Effect of Type of Activator and Ultrasonic Waves on the Chemical

Activation Process on the Characteristics of Activated Charcoal from

the Rubber Fruit Shell (Hevea Brasiliensis)

Sirajuddin, Harjanto and Inzirah

Department of Chemical Engeneering, Polytechnic State of Samarinda, East Kalimantan, Indonesia

Keywords: Activation, Shell for Rubber, Ultrasonic Waves, Type of Activator, Activated Carbon.

Abstract: The potential for rubber fruit shells in East Kalimantan Province in 2019 was 95.327 tons/year. Rubber fruit

shells contain 48.64% cellulose. The content of cellulose are organic compounds that can be used as activated

carbon. The purpose of this study was to determine the effect of the type of chemical activator with the help

of ultrasonic waves on the characteristics of activated carbon according to the SNI 06-3730-1995 standard.

Activated carbon is obtained through 4 stages, namely preparation of raw materials, carbonation at 500°C

for1 hour, chemical activation with variations in the types of activators H

3

PO

4

, H2SO4, KOH and Na2CO3

with a concentration of 10% b/v for 4 hours, then physically activated at a temperature of 600°C for 1 hour.

The best results were obtained in the variation of H

3

PO

4

activator types with I

2

absorption results of

771.3263mg/g, water content of 0.5745%, ash content of 0.4045%, and 9.8200% volatile matter content.

1 INTRODUCTION

Rubber shells are biomass-dense waste and currently

have no commercial value (Harun et al., 2010). The

solid waste is left and not utilized so that it is bad for

the environment (Ngah and Hanafiah, 2008). The

content of cellulose is relatively large so that rubber

shells are very potential to be processed into useful

and high-value activated carbon-making raw

materials (Ioannidou and Zabaniotou, 2007).

Activated carbon can be produced materials

containing cellulose such as wood, hazelnut shells,

peat, coal, bamboo and others. Activated carbon is

widely used in both large and small industries as

coagulation (Stephenson and sheldon, 1996),

chemical oxidation (Salem and El-Maazawi, 2008),

photo catalysts (Bukallah et al., 2008),

electrochemistry (Somasekhar et al., 2001), and

membrane separation (Porter and McKay, 1997).

Pyrolysis processes as one of the most reliable

thermochemical processes for the conversion of solid

waste raw materials into high-value activated carbon

(Somasekhar et al., 2001). Pyrolysis is usually done

in the absence of oxygen depending on the

temperature applied and the rate of heating (Chen et

al., 2018). However, slow pyrolysis often causes the

resulting activated carbon to contain a lot of oxygen

and affects a variety of applications and takes more

than 6 hours (Lee at al., 2017). Current methods that

can produce activated carbon that have high quality

use ultrasonic waves in the chemical activation

process. Ultrasonic is a process that aims to increase

mass transfer through the utilization of sound waves

to produce pressure fluctuations. The cavitation effect

of the wave can increase the temperature thus

accelerating the catalyst into the activated carbon to

remove impurities so that the activated carbon pores

enlarge and cause the active carbon absorption to

increase. Research on the utilization of ultasonic

waves on the manufacture of activated carbon has

been conducted using waste tobacco rods, waste tea,

wood and cotton rods (Ji.Y et al., 2007),(Wang et al.,

2009). The results showed that the process of making

activated carbon using ultrasonic waves in the

chemical activation process had advantages over

conventional pyrolysis methods such as low energy

use, easier to control, and shorter time.

In this study, variations in the type of activator

(H

3

PO

4,

H

2

SO

4,

Na

2

CO

3

and KOH) with a

concentration of 10% b/v each with the process of

carbonization using furnaces at a temperature of

500

o

C for 1 hour. The process of chemical activation

using the help of ultrasonic waves for 4 hours as well

as adding the physics activation process at a

temperature of 600℃ for 1 hour so that activated

carbon is obtained in accordance with the standard.

Sirajuddin, ., Harjanto, . and Inzirah, .

Effect of Type of Activator and Ultrasonic Waves on the Chemical Activation Process on the Characteristics of Activated Charcoal from the Rubber Fruit Shell (Hevea Brasiliensis).

DOI: 10.5220/0010950200003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 633-637

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

633

The purpose of the study was to find out the types

of activators namely H

3

PO

4,

H

2

SO

4,

KOH and

Na

2

CO

3

with the help of ultrasonic waves against the

activated carbon characteristics of rubber fruit shells

resulting in activated carbon that conforms to the

standard of activated carbon quality that refers to the

standard (SNI, 1995).

2 METHODOLOGY

Tools used in this study include furnace, ultrasonic,

oven, desiccator, balance sheet analytics, hotplate and

magnetic stirrer, screening 100 mesh, 120 mesh,

crusher, porcelain cup, mortar stamper, beaker cup

clamp, spatula, funnel, rubber bulp, clamps and

statives, aquades bottle, buret 25 mL, drop pipette, 5

mL, and 10 mL measuring pipette, 10 mL, and 50 mL

volume pipette, erlenmeyer 100 mL and 250 mL,

pumpkin measuring 100 mL and 1000 mL, while the

material used rubber fruit shell, aquadest, solution

(H

3

PO

4,

H

2

SO

4,

Na

2

CO

3

and KOH) 10%, iodine

solution 0.1021 N, thiosulfat sodium solution 0.1033

N, amylum indicator 1% b/v, whatman filter paper

No.42, universal indicator.

The research began from the stage of collecting

dry old rubber shell raw materials. Dry old rubber

shell are cleaned and carbonated at a temperature of

500

o

C for 1 hour. Furthermore activated carbon is

screened and activated with H

3

PO

4,

H

2

SO

4,

Na

2

CO

3

and KOH with a concentration of 10% b/v each with

the help of ultrasonic waves with a frequency of 47

kHz for 4 hours and adds the physics activation

process at 60℃ temperatures for 1 hour. The Analysis

stage is conducted based on standards (SNI, 1995),

covering moisture content (ASTM D-3173), ash

content (ASTM D-3174), volatile matter (ASTM D-

3175), and iodine numbers (SNI 06-3730-1995).

Figure 1: Picture of the raw material and the resulting

activated carbon.

3 RESULT AND DISCUSSION

The purpose of the study was to determine the

influence of activator types H

3

PO

4,

H

2

SO

4,

KOH and

Na

2

CO

3

with the help of ultrasonic waves against the

activated carbon characteristics of rubber fruit shells

resulting in activated carbon that conforms to the

activated carbon quality standards that refer to the

standard (SNI, 1995).

In this study the raw material used is a rubber fruit

shell. The raw material of rubber fruit shells has a

yield of 24.17%, proximate analysis of water content

values of 4.73%, ash levels of 2.65%, volatile matter

levels of 17.62%, and iodine absorption of

469.72mg/g. Rubber fruit shells were previously

carbonated using furnaces with a temperature of

500℃ for 1 hour so that it becomes charcoal. After

the carbonization process is obtained charcoal is then

chemically activated for 4 hours with the help of

ultrasonic waves and without ultrasonic waves. Then

the activation of physics using the help of a furnace

with a temperature of 600℃ for 1 hour. Furthermore,

activated carbon obtained by proximate analysis

includes water content values, ash levels, volatile

matter, and analyzed the absorption of activated

carbon against iodine.

3.1 Moisture Content

Determination of water content aims to find out the

hygroscopic properties of activated charcoal and to

find out the water content in the cavity or cover the

pores in activated charcoal shown with a high water

content in charcoal. Low water content indicates many

cavities or gaps that can be occupied by adsorbate so

that the absorbs process will take place properly.

Figure 2: Graph of the relationship of activator types with

water content.

Based on the graph in figure 1 it can be seen that

the moisture content of activated carbon samples for

each type of activator substance has different values.

The type of activator substance is influential in the

activation process of activated carbon. The presence

of activator agents in relation to water content is as a

hydrating agent. How it works as a binder of water

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

634

molecules contained in raw materials so as to enlarge

the pores of activated carbon and expand the surface

of absorption. Low levels of activated carbon water

indicate the success of chemical activator agents in

binding to water molecules contained in the material

as well as the release of the free water content and

bound water contained in raw materials during the

carbonation process (Ahmed and Theydan, 2013).

Based on the analysis data to find out the effect of

the addition of ultrasonic wave assistance in the

analysis of water content, chemical activation is

carried out with the same treatment without the help

of ultrasonic waves. Based on figure 1 it is known that

the water content is better obtained from activation

with the help of ultrasonic.

On the graph can be seen the lowest percent water

content value obtained by activator substance H

2

SO

4

with and without the help of ultrasonic waves,

respectively, which is 0.32% and 0.42 percent

respectively. The highest water content obtained

KOH activator substances with and without the help

of ultrasonic waves, respectively, is 1.65% and 1.62%

respectively. Based on the data, it is known that acid

activators H

2

SO

4

are more able to dehydrate water

bound in activated carbon when compared to

activators H

3

PO

4

, Na

2

CO

3

and KOH.

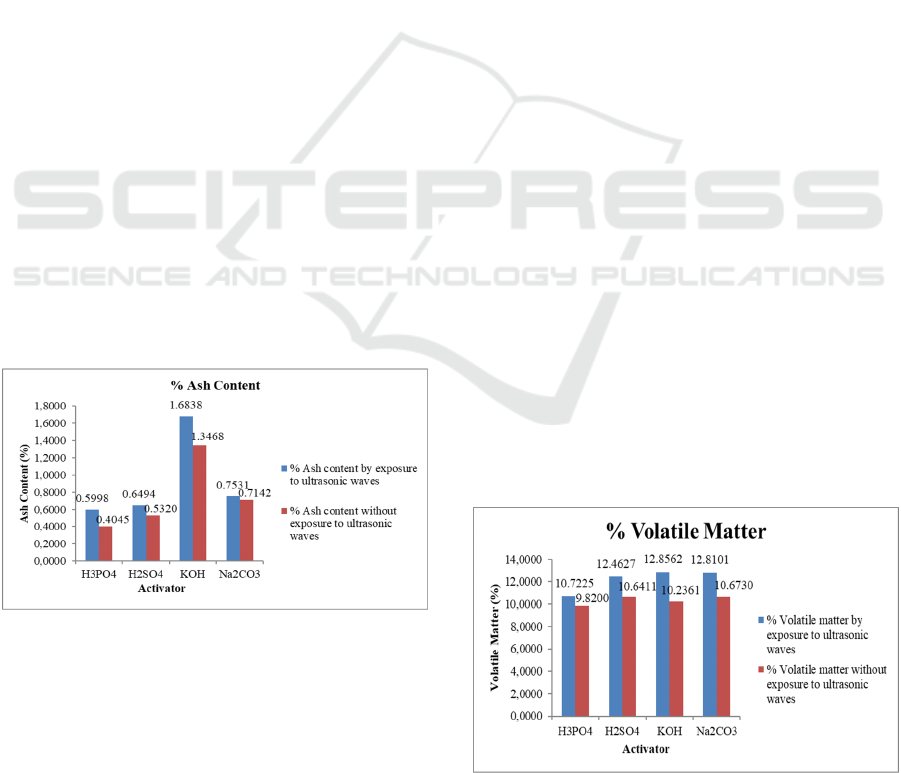

3.2 Ash Content

Determination of ash levels aims to find out the content

of metal oxides in activated carbon. Ash levels are

assumed to be residual minerals left behind from the

rubber shell carbonization process. The results of the

analysis of ash level can be seen at figure 3.

Figure 3: Graph of the relationship of type of activator with

ash levels.

Based on the graph in figure 3 it can be seen that

the ash levels of activated carbon in each type of

activator substance have different values. Activated

carbon consists of layers stacked against each other

that make up pores. Where in the pores of charcoal

there are usually impurities in the form of inorganic

minerals and metal oxides that cover the pores. Ash

levels can occur due to the formation of mineral salts

during the process of authoring which when

continued will form fine particles of the mineral salts.

The use of activator materials can dissolve substances

still present in charcoal such as hydrocarbons, ash,

nitrogen and sulfur. The process of washing on

chemical activation can dissolve metals or minerals

present in activated charcoal so that the ash levels

become relatively lower.

Based on the analysis data to find out the effect

of adding ultrasonic wave assistance to the analysis

of ash levels, chemical activation is carried out with

the same treatment without the help of ultrasonic

waves. Based on the graph in figure 3 it is known that

ash levels are better obtained from activation with the

help of ultrasonic for each type of activator. This is

because ultrasonic waves cause mechanical effects

that can increase reaction speed (Kentish and

Ashokkumar, 2011)

On the graph can be seen the lowest percent ash

levels obtained by activator substance H

3

PO

4

with and

without the help of ultrasonic waves of 0.40% and

0.60% respectively. The highest ash content obtained

KOH activator substances with and without the help of

ultrasonic waves by 1.35% and 1.68% respectively.

Based on the analysis data it is known that acid

activator H

3

PO

4

has the lowest ash levels when

compared to activators H

2

SO

4,

Na

2

CO3

and KOH.

3.3 Volatile Matter

The level of vaporizing substances in carbon is the

amount of substance that evaporates from a material,

which evaporates consisting of flammable gases, such

as hydrogen and carbon monoxide and a small portion

of vapor that can condense. The results of the analysis

of vaporized substance levels using activators

H

3

PO

4,

H

2

SO

4,

KOH and Na

2

CO3 can be seen in

figure 4.

Figure 4: Graph of the relationship of activator types with

volatile matter levels.

Effect of Type of Activator and Ultrasonic Waves on the Chemical Activation Process on the Characteristics of Activated Charcoal from the

Rubber Fruit Shell (Hevea Brasiliensis)

635

Based on the graph in figure 4 it can be seen that

the volatile matter levels of the activated carbon

sample for each type of activator substance have

different values. The high levels of the resulting

flying substance indicate that the surface of activated

charcoal is still covered by non-carbon compounds,

affecting its absorption. The levels of volatile matter

obtained are better with the help of ultrasonic waves

for each type of activator. Ultrasonic waves give rise

to cavitation energy that can increase pores more in

activated charcoal (Hamdaoui et al., 2008).

On the graph can be seen the lowest volatile

matter levels obtained by activator substance H

3

PO

4

with and without the help of ultrasonic waves of

9.82% and 10.72%, respectively. Volatile matter

levels is highest obtained by activator substance

Na

2

CO

3

with and without the help of ultrasonic waves

by 10.67% and 12.81% respectively. Based on the

data of the analysis it is known that acid activator

H

3

PO

4

has the lowest volatile matter levels when

compared to other activators. This suggests that acid

activators are more able to reduce non-carbon

compounds attached to the surface of activated

carbon when compared to activators H

2

SO

4,

Na

2

CO

3

and KOH.

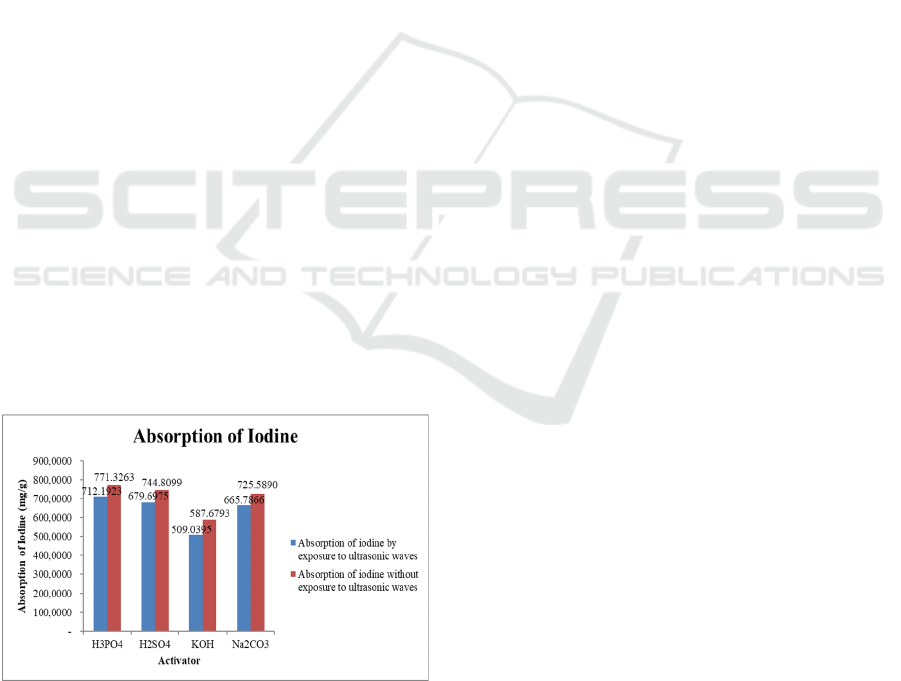

3.4 Absorption of Iodine

The absorption of Iodine solution in activated carbon

is a parameter to determine the ability of activated

charcoal to absorb molecules of small molecular

weight and substances in the liquid phase. The

determination of activated carbon adsorption power

to iodine has a correlation with the surface area of

activated charcoal. The results of the analysis for

iodine absorption are shown in figure 5 below.

Figure 5: Graphic of activator type relationship with iodine

absorption.

Based on figure 4 it can be seen that the iodine

absorption of the activated carbon sample for each

type of activator has different values. The activated

carbon absorption of rubber fruit shells activated with

and without the help of ultrasonic waves in the study

ranged from 575.57mg/g-755.13mg/g and

498.45mg/g-697.38mg/g, respectively. Activated

carbon with the highest iodine absorption capability

is activated carbon with activation using activator

H

3

PO

4

with iodine absorption of 755.13mg/g. A

solution of phosphoric acid (H

3

PO

4

)

as anactivator

also affects the surface area because it is a strong acid

capable of lifting hydrocarbon compounds or

impurities causing the formation of pores on the

surface of carbon. Iodine absorption is affected by

water content, ash content and volatile matter of

activated carbon. The lower the water content, the

water molecules that fill the activated carbon pores

the less so that, the pores are not closed and the ability

of activated carbon in absorbing iodine will be better.

Volatile matter the presence of volatile substances

attached to the surface of activated carbon affects

iodine power. The lower the levels of volatile

substances that cover activated carbon so that

activated carbon can absorb iodine more effectively.

Low water content will increase the effectiveness of

activated carbon in absorbing iodine. The addition of

ultrasonic wave assistance to the absorption of iodine

absorption is better obtained from activation with

ultrasonic assistance for each type of activator.

ultrasonic waves gives the effect of the phenomenon

of cavitation, namely the formation of small bubbles

in the intermediate medium, which over time the

bubbles that get bigger and burst and release large

forces that can be used for chemical processes in

ultrasonic. It is this bubble breakdown that then forms

more pores within the activated carbon, resulting in a

greater surface area of activated

carbon. (Ahmed and

Theydan, 2013),

Hamdaoui et al., 2008)

. This

increased surface area results in increasing adsorption

capabilities from activated carbon. The increasing

adsorption capability of activated carbon, the better

the quality of the activated carbon.

4 CONCLUSIONS

In this study it can be concluded that all types of

activators used for the manufacture of activated

carbon from rubber shells meet the standards (SNI.,

1995) for proximate analysis while for iodine

absorption only H

3

PO

4

activators meet technical

activated charcoal quality standards namely H

3

PO

4

activators at 0.57% moisture content, 0.40% ash

content, 9.82% volatile matter and iodine absorption

of 755.13mg/g. Exposure of ultrasonic waves at the

time of chemical activation for all types of activators

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

636

indicates the effect of ultrasonic waves seen from the

comparative data of proximate analysis and iodine

absorption in each activator with and without the help

of ultrasonic waves.

The use of rubber shells as raw material for

making activated charcoal can reduce environmental

pollution and increase the economic value of rubber

shell.

ACKNOWLEDGEMENTS

The author would like to acknowledge the Center for

Research and Community Service at Polytechnic

State of Samarinda which has provided funding for

this research as well as to the Chemical Engineering

Laboratory of Polytechnic State of Samarinda as a

place for the research to be carried out.

REFERENCES

Bukallah, S.B., M.A. Rauf and S.S. Ashraf, 2007.

Photocatalytic decoration of coomass ie brilliant blue

with titanium oxide. Dyes Pig., 2: 353-356.

Chen, H., Chen, Z., Zhao, G., Zhang, Z., Xu, C., Liu, Y.,

Chen, J., Zhuang, L., Haya, T., Wang, X., 2018.

Enhanced adsorption of U(VI) and241Am (III) from

wastewater using Ca/Al layered double

hydroxide@carbon nanotube composites. J. Hazard.

Mater. 347, 67–77,

Cheung, C.W., J.F. Porter and G. McKay, 1997. Sorption

kinetics for the removal of copper and zinc from

effluents using bone char. Sep. Purf. Technol., 19: 55-

64.

Hamdaoui, O., Chiha, M. and Naffrenchoux, E.,

“Ultrasound assisted removal of malachite green from

aqueous solution by dead pine needles”, Ultrasonic

Sonochemistry, Vol.15, No. 5, (2008), 799-807.

Ioannidou, O. and A. Zabaniotou, 2007. Agricultural

residues as precursors for activated carbon production-

A review. Renewable Sustainable Energy Rev., 11:

1966-2005.

Kentish, S. and Ashokkumar, M., “Physical and chemical

effects of ultrasound”, Ultrasound Technology for Food

and Bioprocessing, (2011), 1-12.

Lee, J., Kim, K.H., Kwon, E.E., 2017. Biochar as a catalyst.

Renew. Sustain. Energy Rev. 77,

MJ Ahmed, SK Theydan, Micro-porous activated carbon

from Siris seed pods by microwave-induced KOH

activation for metronidazole adsorption, J. Anal. Pirole

app., 99 (2013) 101-109

Mouni, L., Belkhiri, L., Bollinger, J.C., Bouzaza, A.,

Assadi, A., Tirri, A., Dahmoune, F., Madani, K.,

Remini, H., 2018. Removal of methylene blue from

aqueous solutions by adsorption on Kaolin: kinetic and

equilibrium studies. Appl. Clay Sci. 153, 38–45.

Noorfidza Yub Harun, MT Afzal, Mohd Tazli Azizan,

Rubber Seed Kernel TGA Analysis, International

Journal of Engineering, 3 (2010) 639-641

Rao, N.N., K.M. Somasekhar, S.N. Kaul and L.

Szpyrkowicz, 2001. Electochemical oxidation of

tannery waste water. J. Chem. Technol. Biotechnol., 76:

1124-1131.

Salem, I.A. and M. El-Maazawi, 2000. Kinetics and

mechanism of color removal of methylene blue with

hydrogen peroxide catalyzed by some supported

alumina surfaces. Chemosphere, 41: 1173-1180.

SNI. (1995). Technical Activated Charcoal (06-3730th–

19th ed.).

Sodeifian, G., Ali, S., 2018. Utilization of ultrasonic-

assisted RESOLV (US-RESOLV) with polymeric

stabilizers for production of amiodinearone

hydrochloride nanoparticles: optimization of the

process. Chem. Eng. Res. Des. 142, 268–284,

Stephenson, R.J. and J.B. Sheldon, 1996. Coagulation and

precipitation of mechanical pueffluent. 1. Removal of

carbon and turbidity. Water Res., 30: 781-792.

T. Wang, S. Tan, C. Liang, Preparation and characterization

of activated carbon from wood via microwave-induced

ZnCl2 activation, Carbon. 47 (2009) 1880-1883.

Wan Ngah, W.S. and M.A.K.M. Hanafiah,

2008.Adsorption of copper on rubber (Hevea

brasiliensis) leaf powder: Kinetic, equilibrium and

thermodynamic studies. Biochem. Eng. J., 39: 521-530.

Y. Ji, T. Li, L. Zhu, X. Wang, Q. Lin, Preparation of

activated carbon by microwave heating activated KOH,

Appl. Surfing. science. 254 (2007) 506-512.

Effect of Type of Activator and Ultrasonic Waves on the Chemical Activation Process on the Characteristics of Activated Charcoal from the

Rubber Fruit Shell (Hevea Brasiliensis)

637