The Effect of Pump House Layout and Compressor Tube Volume

Variations on Efficiency of 2 Inch Hydraulic Ram Pump Performance

Rafael Mado, Alexius Leonardo Johanis, Frans Mangngi

and Irene Budayawati

State Polytechnic of Kupang, Adi Sucipto, Kupang, Indonesia

Keywords: Effect, Hydraulic Ram Pump, Layout, Compressor Tube, Efficiency, Performance, Work.

Abstract: Water is an absolute necessity for the survival of life, because without water there will be no life in this

world. The need for water is not a problem for areas that are close to water sources or are located under

springs. In accordance with the laws of physics, water will naturally flow from a high place to a lower place,

but in reality the land surface is not always flat, there are hilly and bumpy areas. If the area is higher than

the water source, it will be difficult to get a sustainable water supply. One of the efforts to fulfill water

needs in locations that are higher than the springs is by using a water pump. The types of pumps commonly

used today are electric motor-powered water pumps or oil-fueled water pumps (diesel or gasoline). For

urban areas, the need for fuel is not a problem. Meanwhile, in rural areas, fuel is very scarce and very

expensive. The problem is the layout/position of the Input-Compressor-Waste (IKL) is still considered the

same as the position of the Input-Waste-Compressor (ILK) and has no effect on the efficiency of the

hydraulic ram pump performance. The purpose of this research is to design and make a hydraulic ram pump

and to test those two positions (IKL and ILK) with variations in the volume of the compressor tube, so that

it can be seen which position is the most ideal to produce the most optimal and efficient hydraulic ram pump

performance. The methods used were a site survey, literary study, action method by designing a hydraulic

ram pump installation and observing the effect of layout/position (IKL) and (ILK) with variations in the

volume of compressor tube (6350 ml, 7230 ml and 8114 ml) and 3 variations of waste valve weight (130

grams, 190 grams and 357 grams) through the performance of the hydraulic ram pump. The result of this

study indicated that the largest pumping discharge occurred in the compressor tube volume of 2800 ml and

5500 ml with a waste valve weight of 130 grams, 190 grams and 357 grams, which were 0.081 liters per

second and 0.080 liters per second in the ILK hydraulic ram pump arrangement. The smallest average waste

discharge occurred in the ILK hydraulic ram pump arrangement, which was 0.311 liters per second while in

the IKL hydraulic ram pump arrangement it was 0.327 liters per second. The greatest efficiency according

to D'Aubuisson and Rankine occurred in the compressor tube volume of 2800 ml, which increased from

120% and 75% in the IKL position to 127% and 81% in the ILK position.

1 INTRODUCTION

Water is an absolute necessity for survival because

without water there will be no life in this world.

Areas that are close to water sources or are located

under springs, water needs are not a problem but

areas that are located higher than water sources are

difficult to get a continuous supply of water.

One of the efforts to fulfill water needs,

especially in areas that are higher than the springs, is

by using a water pump. The type of water pump that

is commonly used today is a water pump powered

by an electric motors or an engines water pump by

using fuel which is difficult to obtain in rural areas.

The solution is to use a hydraulic ram pump because

the hydraulic pump works without the use of fuel or

electricity.

The problem is that the placement of the pump

house and compressor tube as well as the waste

valve after the intake pipe, both with Input-

Compressor-Waste (IKL) and Input-Waste-

Compressor (ILK) arrangements are considered to

have no effect on the performance of the hydraulic

ram pump.

Various studies have been carried out as an effort

to increase the efficiency of hydraulic ram pump

performance, such as Muhamad Jafri, et al

conducted a study entitled Analisis Pompa Hidram

Mado, R., Johanis, A., Mangngi, F. and Budayawati, I.

The Effect of Pump House Layout and Compressor Tube Volume Variations on Efficiency of 2 Inch Hydraulic Ram Pump Performance.

DOI: 10.5220/0010960700003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1127-1132

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1127

2” dengan Sistim Kompresi Seri, where the results

showed that variations in air tube volume and

pumping vertical lift height affect the efficiency of

the hydraulic ram pump, the highest efficiency for

series compression is 62.29%.

Eko Sulistiawan, et al, also conducted a study

entitled Pengaruh Volume Tabung Udara dan Beban

Katub Limbah Terhadap Efisiensi Unjuk Kerja

Pompa Hidram. The results showed that the highest

efficiency was 40.36% at valve load of 450 grams

and volume of air tube 8100 ml, the lowest

efficiency was 23.00% at valve load of 1220 grams

and volume of air tube 5300 ml.

I Gede Bawa Susama and Rudy Susanto,

conducted a research entitled Peningkatan Kinerja

Pompa Hidram (3 inch) Berdasarkan Posisi Tabung

Kompresor dengan Saluran Keluar di bawah

Tabung Kompresor. The results showed that the

largest output discharge occurred at a height of 4.1

m and increased from 0.112 liters per second in IKL

arrangement to 0.121 liters per second or 121 ml per

second in ILK arrangement. The maximum head

occurred at a 4.1 meter plunge and increased from

12 meters in the IKL arrangement to 16 meters in

the ILK arrangement. Meanwhile, the greatest

efficiency occurred at a height of 3.1 meters and

increased from 2.357% in the IKL arrangement to

2.618% in the ILK arrangement.

Research conducted by Toto Citramurti, et al.,

with the title Pengaruh Beban Katub Buang di

Bawah 450 gram Menggunakan Panjang Input 4

meter dan Ketinggian Output 10 meterTerhadap

Kinerja Pompa Hydraulic ram showed that the

highest efficiency of the hydraulic ram pump

according to D'Aubuisson is 31.48% with a waste

valve weight of 50 grams and the length of the inlet

pipe is 4 m.

Another research conducted previously by Rafael

Mado, et al with the title Design of a 1½” Hydraulic

Ram Pump and Testing the Effect of Variation in

The Launch Pipe Slope Angle Against the

Performance showed that the efficiency of the

hydraulic ram pump decreases with the increasing of

angle of inlet pipe, or the smaller the slope angle of

the inlet pipe, the efficiency of the hydraulic ram

pump increases. Based on previous research, this

research determined the lowest slope angle of the

inlet pipe, which is 5

o

so that the inlet pipe will be

longer (17.24 m) with a height of 1.5 m of water fall.

Generally, research on hydraulic ram

pump is carried out in a limited laboratory, so what

differs from this research is the research is carried

out directly at the water source, the delivery valve

uses a unidirectional valve made of brass material 2

inches, the waste valve from a plastic pipe 2 inch

and compares IKL with ILK on the performance of

the hydraulic ram pump. Research conducted in the

field aims to make it easier to implement.

The main issue raised in this research is the use

of new and renewable energy in fullfil the needs of

clean water for rural communities, especially those

who have not been reached by electricity. The

results of this study are expected to solve the

problems mentioned above, so that the community

can take advantage of the natural resources that are

around them (river water), for the purposes of daily

life such as drinking water, watering plants and

feeding livestock. Thus the standard of living of the

people will be better.

2 RESEARCH METHOD

2.1 Design of 2 Inch Hydraulic Ram

Pump

The hydraulic ram pump is designed with an input

diameter of 2” or 5.075 cm, an output diameter of

1.27 cm, a compressor tube volume (2800 ml, 5500

ml, and 8200 ml), IKL and ILK arrangement, inlet

pipe tilt angle 50, water drop height 1, 5 m, lift

height 5 m. The hydraulic ram pump is made using 2

inch iron pipe (T-shock), 2 inch double nipple, 2

inch elbow, ½ inch elbow, 4 inch iron pipe, 5 mm

thick iron plate, 10 mm solid stainless, 40 mm ø

steel axle, plastic pipe (ø 4 inch, 2 inch dan ½ inch),

50x50 iron elbow, 5 mm thick rubber, bolts and

nuts. The results of the hydraulic ram pump design

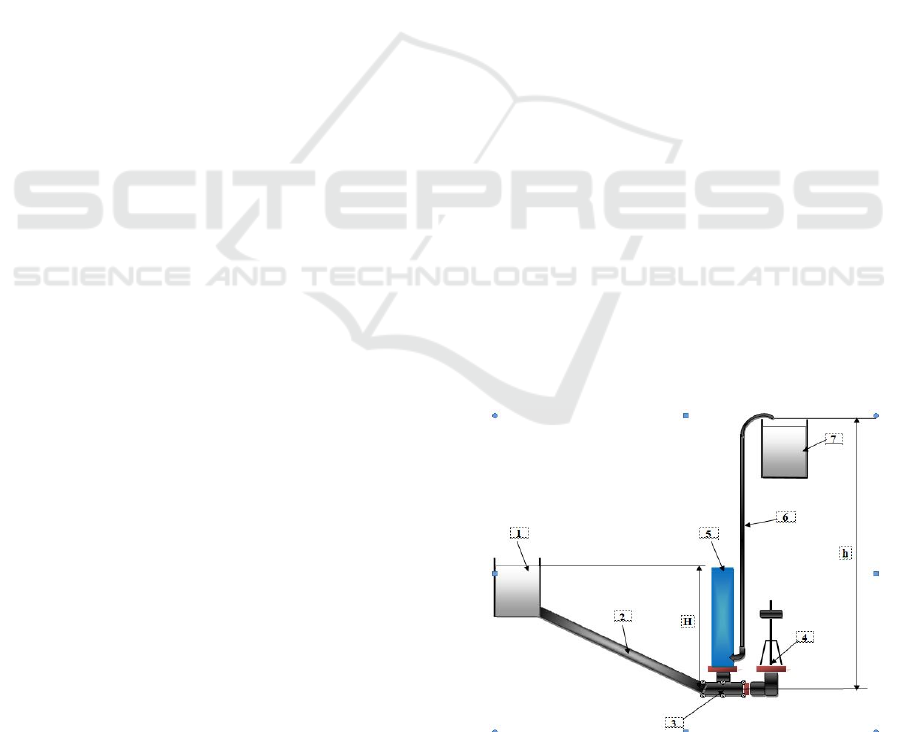

are as shown in Figures 1 and 2 below:

Figure 1: Hydraulic ram Pump Installation IKL

Arrangement.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1128

Figure 2: Hydraulic ram Pump Installation ILK

Arrangement.

Captions:

1. Reservoir/water source 5. Compressor Tube

2. Inlet pipe 6. Delivery pipe

3. Pump housing 7. Reservoir tank

4. Waste valve H = Plunge height

h = Lifting height

2.2 Research Flowchart

2.3 Data Collection Method

The method used is an experimental method with 9

independent variables, namely: water fall height (H)

1.5 m, lift height (h) 5 m with a slope of 21.720

following the contour of the soil and the length of

the exit pipe 13.60 m, the slope angle of the slide

pipe ( 50) with a pipe length of 17.24 m, pump inlet

water discharge (27-55 liters/minute), IKL position,

ILK position, compressor tube volume (2800 ml,

5500 ml, 8200 ml). While the 7 dependent variables

are: waste discharge (Q), inlet water pressure, outlet

pressure, pumping discharge (q), waste valve

weight, waste valve pulse and hydraulic ram pump

efficiency (calculated using equation 1).

Testing and data collection were carried out

directly at the location of the water source by

conditioned the height of the waterfall (H) 1.5 m and

measuring the water flow entering the pump with a

result of 180 liters / minute, while the minimum

water flow for the pump size 2 "is 27-55 liters /

minute. The test will be carried out 9 times

according to 3 variations in the volume of the

compressor tube (2800 ml, 5500 ml, 8200 ml) and 3

variations in the weight of the waste valve (130 g,

190 g, 357 g) both at the IKL and ILK positions. The

results were carefully recorded in the data table that

has been prepared.

The hydraulic ram pump test scheme is as shown

in Figure 3 below:

(a) IKL (b) ILK

Figure 3: Schematic of the hydraulic ram pump test

installation.

In testing process, the researchers used several

supporting equipments such as measuring cup,

buckets, tapes, PVC glue, machete, shovel, roller

The Effect of Pump House Layout and Compressor Tube Volume Variations on Efficiency of 2 Inch Hydraulic Ram Pump Performance

1129

meter, pressure gauges, water fittings, nylon ropes,

bamboo, pipe wrenches, stop watch. Data retrieval is

done by reading the pressure on the pump inlet pipe,

the pressure on the compressor tube and the outlet

pipe, measuring the pulsation of the waste valve,

measuring the waste discharge and pumping

discharge.

2.4 Data Processing Method

The data that has been collected in tabular form is

then made in graphical form to obtain the

relationship between variations in the volume of the

compressor tube, the weight of the waste valve and

the pulse of the waste valve to the pumping

discharge.

The efficiency of the hydraulic ram pump can be

calculated in two ways:

According to D’Aubuisson (Murni, 2016)

(1)

According to Rankine :

(2)

Whereas:

η = hydraulic ram pump efficiency (%)

q = result (m

3

/det.)

Q = waste (m

3

/det.)

h = head out (m)

H = head in (m)

3 RESULTS AND DISCUSSION

The test result data can be seen in Tables 1 and 2

below:

Table 1: IKL Position.

Table 2: ILK Position.

The results of the hydraulic ram pump test on the

layout of the pump house, IKL and ILK with 3

variations in the volume of the compressor tube and

3 variations in the weight of the waste valve, as

shown in tables 1 and 2 above. The relationship

between the volume of the compressor tube and the

pumping discharge on the layout of the pump

housing is presented in Figure 4. The position of the

compressor tube which is placed after the input and

the waste valve (ILK), gives a higher pumping

discharge result compared to the position of the

compressor tube which is placed between the input

and the waste valve (IKL). The volume of the

compressor tube also affects the pumping discharge.

The larger the volume of the compressor tube the

pumping discharge decreases, because the waste

discharge is getting bigger. This is contrary to the

results of research by Eko Sulistiawan, et al. [2]

which showed that the larger the volume of the

compressor tube, the higher the pumping discharge

and the higher the efficiency.

Comparison of the pumping discharge value with

the volume of the compressor tube on the layout of

the pump house/compressor tube as shown in Figure

4.

Figure 4: Comparison of the pumping discharge value

with the volume of the compressor tube on the layout of

the pump house/compressor tube.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1130

The effect of compressor tube volume on the waste

discharge and the location of the pump

house/compressor tube is presented in Figure 5. The

larger the volume of the compressor tube, the higher

the waste discharge and the lower the pumping

discharge. When viewed from the position of the

compressor tube which is placed after the input and

the waste valve (ILK), the result of the waste

discharge is smaller than the position of the

compressor tube which is placed between the input

and the waste valve (IKL).

Figure 5: Comparison of the value of the waste discharge

with the volume of the compressor tube on the layout of

the pump house/compressor tube.

The value of waste valve weight on pumping

discharge and waste discharge at the hydraulic ram

pump with the IKL and ILK arrangement is shown

in Figures 6 and 7. The position of the compressor

tube which is placed after the input and the waste

valve (ILK) shows the best pumping discharge

results and produces less waste compared to the

position of the compressor tube which is placed

between the input and exhaust valves (IKL).

Figure 6: Comparison of the pumping discharge value

with the weight of the waste valve on the layout of the

pump house/compressor tube.

In general, the waste valve weight 130 grams

(the smallest) produce most large pumping discharge

(0.081 liters/sec). This is in line with the results of

research by Toto Citramurti, et al., which showed

that the weight of the 50 gram waste valve (the

smallest) produced the largest pumping discharge

and the highest efficiency, which was 31.48%

(D'Aubuisson efficiency).

Figure 7: Comparison of the value of the waste discharge

with the weight of the waste valve on the layout of the

pump house/compressor tube.

The relationship of the waste valve pulse to the

pumping discharge at the hydraulic ram pump with

the composition of IKL and ILK is shown in Tables

1 and 2. The higher the number of pulses, the higher

the pumping discharge.

The efficiency of the hydraulic ram pump as a

comparison of the pumping discharge with the inlet

and effluent discharge as well as the comparison of

the volume of the compressor tube and the pumping

discharge for both the IKL and ILK arrangements

are presented in Figures 8 and 9.

Figure 8: Graph of the relationship between the volume of

the compressor tube on the efficiency of D'Aubuisson and

Rankine at the IKL position

The Effect of Pump House Layout and Compressor Tube Volume Variations on Efficiency of 2 Inch Hydraulic Ram Pump Performance

1131

Figure 9: Graph of the relationship between the volume of

the compressor tube on the efficiency of D'Aubuisson and

Rankine at the ILK position.

In general, the highest efficiency values

according to D'Aubuisson and Rankine were

obtained in the composition of the ILK hydraulic

ram pump and the three variations in the volume of

the compressor tube (2800 ml, 5500 ml and 8200

ml), they were 127% and 81% at the compressor

tube volume of 2800 ml, 124% and 79 % on the

compressor tube volume of 5500 ml, 124% and 78%

on the compressor tube volume of 8200 ml. The

highest efficiency in the IKL hydraulic ram pump

arrangement was only seen in the compressor tube

volume of 2800 ml, they were 120% and 75%.

This is in line with the research results of I Gede

Bawa Susana (2016), which showed that the highest

efficiency was also obtained from the ILK hydraulic

ram pump arrangement which increased from

2.357% in the (IKL) arrangement to 2.618% in the

ILK arrangement.

The efficiency value obtained according to

D'Aubuisson looks greater than 100%, both in the

IKL and ILK hydraulic ram pump arrangements.

This is due to the large amount of water entering the

pump, which is 180 liters/minute (measurement

results before testing). In addition, if the angle of

inclination of the inlet pipe is smaller (50) and

longer, the suction power and thrust and efficiency

of the hydraulic ram pump will be higher. Research

conducted by R. Sutanto (2019), also shows that the

smaller the plunge angle used, the greater the output

discharge produced; the greater the plunge angle, the

smaller the suction and thrust of the hydraulic ram

pump.

4 CONCLUSION

Based on the results of testing and data processing, it

can be concluded as follows:

a. The largest pumping discharge occurred in the

compressor tube volume of 2800 ml and 5500 ml

with a waste valve weight of 130 grams and 190

grams, namely 0.081 liters per second and 0.080

liters per second in the ILK hydraulic ram pump

arrangement.

b. The smallest average waste discharge occurs in

the ILK hydraulic ram pump arrangement, which

is 0.311 liters per second while in the IKL

arrangement it is 0.327 liters per second.

c. The greatest efficiency according to

D’Aubuisson and Rankine occurred in the

compressor tube volume of 2800 ml. Which

increased from 120% and 75% in the IKL

position to 127% and 81% in the ILK position.

REFERENCES

Muhamad Jafri, dkk (2017). Analisis Pompa Hidram 2

inchi dengan Sistim Kompresi Seri. Prosiding Seminar

Nasional Teknik FST-UNDANA.

Eko Sulistiawan, dkk (2013). Pengaruh Volume Tabung

Udara dan Beban Katub Limbah Terhadap Efisiensi

Unjuk Kerja Pompa Hidram. PROTON Vol. 5 No. 2.

I Gede Bawa Susama dan Rudy Susanto (2016).

Peningkatan Kinerja Pompa Hidram Berdasarkan

Posisi Tabung Kompresor dengan Saluran Keluar di

bawah Tabung Kompresor. Jurnal Dinamika Teknik

Mesin 6.

Toto Citramurti, dkk (2015). Pengaruh Beban Katub

Buang di Bawah 450 Gram Menggunakan Panjang

Input 4 Meter dan Ketinggian Output 10 Meter

Terhadap Kinerja Pompa Hidram. Widya Teknika

Vol. 23 No. 1.

Rafael Mado, dkk (2019). Design of a 1½” Hydraulic

Ram Pump and Testing the Effect of Variation in The

Launch Pipe Slope Angle Against the Performance.

Proceedings of the 1

st

International Converence on

Engineering, Science, and Commerce (ICESC).

Murni, dkk. Kaji Eksperimental Pengaruh Ketinggian

Permukaan Air Pompa Hidram Diameter Inlet ¾ inch

Dengan Sudut Kemiringan 15

0

Terhadap Kinerja

Pompa.

R. Sutanto, dkk (2019). Variasi Sudut Pipa Masukan

Terhadap Unjuk Kerja Pompa Hidram, Dinamika an

Teknik Mesin, 9 (1) (2019) 7 – 14Mesin, Jurnal

Keilmuan dan Terapan Teknik Mesin.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1132