A Design of a Tool of Car Brake Piston Caliper Remover with

Pneumatic Power

I M. Suarta

a

, I P. G. Sopan Rahtika

b

, P. W. Sunu

c

, Santosa Gede and K. Bangse

Department of Mechanical Engineering, Politeknik Negeri Bali, Badung, Bali, Indonesia

Keywords: Brake, Caliper, Piston, Release.

Abstract: The development of automotive technology makes all aspects of life easier. Various work aids have been

designed and created, making it easier for workers to do their jobs. One of the jobs are often done in

automotive service is the brake system. In performing brake service, the work most often done is replacement

of the brake canvass. The second most common job after replacing brake linings is replacing the caliper seals

due to leaks and jammed caliper pistons. Removing the caliper piston is currently done by using an air-gun

or gouging. Releasing using an air-gun often fails due to insufficient compressor pressure. Base on

observation in the workshop, now day we designed a brake caliper piston removing tool using pneumatic

power obtained from the pressure of the hermetic compressor. The tool pressure is set at 300 psi. The test

results show that the process of removing the caliper piston takes 7.6 seconds.

1 INTRODUCTION

Technological developments make all aspects of life

easier, more comfortable and safer. It is the same in

the automotive world. One of the most important

components in vehicles in the automotive world is the

brake system (Toyota, 2007; Daryanto, 2009). The

brake system functions to stop or reduce vehicle

speed to prevent vehicle movement when a fixed

position is required. All brake systems use friction for

their operation. At this time the most widely used is

the hydraulic brake system. The components of the

brake system consist of: brake pedal, brake booster

and caliper. The current research is focused on the

brake caliper component because this component is

the part of the brake system that is most often

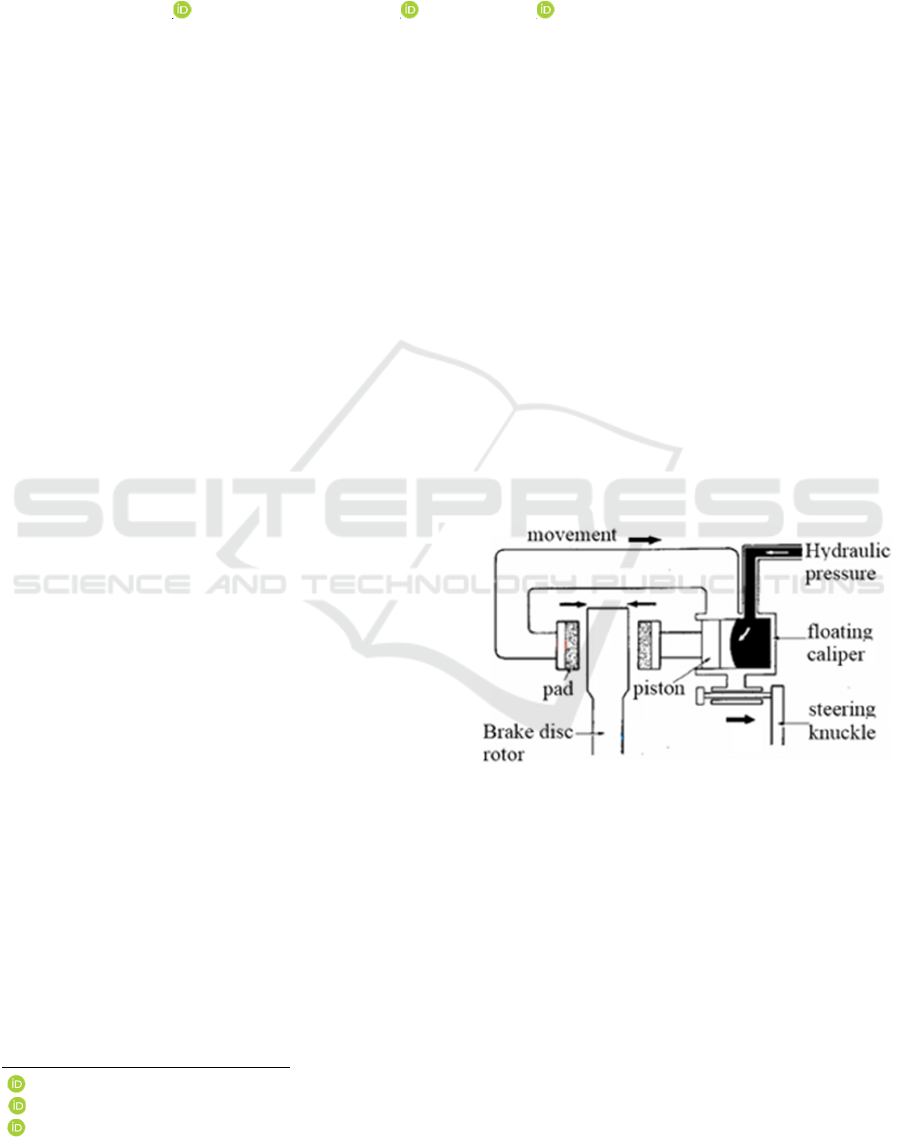

damaged after the brake lining. Figure 1 shows a

picture of the working of brake caliper.

In figure 1, it can be seen that the pressure in the

floating calipers will move the piston to the left and

cause the brake pad to touch the brake disc rotor. If

the pressure is continued again, the floating caliper

will shift to the right against the steering knuckle, so

that the brake disc rotor clamping process occurs by

a

https://orcid.org/0000-0001-5715-7170

b

https://orcid.org/0000-0001-5290-6910

c

https://orcid.org/0000-0001-5715-7170

the pad. So that the braking process occurs (Adhi,

2021; Setiawan, 2014)

Figure 1: The brake caliper work.

At this time the method used to remove the brake

caliper piston is to use an air-gun or gouging. Using

an air-gun to remove the brake caliper pistons is often

difficult. It even had to be knocked and the remaining

brake fluid in the caliper housing was often scattered

and spurted everywhere. This is very dangerous

considering that brake fluid is damaging to the

vehicle body paint. Using an air-gun can be

dangerous for the tool itself and the workers, because

446

Suarta, I., Rahtika, I., Sunu, P., Gede, S. and Bangse, K.

A Design of a Tool of Car Brake Piston Caliper Remover with Pneumatic Power.

DOI: 10.5220/0010947300003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 446-450

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

it can damage the piston if it bounces far and hits the

worker. Until now there is, no special tool used to

remove the brake caliper piston apart from the air-gun

and the help of a screwdriver to remove it. That is why

it is necessary to think about special tools for work in

automotive vehicle repair activities in the workshop.

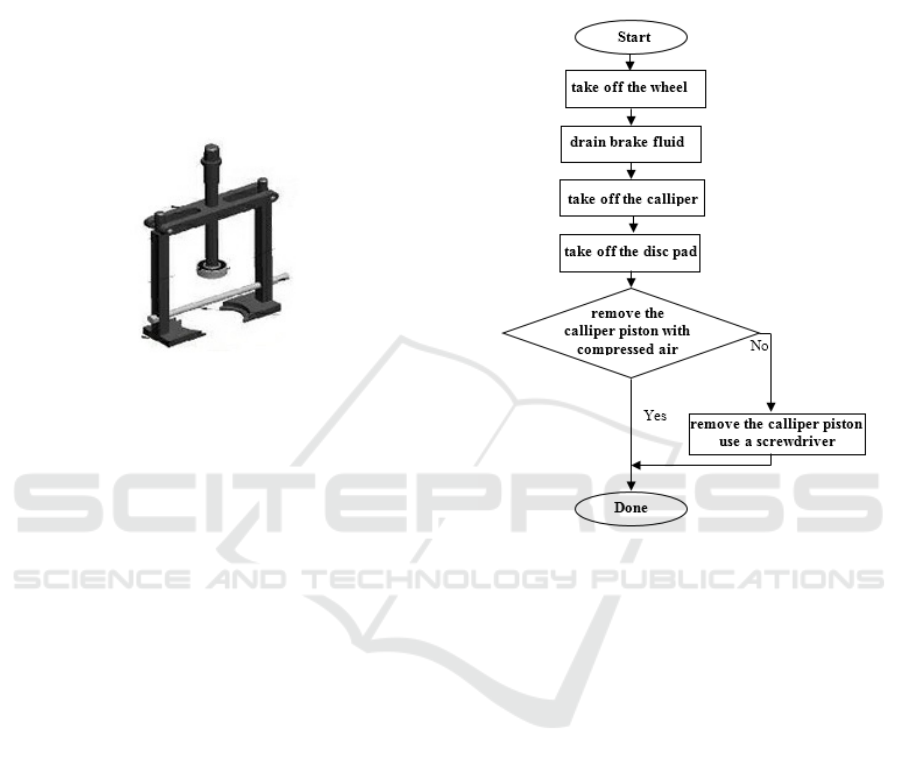

(Setia. 2014) designed the Toyota Fortuner brake

caliper piston remover tool. Using the SST tool he

designed it took 106 minuts to remove the brake

caliper pistons. The design model of the tool he made

is shown in Figure 2.

Figure 2: The caliper piston remover tool designed by Setia

A.

Based on this background, we thought that it was

necessary to make a device that can remove the piston

of the car's disc brake calipers. We conducted

research by designing a car brake caliper piston

release device with pneumatic power. By doing the

design and testing of this tool, it is expected to

facilitate the work in the car repair shop, especially in

removing the pistons of the car brake calipers. Based

on the description on the background, the formulation

of the problem in testing the design of this tool is how

much the car brake caliper piston release tool can

simplify, speed up the work.

Design is planning and engineering calculation of

materials and components, simulation test and

modeling of a tool. The design of a tool must be based

on a careful planning so that the designed tool can

function optimally. Design in a tool or machine

includes everything related to system planning,

machine properties, machine elements, structures,

and instruments so that it involves all mechanical

engineering disciplines. In planning are marked with

technical drawings as a communication tool and pay

attention to design criteria that refer to function,

safety, reliability, cost, manufacturability,

marketability (Achmad, 2006; Juhana, 2000; Nur,

2007; Buchari, 2015; Sumbodo, 2017).

2 MATERIALS AND METHOD

Based on observations made in the workshop that the

flow process of removing the caliper pistons is

currently shown in Figure 3 as follow.

Figure 3: Flow process before improvement.

Car brake caliper piston removal process

previously using an air-gun and duster to spray

compressed air from the compressor to push the

piston out from the caliper housing. The use of an air-

gun and a rag can be used if the brake caliper piston

is easy to remove, or the brake caliper piston is not

stuck or does not rust. The use of the tip of air-gun

and a rag to remove the caliper piston cannot be fully

used because the air pressure is not all compressed, as

a result of the tip of air-gun being less precise with

the brake caliper holes. Also the duster cannot

function as a good seal. Besides the leakage when

putting the air into the caliper housing, it is also due

to the compressor pressure in the workshop which is

usually only 120 psi so it is not enough to push the

piston out of the piston housing. This method of

removing the brake caliper pistons is also less safe,

because the remaining brake fluid can splatter, the

caliper pistons can also bounce. The method of

removing the caliper piston using an air-gun can be

seen in Figure 4.

A Design of a Tool of Car Brake Piston Caliper Remover with Pneumatic Power

447

Figure 4: Releasing the brake caliper piston with an air-gun.

If the brake caliper piston cannot be removed

using an air-gun, the brake caliper piston must be

removed by other means such as pulling with pliers

or gauging with a screwdriver. The process of

removing the caliper piston using pliers or a

screwdriver often results in damage to the brake

caliper piston. Figure 5 shows the process of

removing the brake caliper piston using a

screwdriver.

Figure 5: Removing the brake caliper piston using the

screwdriver.

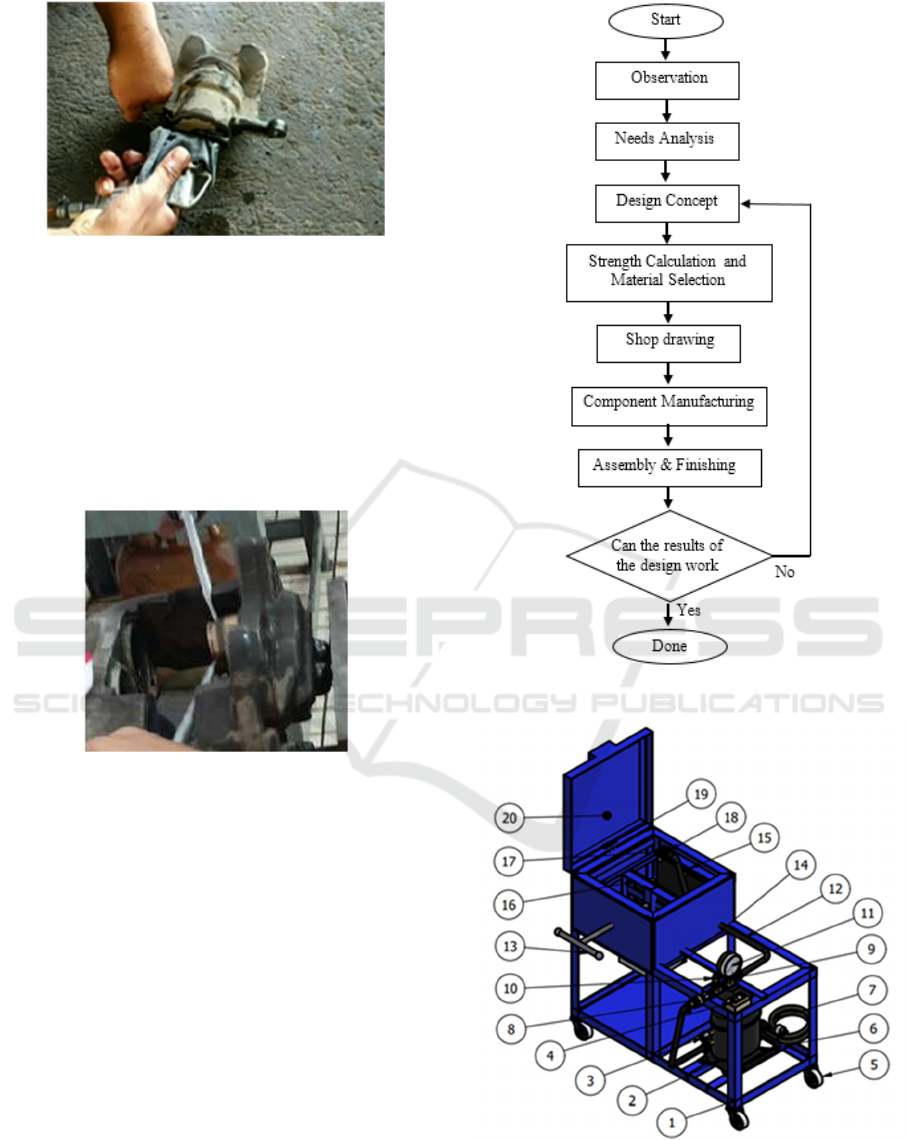

The design of this car brake caliper piston remover

tool utilizes the pneumatic power of a hermatic

compressor. In designing a tool that is needed for a

mature stage to produce a tool that can work well. The

flow chart for making this car brake caliper piston

removing tool can be seen in Figure 6.

The design of this car brake caliper piston

remover tool is designed to be used easily and safely

with fairly affordable manufacturing costs (Achmad,

2006; Nur, 2017; Buchari, 2015; Roslin, 2018; Azmi,

2018; Setia, 2014). This car brake caliper piston

remover tool can assist mechanics in speeding up

their job on repairs and replacement of car brake

caliper pistons. And most important thing is to make

the workers and the components safe. The figure of

the caliper piston remover tool using pneumatic

power can be seen in Figure 7.

Figure 6: Flowchart of making caliper piston removal tool.

Figure 7: The caliper piston release tool uses pneumatic

power.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

448

3 RESULTS AND DISCUSSION

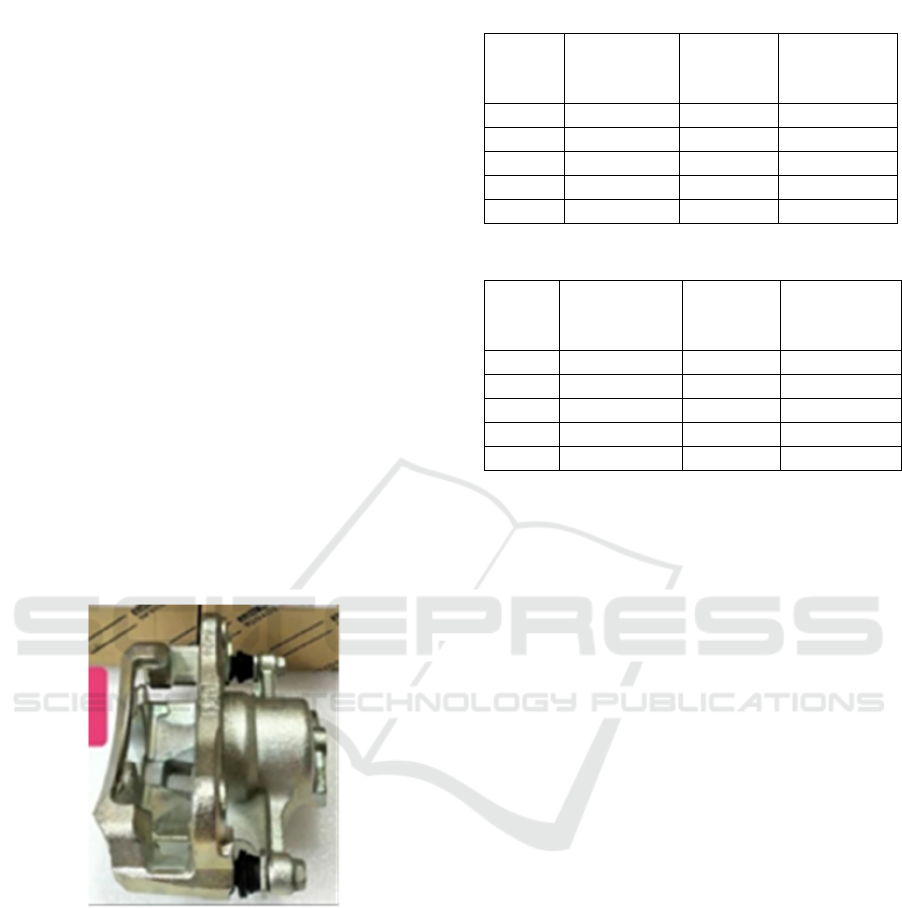

In the brake caliper component, the most common

disturbance is the leakage of brake fluid on the caliper

piston, so the seal must be replaced. Replacement of

the caliper piston seal is done by removing the caliper

piston from its housing. When removing the caliper

piston from the housing, the mechanics often have

difficulty, based on observations in the workshop, we

designed a tool that can assist the mechanics in

completing their work. Figure 8 show the brake

caliper.

Figure 8: Brake caliper.

From the test results, opening the caliper piston

using an air-gun and using pneumatic power obtained

the required time and pressure data. Compressor

working pressure in maintenance and repair

workshops is generally 120 psi. So the working

pressure when opening the caliper piston using an air-

gun is 120 psi. Table 1 presents the test data against

time and pressure using an air-gun.

The working pressure of the hermetic compressor

used for pneumatic power is 500 psi. In table 2 are

test data using pneumatic power with a working

pressure setting of up to 350 psi.

Table 1: Air-gun test.

Caliper

Piston

N

o.

Release

pressure

(psi)

Time

(seconds)

explanation

1

50

25

release

d

2

-

-

not release

d

3

-

-

not release

d

4

75

30

release

d

5

-

-

not release

d

Table 2: Pneumatic power test.

Caliper

Piston

No.

Release

pressure

(psi)

Time

(seconds)

explanation

1

50

5

release

d

2

200

10

release

d

3

180

8

release

d

4

75

5

release

d

5

200

10

release

d

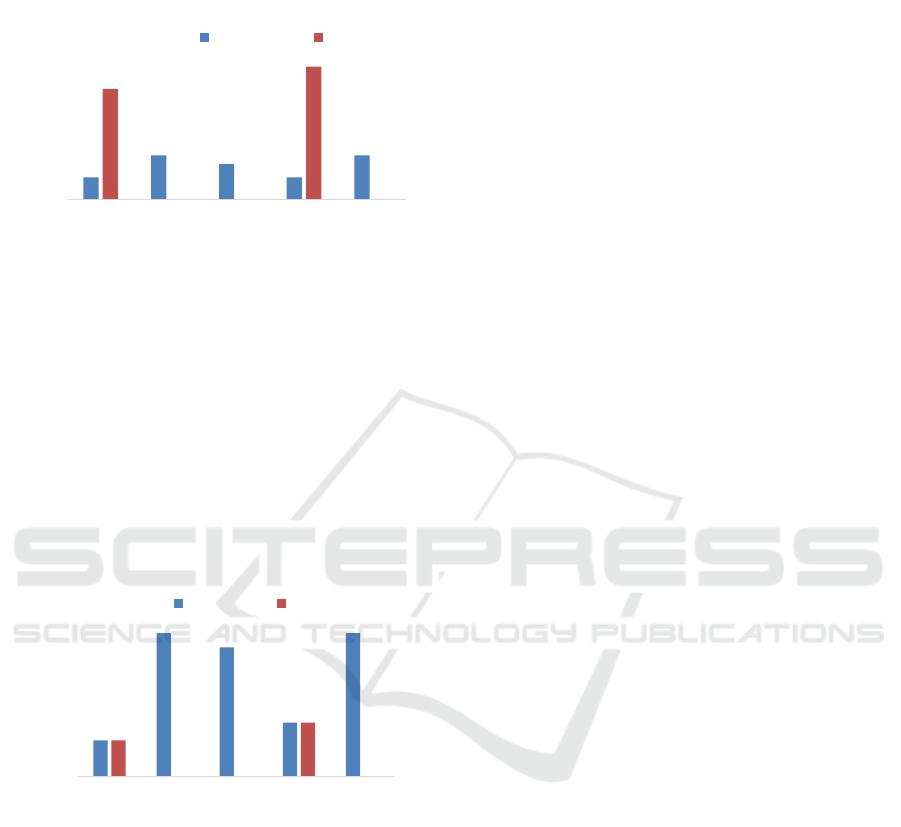

To make it easier to read, from the table results, a

graph of the comparison of the time and pressure

needed to release the caliper piston can be made.

Figure 9 shows the comparison of the time required

to release the caliper piston using an air-gun and using

pneumatic power. Figure 10 shows the ratio of the

pressure required to release the caliper piston.

Figure 9 shows 5 tests using different brake

calipers. Each caliper piston is released using the air-

gun method and pneumatic power. In the first test, it

takes 25 seconds to use an air-gun and 5 seconds to

use pneumatic power to release the same brake

caliper piston. In the 2nd, 3rd and 5th tests the brake

caliper piston could not be released using the air-gun

method. By using pneumatic power the 2nd, 3rd and

5th tests were release at 10, 8 and 10 seconds. It takes

longer to release the same brake caliper pistons that

can be released using an air-gun than using pneumatic

force. The longer time it takes to release the caliper

piston using the air-gun is due to the length of time it

takes to reach the same pressure using pneumatic

power. This is due to a leak during the intake of air

into the caliper housing.

Figure 10 shows the pressure required to release

5 different caliper pistons. In the first test both with

the air-gun and with pneumatic power the brake

caliper pistons were released at 50 psi. In tests 2, 3

and 5 the piston could not be released using an air-

gun. By using pneumatic power the piston can be

released at a pressure of 200, 180 and 200 psi. This

means that in tests 2,3 and 5 the piston is released at

a pressure above the operating pressure of the

compressor usually in the maintenance workshop,

Caption:

1. frame 11. Manometer

2. Compressor 12. Caliper hose

3. Compressor filter 13. Vise drive screw

4. compressor switch 14. Drain

5. Support wheel 15. Permanent vise

6. Compressor bolt 16. Moving vise

7. Power cable 17. Ring

8. Quick Qulper 18. clamp

9. Nepple 19. Hinge, bolt, nut

10. Savety valve 20. Close up

A Design of a Tool of Car Brake Piston Caliper Remover with Pneumatic Power

449

which is 120 psi. In the 4th test the piston can be

released using either an air-gun or pneumatic power.

Piston releases at 75 psi.

Figure 9: Comparison graph of the time required to remove

the calipers piston.

The use of the tip of air-gun and a rag to release

the caliper piston cannot be fully used because the air

pressure is not all compressed, as a result of the tip of

air-gun being less precise with the brake caliper holes.

Also the duster cannot function as a good seal.

Besides the leakage when putting the air into the

caliper housing, it is also due to the compressor

pressure in the workshop which is usually only 120

psi so it is not enough to push the piston out of the

piston housing

Figure 10: Graph of the pressure ratio required to release

the calipers piston.

4 CONCLUSIONS

In terms of workability, based on the design test

results that have been made, the brake caliper piston

remover device using pneumatic power is able to

remove all brake calipers in an average of 7.6

seconds. Compared to removing the brake piston

using an air-gun from 5 times of testing, it only

released twice in an average of 27.5 seconds and

could not be released three times.

In terms of safety, release the caliper piston using

pneumatic power is safer because there is no risk of

tool damage.

ACKNOWLEDGEMENTS

The author expresses his deepest gratitude to the

Ministry of Education and Culture of the Republic of

Indonesia, Bali State Polytechnic for the financial

support. P3M Bali State Polytechnic is also grateful

for the administrative support so that this research can

be carried out. We also thank PT Kharisma Sentosa

Daihatsu for the opportunity to test the tool.

REFERENCES

Toyota Service Training 2007, PT. Toyota Astra Motor.

Chassis Group Step 2

Daryanto. 2009. Car Maintenance Techniques. PT. Bumi

Aksara. Jakarta.

Adhi, A. 2021. Complete Car Disc Brake Components and

Their Functions. Available at: https : // www.

otomaniac. com. Retrieved February 24, 2021

Setiawan., W. 2014. Practical Techniques for Caring and

Repairing Automated Vehicles. Graphic Library CV.

Bandung

Achmad, Z. 2006. Design, PT. Aditya Refika. Bandung

Juhana., Ohan, Suratama., M. 2000. Drawing Mechanical

Engineering with ISO Standards. Graphic Library CV.

Bandung.

Nur. R., Sayuti, M, A. 2017. Design of Industrial

Machinery. CV Budi Utama. Yogyakarta.

Hush, Knneth S. 2009. Principles of Engineering Design..

Erlangga. Jakarta

Buchari, M., Z. Sentinuwo, S. R., Lantang, O. A. 2015.

Design of 3-Dimensional Vodeo Animation for Motor

Vehicle Testing Mechanisms at the Department of

Transportation, Culture, Tourism. Communication and

Information. Informatics Engineering E-journal. 6(1) :

2301-8364

Sumbodo, W. Setiadi, R. Poedjiono, S. 2017. Pneumatics

and Hydraulics. CV. Main Budi. Yogyakarta

Roslin. 2018. What is the normal pressure of a refrigerator

compressor. Available at: https: //www. google.

com/search? q=berap+ normal+ pressure+ refrigerant+

compressor+ refrigerator&oq =chrome. Accessed

February 26, 2021

Azmi. 2018. Utilization of Refrigerator Waste and Freon

Tubes to Make Compressors. Mechanical Engineering

E-journal

Setia A, Arif. 2014. Improved effectiveness of the front

brake piston removal process of Fortuner using SST

BPT-FC. National science and technology seminar.

UNMUH Jakarta.

0

10

20

30

40

12345

Time(Sec)

Nomor of test

pnuematik air-gun

0

50

100

150

200

250

12345

Pressure (psi)

Nomor of test

pneumatik air-gun

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

450