Tofu Industrial Wastewater Treatment using Local Microorganisms

Bio Activator from Banana Weevil

Yuli Patmawati

Department of Chemical Engineering, Polytechnic State of Samarinda, East Kalimantan, Indonesia

Keywords: Banana Weevil, Bio Activator, Bioremediation, Local Microorganisms, Tofu.

Abstract: The tofu industry is one of the industries that produce organic waste in solid and liquid waste. The amount of

organic liquid waste produced, which is directly disposed of into water bodies without going through good

processing, will significantly impact the aquatic environmental ecosystem. The biological treatment of tofu

industrial wastewater by utilizing microorganisms on bioremediation process using local microorganisms bio

activator of banana weevil is one of the easy, cheap, and fast wastewater treatment. This study aims to evaluate

the effect of bio activator volume and the bioremediation process time on Chemical Oxygen Demand (COD)

content, Total Suspended Solid (TSS) content, and pH of tofu industrial wastewater in Samarinda City. Firstly,

add 30, 60, 90, and 120 ml bio activator volume into 500 ml of tofu industrial wastewater and then

bioremedied for two days, four days, and six days. At the end of the process, the remaining COD, TSS, and

pH of tofu industrial wastewater were analyzed. The best results of COD content were 6050 mg/L, TSS

content was 290 mg/L and pH was 8.16 were obtained at bioremediation process time of 6 days and 120 ml

bio activator volume of local microorganisms from banana weevil addition.

1 INTRODUCTION

Liquid wastewater in the tofu industries comes from

the soaking process from the washing process, and

tofu printing which contains high protein and can be

decomposed immediately. The liquid wastewater of

the tofu industry contains organic matter such as

proteins, amino acids, fats, oils, and carbohydrates in

the form of suspended and dissolved solids in very

large amounts, around 40% to 60%. It also contains

gases such as oxygen (O

2

), hydrogen (H

2

O),

hydrogen sulfide (H

2

S), ammonia (NH

3

), carbon

dioxide (CO

2

), and methane (CH

4

) derived from the

decomposition of organic matter in wastewater

(Pohan, 2008).

Approximately 80 home industries are spread

across several sub-districts in Samarinda City area

(such as on Lumba-lumba Street, Selili Village-

Samarinda Ilir District, Tanjung Street 3D, Sungai

Pinang Luar District, etc.) that produces 10 tons

soybeans/month. One tofu home industry can produce

20 m

3

/day of liquid wastewater (Ananda et al., 2018).

Tofu industrial wastewater in Samarinda contains

Biological Oxygen Demand (BOD), Chemical

Oxygen Demand (COD), Total Suspended Solid

(TSS), and oil/fat respectively as follows 4,583 mg/L,

7,050 mg/L, 4,743 mg/L, and 26 mg/L with pH is

around 4-5 (Bangun, et al., 2013).

A large number of tofu home industries cause a

large amount of organic waste to be produced and will

have a significant impact on aquatic environmental

ecosystems if it’s directly disposed of into drainage

or water bodies without prior processing. One of the

easy, cheap, and fast waste treatments is the

biological treatment of the tofu waste treatment

process by utilizing microorganisms (Sari, et al.,

2017).

Bioremediation process using local

microorganisms of banana weevil could be applied

because it produces many microorganisms that

decompose organic compounds. The decomposer

microbes are located outside and inside the banana

weevil (Kesumaningwati, 2013). Banana weevil also

contains high enough nutrients with a complete

composition, namely: carbohydrates (66%), protein

(4.35%), starch (45.4%), water and important

minerals so that they can be used as raw materials for

the formation of local microorganisms

(Kesumaningwati, 2013).

The microorganisms found in banana weevil

include Bacillus sp., Aeromonas sp., Aspergillus

nigger, Azospirillium, Azetobacter and cellulosic

458

Patmawati, Y.

Tofu Industrial Wastewater Treatment using Local Microorganisms Bio Activator from Banana Weevil.

DOI: 10.5220/0010947500003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 458-461

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

microbes. These microbes usually decompose

organic matter (Budiyani et al., 2016). In Yuliansari's

(2020) study on the isolation of bacteria in local

microorganisms of the banana weevil, it was

explained that banana weevil consisted of

pseudomonas sp bacteria which are decomposers.

The research related to the bioremediation process

was carried out by Prabhakar et al., 2021 using

indigenous bacterial isolate Nesterenkonia

lacusekhoensis for removal of azo dyes: A low‐cost

eco-friendly approach for bioremediation of textile

wastewaters. The results of this research showed that

the bacterium not just decolorized dye mixture at high

pH in the presence of indigenous microorganisms of

wastewater but also decreased Chemical Oxygen

Demand (COD). It gradually lowered the pH of the

wastewater from an initial 11.0 to 8.4 during the

treatment.

The other research was conducted by (Erguven et

al., 2017), which has studied “The ability of

Phanerochaete chrysosporium (ME446) on chemical

oxygen demand remediation in submerged culture

medium supplemented with malathion insecticide”.

According to this research results, the fungus has

achieved 99.6, 98.8 and 98.7 % COD reduction at

concentration of 50, 100 and 150 ppm respectively

the end of the 15 days. It’s showed that P.

chrysosporium could be an effective bioremediation

tool for treating malathion-containing wastewater.

Another study has done by Salgueiro et al., 2016

used Chlorella Vulgaris microalga as a potential

candidate for removing the phosphorous and organic

matter from wastewater by bioremediation process.

From this study, obtained microalgae were able to

remove the phosphorus concentration by more than

99%. On the other hand, the chemical oxygen demand

was reduced by 71%. After nine days of cultivation,

the biomass concentration increased from 0.05 to 0.57

g/L wastewater.

This research aims to evaluate the effect of

bioactivator volume and the bioremediation process

time on Chemical Oxygen Demand (COD) content,

Total Suspended Solid (TSS) content, and pH of tofu

industrial wastewater in Samarinda City.

2 METHODOLOGY

The local microorganisms bio activator from banana

weevil is made through anaerobic fermentation by

mixing 2 kg of the mashed banana weevil with 100

grams of diluted brown sugar and 2 liters of a washing

water reservoir for ten days. Bioremediation process

is carried out by adding 30, 60, 90, and 120 ml bio

activator volume into 500 ml of tofu industrial

wastewater (obtained from tofu home industry on

Tanjung Street 3D, Sungai Pinang Luar District

Samarinda City, East Kalimantan) and then

bioremediated for 2, 4 and 6 days. After the anaerobic

bioremediation process, they are followed by an

aerobic process using an aerator to circulate the

oxygen with 4 L/min flow rate of air for 2, 4 and 6

days bioremediation process time. At the end of the

process, the remaining Chemical Oxygen Demand

(COD) content, Total Suspended Solid (TSS) content,

and pH of tofu industrial wastewater were analyzed.

3 RESULT AND DISCUSSION

Before the bioremediation process, the characteristics

of tofu industrial wastewater consist of the parameters

of COD, TSS, and pH, respectively as follows 14,300

mg/L, 4,170 mg/L and 3.4. The results of the anaerob-

aerob bioremediation process of tofu industrial

wastewater using local microorganisms bio activator

from banana weevil at different bio activator volume

and bioremediation process time can be seen in Table

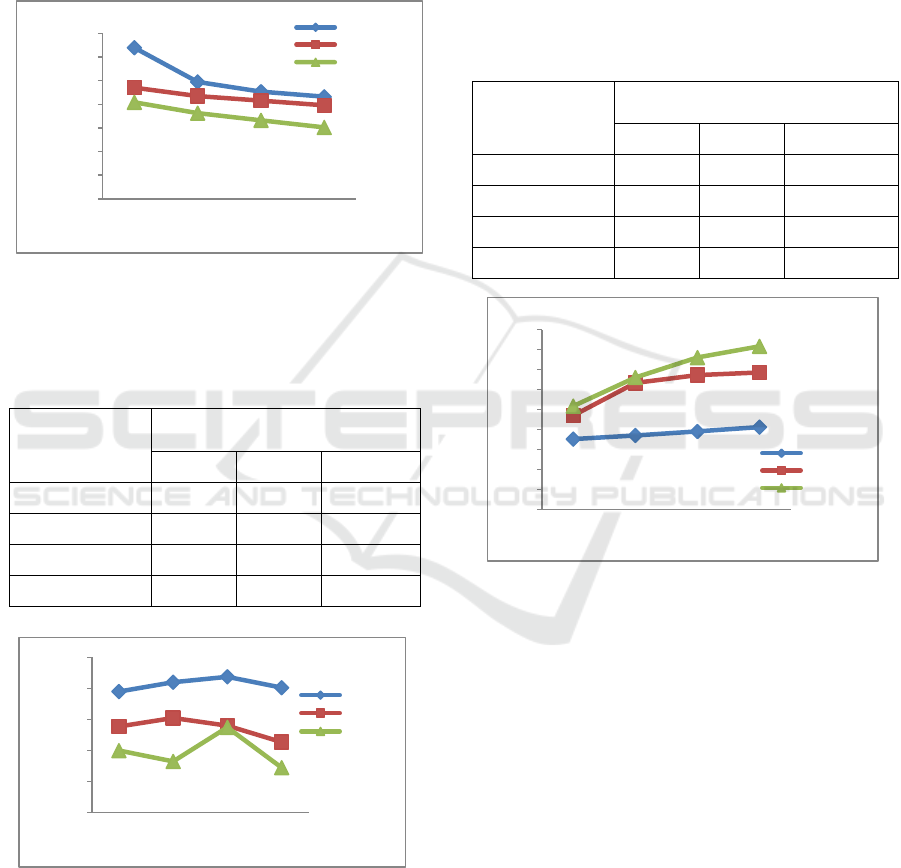

1 and Figure 1 for COD content, Table 2 and Figure 2

for TSS content and the last Table 3 and Figure 3 for

pH.

Table 1: Chemical oxygen demand analysis after

bioremediation process.

Bio activator

volume, ml

COD content at bioremediation

p

rocess time, m

g

/L

2 days 4 days 6 days

30 12,800 9,410 8,170

60 9,900 8,700 7,260

90 9,070 8,310 6,650

120 8,646.67 7,916.67 6,050

The addition of the local microorganisms bio

activator volume of the banana weevil caused the

COD content to decrease quite well, as can be seen in

Table 1 and Figure 1. The larger addition of bio

activator volume in tofu industrial wastewater, the

smaller COD content obtained. It’s due to the larger

the bio activator volume of addition in tofu industrial

wastewater, the larger number of bacteria that could

be broken down organic substances in tofu industrial

wastewater. Figure 1 also shows the correlation

between bioremediation process time and COD

content. The longer the bioremediation process, the

lower COD obtained. It’s due to the longer the

bioremediation process, more organic matter that can

Tofu Industrial Wastewater Treatment using Local Microorganisms Bio Activator from Banana Weevil

459

be decomposed by decomposing bacteria so that

organic matter settle and are oxidized (Haerun et al.,

2018). Based on Figure 1, it can be seen that the best

results of COD content were 6050 mg/L with a

decreased percentage of COD content of 57.69%

were obtained in addition of 120 ml volume local

microorganisms bio activator with a bioremediation

process time of 6 days.

Figure 1: The effect of the local microorganisms bio

activator volume and bioremediation process time on COD

content.

Table 2: Total suspended solid analysis after

bioremediation process.

Bio activator

volume, ml

TSS content at bioremediation

p

rocess time, m

g

/L

2 days 4 days 6 days

30 780 555 400

60 840 610 330

90 875 560 550

120 805 455 290

Figure 2: The effect of the local microorganisms bio

activator volume and bioremediation process time on TSS

content.

Figure 2 showed that over time in bioremediation

process, the TSS content tends to decrease because in

this phase, the microorganisms were in a phase of

rapid bacterial growth, which results in a decrease in

the TSS content. In this study, the larger addition of

bioactivator volume in tofu industrial wastewater, it

did not show consistency in the TSS content. It’s due

to the larger the bio activator volume of addition, and

it did not necessarily indicate the larger the number of

microbes. Based on Figure 2, the best results of 290

mg/L TSS content were obtained at 120 mL bio

activator volume addition with a bioremediation

process time of 6 days.

Table 3: pH analysis after bioremediation process.

Bio activator

volume, ml

pH at bioremediation process time,

m

g

/L

2 days 4 days 6 days

30 3.52 4.7 5.17

60 3.7 6.33 6.6

90 3.9 6.72 7.6

120 4.12 6.85 8.16

Figure 3: The effect of the local microorganisms bio

activator volume and bioremediation process time on pH.

Based on Figure 3, the pH in each treatment of

tofu industrial wastewater increased during the

bioremediation process. The larger the bio activator

volume of the banana weevil added onto tofu

industrial wastewater and the longer the

bioremediation process time, the pH is closer to the

neutral. The increase in pH from acidic to neutral in

tofu industrial wastewater was thought to be due to

the activity of microorganisms both in the tofu

industrial wastewater or in the local microorganisms

bio activator of the banana weevil. Microorganisms

experiencing a growth phase, increasing the number

of groups as a result of the decomposition of sugar

into ethanol so that the pH increased. The best results

of pH were obtained at the addition of 30 ml, 60 ml,

90 ml and 120 ml bioactivator volume, respectively

as follows 5.17; 6.6 ; 7.6 and 8.16.

0

2000

4000

6000

8000

10000

12000

14000

30 60 90 120

COD Content. mg/L

Bioactivator Volume, mL

days 2

days 4

days 6

0

200

400

600

800

1000

30 60 90 120

TSS content, mg/L

Bioactivator Volume, mL

2 days

4 days

6 days

0

1

2

3

4

5

6

7

8

9

30 60 90 120

pH

Bioactivator Volume, mL

2 days

4 days

6 days

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

460

4 CONCLUSIONS

1. The results of this study showed that the COD

content decreased and the pH of tofu industrial

wastewater closer to a neutral value as the volume

addition of local microorganisms bio activator

became larger. However, it did not show a

consistent increase/decrease in TSS content.

2. The COD and TSS content decrease as the longer

of bioremediation process time.

3. The best results of COD content were 6050 mg/L,

the TSS content was 290 mg/L, and pH was 8.16

were obtained at a bioremediation process time of

6 days with the addition of 120 ml volume of local

microorganisms bio activator from banana

weevil.

ACKNOWLEDGEMENTS

The author would like to acknowledge the Center for

Research and Community Service at Polytechnic

State of Samarinda, which has provided funding for

this research as well as to the Chemical Engineering

Laboratory of Polytechnic State of Samarinda as a

place for the research to be carried out.

REFERENCES

Ananda, E. R., Irawan, D., Wahyuni, S. D., Kusuma, A. D.,

Buadiarto, J., & Hidayat, R. (2018). Pembuatan Alat

Pengolah Limbah Cair Dengan Metode

Elektrokoagulasi Untuk Industri Tahu Kota Samarinda.

JTT (Jurnal Teknologi Terpadu), 6(1), 54.

https://doi.org/10.32487/jtt.v6i1.439.

Bangun, A. R., Aminah, S., Hutahaean, R. A., & Ritonga,

M. Y. (2013). Pengaruh Kadar Air, Dosis Dan Lama

Pengendapan Koagulan Serbuk Biji Kelor Sebagai

Alternatif Pengolahan Limbah Cair Industri Tahu.

Jurnal Teknik Kimia USU, 2(1), 7–13.

https://doi.org/10.32734/jtk.v2i1.1420.

Budiyani, N., Soniari N., & Sutari, N. (2016). Analisis

Kualitas Larutan Mikroorganisme Lokal (Mol)

Bonggol Pisang. E-Jurnal Agroekoteknologi Tropika

(Journal of Tropical Agroecotechnology), 5(1), 63–72.

Erguven, G. O., Yildirim, N., & Adar, E. (2017). The ability

of Phanerochaete chrysosporium (ME446) on chemical

oxygen demand remediation in submerged culture

medium supplemented with malathion insecticide.

Desalination and Water Treatment, 94, 231–235.

https://doi.org/10.5004/dwt.2017.21556.

Haerun, R., Mallongi, A., & Natsir, M. F. (2018). Efisiensi

Pengolahan Limbah Cair Industri Tahu Menggunakan

Biofilter Sistem Upflow Dengan Penambahan Efektif

Mikroorganisme. JURNAL NASIONAL ILMU

KESEHATAN (JNIK) Volume 1. Edisi 2 2018, 1, 1–11.

Kesumaningwati, R. (2013). Penggunaan Mol Bonggol

Pisang (Musa paradisiaca) Sebagai Dekomposer Untuk

Pengomposan Tandan Kosong Kelapa Sawit. Persepsi

Masyarakat Terhadap Perawatan Ortodontik Yang

Dilakukan Oleh Pihak Non Profesional, 53(9), 1689–

1699.

Pohan, N. (2008). Pengolahan Limbah Cair Tahu dengan

Proses Biofilter Aerobik. Skripsi. Medan: Sekolah

Pascasarjana Universitas Sumatera Utara.

Prabhakar, Y., Gupta, A., & Kaushik, A. (2021). Using

indigenous bacterial isolate Nesterenkonia

lacusekhoensis for removal of azo dyes: A low-cost

ecofriendly approach for bioremediation of textile

wastewaters. Environment, Development and

Sustainability, 0123456789.

https://doi.org/10.1007/s10668-021-01661-0.

Salgueiro, J. L., Pérez, L., Maceiras, R., Sánchez, A., &

Cancela, A. (2016). Bioremediation of wastewater

using chlorella vulgaris microalgae: Phosphorus and

organic matter. International Journal of Environmental

Research, 10(3), 465–470.

https://doi.org/10.22059/ijer.2016.58766.

Sari, K. L., Zulfikar Ali As, H. (2017). Penurunan Kadar

BOD, COD DAN TSS Pada Limbah Tahu

Menggunakan Effective Microorganism-4 (EM4)

Secara Aerob. 4(1).

Tofu Industrial Wastewater Treatment using Local Microorganisms Bio Activator from Banana Weevil

461