Application of Shell and Tube Model Condenser on Alcohol Content

on the Arak Distillation Prototype Equipment

I Made Sudana, I Gede Nyoman Suta Waisnawa and I Made Rajendra

Department of Mechanical Engineering, Bali State Polytechnic, Badung, Bali, Indonesia

Keywords: Nira, Heating, Distillation, Condenser, Shell and Tube, Arak.

Abstract: The process of making Balinese wine using a coconut sap distillation tool (tuak) into arak still uses the

traditional way with firewood, through a heating and cooling process of sap steam which is heated so that it

becomes arak with an alcohol content. The research method is the application of a shell and tube condenser

model in a distillation apparatus, where the condenser cooling water is circulated through a tube using cooling

water from the reservoir tube to release heat into the atmosphere. The results of the study at a reactor tube

temperature of 80°C, a condenser temperature of 40°C with an alcohol content of 25%, and a reactor tube

temperature of 85°C, a condenser temperature of 35°C with an alcohol content of 48%, and a reactor tube

temperature of 90°C, condenser temperature 35°C alcohol content of 46%. The highest alcohol content of the

distillation apparatus is 48% and the lowest alcohol content is 25%, while the volume of alcohol produced

increases with each heating of the reactor tube, this is influenced by the heating rate of the reactor tube and

the cooling temperature of the shell and tube condenser.

1 INTRODUCTION

Balinese wine is made by distillation from coconut

sap through a heating process and condensation of the

juice vapor which triggers the process of producing

alcohol with alcohol content. The tool for distilling

coconut sap into arak is still using the traditional

method with firewood.

The condenser is a very important cooling

component that functions to maximize the efficiency

of the cooler. In general, using a surface type

condenser (surface condenser), this type of condenser

is a shell-tube type in which cooling water is

circulated through the tube. Condensers usually use

circulating cooling water from the cooling tower to

release heat to the atmosphere, or once-through water

from the reservoir tube. (Ratnawati et al.,2018)

Shell and tube type heat exchangers are the most

widely used heat exchangers in various industries and

the simplest compared to other heat exchangers, this

is because:

a. It only consists of a tube and a shell, where the

tube is located concentrically inside the shell.

b. Ability to work in high pressure and

temperature.

c. Its ability to be used on one large volume

stream.

d. Its ability to work with working fluids that have

a large volume flow difference.

e. Available in various materials or materials.

f. Sturdy and safe construction.

g. Mechanically can operate properly and reliably

(high reliability).

h. Tube is called shell side

(Budi et al.,2018)

Arak Bali is one of the two types of traditional

Balinese drinks that are popular and favored by young

and old people. Besides drinking wine, it is also

commonly used as a means of offering in Hindu

religious ceremonies in Bali. Arak is a type of

fermented liquor containing 37%-60% alcohol (ethyl

alcohol) which has been known in Bali since ancient

times. Arak is generally made from palm wine by

distillation. Arak is divided into several grades of

alcohol content. For class one, the alcohol content is

between 35 and 40 percent, for class two the alcohol

content is 30 percent, while for class 3 the alcohol

content is 25 percent.

(Kadek et al.,2020)

The distillation method is usually taken if you

want to increase the alcohol content in the previous

fermented product which after being distilled to

separate the ethanol from the ethanol mixture, the

Sudana, I., Waisnawa, I. and Rajendra, I.

Application of Shell and Tube Model Condenser on Alcohol Content on the Arak Distillation Prototype Equipment.

DOI: 10.5220/0010943200003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 249-253

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

249

levels increase to a minimum of 29% and a maximum

of 50%, distillation is the easiest and most efficient

way to operate a solution consisting of components -

components with different boiling temperatures

(Ratnaningtyas et al.,2017)

Through research on the application of shell and

tube condensers in wine distillation equipment, it is

hoped that this can be one of the innovations in

developing appropriate technology to support home

industries, especially wine distillation.

2 RESEARCH METHOD

This research includes experimental research through

testing the shell and tube condenser distillation

apparatus with a reactor tube heater using an LPG

stove. Before carrying out the test (distillation

process), the coconut sap was treated with the sample

material by fermentation for 8 hours, so that the sap /

raw material for the sample to be tested included good

quality sap. Furthermore, testing was carried out on

the distilled wine to obtain the alcohol content.

2.1 Distillation Equipment Test

1. Setting the heating temperature on the reactor tube

with a Solenoid Valve Gas to regulate the flame

of the stove in order to get the desired temperature

in the reactor tube so that the temperature of the

palm wine heating can be adjusted and equipped

with a temperature detection device (thermo-

couple) to determine the temperature rate in the

process of heating palm wine in the reactor tube.

2. Setting the temperature of the cooling water in the

shell and tube condenser tube which distributes

the steam from the heating of palm wine in the

reactor tube to the condenser tube, to control the

cooling water, a Solenoid valve is installed. so that

the water temperature can be controlled.

3. Measurement of the percentage of alcohol

content. To get the alcohol content in the

distillation apparatus using an Alcoholmeter

measuring instrument, in this test using palm wine

fermentation for 8 hours at a heating temperature

of 80°C, 85°C and 90°C reactor tubes and shell

and tube condenser cooling temperatures of 30°C,

35°C and 40°C

2.2 Alcohol Level

The instrument used to measure alcohol content is an

alcoholmeter. Measurement of alcohol content was

carried out after each distillation and the

measurement was stopped when the measured

alcohol content was 90% (alcohol content according

to ASTM for liquid fuel) and the ethanol content was

94%. The measurement steps using an alcoholmeter

are to put 100 ml of distillate into a measuring cup,

then the alcoholmeter is dipped into the distillate. The

immersed boundary on the surface of the distillate

indicates the alcohol content of the sample being

tested. (IM Sudana et al.,2019)

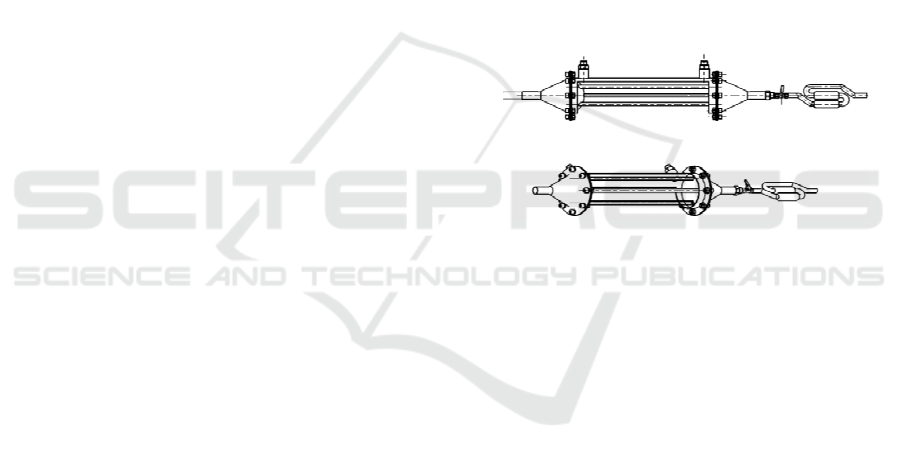

2.3 Shell and Tube Condenser

This type of heat exchanger is one type of heat

exchanger which according to its construction is

characterized by a set of tubes mounted in a

cylindrical shell in which two types of heat exchange

fluids flow separately, respectively through the tube

side and the shell side. (Devia et al.,2018) As in

Figure 1.

Figure 1: Condenser Shell And Tube.

Condenser Tube cooling water volume

The condenser tube is 36cm high and 5,08cm in

radius as follows:

V= π ∙ r

∙ t (1)

V=2.917 cm

= 2,9 liter

Convective heat transfer in the reactor tube Is known:

𝑄

= Heat transfer rate (W/m

℃)

ℎ =

Convection coefficient (14 W/m

2 °

C)

𝐴

= Cross-sectional area

31,5 𝑐𝑚

= (0,035 𝑚

)

𝑇

= Tube outer wall surface temperature (30°C)

𝑇

= Fluid temperature (90°C)

𝑄

= ℎ (𝐴) ∙

(

𝑇

−𝑇

)

(2)

𝑄

= 26,46 𝑤/𝑚℃

So the heat transfer rate in the reactor tube is

26,46W/m℃

2.4 Shell and Tube Condenser

Distillation Working Principle

Arak distillation equipment using a Shell and tube

condenser is designed with a controlled heating and

cooling system, the heating system uses a gas stove

with a solenoid valve controlled by thermo control in

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

250

order to stabilize the temperature in the reactor tube

as a place for heating coconut sap. The reactor tube is

cylindrical in shape which is equipped with a conical

cap so that it can close the gap for steam exit from the

reactor tube so that the process of flowing steam to

the condenser tube is more optimal. When steam

flows from the reactor tube to the shell and tube

condenser tube, a condensation process will occur. In

the condenser the cooling system uses water which is

circulated using a pump equipped with a solenoid

valve controlled by thermo control, aiming to

maintain the temperature of the cooling system in the

shell and tube condenser to remain stable.

In this process, the steam will change phase to

liquid where the liquid is the result of the distillation

device, namely the wine that comes out dripping from

the condenser tube channel. The distillation apparatus

uses a shell and tube condenser as shown in Figure 2.

Figure 2: Shell and Tube Condenser Distillation Equipment.

Information:

1. Stove Storage Rack and LPG Gas Cylinder

2. Reactor

3. Distillation pipe

4. Temperature Control Box

5. Reservoir (Cooling water)

6. Shell and tube condenser

3 RESULTS AND DISCUSSION

The process of distillation of coconut sap into arak is

carried out using a shell and tube condenser equipped

with cooling water temperature control, and heating

the reactor tube using a gas stove fueled by LPG.

3.1 Discussion

The results of the first test of the application of a shell

and tube condenser on a distillation apparatus for a

reactor tube heating temperature of 80°C with respect

to alcohol content with condenser temperatures of

30°C, 35°C and 40°C as shown in Figure 3.

Figure 3: Heating reactor tube 80ºC.

The alcohol content of the shell and tube condenser

application after distillation was seen to decrease. A

drastic decrease occurred in the third distillation at a

condenser temperature of 40ºC with an alcohol

content of 22%. Based on the results of distillation, it

can be seen that the average alcohol content

decreased gradually by 5%, 6% and 7% this is

because at a temperature of 80°C the coconut sap in

the reactor tube has not experienced an increase in

evaporation.

1. Reactor Heating 85ºC to Alcohol Content

The results of the second test apply the shell and tube

condenser to the distillation apparatus for the reactor

tube heating temperature of 85°C to the alcohol

content with condenser temperatures of 30º C, 35ºC

and 40ºC as shown in Figure 4.

Figure 4: Heating reactor tube 85ºC.

The alcohol content in the application of shell and

tube condenser distillation seems to have decreased.

Application of Shell and Tube Model Condenser on Alcohol Content on the Arak Distillation Prototype Equipment

251

A drastic decrease occurred in the second and third

distillations at a condenser temperature of 30ºC and

40ºC, while at a condenser temperature of 35ºC the

highest alcohol content was 55%. Based on the results

of three times distillation, it can be seen that there was

a decrease in the alcohol content not too large an

average of 6%, 4% and 5% this is because at the

heating temperature of 85ºC coconut sap has occurred

stable evaporation in the reactor tube.

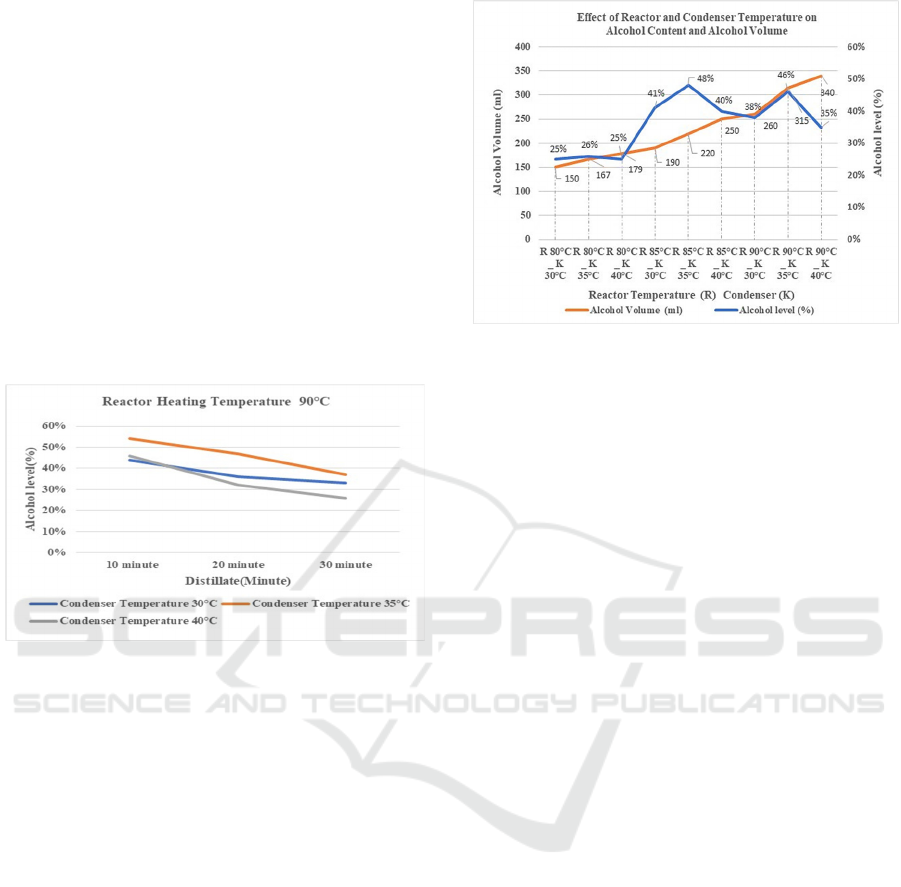

2. Reactor Heating 90ºC to Alcohol Content

The results of the third test apply the shell and tube

condenser to the distillation apparatus for the reactor

tube heating temperature of 90ºC to the alcohol

content with condenser temperatures of 30ºC, 35ºC

and 40ºC as shown in Figure 5.

Figure 5: Heating reactor tube 80ºC.

The alcohol content for the application of shell and

tube condensers seems to have decreased. A uniform

decrease occurred in the second and third distillations

at a condenser temperature of 30ºC and 40ºC, while

at a condenser temperature of 35ºC the highest

alcohol content was 54%. Based on the results of

three times distillation, it can be seen that there is a

decrease in alcohol content that is not too large an

average of 3%, 7% and 6% this is because at the

heating temperature of 90ºC coconut sap has occurred

too fast evaporation so that the alcohol content will

quickly decrease because it is approaching boiling

point of water

3. Effect of Reactor and Condenser Temperature on

Alcohol Content and Alcohol Volume

Based on the test results at reactor tube temperatures

of 80°C, 85°C and 90°C with shell and tube

condenser cooling temperatures of 30°C, 35°C and

40°C, it can be seen as Figure 6.

Figure 6: Effect of temperature on alcohol content and

alcohol volume.

Based on the results of graphic observations about

the effect of the 80°C reactor temperature and the

shell and tube condenser cooling temperature for

three times, the condenser temperature test of 30°C,

35°C and 40°C obtained a stable alcohol content of

25% while the alcohol volume continued to increase.

In testing the reactor temperature of 85°C and the

condenser cooling temperature of 30°C, 35°C and

40°C, the alcohol content increased by 48% at the

condenser temperature of 35°C, while the alcohol

volume continued to increase. For testing at a reactor

temperature of 90°C and condenser cooling at 30°C,

35°C and 40°C, the highest alcohol content was up

and down 46% and the lowest was 35%, while the

alcohol volume continued to increase.

The average alcohol content produced in the

application of the shell and tube condenser in the

distillation apparatus will be influenced by the

heating temperature of the reactor and the cooling

temperature of the shell and tube condenser.

(Mardiyah, 2017)

The highest alcohol content of the distillation

apparatus is 48% and the lowest alcohol content is

25%, while the volume of alcohol produced increases

with each heating of the reactor tube, this is

influenced by the heating rate of the reactor tube and

the cooling temperature of the shell and tube

condenser.

4 CONCLUSION

Based on the data analysis of the test results of the

shell and tube condenser application in the distillation

apparatus, it can be concluded that the alcohol content

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

252

produced is influenced by the heating temperature of

the reactor tube and the cooling temperature of the

shell and tube condenser. The average alcohol content

of the highest distillation apparatus is 48% and the

lowest alcohol content is 25%, while the volume of

alcohol produced increases with each heating of the

reactor tube, this is influenced by the heating rate of

the reactor tube and the cooling temperature of the

shell and tube condenser.

REFERENCES

Budi Rubianto, Rochmad Winarso,Rianto W. (2018)

Design and build a condenser on a bioethanol distillator

with a capacity of 5 liters / hour with a scale of UMKM,

Jurnal CRANKSHAFT, Vol.1 No1 September, ISSN:

2623-0720

Devia Gahana C A , Didik S. (2018). Performance analysis

of high pressure heater (hph) type shell and tube heat

exchanger. Journal of Science and Applicative

Technology – Institut Teknologi Sumatera Vol II. No.2

December

IM Sudana, IGNS Waisnawa. (2019) The influence of

coconut sap heating temperature on the content of

alcohol elements in arak distillation process. iCAST-ES

Journal of Physics: Conference Series, IOP Publishing

1450

Kadek Januarsa Adi Sudharma, Ni Ketut Elly Sutrisni, Sang

Putu Dimas Adhitya, Mawar Farah Adibah. (2020).

Arak as a Local Product in Supporting Tri Eka Buana

Village Towards a Tourism Village. Journal

Masyarakat Merdeka. Volume 3 Nomor 1, Mei.

Mardiyah, S. (2017). The Effect of Heating Time on

Alcohol Levels in Siwalan Nira (Borassus flabellifer).

Surabaya: The Journal of Muhamadiyah Medical

Laboratory Technologist.. Vol: 2, No.1 (9-15).

Ratnawati, Amir S. (2018). Redesign of shell and tube type

heat exchanger with carbon steel tube and 304 stainless

steel tube material. TURBO Vol. 7 No. 1

Retnaningtyas, Aprilia Yasinta. (2017). Preliminary Study

of the Fermentation Process on the Design of a

Bioethanol Plant from Molasses. Jurnal Teknik ITS.

Vol. 6. No.1

Application of Shell and Tube Model Condenser on Alcohol Content on the Arak Distillation Prototype Equipment

253