to adopt some changes,

suggested by academic experts and industry

specialists (Frascati Manual by OECD, 2018). After

it was completed, it was sent to 500 managers of large

machine-building enterprises in Bulgaria, Germany,

Japan and the USA.

Festo Vertrieb GmbH&Co. KG – Germany; The

American Investment Fund Anchorage Capital

Partners, Sydney, Australia and Advanced

Technological R&D and Product sales, Yazaki

Corporation, Japan provided the contacts of 500

managers, selected randomly according to their

participation in machine-building enterprises. Their

parameters were as product managers, with positions

and geographical locations in four sectors (production

of automobile components and parts; refrigeration

equipment; hydraulic systems; medical and

physiotherapy equipment) with codes according to

the standardized industrial classification (SIC) 34, 35,

36, and 37. The answers in the initial pilot study are

excluded from the full survey and the enterprises

included in the pilot study are not present in the list

for the large study. These steps have been undertaken

in order to ensure the above-mentioned desired

characteristics. The instruments used in the large-

scale survey are shown in Appendix 1. The answers

have been measured against five-stage Likert scales.

The period of conducting the main survey was June-

September 2018.

2.2 Sample

Of the total of 500 companies, 30 respondents were

used for the pilot study and 205 – for the large one.

205 credible responses came from refrigeration

manufacturers (22.93%); manufacture of gaming

equipment (7.32%); medical and physiotherapy

equipment (17.56%); production of automobile com-

ponents and parts (30.12%) and hydraulic systems

(16.32%). The positions of the respondents are as

follows: executive directors/presidents (2.44%),

senior managers (36.10%), project managers

(32.68%), and others (28.29%). More than 70% of the

interviewed persons have a real experience in

managing multi-functional international project

teams. The number of employees in the respondents’

companies is: less than 500 (40%); 500-599

(15.12%); 1000-4999 (22.44%), 5000-9999 (8.78%)

and over 10000 (12.20%). The companies with over

1000 employees are 43.42 % of the total.

Knowledge Sharing Model for Integrated Development of Products in Machine-building (Results of the Exploratory Study)

127

3 METHODS FOR DATA

ANALYSIS

Linear modelling of structural equations (LISREL) is

applied to describe the strength of the correlations

among: Shared knowledge of core/basic organization

competencies; Shared knowledge of consumers

(users) and supplier; Process performance; Time to

commercialization; and Value for consumers (users).

LISREL provides an accurate method for testing

conditional models, as it can implement simulative

evaluation of both conditional components and

indicators in complex models. Standardized

coefficients and t-values of conditional links between

the elements are applied to test the hypotheses set in

the study. The software package LISREL, applied for

the calculations in the study is described as: Software

for modelling structural equations, generated by the

path of diagrams in an easy-to-use interface and

syntax that is generated directly from the scheme. The

calculations were performed with SSI's LISREL 8.8

licensed software for Microsoft Windows Vista.

4 RESULTS AND DISCUSSION

For the first time, an analysis of the state of product

design was conducted by the Product Development

and Marketing Association (PDMA), USA, through a

survey among 189 American companies in 1989,

followed by a second survey in 1995 with 383

respondents. The third application of the methodology

was in 2003 (Barczak et al., 2009). The questionnaire

developed by PDMA, as the main tool of the survey in

2003, contains 7 modules: (1) Shared knowledge of

users (AD); (2) Shared knowledge of core (basic)

competencies (AF, AE, AH, AN); (3) Process

performance (DEVPRO); (4) Value for consumers

(users) (CA, CC,CK, CM); (5) Shared Supplier

Knowledge (AG,AK, AC, AJ, AA); (6) Teamwork

and (7) Time to commercialisation (CIE, CIL, CIK).

The encoding is done by PDMA.

Later, the PDMA tool was partially used to survey

industrial companies in Sweden in 2004 (Rundquist,

Chibba, 2004). A follow-up survey focusing solely on

outsourced NPD was conducted in 2008 by Rundquist

and Halila (Rundquist, Halila, 2010).

A parallel study on the NPD process took place in

Malaysia in 2006, based on the methodological

foundations of PDMA (1995) and Sweden (2004).

The project coordinators are Shalabi, Omar and

Rundquist (Shalabi et al., 2008). The study covers:

documented process and strategies in NPD,

outsourcing and organization of the process in NPD.

Another independent parallel study of integrated

product development that surveyed 205 US

automotive engineers also reveals some

interconnections with knowledge sharing with

customers and suppliers (Hong et al., 2004).

In this research to test hypothetical links, a

Confirmatory Factor Analysis (CFA) is done. A lot of

the literature on CFAs is based on LISREL modelling.

The co-variant structure of the model includes two

components: a measurement model and a structural

model. The measurement model establishes how

hypothetical (latent) concepts are evaluated against

observed variables. One of the dimensions is defined

as the presence of a latent distinctive characteristic of

the concept that gives grounds for a set of indicators.

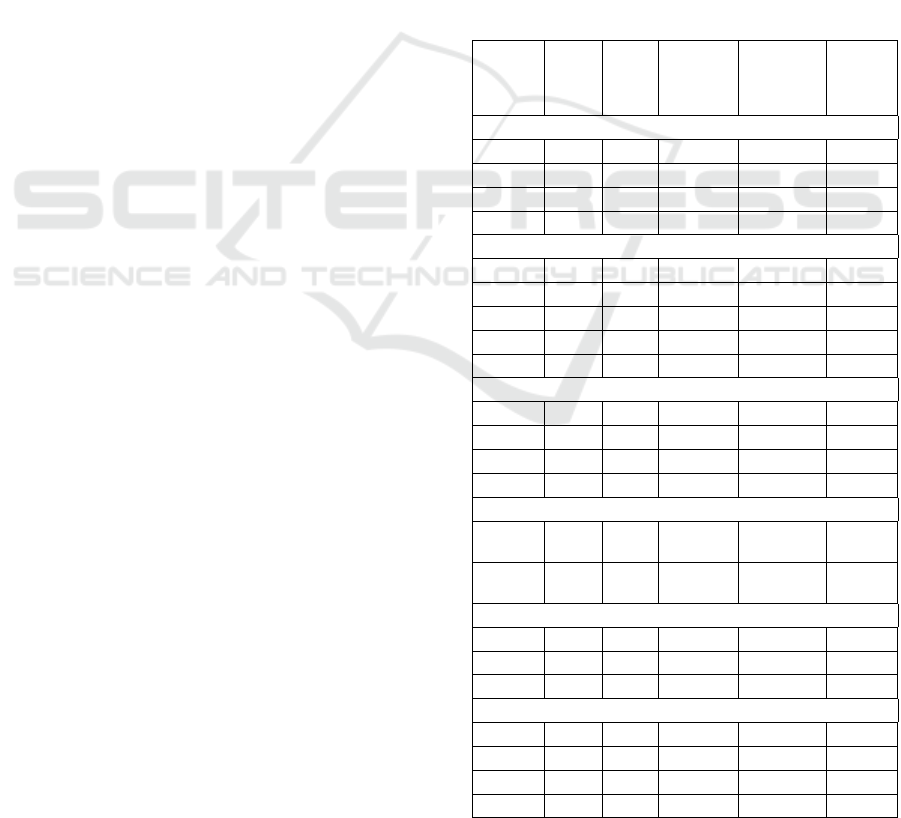

Table 1: Investigated model: assessment of the parameters

of the measured variables (n=205). Source: authors’

elaboration, adapted from PDMA model, 2019.

Indicators

Factor

loading

t-

value

Total

standard

factor load

Uniqueness/

term of the

error

R

2

-

reliability

Shared knowledge of users

AID 1.00 0.61 0.62 0.58

A2D 1.36 8.01 0.75 0.44 0.56

А2К 1.56 9.42 0.86 0.25 0.75

A3D 1.54 9.10 0.88 0.20 0.77

Shared Supplier Knowledge

A1G 1 0.77 0.30 0.62

А1К 1.06 11.17 0.77 0.40 0.60

А2С 0.91 9.90 0.69 0.52 0.48

A2J 1.05 10.81 0.85 0.44 0.56

АЗА 1.04 10.70 0.84 0.45 0.55

Shared knowledge of core (basic) competencies

A1F 1.00 0.81 0.35 0.65

АП 0.99 10.66 0.78 0.40 0.60

АЗЕ 0.76 8.52 0.62 0.62 0.58

АЗН 0.77 8.05 0.59 0.65 0.35

Process performance

Тeam-

wor

k

0.90 0.67 0.24 0.67

DEVPR

O

1.00 15.78 0.66 0.23 0.67

Time to comme

r

cialisation

С1Е 1.00 0.95 0.09 0.91

C1L 0.68 10.25 0.63 0.60 0.40

C1

K

0.90 15.34 0.84 0.30 0.70

Value for consumers (users)

C2A 1.00 0.74 0.46 0.54

C2C 1.30 11.86 0.85 0.20 0.72

C2

K

1.14 11.64 0.83 0.31 0.69

C2M 1.30 11.53 0.82 0.32 0.68

KMIS 2021 - 13th International Conference on Knowledge Management and Information Systems

128

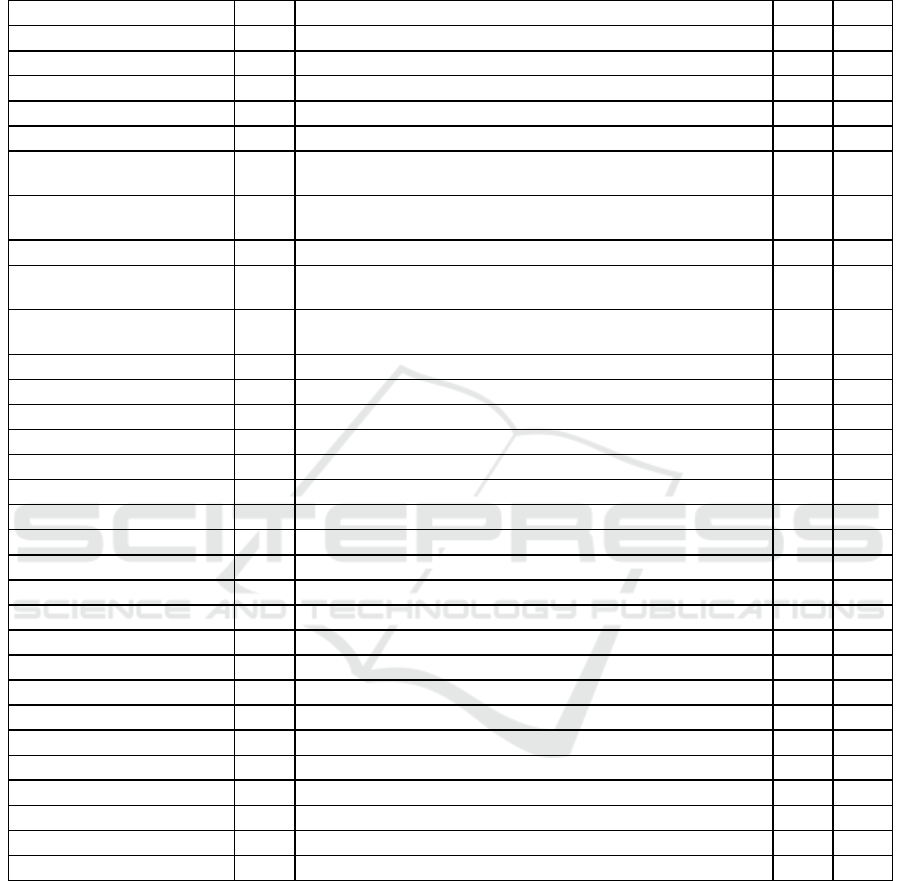

Table 2: Levels of reliability, correlation, and discriminant validity of the components. Source: authors’ elaboration, adapted

from PDMA model, 2019.

1 2 3 4 5 6

1. Shared knowledge of users 0.86

2. Shared Supplier Knowledge 0.21

3. Shared knowledge of basic competencies 347.47

0.52

0.82

0.44 0.85

4. Process performance 163.28

0.68

171.15

0.41 0.64

0.90

5. Time to commercialisation 192.78

0.47

371.88

0.28

135.00

0.44

0.69

0.88

6. Value for consumers (users) 252.74

0.54

282.51

0.33

157.79

0.51

171.61

0.80

0.55

0.91

7. Mean 3.92 3.10 3.79 3.52 3.57 3.77

SD 0.08 0.80 0.64 0.73 0.97 0.92

Based on the assessment of the compliance of a

one-dimensional model for each variable, iterative

modifications were undertaken. Modifications are

made to improve the model's compliance, as well as

to deliver parameters that are of real importance and

significance.

The greater the loading of the factor or the

coefficient, compared to its standard error and

displayed by the corresponding t-values, the stronger

the proof that the measured variables or factors

confirm the basic ideas. Generally, if these t-values

are greater than 2 or 2.576, they are considered

significant at a level of 0.05 to 0.01. In Table 1 above,

it can be seen that all t-values exceed 2.576.

Consequently, all indicators are significantly

related to their defined concepts. Factor loads are over

0.5, which means that all indicators have good values

compared to their thresholds. The R2 values refer to

the reliability of the indicators. The values of R2 over

0.5 mean that less than 50% variation will be a

variation error, which provides evidence of

acceptable reliability.

Most of the R2 values are above 0.5. The values

of R2 and t-values provide evidence of convergence

validity. Table 2 shows a correlation matrix, as well

as the internal consistency coefficients Cronbach

Alpha. The reliability of all metrics is over 0.80.

According to similar calculations (Nunnally, 1978),

reliability over 0.70 is considered satisfactory.

Discriminant validity is reached when the difference

between a restricted and an unlimited model is

significant (x2 of df, x2=1). As shown in Table 2

above Chi-square values are all at a significant level.

With these results, the testing of the proposed

models was done using LISREL. Analysis of

structural equations was used to test these models.

The results are shown in Table 1. For a complete

assessment of the conformity data-model x2, the

Number of Degrees of Freedom, Compliance Index

(CFI), and Bonnett Non-Shared Compliance Index

(NNFI) were used. With respect to NNFI and CFI,

values between 0.80 and 0.89 represent a good match

data-model, while values of 0.90 or higher represent

a very good match. This shows a range of indices

from 0.0 (no match) to 1 (full match). The RMSEA

(square estimate value error) of less than 0.05 is a

close match data-model. As shown in Table 2, the

structural model outputs the covariate matrix very

well (x2=298.71; df=201; NNFI=0.96; CFI=0.96,

RMSEA=0.049). Because the structural model has a

reasonably matching model-data pattern, a study over

the path of the coefficients might be done. Figure 1

bellow shows the test results of the proposed

hypothesises.

H1 – Н3 provide that the shared knowledge of

users, suppliers and core competences will be directly

connected to the results from the presentation of the

process. As seen in Fig. 1, the maximum probability

estimations for the path from shared knowledge of

users, suppliers and core competences are significant

and positive (standard coefficients of 0.48, 0.17 and

0.35, with t-values of 5.71, 2.58 and 3.79,

respectively). This shows that teams, operating with

high levels of shared knowledge of users, suppliers

and core competences demonstrate much better

results in presenting the process than those with low

levels of shared knowledge.

Knowledge Sharing Model for Integrated Development of Products in Machine-building (Results of the Exploratory Study)

129

Figure 1: Evaluation of the elaborated model by analysis of structural equations.

Н4 and Н5 provide that the degree of presentation

of IKNPD process (i.e. team work and R&D

productivity) will be connected to the results from the

presentation of the product (i.e. the time to

commercialisation and value for the user). In Fig. 1 it

is clearly seen that the maximum probability

estimations for the path from the presentation of the

process to the time to commercialisation and value for

the user are significant and positive (standard

coefficients of 0.69 and 0.80, with t-values of 10.45

and 9.81, respectively). This shows that the higher

levels of team work and R&D productivity lead to

shorter time to commercialisation and provide higher

value for the users.

5 CONCLUSIONS

First of all, one contribution of this study is the

amplification of a reliable tool for measuring the level

of knowledge sharing in the field of IKNPD, which

can be used to assist future studies. The results

obtained from the survey of managers in machine-

building prove that knowledge generation is a pre-

requisite for creating successful innovation projects

not only in the Hi Тech Industries, as it is commonly

believed, but also in traditional ones. Identifying

streams of shared knowledge allows researchers to

implement the approach of knowledge management

in applied fields such as NPD, e-commerce or

marketing of industrial products.

Secondly, as it was assumed, the three

components of shared knowledge (users, suppliers

and core competences) are positively related to the

presentation of NPD process. The influence of shared

knowledge is reviewed in another context as well – as

characterisation of research teams, defining success

in outsourcing and building capacity for NPD. This

study shows how the specific components of

knowledge sharing support the IKNPD process (i.e.

team work and R&D productivity) and what the

strategic results (i.e. time to commercialisation and

value for the user) are. The study confirms the fact

that when teams act in an external environment that

fosters knowledge sharing between users, suppliers

and core company competences, the presentation of

the process (team work and R&D productiveness)

connects the effect of knowledge sharing with

strategic directions - time to commercialisation and

value for the users. The results from the study propose

that knowledge must be shared reasonably within the

members of the teams in their efforts to design

products or processes. Managers should concentrate

on methods for improving team work and R&D

productiveness through intensifying the knowledge

sharing among the team members.

Thirdly, if time to commercialisation and value

for the users represent strategic directions, knowledge

sharing is an important driving force. It can also be a

drive for other strategic imperatives like production

opportunity and thus enhance the general

organisational competitiveness.

KMIS 2021 - 13th International Conference on Knowledge Management and Information Systems

130

Last but not least, in order to introduce IKNPD

efficiently, integration must take place at conceptual

level first because product development is a job,

related to intensive use of knowledge. The study

conducted provides support for the five hypotheses

and better understanding of the elements in the

foundation of shared knowledge in IKNPD, as well as

proofs of claims not tested before with regard to the

elements of integrated knowledge.

REFERENCES

Antonova, D. et al. (2018). Concept of Online Distance

Learning System on Sustainable Development in the

Cross-border Region. TEM Journal, 7(4), 915-923.

Antonova, D., Stoycheva, B. (2018). Approved model of

factors, influencing the management process in

developing new products. In The 6th International

Conference Innovation Management, Entrepreneurship

and Sustainability (IMES 2018), Czech Republic, 38-

54.

Barczak G., Griffin A., Kahn K. (2009) Perspective: Trends

and drivers of success in NPDpractices: results of the

2003 PDMA best practices study, The journal of

product innovation management, 26, 3 – 23.

DOI:10.1111/j.1540-5885.2009.00331.x

Griffin, Ab. (1997). PDMA Research on New Product

Development Practices: Updating Trends and

Benchmarking Best Practices. Journal of Product

Innovation Management, 14(6), 429-458. DOI

10.1016/S0737-6782(97)00061-1.

Hong, P., Doll, W., Nahm, Ab., Li, X. (2004). Knowledge

sharing in integrated product development. European

Journal of Innovation Management, 7. 102-112. DOI

10.1108/14601060410534393.

Iliev, S., Gunev, D., Kadirova, S., Nenov, T., Ivanov, I.,

Kunev, S. (2018). Improving Practical Experience of

Students in Pre-production and Production Stages of

New Products. DOI 10.1109/SIITME.2018.8599282.

In 2018 IEEE 24th International Symposium for Design

and Technology in Electronic Packaging (SIITME),

Oct. 25–28, Iasi, Romania, IEEE, 2018.

Kostadinova, I. et al. (2019). Integration of principles of

responsible management education in regard of social

resposibility’s learning needs. Annals of „Eftimie

Murgu” University Reșița. Fascicle II. Economic

Studies, XXVI edition, 132-142.

Kunev, S. et al. (2012). Algorithm for factor determination

of innovation activeness of machine-building SMEs

(the case of Bulgaria, example of Ruse region). In 2nd

International Conference on Logistics and Maritime

Systems, University of Bremen, Germany, Imprint:

University of Bremen, Faculty 7: Business Studies&

Economics, Chair of Logistics, 2012, 293-302

Kunev, S. (2010). Using Case Study in Entrepreneurship

and Innovation Education: Methodological Aspects.

Journal of Entrepreneurship and Innovation, year II, 2,

45-56.

Nunnally, J. C. (1978). Psychometric theory (2nd ed.). New

York: McGraw-Hill, 1978.

Ostravik, F. (2004). Towards a communicative theory of

diverse innovation systems. Diversity of Knowledge

Economy and Society, Series editors: E. Karayaniss &

A. Kaloudis, Cheltenham, U.K., 117-140.

Rundquist, J., Chibba, A. (2004). The use of processes and

methods in NPD-A survey of Swedish industry.

International Journal of Innovation and Technology

Management, 21, 37-54. DOI 10.1142/S02198770040

00076.

Rundquist, J., Halila, F. (2010). Outsourcing of NPD

activities: A best practice approach. European Journal

of Innovation Management, 13, 5-23. DOI 10.1108/

14601061011013203.

Ruskova. S., Ruseva, I. (2018). Empirical study on the

impact of the conflicts on the motivation of the

employees.

Annals of “Eftimie Murgu” University

Resita, XXV, 206-215.

Ruskova, S. (2012). Research of the Motivational Factors

Affecting the Different Categories of Consumers

according to the Rogers’ Model. Entrepreneurship and

Innovation, 3, 51-74, ISSN 1314-0175

Shalabi, Am., Omar, M., Rundquist, J. (2008). Processes

and strategies of NPD: A survey of Malaysian Industry.

International Journal of Manufacturing Science and

Technology, 10, 91-95.

Shah N., Tsai, C., Marinov, M., Cooper, J., Vitliemov, P.,

at al. (2009). Ontological On-line Analytical Processing

for Integrating Energy Sensor Data. IETE Technical

Review, 26, 375-387.

Stoycheva, B., Antonova, D. (2016). Improving

Management Functions in Developing New Products in

Medium-sized and Large Enterprises (a Comparative

Study of Bulgarian and American Processing Industry).

In Kotzab H., Pannek Jürgen, Thoben Klaus-Dieter

(eds.). Dynamics in Logistics. Springer International

Publishing Sw. Berlin-Heidelberg, Germany, LDIC

2014, 667-674.

Stoycheva, B., Antonova, D. (2018). Investigating Factor

Interactions in Formalising the Process of Developing

New Products. Serbian Journal of Management, 1(13),

173-184.

Todorova, M., Ruskova, S. et al. (2011) Method for

Studying the Students Needs of Training in

Entrepreneurship. Scientific Bulletin of Politehnica

University of Timisoara, 5, 5-14, ISSN 1224-6050.

Vitliemov P, Ivanov, S. (2001). Parametric Assembly

Design. Advances in Manufacturing Technology, XV,

Cardiff, UK.

Zlatarov P., Ivanova G. et al. (2018). Adaptive Software

System for Optimization of the Admission and

Management Process for Doctoral Students,

https://doi.org/-10.1007/978-3-030-00184-1_30. In

Silhavy R., Silhavy P., Prokopova Z. (eds.) Intelligent

Systems in Cybernetics and Automation Control Theory.

CoMeSySo 2018. Advances in Intelligent Systems and

Computing. Springer, 2018, (860), 323-332.

Knowledge Sharing Model for Integrated Development of Products in Machine-building (Results of the Exploratory Study)

131

APPENDIX

Indexes included in the basic study (end indexes)

Indexes Measured indexes Mean SD

This IKNPD team shares knowledge of

Shared knowledge of users A1D Customer’s requirements 4.18 0.84

A2D Which characteristics are most valued by the target customers 3.93 0.94

A2K Current needs of the customer 3.93 0.94

A3D What does our customer want 4.02 0.91

Shared Supplier Knowledge A1G What are the capacities of our suppliers for implementing the

process

3.11 0.92

А1К

Capacities of our supplier to meet the requirements for target

expenses

3.03 0.99

А2С Supplier capacities for design 2.98 0.95

А2J Capacities of our supplier to meet the requirements about the time

factor

3.29 1.01

Shared knowledge of basic

competencies

А3А Capacities of our supplier to meet the requirements about quality 3.17 1.02

А1F Capacities of our engineering staff 3.95 0.80

А1I Strengths of the capacities of engineering staff 3.91 0.82

А3Е Strengths of our production facilities 3.73 0.84

А3Н Capacity of the technologies used in the process 3.61 0.84

This R&D team

Team work С1С Good teamwork 3.82 0.92

С1Н Activities are well-coordinated 3.51 0.98

С1М Solutions are successfully implemented 3.57 0.95

С1N Communication is carried out smoothly 3.53 0.97

NPD activity С1D Productive 3.97 0.85

C1G Uses financial resources rationally 3.58 0.90

C1J Uses all resources for R&D rationally 3.33 0.98

С1L Uses time for engineering work efficiently 3.32 0.95

Market launch time С1В Keeps the deadline for launching on the market 3.69 1.18

С1Е Develops the product on time 3.60 1.11

С1I Reduces the product development time 3.29 1.13

Value for the customer С2А The product is of high quality 4.00 0.94

С2С The product surpasses the customer’s expectations 3.57 1.06

С2К This product is of high value for the customer 3.91 0.95

A3D What does our customer want 4.02 0.91

С2М This product is successful in the market 3.79 1.10

KMIS 2021 - 13th International Conference on Knowledge Management and Information Systems

132