Experimental Study on Riprap Layer Design for Circular Bridge Pier

Efferiki

a

, Robby Yussac Tallar

b

and Alexander Yovan Suwono

c

Civil Engineering Department, Maranatha Christian University, Jl. Surya Sumantri 65, Bandung, Jawa Barat, Indonesia

Keywords: Circular Bride Pier, Riprap Layer Design, Local Scour.

Abstract: Scouring is a natural phenomenon that often occurs in streams. Scouring can also occur locally if there are

any changes in streams such as structural components within. A review of the literature has been accomplished

to investigate the previous results of the effectiveness of riprap design. However, few studies were focused

on the position of riprap layer design. Therefore, the main purpose of this study is to compare the effectiveness

of riprap layer design for circular bridge pier by experimental study. Several scenarios have been set up by

compared two layers conditions (the lower and upper sediment-based riprap layer design). The flow sediment

condition used in this research is clear water condition. The stable riprap size and the optimized extension of

the riprap layer around the circular pier along the flow direction were studied experimentally. The result

indicates that the lower sediment-based riprap layer design is ±10 to 20% more effective compared to the

upper sediment-based riprap layer design with different discharge flow scenarios. Further studies are also

needed regarding the effect of riprap characteristics such as shape and diameter, variations of riprap thickness,

and other related variables.

1 INTRODUCTION

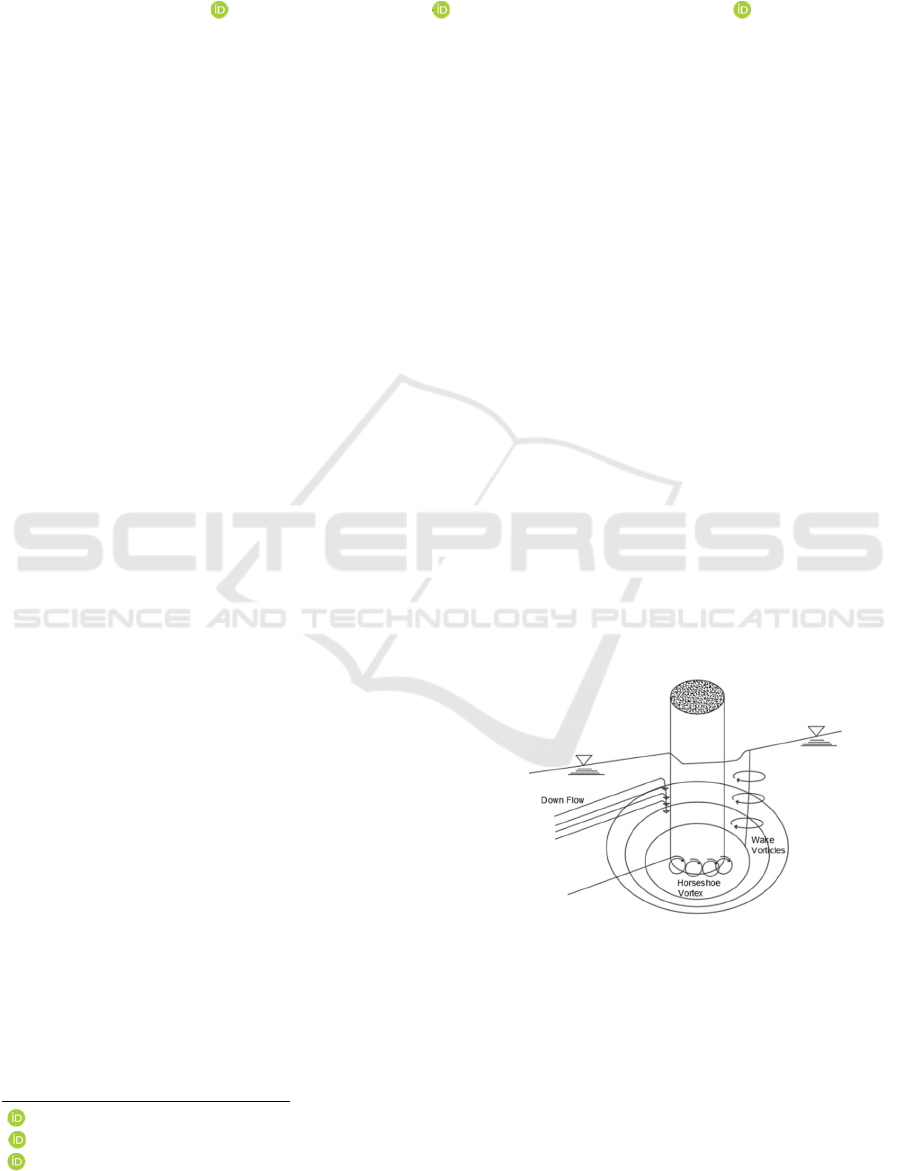

Scouring is a natural phenomenon that often occurs in

streams (Mashahir, Zarrati, & Mokallaf, 2010;

Youssef, 2018). Scouring can also occur locally if

there are any changes in streams such as structural

components within (Tallar & Suen, 2015). Structural

components will block water flow that creates

horseshoe vortex system (Graf & Istiarto, 2002). This

horseshoe vortex causes water level drops and called

local scouring. Local scouring can be identified as an

abrupt decline in bed level due to erosion of bed

material by the local flow structure induced by

obstruction such as bridge pier set in the river (Figure

1).

Bridge is one of the most common structural

components built-in streams to connect two or more

places (Chiew & Lim, 2000). Local Scouring may

endanger the structural components of the bridge,

especially bridge piers. These days, there are so many

ways used to prevent local scouring. Riprap is a

common structure used to protect pier and abutment

of the bridge, stilling basin and other structures within

stream being vulnerable to deteriorative erosion

a

https://orcid.org/0000-0002-4408-6120

b

https://orcid.org/0000-0001-7307-3348

c

https://orcid.org/0000-0002-2577-8519

caused by flow velocity (Lagasse, 2006). Riprap

consists of stones that are installed in the bridge pier

base. The reason why riprap is still commonly used to

protect structural components, because it is easy to

repair the riprap, and riprap construction does not cost

much.

Figure 1: Local scouring at bridge pier.

A review of the literature has been accomplished

to investigate the previous results of the effectiveness

of riprap design (Tabarestani & Zarrati, 2013).

However, few studies were focused on the position of

riprap layer design. Some facts that happen in the

172

Efferiki, ., Tallar, R. and Suwono, A.

Experimental Study on Riprap Layer Design for Circular Bridge Pier.

DOI: 10.5220/0010747500003113

In Proceedings of the 1st International Conference on Emerging Issues in Technology, Engineering and Science (ICE-TES 2021), pages 172-175

ISBN: 978-989-758-601-9

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

field also show that riprap stones are carried away by

streams. Therefore, the main purpose of this study is

to compare the effectiveness of riprap layer design for

circular bridge pier. The scope of this experimental

study was performed in rectangular channel with

clear-water condition.

2 METHODS

To study the effectiveness of riprap layer design,

experimental research was carried out. This research

used average discharge (Q

50%

) and optimum

discharge (Q

75%

) to validate the results of this

research. The parameter used to study the

effectiveness of the riprap layer design was score

depth and the stability of the riprap. The open channel

was used in this research to determine the

effectiveness of the riprap layer design.

2.1 Method for Discharge Analysis

To change the discharge of this experimental

research, discharge rating curve was needed.

Discharge data are important to determine the

effectiveness of the riprap layer design modelled in

this research. Discharge rating curve was drawn to

determine Q

50%

and Q

75%

, which will be used in this

research.

2.2 Method for Sieve Analysis

Sieve analysis was carried out to find the stone size

of the riprap. the stone size of the riprap will be used

as the control variable, so it is important to ensure that

the stone size of every riprap used in this research is

the same size which is average diameter (Dr

50

). Sieve

analysis was carried out by using a defined sieve.

These sieves come with different opening size, to

determine the stone grading.

2.3 Scenarios of Riprap Model

The first condition of this research used average

discharge (Q

50%

). Two scenarios were set up to

determine the effectiveness of riprap layer design.

The upper layer design was used in the first scenario

and the lower layer design was used in the second

scenario (Figure 2, 3, and 4). The thickness of the

riprap layer, the size of the pier, the stone size of the

riprap used as the control variable. The diameter of

the pier used in this research is 8 cm and placed 120

cm from downstream of the weir. Based on previous

research, the thickness of the riprap layer used in this

research was 2,5 cm.

The riprap was installed circular around the pier

with a diameter of 28 cm. The second condition used

Q

75%

to validate the first case. The scenarios and the

control variable for the second condition were set up

similar to the first condition.

Figure 2: Side view of upper layer design.

Figure 3: Side view of lower layer design.

Figure 4: Top view of lower and upper layer design.

Experimental Study on Riprap Layer Design for Circular Bridge Pier

173

3 RESULTS AND DISCUSSION

3.1 Discharge Analysis Result

From the experiment in the laboratory, discharge

curve rating was drawn. After that, the Q

50%

and Q

75%

can be determined from the discharge curve rating

(Figure 5).

Figure 5: Discharge curve rating.

Based on the curve rating above, the value of Q

50%

=

0.0125 m

3

/s, and Q

75%

= 0.0188 m

3

/s

3.2 Sieve Analysis Result

From the sieve analysis experiment in the laboratory,

Dr

50

can be determined based on soil particle size

distribution (Figure 6).

Figure 6: Soil particle distribution.

Based on the soil particle distribution above, Dr

50

of

the riprap stone is 3.8 mm.

3.3 Riprap Model Result

After the discharge analysis and sieve analysis

experiment, we can continue the research with riprap

modelling. The effectiveness of riprap layer design is

determined by the depth of scouring. The depth of

scouring in the upper layer design was compared to

the depth of the scouring in the lower layer design.

The result of the first condition of the riprap model

using Q

50%

(Table 1):

Table 1: Result of the first condition of riprap model.

Scenario Thickness of

the riprap (mm)

Depth of

Scouring D

s

(mm)

Upper la

y

e

r

25 -11

Lowe

r

la

y

e

r

25 -9

𝐸𝑓𝑓𝑒𝑐𝑡𝑖𝑣𝑒𝑛𝑒𝑠𝑠

𝑑

𝑑

𝑑

𝑥 100%

𝐸𝑓𝑓𝑒𝑐𝑡𝑖𝑣𝑒𝑛𝑒𝑠

11 9

11

𝑥 100%

𝐸𝑓𝑓𝑒𝑐𝑡𝑖𝑣𝑒𝑛𝑒𝑠 18.18 %

The result of the second condition of the riprap model

using Q

75%

(Table 2):

Table 2: Result of the second condition of riprap model.

Scenario Thickness of

the riprap

(mm)

Depth of

Scouring D

s

(mm)

Upper La

y

e

r

25 -21

Lowe

r

La

y

e

r

25 -18

𝐸𝑓𝑓𝑒𝑐𝑡𝑖𝑣𝑒𝑛𝑒𝑠𝑠

𝑑

𝑑

𝑑

𝑥 100%

𝐸𝑓𝑓𝑒𝑐𝑡𝑖𝑣𝑒𝑛𝑒𝑠

21 18

21

𝑥 100%

𝐸𝑓𝑓𝑒𝑐𝑡𝑖𝑣𝑒𝑛𝑒𝑠 14.29 %

4 CONCLUSIONS

Based on the experiment, the result indicates that the

lower sediment-based riprap layer design is ±10 to

20% more effective compared to the upper sediment-

based riprap layer design with different discharge

flow conditions. With Q

50%

that was used in the first

condition shows that the lower sediment-based riprap

layer design is 18.18% more effective than the upper

sediment-based riprap layer design. In the second

condition, the lower sediment-based riprap layer

design is 14.29% more effective than the upper

sediment-based riprap layer design.

This research can be used to another structure

components beside piers along the stream. Further

studies are also needed regarding the effect of riprap

characteristics such as shape and diameter, variations

of riprap thickness, and other related variables.

0

20

40

60

80

100

120

0,1 1 10 100

PercentPassing(%)

Diameter(mm)

0

0,05

0,1

0,15

0,2

0,25

0 0,01 0,02 0,03 0,04

h(m)

Discharge(m

3

/s)

ICE-TES 2021 - International Conference on Emerging Issues in Technology, Engineering, and Science

174

ACKNOWLEDGEMENTS

The authors gratefully appreciate the support from

Civil Engineering Department, Maranatha Christian

University, Indonesia.

REFERENCES

Chiew, Y.-M., & Lim, F.-H. (2000). Failure behavior of

riprap layer at bridge piers under live-bed conditions.

Journal of Hydraulic Engineering, 126(1), 43–55.

Graf, W. H., & Istiarto, I. (2002). Flow pattern in the scour

hole around a cylinder. Journal of Hydraulic Research,

40(1), 13–20.

Lagasse, P. F. (2006). Riprap design criteria, recommended

specifications, and quality control (Vol. 568).

Transportation Research Board.

Mashahir, M. B., Zarrati, A. R., & Mokallaf, E. (2010).

Application of riprap and collar to prevent scouring

around rectangular bridge piers. Journal of Hydraulic

Engineering, 136(3), 183–187.

Tabarestani, M. K., & Zarrati, A. R. (2013). Design of

stable riprap around aligned and skewed rectangular

bridge piers. Journal of Hydraulic Engineering, 139(8),

911–916.

Tallar, R. Y., & Suen, J.-P. (2015). Identification of

waterbody status in Indonesia by using predictive index

assessment tool. International Soil and Water

Conservation Research, 3(3), 224–238.

Youssef, I. H. (2018). A novel method for riprap design of

scour protection at bridge piers. MOJ Civil Eng, 4(2),

109–119.

Experimental Study on Riprap Layer Design for Circular Bridge Pier

175