Study the Effect Diffuser Length and Degree

to Horizontal Wind Turbine

Fatahul Arifin

1,2

, R. D. Kusumanto

2,3

, Yohandri Bow

2

, Rusdianasari

2

, Ahmad Taqwa

2

,

Afries Susandi

2

, Yusuf Dewantoro Herlambang

4

, Min Wen Wang

5

and Carlos R. Sitompul

3

1

Department of Mechanical Engineering, Politeknik Negeri Sriwijaya, Jalan Srijaya Negara, Palembang, Indonesia

2

Department of Renewable Energy Engineering, Politeknik Negeri Sriwijaya, Jalan Srijaya Negara, Palembang, Indonesia

3

Department of Electrical, Politeknik Negeri Sriwijaya, Jalan Srijaya Negara, Palembang, Indonesia

4

Department of Mechanical Engineering, Politeknik Negeri Semarang, Jl. Prof. Sudarto, Semarang, Indonesia

5

Department of Mechanical Engineering, National Kaohsiung University Science and Technology,

No. 415, Jiangong Rd., Kaohsiung, Taiwan

mwwang@nkust.edu.tw, afriessusandi@gmail.com

Keywords: Diffuser, Wind Energy, Length, Angle, Power.

Abstract: Nowadays, Diffuser Augmented Wind Turbine (DAWT) has been used to improve wind turbine use in a low

wind speed area by directing the wind speed. The technology is the pressure difference between inside and

outside of DAWT, which is occurred. So, it increases the velocity of wind, and the power enhance as well.

The software ANSYS was conducted to examine this study. The variation diffuser length (L) and angle were

in range 0.5D-1.25D and the range 4

o

-16

o

. Experiments were also carried out under 3 conditions: wind turbine

only, DAWT (L=0.5D) at 8

o

diffuser angle, and DAWT at 12

o

diffuser angle to observe voltage and electric

current, power generated, and rotor rotation. The results show that installing a diffuser with a certain length

and angle increases the power generated by 1.6-2.1 times higher than without a diffuser.

1 INTRODUCTION

The national and global energy problem is the rising

cost of fossil energy; coal, gas, and oil. Naturally,

energy prices will continue to increase, along with the

accumulative scarcity of non-renewable energy

sources and the rising demand for energy (

Ploetz,et. al

2016).

Presently Wind turbine industry is becoming one

alternative for energy production. In the financial

aspect, the wind industry shows very intense

progress, which is expected to participate in fossil

fuel energy generation this decade.

On the topic of the importance of the turbine blade

in its energy generation, lots of research has been

developed to make the blade more efficient. Nicolette

Arnalda Cencelli optimized a designed blade. In this

research, some airfoils. They created the airfoil by

using Xfoil software for different sections, then

theresult showed new airfoils could increase the

output power (

Mohammadi, et. al 2016). The influence

of the air density variation with altitude on the

performance of a small horizontal axis wind turbine

blade was studied by Pourajabian et al. (2014). Sharifi

and Nobari studied in optimization of pitch angle

along with wind turbine blades, based on a coding of

aerodynamic. They obtained a coding of aerodynamic

that could accurately predict the aerodynamics of

horizontal axis wind turbines (Sharifi and Nobari.

2013). The type of vertical turbine strongly

influenced by the swept area. The swept area affected

drag and lift force, and then they applied dimensional

engineering to obtain the optimal performance of the

wind turbine (Yuliandi, et. al. 2021).

Diffuser Augmented Wind Turbine (DAWT) can

be a favorable solution to solve those problems by

adding a shroud to the turbine in increasing the wind

turbine power output. The diffuser's working

principle is to result in a pressure difference between

the inside and outside the diffuser. This technology

has developed in the early 1950s. These theoretical

results were presented on small-scale wind turbines

with shroud and increased power by 4% compared to

lacking shroud in wind turbines (

Putra, et. al 2018). The

wind velocity profile around the diffuser, which

Arifin, F., Kusumanto, R., Bow, Y., Rusdianasari, ., Taqwa, A., Susandi, A., Herlambang, Y., Wang, M. and Sitompul, C.

Study the Effect Diffuser Length and Degree to Horizontal Wind Turbine.

DOI: 10.5220/0010951000003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 681-685

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

681

previously modified the diffuser in the form of

additional inlet and flange curvature, had been

studied by Putra, et. al. (2018).

Many researchers used the software to solve the

design of the wind turbine. Susandi et al. studied

Diffuser Parameters in the Performance of Horizontal

Axis Wind Turbine using Computational Fluid

Dynamics using Ansys software (Susandi et.al.

2021). Garmana et al. used the solid work software to

investigate the combination of Savonius and Darrieus

Turbine with differences in the Number of Savonius

Turbine Blades (Germana et. al. 2021). Paranjape et

al. (2020) studied the various designs, experiments,

and CFD simulations of wind deflectors on Savonius

wind turbine type using CFD software then concluded

that installing a flat-plate deflector in the Savonius

turbine can increase the power coefficient by 27%.

This study aims to analyze the performance of a

horizontal axis wind turbine by applying variations in

the length and angle of the diffuser.

2 METHODOLOGY

The design of the diffuser geometry is illustrated in

Figure 1 (a). The design HAW turbine with and

without a diffuser is shown in Figure 1 (b). The wind

blows to the turbine entering through a diffuser with

a smaller inlet cross-section than the outlet section.

Formula 1 shows the calculation of the amount of

power generated in the diffuser based on density,

area, and velocity (

Bussel. (2007).

𝑃=

1

2

𝐴

𝜌 𝑣

𝐶𝑝

(1)

where P is power (W), ρ is air density (1.225 kg/m3),

A is turbine swept area (m2), and v is wind velocity

(m/s)3, and Cp is power coefficient. In this paper, Cp

= 0.59 is the maximum value theoretically for the wind

turbine, which is called the Betz Limit (Spera 2009).

Figure 1: (a) Design Diffuser (b) Design of wind turbine

with and without Diffuser.

The generator, measuring equipment, panel boxes,

lights, sensors, and electrical installation is placed in

the tower. The output of the wind generator is

measured with voltage and current metering.

Furthermore, the wind generator output is converted

from Alternating Current (AC) to Direct Current (DC)

through the Wind Charge Controller. The output of the

Wind Charge Controller will supply the battery and

LED lights. The voltage and current of the LED lamps

are measured using a meter (power data logger). RPM

on the wind generator is calculated using an RPM

sensor that reads the rotation of the wind generator.

The design of a horizontal axis wind turbine equipped

with measuring tools can be seen in Figure 2.

Figure 2: Structural Design of DHAW Turbine.

The study steps are reviewing the literature, running

CFD simulation, designing and manufacturing wind

turbines, finally collecting data. The flowchart of the

study can be seen in Fig 3.

3 RESULT AND DISCUSSION

3.1 CFD Analysis Results

According to the result of running CFD, Ansys

applied in this research with a magnitude velocity of

5 m/s. Then, the diffuser angles were changed 4

o

, 8

o

,

12

o

, 16

o,

and the L = 0.5D to 2.5D while D = 1200

mm. The result is shown that the optimum diffuser

angles are 8

o

to 16

o,

and the length is 0.25D to 1.25D

(Susandi, et al 2021).

As shown in Figure 4, the wind enters the diffuser

with the high velocity and then out the diffuser with

low velocity. The best profile velocity contour can be

obtained at a higher diffuser angle, and then the

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

682

diffuser length gave an excellent performance from

0.5D until 1.25D.

Figure 3. Research Flow chart.

Figure 4: CFD of Ansys Fluent Simulation for Diffuser

Length 0.5D to 1.25D angle 4

o

to 16

o

.

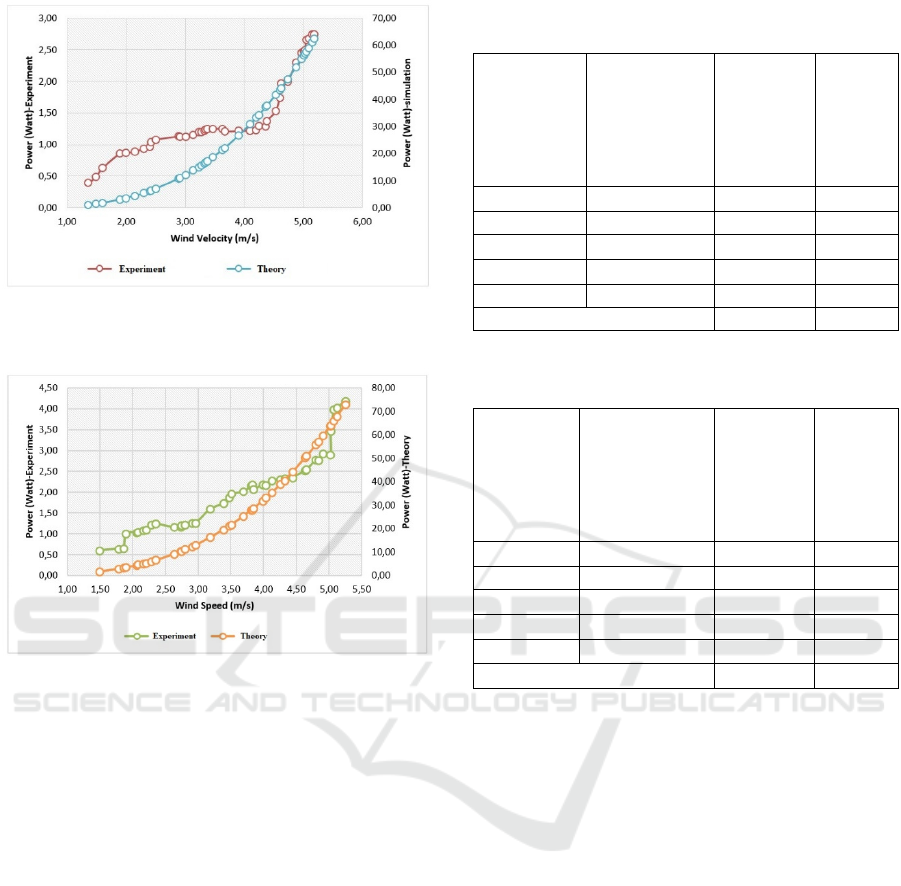

3.2 Comparison of the Power

Generated in Theory and

Experiment Results

Based on theories and experiments, it is possible to

compare the power generated in the turbine without

and with a diffuser. The values for calculating turbine

power in theory and their comparison with turbine

power experimentally can be seen in Figs. 5 – 7. It can

be observed that by theory, there is an increase in

power (P

Augmented

) in the wind speed range of 1-5.5 m/s

for each diffuser angle compared to the power of a

horizontal axis wind turbine without a diffuser is 1.3-

1.4 times. A diffuser with a length of L=0.5D and an

angle of 8

o

can simulate an increase in turbine power

of about 1.3 times.

Meanwhile, a diffuser with a length of L=0.5D and

an angle of 12° can increase power up to 1.4 times.

When compared to the power generated by theory and

experiment in Figs. 5 -7 shows that the power

generated by the approach is greater than the power

induced experimentally. For example, at a wind speed

of 3.5 m/s DAWT 12

o

, the Theory is 21.74 Watts,

while the Experiment is 1.96 Watts.

The power generated in this theory is the available

power from the wind turbine. The electrical power

induced experimentally will be smaller than the

available wind power. This is influenced by many

factors, including the friction factor in the turbine,

transmission efficiency, and generator efficiency,

which causes the power generated by the system to be

lower. It can be seen in Figures. 5 - 7 that the wind

speed is directly proportional to the electrical power

produced, meaning that the increase in wind speed

and the electrical power generated are increasing.

Figure 5: Power Generate by HAWT (Without Diffuser)

Theory and Experiment.

Study the Effect Diffuser Length and Degree to Horizontal Wind Turbine

683

Figure 6: Power Generate by Wind Turbine with Diffuser

8

o

.

Figure 7: Power Generate by Wind Turbine with Diffuser

12

o

.

This is inseparable from the rotation. The increase

in rotation of the turbine is in line with the increase in

rotation of the generator. When the generator shaft

starts to rotate, there will be a change in flux in the

stator. Eventually, this flux change will produce a

particular voltage and current whose value is directly

proportional to the wind speed. This is also by the

Betz Limit, which states that the maximum energy

that can be converted is about 59% of the total kinetic

energy of the wind and is commonly known as the

power coefficient (Cp).

As can be seen in Table 1, the average

enhancement of Turbine power theory is 1.3 for

DAWT 8

o

and 1.4 for DWAT 12

o

higher than without

diffuser, while in Table 2, the moderate enhancement

of Turbine power experiment is 1.602 for DAWT 8

o

and 2.163 for DWAT 12

o

higher than without diffuser.

Table 1: The average enhancement of turbine power in

theory.

Wind Speed

(m/s)

Turbine

power without

diffuser

(Watt)

Turbine

Power

with

DAWT 8

o

(Watt)

Turbine

Power

with

DAWT

12

o

(Watt)

1.0-2.5 2.011 4.042

4.334

2.6-3.5 10.894 14.739 14.561

3.6-4.5 23.375 32.829

33.479

4.6-5.5 43.950 55.139

60.834

Average 20.057 26.687 28.302

(P

diffuser

/P

tanpa diffuser)

Average 1.3 1.4

Table 2: The average enhancement of turbine power in

experiment.

Wind

Speed

(m/s)

Turbine power

without

diffuser (Watt)

Turbine

Power

with

DAWT 8

o

(Watt)

Turbine

Power

with

DAWT

12

o

(Watt)

1.0-2.5 0.460 0.816 0.961

2.6-3.5 0.783 1.188 1.442

3.6-4.5 1.069 1.335 2.201

4.6-5.5 1.300 2.449 3.210

Average 0.903 1.447 1.954

(P

diffuser

/P

tanpa diffuser

)

Average

1.602 2.163

4 CONCLUSIONS

The simulation results show that the length of the

diffuser gives a better effect on the performance of

the wind turbine, namely the length of the diffuser L

is 0.25D to 1.25D, and the angle of the diffuser angle

is 8

o

to 16

o

.

The experiments were carried out on 3 wind

turbine conditions, namely on wind turbines only

(without using a diffuser), a diffuser with a diffuser

length of L=0.5D, and a diffuser angle of 8°, and a

diffuser with a diffuser length of L=0.5D and a

diffuser angle. 12°. Experimental data and graphs

show the wind speed dramatically affects the voltage

and electric current generated. If the wind speed is

higher, voltage and electric current generated will be

higher too. Be higher. The effect of installing a

diffuser with a certain length and angle can increase

the power generated by the wind turbine. The ratio of

enhancement of the power of a diffuser wind turbine

to a wind turbine without a diffuser is 1.6-2.1 times.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

684

ACKNOWLEDGEMENTS

This work was supported by Minister of Education,

Culture, Research and Technology Republic

Indonesia, Politeknik Negeri Sriwijaya. The financial

support is acknowledged,

REFERENCES

Bussel, G.J.W.V. (2007). The science of making more

torque from wind: diffuser experiments and theory

revisited, J. Phys.: Conference Series 75, pp. 1-12.

Garmana, A., Arifin, F., Rusdianasari, (2021). "CFD

Analysis for Combination Savonius and Darrieus

Turbine with Differences in the Number of Savonius

Turbine Blades. International Conference on Artificial

Intelligence and Mechatronics Systems (AIMS), pp. 1-

5, DOI: 10.1109/AIMS52415.2021.9466009.

Mohammadi, M., Mohammadi, A., Mohammadi, M.,

Minaei, H. N. (2016). Optimization of Small Scale

Wind Turbine Blades for Low-Speed Conditions, Vol.

4, No. 2,, Journal of Clean Energy Technologies, 2016,

DOI: 10.7763/JOCET.2016.V4.268.

Paranjape, A. D., Bajaj, A. S., Palanganda, S. T., Parikh, R.,

Nayak, R., Radhakrishnan, J., (2020). Computational

Analysis of High Lift Generating Airfoils for Diffuser

Augmented Wind Turbines, Wind Energy Science-

Discussions, EAWE.

Ploetz, R., Rusdianasari, Eviliana. E. (2016). Renewable

Energy: Advantages and Disadvantages, Proceeding

Forum in Research, Science, and Technology (FIRST)

Pourrajabian, A., Mirzaei, M., Ebrahimi, R., Wood, D.,

(2014) “Effect of air density on the performance of a

small wind turbine blade A case study in Iran,” Journal

of Wind Engineering and Industrial Aerodynamics,

Vol. 126.

Putra, F. Q., Rifai, D., Suryopratomo, K., Budiarto, R.,

(2018). Multilevel Diffuser Augmented for Horizontal

Axis Wind Turbine, In proceeding of E3S Web of

Conferences (42), 01001, 2018.

Sharifi, A. and Nobari. M. R. H., (2013). Prediction of

optimum section pitch angle distribution along wind

turbine blades, Energy Conversion and Management,

vol. 67.

Susandi, A., Arifin, F., Kusumanto, RD., (2021). Theory of

Diffuser Parameters in the Performance of Horizontal

Axis Wind Turbine using Computational Fluid

Dynamics, Vol. 63, Issue 06, Journal Technology

Reports of Kansai University,

Spera, D.A. (2009). Wind Turbine Technology-

Fundamental Concepts of Wind Turbine Engineering,

Second Edition. ASME Press, USA

Yuliandi, R. B., Rusdianasari, Dewi, T., (2018).

Comparison of blade dimension design of a vertical

wind turbine applied in low wind speed, In proceeding

of E3S Web of Conference EDP Science, Vol. 68.

.

Study the Effect Diffuser Length and Degree to Horizontal Wind Turbine

685