Smart Controller Design of Solar Home System (SHS) for Load

Management with Grid Connected

Mychael Gatriser Pae

1

, Daniel M. D. U. Kasse

1

, and Ronald Enstein Renoat

2

1

Electrical Engineering, State Kupang Polytechnic, Adisucipto Street, Kupang, Indonesia

2

Company Management, State Kupang Polytechnic, Adisucipto Street, Kupang, Indonesia

Keywords: Solar Power, PLTS, PLN, Grid, Management, Renewable.

Abstract: As one of the largest archipelagic countries in the world, Indonesia still faces electricity problems due to

geographical reasons. One of the provinces which have a fairly low electrification ratio is the Province of East

Nusa Tenggara (NTT). In terms of the potential of natural resources, especially renewable energy sources,

NTT has great potential for the development of solar power plants. The ranges intensity of solar energy in

NTT are 4.5 - 5 kWh/M

2

. To take advantage of these renewable energy sources, this research offered the best

solution to reduce community problems by providing electrical energy for residential homes, namely

designing a smart controller by utilizing electricity from a solar power plant connected to the State Power

Station electricity network. A specification of this system is the management of the use of electrical energy

sources for loads. The test results show that the total consumption of electrical energy are 4678 watts/hour,

while the total production of electrical energy from the solar power plant are 3622 watts/hour. With this load

management system, the contribution of the solar power plant can save electricity consumption by 1056

watts/hour. With this system was known that the efficiency of the solar power plant are 77.4%.

1 INTRODUCTION

As one of the largest archipelagic countries in the

world, Indonesia still faces electricity problems due

to geographical reasons. One of the provinces that

have a low electrification ratio is the Province of East

Nusa Tenggara (NTT). Based on the Central Statistics

Agency (BPS) in 2018, the electrification ratio of

NTT under below the national electrification ratio,

which are 68.82%. One of the problems faced by the

government is the limited funding for electricity

infrastructure development and the low interest in

buying Public to meet basic needs and the

geographical conditions of the hilly islands of NTT,

making it difficult to provide access to new electricity

networks.

Until now, there are still 11,944,675 out of

65,254,000 households in Indonesia that have not

received a supply of Electrical Energy Channels

(SEL) with an electrification ratio of 81.70%. Some

provinces even have electrification ratios below 60%

such as Jambi, West Sulawesi, West Papua, and East

Nusa Tenggara (NTT) due to the accessibility of

electricity infrastructure. PLN noted that there were

532,204 out of 1,104,500 households in Province

NTT that had not received SEL supply with an

electrification ratio of 51.81% (PLN, 2015).

Meanwhile, from BPS data in 2015, there were

30,910 out of 78,011 households spread across 32 of

177 villages in Kupang Regency, NTT Province that

had not yet received a supply of SEL (electrification

ratio of 60%) (Sinaga, Tambunan, and Prastowo

1981).

The Government's efforts to increase the

electrification ratio continue to be carried out with

government programs. In Indonesia, the National

Priority for Energy Sustainability includes two

Priority Programs, namely: New and Renewable

Energy (EBT) and Energy Conservation, as well as

Meeting Energy Needs (Winanti et al. 2018). A

follow-up to the government's efforts to utilize

renewable energy such as solar radiation for the

construction of solar power plants. It is proven that

until now there have been additions and expansions

of electricity networks to remote areas. However, the

current problems are the low purchasing power of

electricity from customers due to economic

constraints and the increasing price of electrical

energy. Other problems that are still felt by the

community such as power outages that still often

298

Pae, M., Kasse, D. and Renoat, R.

Smart Controller Design of Solar Home System (SHS) for Load Management with Grid Connected.

DOI: 10.5220/0010944400003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 298-303

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

occur at peak load conditions and other external

disturbances.

In 2018, NTT's electrification ratio increased to

68.82% but was still below the national average

electrification ratio. The increase in the electrification

ratio in 2018 shows the performance of PLN which

continues to improve in a better direction, as

evidenced by the expansion of new networks. When

viewed from the natural potential, NTT is one of the

provinces that have a source of electrical energy from

renewable energy which is quite high, including

electrical energy from the sun and electrical energy

from wind power. The average intensity of solar

radiation in NTT are 5 kWh/m2 with an average wind

speed of 5.5-6.5 m/s (NASA 2017). If that the

potential was utilized optimally, it will have an

impact on increasing the electrification ratio and

meeting the electricity needs of the NTT community.

To take advantage of the natural potential that exists,

this research will offer the best solution to overcome

public problems associated with the provision of

electrical energy for residential homes, namely by

designing a smart controller by utilizing electricity

from a Solar Power Plant that are connected to the

PLN Grid. The existence of this system can meet the

basic lighting needs of households as well as for other

electrical needs. The results of this research will be

recommended were systems are more efficient and

effective to meet the needs of electrical loads with

low cost and high reliability.

2 PURPOSED TECHNOLOGY

DESCRIPTION

A smart home system is a system that provides

service, convenience, and comfort for consumers or

residents. The smart home system provides optimal

service and provides control over the use of electrical

energy so that it has an impact on saving electrical

energy costs. Previous research related to the

management of electrical energy consumption,

namely the management of voltage on the battery.

Arduino acts as switching between local energy

(PLTS) and main energy. When Arduino reads the

voltage on the battery less than 11 volts, the system

will prioritize the use of energy from the main energy.

On the other hand, when the battery charging process

reaches 13 volts, Arduino will prioritize the use of

electrical energy from local energy (PLTS) (Mehdi

et al. 2018).

Figure 1: Smart Energy Management (Mehdi et al. 2018).

The research previously discussed above uses an

on-grid system, namely local energy sourced from

Solar Power Plants (PLTS) which are connected to

the main grid (PLN). That system was equipped with

a GSM SIM900 card to connect to an IoT-based

smartphone for coordinated control and system

interconnection via a mobile application. The results

of this study indicate significant cost savings and

more efficient management of electrical energy

consumption compared to conventional systems (not

using a management system for electricity

consumption). The main disadvantage of an off-grid

solar power plant is the durability of the battery life

must be continuously replaced so that the customer or

user has to replace the battery for about 5 to 6 years

and it will cost 20% - 25% of the total normal project

calculation (Jose and Itagi 2015). The solution to

overcome their problems are to design the control

system for the efficient performance of solar power

plants, both off-grid systems, and on-grid systems.

One such system design, such as the research

conducted by Sam Jose and Dr. Raieshwari L Itagi in

2015 about “Smart solar power plant” as follows:

a) b)

Figure 2: a) Off Grid System. b) Mini Smart Grid for Died

Grid system (Jose and Itagi 2015).

The results show that a smart controller system

was increased battery life, and the efficiency level of

the off-grid and on-grid systems more than higher and

the cost of the customer or user can be reduced. The

Charger controller can also manage costs well. In

addition, it can also provide overcharge protection for

the battery to prevent over discharger in the battery.

Smart Controller Design of Solar Home System (SHS) for Load Management with Grid Connected

299

Based on the literature study described above, the

framework for designing a Solar Home System (SHS)

with the Application of a Smart Grid Controller are

shown in Figure 3.

Figure 3: Blog Diagram Smart Solar Home System.

Overall, the Solar Home System (SHS) Design

System with the Implementation of the Smart Grid

Controller consists of three main parts. The first part

is the source of power generation, namely PLTS

which are connected to the PLN network. The second

part is load power management. In this section,

current and voltage measurements will be carried out

using current and voltage sensors. The results of the

measurements will be processed by Arduino to

determine which power plant source will supply the

electrical load. Switching between PLTS and PLN

Grid was automatically controlled using an automatic

transfer switch (ATS). The PLN grid will back up the

PLTS system to supplying the load when the load

capacity has exceeded the PLTS capacity. When the

capacity of PLTS produces electrical energy more

than the load capacity, the main energy source used

comes from PLTS. The third part are the electrical

loads. Electrical loads in the form of electronic

equipment and other electrical equipment.

Meanwhile, the PLN grid power was adjusted to the

900 Watt kWh meter electric power.

3 DESCRIPTION OF THE

TECHNOLOGY

The first step in this research are the design of Solar

Power Plant (PLTS). The PLTS system design

consists of several components, namely solar panels,

solar charge controllers, batteries and inverters. The

next step are the design of the ATS system. The ATS

system was designed using 3 contactors that will

work based on current and voltage sensors. The next

stage is the design of the load management system.

Load management system using Arduino. The current

sensor will provide an input signal for the Arduino

and the Arduino will turn on which contactor will

work.

The way system works in the management of

electrical energy consumption was shown in Figure 4.

The sensor will measure the current and voltage at the

load by prioritizing the main source of the PLTS. The

maximum power was set from Arduino for PLTS are

400 Watts. When the load was less than 400 watt,

PLTS will take over the load. If the load more than

400 Watts. For example, 500 watts, the PLTS will

still supply 400 watts of power and the remaining 100

watt will be taken from the PLN grid.

Figure 4: The Working Principle of Energy Management

Solar Home System.

3.1 Load Profile

Based on the measurement results of the load data

was known that the total power requirement for one

day are 11,709 Watt with a total consumption of

electrical energy of 11.27 kWh/day. The

measurement results were known that the peak and

load are 890 Watt which occurs from 18.00 to 19.00.

This is because all electronic and lighting equipment

starts operating. While the lowest power requirement

of the load are 114 Watt from 07.00 until 09.00. In

this state, some lighting loads have been turned off

and some electronic equipment has not been

operating.

Figure 5: Daily Load Profile.

3.2 Determination of Solar Power Plant

To calculate the capacity of solar panels, it is

necessary to know the total electrical load that will be

supplied by the PLTS. In addition to the load

capacity, it is necessary to calculate the peak solar

131

114

114

114

392

600

660

600

504

516

594

640

890

890

790

829

491

623

502

470

380

310

310

245

1357911131517192123

Load (Watt)

Hour

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

300

radiation that occurs in one day. Another parameter to

determine the capacity of solar panels are the

efficiency of the system. Efficiency can be calculated

based on solar panel losses, battery losses, inverter

losses, and cable losses. To maintain stability in

producing electrical energy, the total system losses

are 30% so that the system efficiency are 70%

(Sreewirote and Leelajindakrairerk 2016). To

calculate the power of solar panels can use the

equation:

P

pv =

E

load

/

(PSH X

n

system )

(1)

When:

Ppv = PV panel nominal peak power (W)

E

load

= Total energy demand for a day (Wh)

PSH

= Peak sun hour (hr)

n

system

= overall system efficiency

With a total load power of 400 watts and an

assumed operating time of 2.5 hours, the total energy

required by the load are 1 kWh. While the peak solar

radiation (PSH) for the NTT area is an average of 5

hours starting from 09.00-14.00 (NASA 2017). From

the calculation results, it is known that the solar panel

power should not be less than 286 Wp so that in this

design a solar panel with a capacity of 310 Wp is

used.

To determine the battery capacity, it can be

calculated using equation 2 (Sreewirote and

Leelajindakrairerk 2016) (Duan et al. 2018).

BC = (P

load

x h ) / (V

batt

x n

system

x DOD) (2)

When:

BC = Battery capacity (Ah)

P

load =

Demand power (W)

V

batt

= Battery voltage (v)

h = Discharge times (h)

n

system =

Battery efficiency

DOD = Dead of Discharge

From the results of calculations with a battery

voltage capacity of 12 volts and battery efficiency of

80%, it is known that the battery capacity that must

be used should not be less than 100 Ah. Thus, in this

study, the battery used was 100 Ah.

The type of inverter used is a Grid Tie inverter

which was connected to the PLN electricity network.

Inverter capacity is adjusted to the capacity of PLTS,

so this study using an inverter with a capacity of 600

Watt. While the Solar Charge Controller used in this

design is MPPT type with a capacity of 12/24 V 30

Ampere.

3.3 PV and Main Grid Switching

System

The switching system between the PLTS and the PLN

Grid to supply electrical energy to the load will be

taken over by the Automatic Transfer Switch (ATS)

system. The ATS circuit was equipped with sensors

and relays that will be ordered by Arduino based on

current and voltage sensors on the load. In this design,

2 relays are used namely relay one for PLTS and relay

two for the PLN grid. Both relays will work based on

current and load voltage sensors. The value of

current, voltage, and electric power generated from

the load will be displayed on the LCD. Power is set in

this design process are when the load is greater than

400 watts, PLN will help supply excess electrical

energy to the load. When the load is less than 400

watts, PLTS will take over the load.

ATS circuits are equipped with 3 contactors and a

timer. In this design, the system only uses two

contactors, namely a contactor for PLTS and a

contactor for PLN. While the third contactor is

planned for the use of a generator set. The timer

functions as a delay time setting when switching

between PLTS and PLN sources.

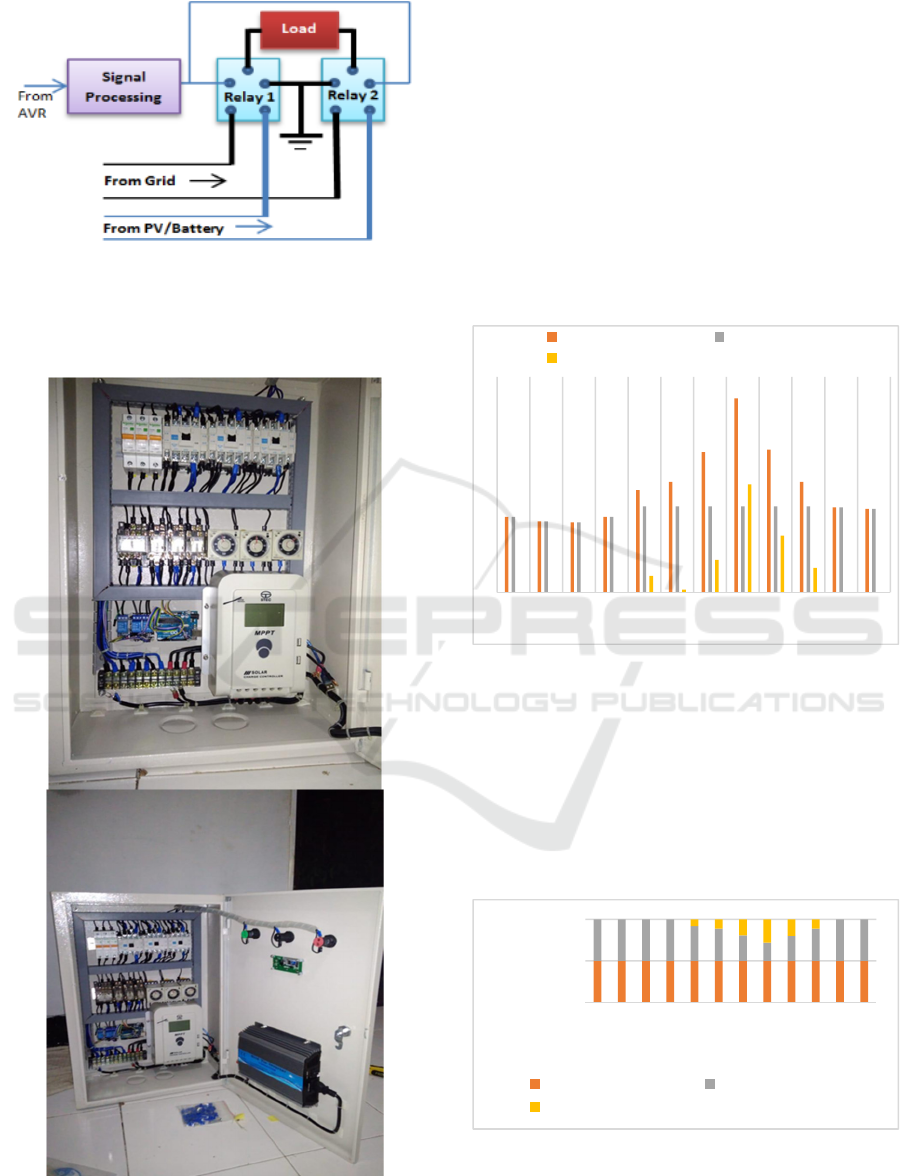

Figure 6: PLTS and PLN Grid Switching.

For electrical power to the load, the two relays are

connected with 2 different conditions. PLTS is

prioritized as the main source of electrical energy so

that the PLTS relay was installed in the Normally

Closed (NC) position while the PLN relay was in the

Normally Open (NO) state. The PLTS relay will be

directly connected to the load through the PLTS

contactor, while the PLN relay will work when there

input signal from Arduino when the load is more than

400 watts. Relay installation in this system are shown

in Figure 7.

Smart Controller Design of Solar Home System (SHS) for Load Management with Grid Connected

301

Figure 7: Relay installation.

Overall, the electrical installation of a smart solar

Home system for electrical load management with a

grid-connected system are shown in Figure 8.

Figure 8: System Electricity Smart Controller SHS for Load

Management.

4 PERFORMANCE OF THE

SYSTEM

The test results show a significant contribution to

saving electricity consumption. However, in this test,

the inverter did not work optimally. The 600-watt

inverter capacity was only capable of producing a

maximum output power of 319 watts. Thus, the

inverter efficiency can be calculated by 53%.

Because the maximum output power of the inverter is

below 400 watts, the Arduino algorithm for the load

power priority switching system was reduced to 300

watts. The test results are shown in Figure 9.

Figure 9: System Test Results.

The test results show that the total consumption of

electrical energy are 4678 watts/hour, while the total

production of electrical energy from the solar power

plant are 3622 watts/hour. Thus, with this load

management system, the contribution of the solar

power plant can save electricity consumption by 1056

watts/hour. Thus, are known that the efficiency of the

solar power plant was 77.4%.

Figure 10: System Efficiency.

The total efficiency of the system is highest when

the total electrical energy of the load can be taken

over by the solar power plant. While the lowest

280

263

260

280

380

410

520

720

530

410

315

310

280

263

260

280

319

319

319

319

319

319

315

310

0

0

0

0

61

10

120

401

211

91

0

0

123456789101112

POWER (WATT)

HOUR

Load (watt) Power PV (Watt)

Power Grid (Watt)

0%

50%

100%

123456789101112

EFFICIENCY

HOUR

Load (watt) Power PV (Watt)

Power Grid (Watt)

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

302

efficiency occurs at peak load, namely the

consumption of electric power of 720 watts. At this

peak load, the total purchase of electrical energy from

the PLN Grid are 401 watts while the contribution

from the solar power plant are 319 watts.

5 CONCLUSION

The Smart Controller Design of Solar Home System

(SHS) for Load Management With Grid Connected

has a performance efficiency of 77%. By saving

electricity consumption of 1.5 kWh of the total

electrical energy consumption of 4,678 kWh. The

highest electricity consumption from the PLN Grid

are 720 watts while the total electricity production

from the solar power plant are 319 watts. One of the

obstacles that occur in this design is the performance

of the inverter not optimal. In addition, the lack of

sensitivity of current and voltage readings from the

sensor so that the need for a proper calibration

system. The above constraints can be an open

problem for further system development.

REFERENCES

Duan, Xiaoyu, Sirui Wu, Rui Diao, and Aobo Yang. 2018.

“Design of Hybrid Solar-Hydro Microgrid for Village

School in China.” 2018 IEEE Global Humanitarian

Technology Conference (GHTC), 1–7.

Jose, Sam, and Rajeshwari L. Itagi. 2015. “Smart Solar

Power Plant.” 2015 International Conference on

Communication and Signal Processing, ICCSP 2015,

850–54. https://doi.org/10.1109/ICCSP.2015.7322615.

Mehdi, Laraki, Yassine Ouallou, Oussa Mohamed, Aawatif

Hayar, Smart City, Team Ritm, Ensem Greentic,

Université Hassan, and I I Casablanca. 2018. “New

Smart Home ’ s Energy Management System Design

and Implementation for Frugal Smart Cities.” 2018

International Conference on Selected Topics in Mobile

and Wireless Networking (MoWNeT), 149–53.

https://doi.org/10.1109/MoWNet.2018.8428865.

NASA. 2017. “NASA Surface Meteorology and Solar

Energy.” 2017. https://eosweb.larc.nasa.gov/cgi-

bin/sse/grid.cgi?&num=291082&lat=-

8.5&submit=Submit&hgt=100&veg=17&sitelev=&e

mail=&p=grid_id&p=swvdwncook&p=swv_dwn&p=

sol_noon&p=ret_tlt0&p=mnavail1&p=surplus1&p=da

y_cld&p=T10M&p=wspd50m&p=pct10m_wnd&p=R

H10M&step=2&lon=110.

Sinaga, Rusman, Armansyah Halomoan Tambunan, and

Prastowo. 1981. “Analisis Alternatif Solusi Penyediaan

Sumber Energi Listrik Studi Kasus: Kabupaten

Kupang.” Journal of Chemical Information and

Modeling Bintang Charles Hamonangan

Simangunsong 53 (9): 1689–99.

Sreewirote, B, and M Leelajindakrairerk. 2016. “Design

and Development of Solar Water Pump.” IEEE.

Winanti, Naftalin, Burhanuddin Halimi, Agus Purwadi, and

Nana Heryana. 2018. “Study and Design of Energy-

Saving Solar Lamp for Rural Area in Indonesia.”

Proceedings - 2018 2nd International Conference on

Green Energy and Applications, ICGEA 2018, no. 79:

98–102. https://doi.org/10.1109/ICGEA.2018.8356307.

Smart Controller Design of Solar Home System (SHS) for Load Management with Grid Connected

303