Effect of Stainless Steel Duplex Electrode Size on Hydrogen

Production through Electrolysis Process

Yohandri Bow

1a

, Rusdianasari

1b

, Anerasari Meidinariasty

1

and Muhammad Yori Pratama

2

1

Department of Chemical Engineering, Politeknik Negeri Sriwijaya, Jalan Srijaya Negara, Palembang, Indonesia

2

Department of Chemical Engineering, Institut Teknologi Bandung, Bandung, Indonesia

Keywords: Electrode, Duplex Stainless Steel, Hydrogen, Electrolysis.

Abstract: Renewable energy development is the focus of attention at this time, using environmentally friendly energy

sources and zero emission by utilizing water to make hydrogen through the electrolysis process. The electrode

material is selected from materials that have good electrical conductivity and corrosion resistance. Duplex

Stainless Steel (DSS) is a material with a combination of two phases, namely austenite and ferrite. The process

includes designing tools, manufacturing, and testing the performance of the electrolyzer against the variation

in the cross-sectional area with a voltage of 12V and variations in current and electrolytes used are brackish

water with a salinity of 8 ppt. The larger the cross-sectional area, the easier the electron transfer that occurs

during the electrolysis process, which causes the charge of electrons to react more, then the resulting current

will be more significant, this results in a large amount of power generated, while efficiency is inversely

proportional to power. Electrode size is also proportional to the current. Electrode 2 inch is more effective

than electrode 1.5 inch because, at current 35 A, an efficiency of 93.33% is obtained with the volume of gas

produced is 1.9087 Liters.

1 INTRODUCTION

Electrolysis of water is the decomposition of water

compounds (H

2

O) into hydrogen gas (H

2

) and oxygen

(O

2

) by using an electric current through water

(Ploetz et al., 2016; Rusdianasari et al., 2019).

Hydrogen is one of the new renewable energy sources

that can reduce exhaust emissions by using water as

fuel through the process of electrolysis of water

compounds (H

2

O) which is converted into its

constituent components, namely oxygen and

hydrogen (Kassaby et al., 2016; Imperiyka et al.,

2017; Irtas et al., 2021; Jannah et al., 2020).

The production of hydrogen gas from seawater

containing NaCl can take place quickly because NaCl

itself functions as a natural catalyst. The content of

the natural catalyst or commonly referred to as

salinity, affects the electrolysis process. In the study

of electrolysis made from water and seawater based

on variations in current and salinity, the salinity used

was 0.05 ppt, 15 ppt, and 35 ppt with the best gas

conversion at a salinity variation of 35 ppt

a

https://orcid.org/0000-0002-2741-7477

b

https://orcid.org/0000-0003-1955-396X

(Phalakornkule et al., 2020; Purnamasari et al., 2019;

Rusdianasari et al., 2020; Rusdianasari et al., 2020).

The production of H

2

gas by electrolysis of water

and seawater obtained the highest concentration of H

2

gas formed, namely the electrolysis of aqua DM,

which was added with NaCl and NaOH of 4500 ppm.

In this study, the concentration of NaOH catalyst was

not varied in the electrolysis process (Imperiyka et al.,

2017). The results of another study stated that in the

production of hydrogen gas with an H

2

SO

4

catalyst,

the greater the current and the greater the number of

electrodes provided with the same sulfuric acid

concentration, the greater the concentration of

hydrogen gas produced (Syakdani et al., 2019; Bow

et al., 2018; Amelia et al., 2021). The greater the

concentration of the catalyst, the greater the

precipitate formed during the electrolysis process and

causes obstruction of the process of forming gas

bubbles at the electrode (Hadi, 2020).

A catalyst is a substance that can accelerate the

rate of a chemical reaction which at the end of the

reaction is obtained in its original state or does not

Bow, Y., Rusdianasari, ., Meidinariasty, A. and Yori Pratama, M.

Effect of Stainless Steel Duplex Electrode Size on Hydrogen Production through Electrolysis Process.

DOI: 10.5220/0010946400003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 393-397

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

393

react (Sellami and Loudiyi, 2017). In the electrolysis

of water, a catalyst is used to facilitate or accelerate

the decomposition of water into hydrogen and oxygen

because the catalyst ions are able to affect the stability

of water molecules into H

+

and OH

-

ions which are

easier to electrolyze due to a decrease in activation

energy (O’Neil et al., 2016).

Research using stainless steel electrodes produced

95.8 ml and 82.6 ml of HHO gas, respectively. The

electrolyte used is KOH and electrodes made of

Stainless Steel with variations in the cross-sectional

area of the electrode with sizes 9 cm x 11 cm and 9

cm x 14 cm (Meier, 2014).

The most important components of the electrolysis

process are electrodes and electrolyte solutions (Irena,

2020). One of the raw materials for electrolysis is

water. Electrolysis of water which has the chemical

formula H

2

O is the event of the decomposition of water

compounds (H

2

O) into its constituent elements,

namely hydrogen (H

2

) and oxygen (O

2

), by using an

electric current. Electrolysis is an event that occurs

when an electric current is passed through an ionic

compound and the compound undergoes a chemical

reaction (Abdel-AaL et al., 2020).

Hydrogen gas as the main product and oxygen

produced from the electrolysis of water form bubbles

at the electrodes and can be collected in a reservoir.

This principle is then used to produce hydrogen that

can be used as fuel for hydrogen vehicles. Michael

Faraday discovered the electrolysis process in 1820.

Factors that affect the electrolysis process include the

use of a catalyst, the immersed surface area, the

nature of the electrode raw material, the concentration

of the reactants, and the amount of external voltage

(Moulita et al., 2020).

The main product, hydrogen in the water

electrolysis process, is highly flammable and will

burn at a concentration of 4% in free air. The enthalpy

of combustion of hydrogen gas is -286 kJ/mol

(Yunsari et al., 2019). Based on this, safety is needed

when burning hydrogen gas. The arrestor is a tool

component that reduces the risk of work accidents

such as explosions due to flashback fires during the

hydrogen gas flame test (Bow et al., 2020). In this

study, electrolysis was carried out using a prototype

electrolysis reactor equipped with an arrestor in terms

of the effect of the size of Duplex Stainless Steel on

hydrogen production through the electrolysis process.

2 METHODOLOGY

The material used in this study is water with a salinity

of 8 ppt which was taken according to seawater

sampling standards (SNI 6964.8:2015). After

knowing the salinity that produces hydrogen gas

optimally, variations in the size of the stainless steel

duplex electrode are carried out. The seawater

electrolysis prototype consists of five main units,

namely, feed tank, electrolyzer tube, electrodes, H

2

and O

2

gas cylinders, flashback arrestor, and control

panel. The system is equipped with measuring

instruments, namely digital pressure detectors, digital

temperature detectors, H

2

smart sensors, and O

2

smart

sensors. The electrolysis equipment used can be seen

in Figure 1.

Figure 1: Electrolyzer Prototype.

The electrolysis process is carried out using the

Hydrogen Generator Using Water Electrolysis

Process method based on ISO 22734-1:2008 with

adjustments to the design and condition of the tool.

The electrolysis process in the electrolysis reactor

used is that the feed is pumped into the electrolyzer

as much as 17 liters. The electrolysis process is

carried out with a certain current. The electrolysis

results obtained are in the form of hydrogen and

oxygen gas in the electrolyzer, which will then be

temporarily accommodated in the gas holding tank.

During the electrolysis process, data is collected

every 2 minutes in the form of operational condition

data in the form of pressure, temperature, and voltage.

After hydrogen gas is obtained, then temperature data

is taken on the arrestor every 2 minutes.

3 RESULT AND DISCUSSION

In this study, we want to get the effect of Duplex

Stainless Steel as an electrode and the electrolyte

used is brackish water on the production of

hydrogen gas produced. The prototype for making

hydrogen was carried out by varying the size of the

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

394

electrode with the respective electrode diameters (2

inches and 1.5 inches), the thickness was 0.33 mm,

and the electrode height was 40 cm, and the current

variation with a voltage of 12 Volts for 480 seconds

and using an electrolyte, namely water. brackish

with a salinity of 8 ppt. The production of hydrogen

gas produced by varying the size of the electrodes

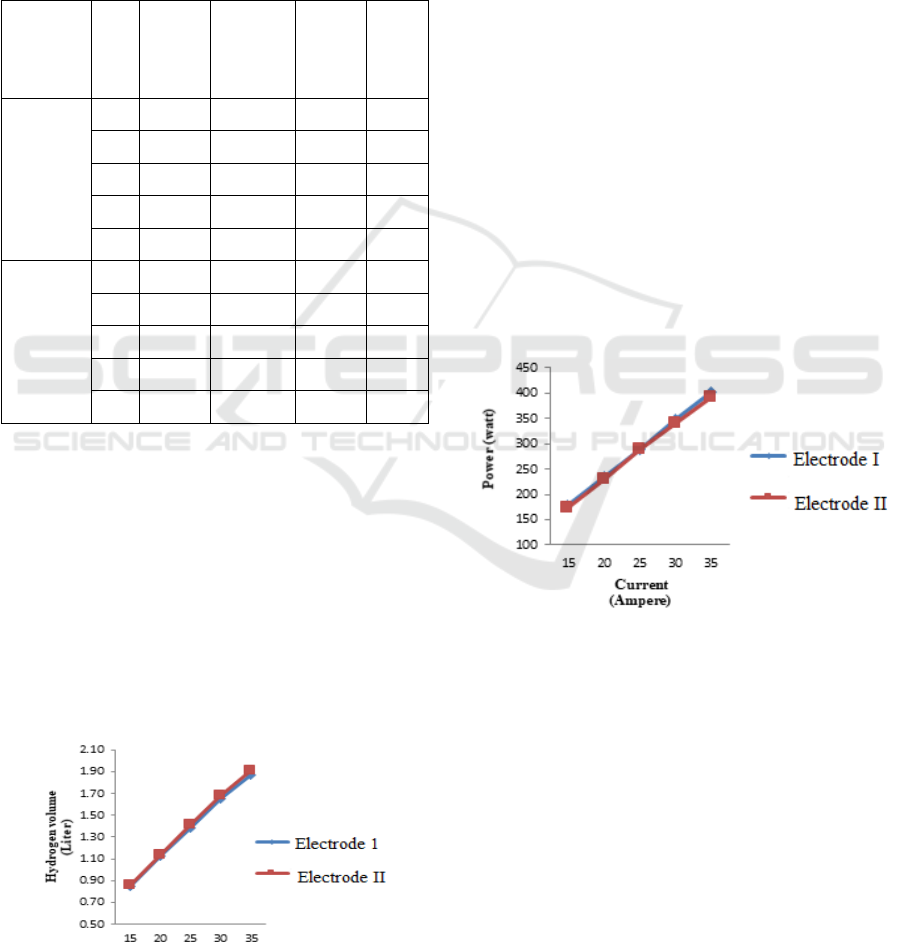

can be seen in Table 1.

Table 1: Hydrogen production based on electrode cross-

sectional area.

Electrode

Size

I

(A)

V

(Volt)

H

2

Gas

Volume

(Liter)

P

(Watt)

η (%)

Electrode

I

(D= 2 inch,

t= 40cm)

15 11.9 0.8512 178.5 99.17

20 11.7 1.1251 234 97.50

25 11.6 1.3877 290 96.67

30 11.6 1.6538 348 96.67

35 11.5 1.8719 402.5 95.83

Electrode

II

(D= 1,5

inch,

t=40cm)

15 11.6 0.8539 174 96.67

20 11.5 1.1407 230 95.83

25 11.5 1.4179 287.5 95.83

30 11.3 1.6769 339 94.17

35 11.2 1.9087 392 93.33

3.1 Effect of Current and Electrode

Size on the Volume of Hydrogen

Produced

The formation of hydrogen gas in the electrolysis

process has a directly proportional relationship

between gas yield, time, and current strength. The

results of measuring the volume of hydrogen gas

produced at different electric currents and the cross-

sectional area of the duplex stainless steel electrodes

used during the electrolysis process can be seen in

Figure 2.

Figure 2: The volume of hydrogen gas produced is based on

the curren t and the size of the electrode.

Figure 2 shows that the transfer of electrons

during electrolysis results in an increase in the

production rate of hydrogen gas produced. This is

indicated by an increase in current and a different size

of the electrode. The size of electrode I (2 inches) is

obtained with a current of 35A, the volume of gas

produced is 1.8719 liters, while the size of the

electrode II (1.5 inches) is that the volume of gas

produced is 1.9087 liters. The increase in the volume

of gas produced at different electrode sizes is not

significant, this occurs because the electrode sizes are

2 inches and 1.5 inches respectively, with the same

electrode height. The increase in current and voltage

causes the electrolysis process to occur quickly

because the movement of the molecules is also

increasing. The temperature in this process also

increases due to the faster movement of electrons

during the electrolysis process (Ploetz, R.

Rusdianasari and Eviliana, 2016).

3.2 Effect of Current and Electrode

Size on the Electric Power

Generated

The relationship between current and power

generated by using different sizes of electrodes can be

seen in Figure 3.

Figure 3: The electric power generated is based on the

current and the size of the electrode.

Figure 3 shows that the relationship between the

current and the supplied power is less significant for

different electrode sizes, this happens because the

electrode sizes are 2 inches and 1.5 inches,

respectively with the same electrode height. At the

size of the electrode I obtained with a current of 35A,

the power supplied was 402.5 Watts, while the size of

the electrode II obtained a power supply of 392 Watts.

However, if the cross-sectional area affects the power

supply, the larger the size of the electrode, the easier

it will be for the transfer of electrons that occurs

during the electrolysis process, causing more

electrons to react, so the current generated will be

Effect of Stainless Steel Duplex Electrode Size on Hydrogen Production through Electrolysis Process

395

even greater, this results in a large amount of power

being generated directly proportional to the current

(Purnamasari, I., Yerizam, M., Hasan, A., Junaidi, R.,

2019).

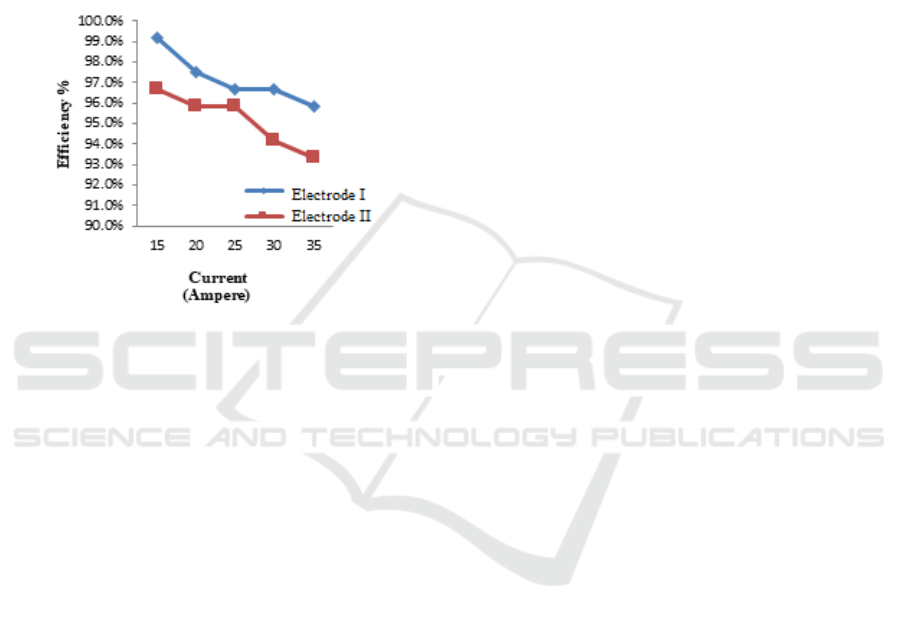

3.3 Electrolyzer Efficiency

The performance of the electrolyzer prototype that

converts seawater into hydrogen gas with variations

in electric current and different sizes of stainless steel

duplex electrodes can be seen in Figure 4.

Figure 4: Electrolysis efficiency based on the electrode size.

Figure 4 shows that the greater the electric

current, the greater the power produced because

power is directly proportional to current, while

efficiency is inversely proportional to power. So that

the highest efficiency obtained at electrode I is

99.17% with an electrode size of 2 inches at a current

of 15A, while the lowest efficiency obtained at

electrode II is 93.33% with an electrode size of 1.5

inches at a current of 35A. The relationship between

current and efficiency generated, this happens, when

an increase in current occurs, the power generated is

more significant and the efficiency of the electrolyzer

is getting smaller. The efficiency of the electrolyzer

is not only affected by the increase in current and

power but is also affected by the heat energy

produced, which is directly proportional to hydrogen

gas. The type of electrode greatly affects the

efficiency of the electrolyzer. The electrode used is

Duplex Stainless Steel. Besides being able to produce

a larger current, this type also reacts and produces a

constant and relatively large gas in the long term.

4 CONCLUSIONS

The production of hydrogen has been carried out by

the electrolysis method using a prototype electrolyzer

which has an electrolysis cell with a capacity of 15-

20 liters. The electrodes used are Duplex Stainless

Steel with varying diameter sizes, namely 1.5 inches

and 2 inches with a height of 40 cm and an electrode

thickness of 0.3 mm. In this process, the highest

volume of gas produced with different electrode sizes

is found in the size of electrode II (D = 1.5 inches, t =

40cm) at a current of 35A of 1.9087 Liters. The power

generated is more significant because the power is

directly proportional to the current so that the highest

power is obtained at 402.5 Watt with a current of 35A

at the electrode size I (D = 2 inches, t = 40cm). The

highest efficiency was obtained at the size of the

electrode I (D = 2 inches, t = 40cm) with a current of

15A of 99.17%.

ACKNOWLEDGEMENTS

The authors would like to thank the Ministry of

Education, Culture, Research, and Technology; The

Directorate General of Vocational Studies has funded

this applied research for the 2021 fiscal year.

REFERENCES

Abdel-AaL, H.K., Zohdy, K.M.., Kareem, M.A. (2010).

Hydrogen Production using Sea Water Electrolysis. The

Open Fuel Cell Journal, Vol. 3, pp. 1-7.

Amelia, I., Rohendi, D., Rachmat, A., Syarif, N. (2021).

Hydrogen Adsorption/Desorption on Lithium alanat

Catalyzed by Ni/C for Sustainable Hydrogen Storage.

Indonesian Journal of Fundamental and Applied

Chemistry, Vol. 6(2), pp. 59-63.

Bow, Y., Dewi, T., Taqwa, A., Rusdianasari, Zulkarnain.

(2018). Power Transistor 2N3055 as a Solar Cell

Device. In International Conference on Electrical

Engineering and Computer Science (ICECOS), IEEE.

Bow, Y., Rusdianasari, Yunsari, S. (2020). CPO based

Biodiesel Production using Induction Heating Assisted.

Oil Palm Research and Review, Vol. 1(1), pp. 1-6.

Hadi, S. (2020). Effect of Electrodes, Electric Current, and

NaHCO

3

Concentration against HHO Pressure

Generator. Int. Journal of Engineering Science, Vol. 10

(4), pp. 1-3.

Imperiyka, MH., Rahuna, MN., Iman, EA. (2017).

Hydrogen Production using Mediterranean Sea Water

of Benghazi Shore and Synthetic Sea Water

Electrolysis. Academic Journal of Chemistry, Vol. 2

No. 1, pp. 8-15.

Irtas, D., Bow, Y., Rusdianasari. (2021). The Effect of

Electric Current on the Production of Brown’s Gas

using Hydrogen Fuel Generator with Seawater

Electrolytes. In IOP Conf. Ser., Earth Environ. Sci.

79(012001).

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

396

IRENA. (2020). Green Energy: A Guide to Policy Making,

International Renewable Energy Agency, Abu Dhabi.

Jannah, Z., Susilo, S.H. (2020). Effect of Electrodes,

Electric Currents, and NaHCO3 Concentration Against

HHO Pressure Generator. International Journal of

Engineering Science, Vol. 10, pp. 1-3.

Kassaby, E., Eldrainy, MM., Khidr, EA., Khidr, K. I.

(2016). Effect of Hydroxy (HHO) Gas Addition on

gasoline Engine Performance and Emissions.

Alexandria Engineering Journal, Vol. 55, pp. 243-251.

Meier, K. (2014). Hydrogen Production with Sea Water

Electrolysis using Norwegian offshore Wind Energy

Potentials. Int. J. Energy Environ. Eng. Vol 5(104).

Moulita, RAN., Rusdianasari, Kalsum, L. (2020).

Biodiesel Production from Waste Cooking Oil using

Induction Heating Technology. Indonesian Journal of

Fundamental and Applied Chemistry, Vol. 5 (1), pp.

13-17.

O’Neil, G.D., Christian, C.D., Brown, D.E., Esposito, D.U.

(2016). Hydrogen Production with a Simple and

Scalable Membraneless Electrolyzer. Journal of the

Electrochemical Society, Vol. 163(4), pp. 3012-3019.

Phalakornkule, C., Sukkasem, P., Mutchimsattha, C.

(2020). Hydrogen Recovery from the

Electrocoagulation Treatment of Dye-Containing

Wastewater. International Journal of Hydrogen

Energy, Vol. 35, pp. 10934-10943.

Ploetz, R. Rusdianasari, Eviliana. (2016). Renewable

Energy: Advantages and Disadvantages. In Proceeding

Forum in Research, Science, and Technology (FIRST).

Purnamasari, I., Yerizam, M., Hasan, A., Junaidi, R. (2019).

Oxygen Adsorption Kinetics Study used Pressure

Swing Adsorber (PSA) for Nitrogen Production. J.

Phys.: Conf. Ser., 1167(012049),

Rusdianasari, Bow, Y., Dewi, T. (2019). HHO Gas

Generation in Hydrogen Generator using Electrolysis.

In IOP Conference Series: Earth and Environmental

Science, 258 (012007). https://doi.org/10.1088/1755-

1315/258/1/012007

Rusdianasari, Bow, Y., Dewi, T., Risma, P. (2020).

Hydrogen Gas Production using Water Electrolyzer as

Hydrogen Power. In 2019 International Conference on

Electrical Engineering and Computer Science

(ICECOS), IEEE.

Rusdianasari, Bow, Y., Dewi, T., Taqwa, A., Prasetyani, I.

(2020). Effect of Sodium Chloride Solution

Concentartion on Hydrogen Gas Production in Water

Electrolyzer Prototype. In 2019 International

Conference on Technologies and Policies in Electric

Power and Energy, IEEE.

Sellami, M.H., Loudiyi, K. (2017). Electrolytes Behavior

during Hydrogen production by Solar Energy.

Renewable and Sustainable Energy Reviews, Vol. 70,

pp. 1331-1335.

Syakdani, A., Bow, Y., Rusdianasari, Taufik, M. (2019).

Analysis of Cooler Performance in Air Supply Feed for

Nitrogen Production Process using Pressure Swing

Adsorption (PSA) Method. In J. Phys.: Conf. Ser.,

1167(012055).

Yunsari, S., Husaini, A., Rusdianasari. (2019). Effect of

Variation of Catalyst Concentration in the Producing of

Biodiesel from Crude Palm Oil using Induction Heater.

Asian Journal of Applied Research and Community

Development and Empowerment, Vol. 3(1), pp. 24-27.

Effect of Stainless Steel Duplex Electrode Size on Hydrogen Production through Electrolysis Process

397