Investigation on Performance of Solar Collector in the Adsorption

Process with Variation of Angle of Surface Plate

Hidayat

1a

, Sudarsono

2

, Rozaini Othman

3

, Mangkona

1

, Abdul Muis

1

,

Darma Aviva

1

and Abdul Halik

1

1

Department of Mechanical Engineering, Politeknik Negeri Samarinda, Jl. Ciptomangunkusumo, Samarinda, Indonesia

2

Department of Mechanical Engineering, Universitas Halu Oleo, Kampus Hijau, Kendari, Indonesia

3

Faculty of Mechanical Engineering, Universiti Teknologi MARA, Pematang Sauh, Malaysia

muis_64@yahoo.co.id, darmaaviva70@gmail.com, abdul.halik@polnes.ac.id

Keywords: Adsorbent, Solar Collector, Radiation Intensity, Charcoal Adsorbent, Temperature.

Abstract: Sunlight radiation energy is currently being used as an alternative energy source in order to replace energy

that is derived from petroleum fuel. Therefore the sun’s energy that never runs out can be utilized. This

research aims to determine the heat used by the collector for the desorption process and the angle variations

of the collector effect for collector efficiency using activated charcoal adsorbent. Accordingly that, one of

them can be used for the water cooling process using a solar collector device on a solar heat adsorption cycle

cooling machine. This research was conducted by varying the angle of the collector’s refrigeration with an

adsorption cycle using solar energy. The test results show that the average useful heat of the collector (Qu)

obtained by the 0° collector angle is 183.3 Watt, for 15° collector angle is 173.3 Watt, and for 30° collector

angle is 158,2 Watt. The average efficiency of the collector (η) obtained by the 0° collector angle is 48,22%,

15° collector angle is 45,322% and for 30° collector angle is 41,573%.

1 INTRODUCTION

Indonesia has substantial solar energy resources, with

an average solar radiation intensity of roughly 4.8

kWh/m

2

per day due to its equatorial location

between 6°N and 11°N and 9°E and 141°E. The total

annual solar radiation received by all regions of

Indonesia is around 2500 hours, with an average of

14.5 MJ/m

2

/day. Thus, unlimited solar energy may be

used to power the Indonesian people. Solar radiation

energy is currently used as an alternative energy

source to replace petroleum-based energy. One

application of radiation energy is water cooling via a

solar collector device on a solar heat adsorption cycle

cooling system.

Many researchers performing research to

investigate the performance of solar collectors. The

analysis was undertaken for a small public office

building in Bialystok (Poland), where solar collectors

were regarded as the primary source of renewable

energy for the domestic hot water (DHW) system,

with the idea that the existing oil boiler would serve

a

https://orcid.org/0000-0003-3672-1304

as a backup (Krawczyk, Żukowski, & Rodero, 2020).

The article discusses the viability of employing a non

concentrating direct absorption solar collector (DAC)

and compares its performance to that of a

conventional flat-plate collector (Tyagi, Phelan, &

Prasher, 2009). Experiments are conducted to

determine the influence of a CuO–water nanofluid as

the working fluid on a flat-plate solar collector

(Moghadam, Farzane-Gord, Sajadi, & Hoseyn-

Zadeh, 2014). Experiments were conducted to

determine the efficiency of a novel design and

production process for flat plate solar collectors.

Solar collector design adjustments are always a viable

option for improving thermal efficiency significantly

(Verma, Sharma, Gupta, Soni, & Upadhyay, 2020). a

novel technique for optimizing the performance of

solar thermal collectors The solar reflector is used in

conjunction with the solar collector to boost the

collector's reflectivity (Bhowmik & Amin, 2017).

research and optimization of the thermal performance

of an evacuated CPC (Compound Parabolic

Concentrator) solar collector equipped with a

Hidayat, ., Sudarsono, ., Othman, R., Mangkona, ., Muis, A., Aviva, D. and Halik, A.

Investigation on Performance of Solar Collector in the Adsorption Process with Variation of Angle of Surface Plate.

DOI: 10.5220/0010941100003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 125-129

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

125

cylindrical absorber (Kim, Han, & Seo, 2008).

Artificial neural networks (ANNs), least squares

support vector machines (LSSVMs), and neuro-fuzzy

are utilized to advance prediction models for

photovoltaic-thermal solar collector (PV/T) thermal

performance (Ahmadi et al., 2020). a numerical

simulation of forced convective heat transfer using a

two-dimensional heat function formulation through a

direct absorption solar collector (DASC) packed with

water-copper nanofluid (Nasrin, Parvin, & Alim,

2015). Experiments have been done to ascertain the

collector's dual function. It is demonstrated that the

collector's thermal efficiency reached 50% when used

for water heating and fluctuated between 41% and

55% when used for air heating, depending on the

ambient temperature and flow velocity (Ma et al.,

2011). Dispersing nanometer-sized particles into the

base fluid is offered as an efficient way for improving

the working fluid's heat transfer capabilities (Amin,

Roghayeh, Fatemeh, & Fatollah, 2015).

As far as we know, no researcher carried out the

efficiency of the solar collector by varying the angle

of the surface to horizontal.

This research aims to ascertain the amount of heat

absorbed by the collector during the desorption

process and the angle variations in the collector's

effect on collector efficiency. The angle of the solar

collector’s surface was varied with the values 0

o

, 15

o

and 30

o

. The research was carried out by drying the

adsorber in the sun. The desorption process lasts ± 9

hours from 08.00 WIB - 17.00 WIB.

2 MATERIALS AND METHOD

2.1 Dimension of Solar Collector

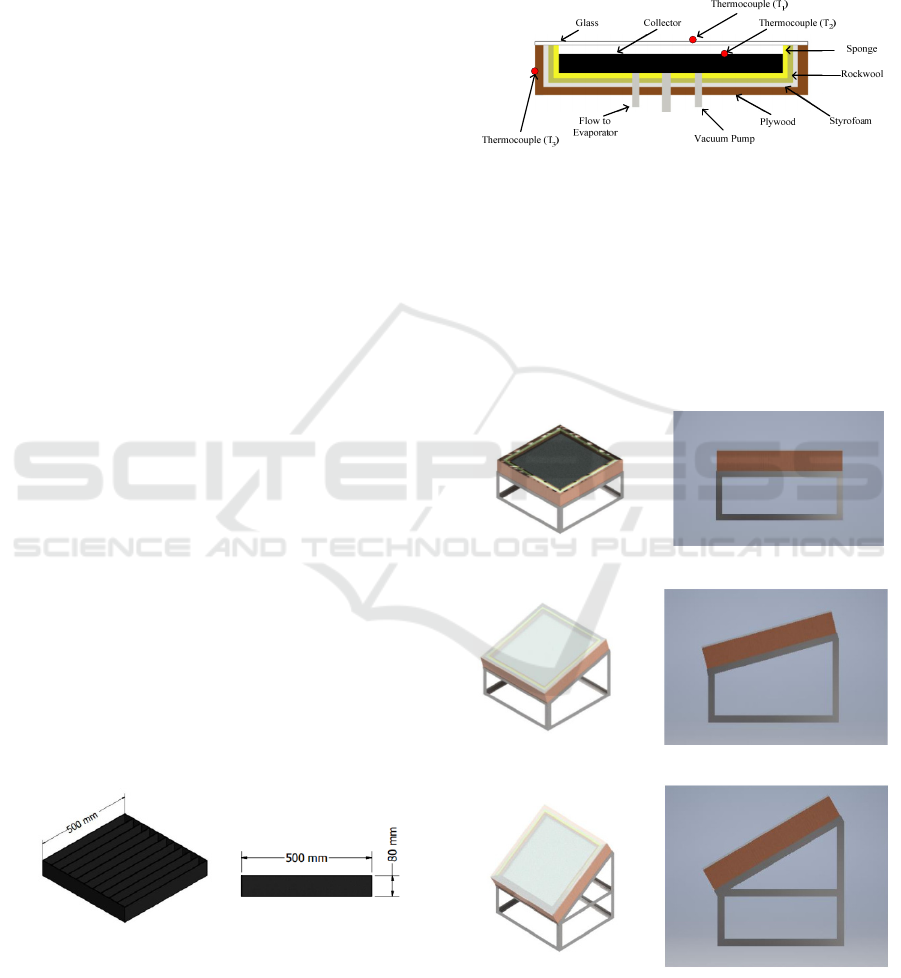

Figure 1 shows the three-dimensional model of the

solar collector. The dimension of the solar collector is

500 mm x 500 mm x 80 mm.

Figure 1: Three Dimensional Model of Solar Collector.

Figure 2 shows the inside part of the solar collector.

This part consists of glass, active charcoal, sponge,

Rockwool, plywood and styrofoam. Solar collectors

are a type of heat exchanger that generates heat

energy by employing solar radiation as the primary

energy source. When sunlight strikes the solar

collector's adsorber, some of the light is reflected

back into the environment. At the same time, the

majority is absorbed and converted to heat energy,

which is then transported to the solar collector's

circulating fluid for use in a variety of applications.

Figure 2: Inside Part of Solar Collector.

On solar collectors, three thermocouples are used

to determine the temperature of the glass surface, the

adsorbent plate surface, and the ambient temperature,

respectively. Before installing the thermocouple, it

should be checked at every point to make sure there

is no error in connection.

2.2 Material Properties

(a) Solar Collector with angle 0

o

(b) Solar Collector with angle 15

o

(c) Solar Collector with angle 30

o

Figure 3: Angle Variation of Solar Collector.

Figure 3 shows the angle variation of the solar

collector. The solar collector's angle is modified

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

126

utilizing three different angles, namely 0, 15 and 30.

Angle adjustments are included to demonstrate the

angle's effect on the intensity of sunlight striking the

collector. The intensity of the sunlight can be

calculated using the equation :

𝐺

=𝐺

×𝑐𝑜𝑠𝜃

(1)

where :

G

bT

: solar intensity on an inclined plane (W/m

2

)

G

bn

: solar radiation intensity at an angle of entrance

normal to the horizontal surface (W/m

2

)

θ

T

: the angle between the direction of the sun's rays and

the direction perpendicular to the inclined surface.

Calculation of heat absorbed at the collector can be

calculated using the formula :

𝑆=(𝜏𝛼)

×𝑄

×𝐴

(2)

where :

S : heat absorbed (J)

(τα) : the average absorptive transmissivity of glass

Q

it

: intensity of solar radiation (J/m

2

)

A

c

: collector cross-sectional area (m

2

)

Then, the heat loss coefficient lost to the collector can

be calculated using the formula:

𝑄𝐿 = 𝑄

×𝑄

×𝑄

(3)

where :

Q

T

: total heat loss at the top of the collector (W)

Q

B

: total heat loss at the bottom of the collector (W)

Q

E

: total heat loss on the sides of the collector (W)

Q

L

: total heat loss on each side of the collector (W)

The actual efficiency of the solar collector during the

test can be calculated in the empty state and contains

activated carbon. Empty collector efficiency can be

calculated using the following formula:

𝜂=

×

(4)

where :

η : collector efficiency (%)

Q

u

: heat absorbed by collector (W)

I

bn

: intensity of sunlight through the collector (W/m

2

)

A

c

: area of collector’s surface (m

2

)

3 RESULT AND DISCUSSION

3.1 Calculation of Solar Radiation

Intensity

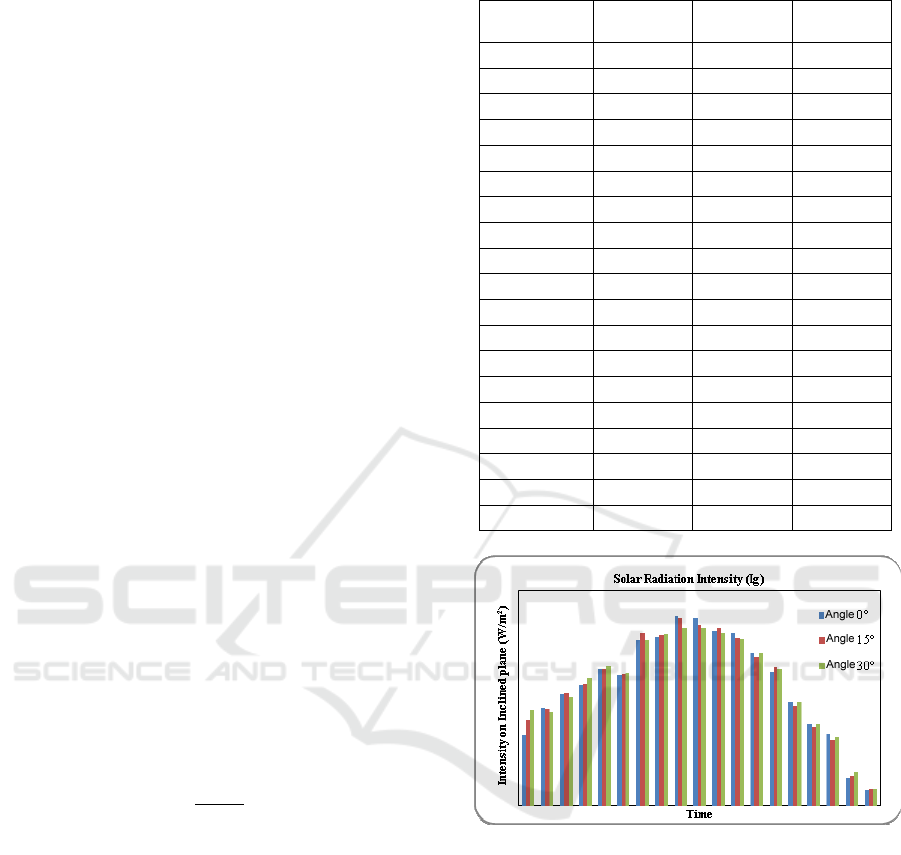

Table 1 shows the result calculation of solar radiation

intensity from 08:00 to 17:00. The maximum

intensity of solar radiation occurs around 12 o'clock

with the solar collector tilted at a 0-degree angle to

the horizon.

Table 1: The result calculation of solar radiation intensity.

Time

(WITA)

Angle 0° Angle 15° Angle 30°

08:00 259.94 319.63 353.74

08.30 361.56 358.71 349.16

09.00 413.22 416.16 426.35

09.30 448.29 451.53 475.96

10.00 505.46 506.41 517.54

10.30 483.69 488.89 493.63

11.00 614.52 638.60 632.74

11.30 625.73 633.84 651.98

12.00 703.34 698.76 691.79

12.30 697.89 672.02 689.83

13.00 649.63 663.38 647.75

13.30 641.09 621.48 638.69

14.00 568.48 551.86 584.76

14.30 494.56 514.00 507.05

15.00 384.92 370.63 400.06

15.30 299.75 290.80 313.36

16.00 263.74 243.18 253.85

16.30 103.23 111.37 124.14

17.00 54.41 60.65 58.44

Figure 4: Solar Radiation Intensity on an Inclined Plane.

Figure 4 shows the radiation intensity on an inclined

plane. It can be seen that the intensity of solar

radiation is almost the same and changes over time.

Overall, the highest global radiation intensity (Ig) lies

in the 0° collector angle test at 12.00, which is 703.34

W/m

2

. Meanwhile, the lowest global radiation

intensity (Ig) is in the 0° collector angle test at 17.00,

which is 54.41 W/m

2

. The average global radiation

intensity (Ig) from 08.00 – 17.00 WITA obtained by

collector angle 0° is 451.24 W/m

2

, collector angle 15°

453.259 W/m

2

, and collector angle 30° is 463.73

W/m

2

on each test day.

Investigation on Performance of Solar Collector in the Adsorption Process with Variation of Angle of Surface Plate

127

3.2 Calculation of the Heat Absorbed

by the Collector

Table 2: The results of the calculation of the heat absorbed

by the collector.

Time (WITA) Angle 0° Angle 15° Angle 30°

08:00 130,02 159,87 176,93

08.30 190,46 188,95 183,93

09.00 223,74 225,33 217,43

09.30 246,48 248,26 260,41

10.00 280,4 280,93 287,1

10.30 269,75 272,66 275,3

11.00 343,81 357,29 344,42

11.30 350,7 355,25 357,2

12.00 430,23 427,43 405,06

12.30 391,14 376,64 370,19

13.00 363,46 371,15 357,61

13.30 357,54 346,60 344,04

14.00 315,36 306,14 315,9

14.30 271,92 282,6 278,78

15.00 208,41 200,67 208,78

15.30 157,9 153,18 159,48

16.00 131,92 121,64 126,97

16.30 46,56 50,23 55,99

17.00 19,63 21,89 21,09

The relationship between the heat absorbed by the

collector and time can be seen from Figure 5 below:

Figure 5: Heat absorbed by Collector.

It can be seen that the heat absorbed by the collector

(S) is almost the same and changes over time

according to the angle of each collector. Similar to the

intensity of solar radiation (G

bT

), the heat absorbed by

the collector (S) can also be affected by erratic

weather factors, wind speed and the angle of

incidence of light on the collector surface (θ

1

).

Overall, the highest heat absorbed by the collector (S)

lies in the 0° collector angle test at 12.00 which is

430,23 Watt. Meanwhile, the lowest heat absorbed by

the collector (S) lies in the 0° collector angle test at

17.00, which is 19,63 Watt. The average heat

absorbed by the collector (S) obtained by the 0° angle

collector is 248,916 Watt, the 15° collector angle is

249,826 Watt, and the 30° angle collector is 249,821

Watt on each test day.

3.3 Calculation of the Collector

Efficiency

Figure 6: Efficiency of Solar Collector.

It can be seen that the efficiency (η) tends to be almost

the same. In general, collector efficiency is the ratio

between useful heat and the intensity of solar

radiation entering the absorber. The useful heat from

the collector is the heat flux absorbed by the absorber

minus the rate of heat loss to the environment. The

amount of useful calorific value does not necessarily

cause the value of useful efficiency to be large. The

useful calorific value is obtained from the difference

between the heat absorbed by the collector and the

heat loss lost to the collector. The greater the heat

absorbed by the collector, the greater the heat loss lost

to the collector to the environment.

Similar to the discussion of the useful heat graph

(Qu), in this measurement at 16.30 the calculation of

efficiency (η) began to get a negative value. This

happens as described because at the time of the test

the heat loss lost to the collector (Ql) is greater than

the heat absorbed by the collector (S). The peak of

heat absorbed by the collector occurred at 12.00, after

which the heat absorbed began to decline. While the

heat loss lost from the collector decreases according

to the measurement of the heat temperature that has

been obtained. Therefore, to get the average

efficiency (η) that is effective, it is taken from 08.00

to 16.00 . Overall the highest efficiency (η) lies in

testing the 0° angle collector obtaining a value of

48,22 %, the 15° angle at 45,32 % and the 30° angle

collector getting a value of 41,57 %.

Heat Absorbed by Collector (W)

Time (WITA)

Heat Absorbed (S) by Time

Sudut 0°

Sudut 15°

Sudut 30°

Efficiency (%)

Time (WITA)

Efficiency (η) by time

Sudut 0°

Sudut 15°

Sudut 30°

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

128

3.4 Discussion

The researcher suggests that this can be accomplished

by adding an angle regulator to the collector that

allows it to be adjusted in response to the angle of

incidence of the sun and variations in other adsorbent

materials, as well as by selecting a good insulating

material to minimize heat loss to the collector.

4 CONCLUSIONS

From the results of tests and analyzes that have been

carried out, conclusions can be drawn from this

research, namely as follows:

1). The highest useful heat in the collector (Qu) lies

in testing the collector at an angle of 0° at 12.00

which is 272.064 Watt. Meanwhile, the lowest

useful heat in the collector (Qu) lies in the

collector test at an angle of 0° at 17.00, which is

-42.18 Watt. The average proper heat at the

collector (Qu) obtained by the 0° angle collector

is 139.878 Watt, the 15° collector angle is

118.624 Watt, and the 30° angle collector is

113.611 Watt on each test day.

2). Collector efficiency (η) from 08.00–16.00

WITA. The 0° angle collector gets a value of

42.617%, the 15° angle is 36.377% and the 30°

angle collector gets a value of 33.708%.

REFERENCES

Ahmadi, M. H., Baghban, A., Sadeghzadeh, M., Zamen,

M., Mosavi, A., Shamshirband, S., … Mohammadi-

Khanaposhtani, M. (2020). Evaluation of electrical

efficiency of photovoltaic thermal solar collector.

Engineering Applications of Computational Fluid

Mechanics, 14(1), 545–565. https://doi.org/10.1080

/19942060.2020.1734094

Amin, T. E., Roghayeh, G., Fatemeh, R., & Fatollah, P.

(2015). Evaluation of Nanoparticle Shape Effect on a

Nanofluid Based Flat-Plate Solar Collector Efficiency.

Energy Exploration & Exploitation, 33(5), 659–676.

https://doi.org/10.1260/0144-5987.33.5.659

Bhowmik, H., & Amin, R. (2017). Efficiency improvement

of flat plate solar collector using reflector. Energy

Reports, 3, 119–123. https://doi.org/10.1016/j.egyr.2

017.08.002

Kim, Y., Han, G., & Seo, T. (2008). An evaluation on

thermal performance of CPC solar collector.

International Communications in Heat and Mass

Transfer, 35(4), 446–457. https://doi.org/10.

1016/j.icheatmasstransfer.2007.09.007

Krawczyk, D. A., Żukowski, M., & Rodero, A. (2020).

Efficiency of a solar collector system for the public

building depending on its location. Environmental

Science and Pollution Research, 27(1), 101–110.

https://doi.org/10.1007/s11356-019-05077-2

Ma, J., Sun, W., Ji, J., Zhang, Y., Zhang, A., & Fan, W.

(2011). Experimental and theoretical study of the

efficiency of a dual-function solar collector. Applied

Thermal Engineering, 31(10), 1751–1756.

https://doi.org/10.1016/j.applthermaleng.2011.02.019

Moghadam, A. J., Farzane-Gord, M., Sajadi, M., &

Hoseyn-Zadeh, M. (2014). Effects of CuO/water

nanofluid on the efficiency of a flat-plate solar

collector. Experimental Thermal and Fluid Science, 58,

9–14. https://doi.org/10.1016/j.expthermflusci.2014.

06.014

Nasrin, R., Parvin, S., & Alim, M. A. (2015). Heat Transfer

and Collector Efficiency through a Direct Absorption

Solar Collector with Radiative Heat Flux Effect.

Numerical Heat Transfer, Part A: Applications, 68(8), 88

7–907. https://doi.org/10.1080/10407782.2015.1023122

Tyagi, H., Phelan, P., & Prasher, R. (2009). Predicted

Efficiency of a Low-Temperature Nanofluid-Based

Direct Absorption Solar Collector. Journal of Solar

Energy Engineering, 131(4). https://doi.org/10.1115/1

.3197562

Verma, S. K., Sharma, K., Gupta, N. K., Soni, P., &

Upadhyay, N. (2020). “Performance comparison of

innovative spiral shaped solar collector design with

conventional flat plate solar collector.” Energy, 194,

116853. https://doi.org/https://doi.org/10.1016/j.energ

y.2019.116853

Investigation on Performance of Solar Collector in the Adsorption Process with Variation of Angle of Surface Plate

129