The Optimization of Coal Supply for Planned PLTU in West

Kalimantan Province

Sartika

Department of Mining Engineering, Politeknik Negeri Ketapang, Dalong, Ketapang, Indonesia

Keywords: Optimization, Coal, PLTU, Linear Programming.

Abstract: Based on PLN's RUPTL, to improve the reliability of the electricity system in West Kalimantan, the

construction of non-fuel power plants such as the Parit Baru PLTU (FTP1 and FTP2) and the Pantai Kura-

Kura PLTU (FTP1). In West Kalimantan, coal has not been exploited and coal reserves have also not been

identified, so coal for PLTU must be supplied from other provinces. The effort to get the lowest overall coal

procurement costs for PLTU demands, a study on optimization of coal supply for PLTU plans in West

Kalimantan Province using the Linear Programming method. Linear Programming consists of objective

functions and constraint functions. The objective function informing the model is used to minimize the total

cost of procuring coal for power generation. While the constraint function is a linear relationship of the

decision variable that reflects the limited supply of coal. The constraint function is divided into two types

namely the constraint function from the supply and demand sides. The output is the distribution of coal from

the Coal Company to the planned PLTU with the lowest total procurement costs. The minimum cost of

procuring coal for PLTU demands is USD 2,565,963,000 in a year.

1 INTRODUCTION

Coal is an accumulation result of organic material

derived from plant residues that have through a

lithification process and become coal seams (Yonas,

2016). Based on the Handbook of Energy and

Economic Statistics of Indonesia, the amount of

Indonesia's coal reserves is 32 billion tons which are

spread on the Sumatra and Kalimantan islands. Coal

can be used in human life, such as power plant, iron

and steel industry, space heating, fuel for cement

production, fertilizer, paper mills, chemical, and

pharmaceutical industries. Most of the domestic coal

demand is currently used as a PLTU (Electric Steam

Power Plant) fuel to produce electricity. Coal PLTU

is the main source of electrical energy in Indonesia

because of a large number of coal resources and the

price is relatively cheaper than fuel oil.

Based on Government Regulation Number “PP

79 Tahun 2014” concerning the National Energy

Policy, the optimal primary energy mix target by

using primary energy sources for coal at least 30%,

natural gas at least 22%, petroleum less than 25%, and

EBT at least 23%. To support this achievement,

RUPTL stated the electricity development plan for

2015 until 2019 includes the development of power

plants, transmission networks, substations, and

distribution networks. The addition of new power

plants require for 5 years is 35 GW which is the PLTU

provides the largest contribution.

Based on the MP3EI document (Master Plan for

the Acceleration and Expansion of Indonesia's

Economic Development) the theme of the

development in Kalimantan Economic Corridor is as

a Center for Production and Processing of National

Energy and Mining Products. These economic

activities can be developed and become engines of

economic growth. West Kalimantan is one of the

provinces which is the center of development in the

corridor, so far most of the electricity supply in West

Kalimantan is sourced from oil fuel power plants.

Based on the RUPTL (Electricity Supply

Business Plan), at the end of 2015, the

interconnection between West Kalimantan and

Sarawak (Malaysia) began operations to reduce the

cost of production by replacing oil fuel power plants,

increasing the reliability of the West Kalimantan

system, and anticipating delays in the construction of

the PLTU project. Anticipate short-term power

shortages, the Pontianak 100 MW Mobile Power

Plant (MPP) was built. MPP can be mobilized if the

power from the PLTU is sufficient.

Sartika, .

The Optimization of Coal Supply for Planned PLTU in West Kalimantan Province.

DOI: 10.5220/0010964000003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1293-1298

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1293

The reliability of the electricity system in West

Kalimantan is enhanced through the construction of

non-oil fuel plants such as the Parit Baru PLTU

(FTP1 and FTP2) and the Kura-Kura Beach PLTU

(FTP1). It’s interconnected to the Equator system.

Meanwhile, to reduce the cost of production in other

subsystems, by build small-scale PLTUs such as

Sintang PLTU and Ketapang PLTU. But West

Kalimantan has not exploited coal and coal reserves

have also not been identified, so coal for PLTU must

be supplied from other provinces. To obtain the

lowest overall coal procurement costs for the demand

of PLTU while ensuring the continuity of electricity

supply, it is necessary to study the optimization of

coal supply for PLTU using the Linear Programming

method (Mitra & Avittathur).

2 METHOD

Solving problems using Linear Programming

required a model consisting of objective functions

and constraint functions. The objective function is to

minimize coal procurement costs with supporting

variables including unit costs of coal production and

transportation. While the constraint function consists

of the demand function obtained from the calculation

of coal demand from each PLTU and the supply

function obtained from coal production for each type.

These are steps to obtain coal distribution for

PLTU with the optimum cost.

1. Calculate the coal demand of PLTU.

2. Find the calorie value and coal reserves of each

company that is obtained from the Ministry of

Energy and Mineral Resources and the

Indonesian Coal Book.

3. Find the quality of coal that will be used in each

PLTU.

4. Design the objective function as well as the

constraint function.

5. Solve optimization problems using WinQ SB

software.

3 LINEAR PROGRAMMING

Linear programming is a mathematical application

technique in determining problem-solving to

maximize or minimize something that is limited by

certain constraints, it also known as optimization

techniques (Indah & Sari, 2019). Linear

programming can be used as a deterministic tool,

which means that a parameter model is assumed with

certainty. Generally, the characteristics of Linear

programming problems are the objective function in

the form of minimization or maximization, and all

constraints are in the form of equations or inequalities

and the decision variable is not negative.

The following are the steps in Linear

Programming modeling:

1. Determine unknown variables (decision

variables) and express them in mathematical

symbols.

2. Determine all the constraints of the problem and

express in the equation or inequality which is also

a linear relationship of the decision variable that

reflects the limited resources or system

boundaries that are modeled from the problem.

A

i

j

X

i

j

{

≤ or = or ≥} B

i

, X

j

≥ 0,

(1

)

Index:

n = Types of activities that use the source or

facility

i = Number of each type of source or available

facility

j = Number of each type of activity that uses

resources or facilities

X

j

= j

th

activity (decision variable)

A

ij

= Number of sources i

th

needed to produce each

activity output unit j

th

B

j

= The number of available sources i

th

3. Determine the goal (maximum or minimum) that

must be achieved to determine the optimum

solution of all feasible values of the variable

(Putri, 2015).

Z

=

C

1

X

1

+

C

2

X

2

+ ...+

C

n

X

n

(2

)

Index:

Z = Optimized value

Cn = Contribution of each unit of activity output

n to the value of Z

Xn = n

th

activity (decision variable)

4 PARAMETERS

4.1 Coal Demands

Based on the RUPTL, there are 5 PLTU in West

Kalimantan Province that are under construction,

including the Sintang PLTU, Ketapang PLTU, Baru

Parit PLTU (FTP1 and FTP2), and Pantai Kura-Kura

PLTU. Each PLTU has different generating power so

that the coal demand for each PLTU is different. The

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1294

Table 1: Coal Demand of PLTU.

PLTU Power (MW) Calory (kkal/kg) Coal Demand (kg)

Sintang 3 x 7 4,000 76,414,154

Keta

p

an

g

10 4,200 34,654,945

Parit Baru FTP 1 2 x 50 4,200 346,549,451

Parit Baru FTP 2 2 x 50 4,200 346,549,451

Pantai Kura-Kura FTP 1 2 x 27.5 4,000 200,132,308

Table 2: Coal Production in Mining Company.

Mining Company

Calory

(kcal/kg)

TM (%) TS (%) Ash (%) Production (ton)

PT Adaro Indonesia 4,000 40.00 0.20 3.00 50,601,101.00

PT Bara Multi Susksessarana 4,065 35.40 0.34 3.70 1,500,000.00

PT Borneo Indobara 4,000 38.00 0.50 6.00 4,003,273.74

PT Jorong Barutama Greston 4,400 32.00 0.25 4.15 203,887.00

following approach is used in calculating coal

demand for each PLTU (Naiborhu, 2015).

𝑉 =

𝑃 × 𝐹 × 𝑐𝑓 × 𝑡

𝑒

𝑓𝑓

× 𝐸

(3)

Index:

V = Total Coal Demands (kg)

P = Generating Power (MW)

F = Conversion Factor

cf = Factor Capacity

t = Time in 1 year (hour)

eff = Combustion Efficiency

E = Coal Calorie (kcal/kg)

Energy unit conversions According to James Prescott

Joule, a conversion factor value of 1 MWh = 8.64 ×

105 kcal. In this study using a factor capacity value of

75%, generating efficiency of 39%, and the amount

of time in a year is 8,760 hours (Sartika &

Septiansyah, 2018). The calculation of coal demands

in each PLTU are shown in Table 1.

Based on Table 1, it is known that the Sintang and

Ketapang PLTUs are small-scale PLTUs with a

capacity of 7 MW and 10 MW. Meanwhile, the PLTU

Parit Baru and Pantai Kura-Kura are medium-scale

power plants with a capacity of 50 MW and 27.5 MW.

This affects the amount of coal demand needed to

generate electricity. The demand for coal shows a

large value with a large power generation capacity.

4.2 Coal Production

The coal used for a power plant is generally low-

calorie coal (less than 4,200 kcal/kg). Each coal

mining company produces coal with different

specifications, from calories, total moisture, total

sulfur, and total ash. In this case mining companies

that will supply coal for PLTU from the island of

Kalimantan. These following are the company that

will supply coal to the planned PLTU in West

Kalimantan.

Based on Table 2, it is known that PT Adaro

Indonesia produces the most low-calorie coal which

is 50 million tonnes with 4,000 kcal/kg calories.

Meanwhile, PT Jorong Barutama Greston Indonesia

produces the most low-calorie coal, which is 0.2

million tons with 4,400 kcal/kg calories.

4.3 The Selling Price of Coal

Coal has different selling prices, depending on the

specifications of calories, moisture, total sulfur, and

ash. The selling price of coal for PLTU has been

regulated in Ministerial Decree of ESDM (Energy

and Mineral Resources) Number:

1395K/30/MEM/2018 concerning the Selling Price

of Coal to the Provision of Electric Power for Public

Interest. The selling price of coal to the electricity

supply for public use is USD 70 per metric ton of Free

on Board (FOB) vessels, based on reference

specifications on calories 6,322 kcal/kg GAR, total

moisture 8%, total sulfur 0.8%, and ash 15%. Based

on the selling price of coal aquation contained in the

Minister of Energy and Mineral Resources Number

1395K/30/MEM/2018, the selling price of coal for

each company is shown in Table 3.

Based on Table 3, it is known that the higher the

coal calories, the higher the coal selling price. It will

affect the cost of procuring coal. the cost of procuring

coal will also increase with the use of coal for higher

calories.

The Optimization of Coal Supply for Planned PLTU in West Kalimantan Province

1295

Table 3: The Selling Price of Coal.

Mining Company Calory (kcal/kg) TM (%) TS (%) Ash (%) Selling Price (USD/ton)

PT Adaro Indonesia 4,000 40.00 0.20 3.00 28.87

PT Bara Multi Susksessarana 4,065 35.40 0.34 3.70 28.69

PT Borneo Indobara 4,000 38.00 0.50 6.00 34.53

PT Joron

g

Barutama Greston 4,400 32.00 0.25 4.15 42.55

Table 4: The Distance between the Seaports of Mining Company.

Mining Company

Distance from Mining Company to the PLTU (NM)

Sintang Ketapang Parit Baru FTP 1 Parit Baru FTP 2 Pantai Kura-Kura

PT Adaro Indonesia 892 533 660 660 703

PT Bara Multi Susksessarana 1,114 755 882 882 925

PT Borneo Indobara 898 538 666 666 709

PT Jorong Barutama Greston 834 475 602 602 645

Table 5: Coal Transportation Costs.

Mining Company

Transportation Costs from Mining Company to the PLTU

(USD/ton)

Sintang Ketapang Parit Baru FTP 1 Parit Baru FTP 2 Pantai Kura-Kura

PT Adaro Indonesia 23.45 15.52 18.33 18.33 19.28

PT Bara Multi Susksessarana 28.36 20.43 23.23 23.23 24.18

PT Borneo Indobara 23.59 15.63 18.46 18.46 19.41

PT Jorong Barutama Greston 22.17 14.24 17.04 17.04 18.00

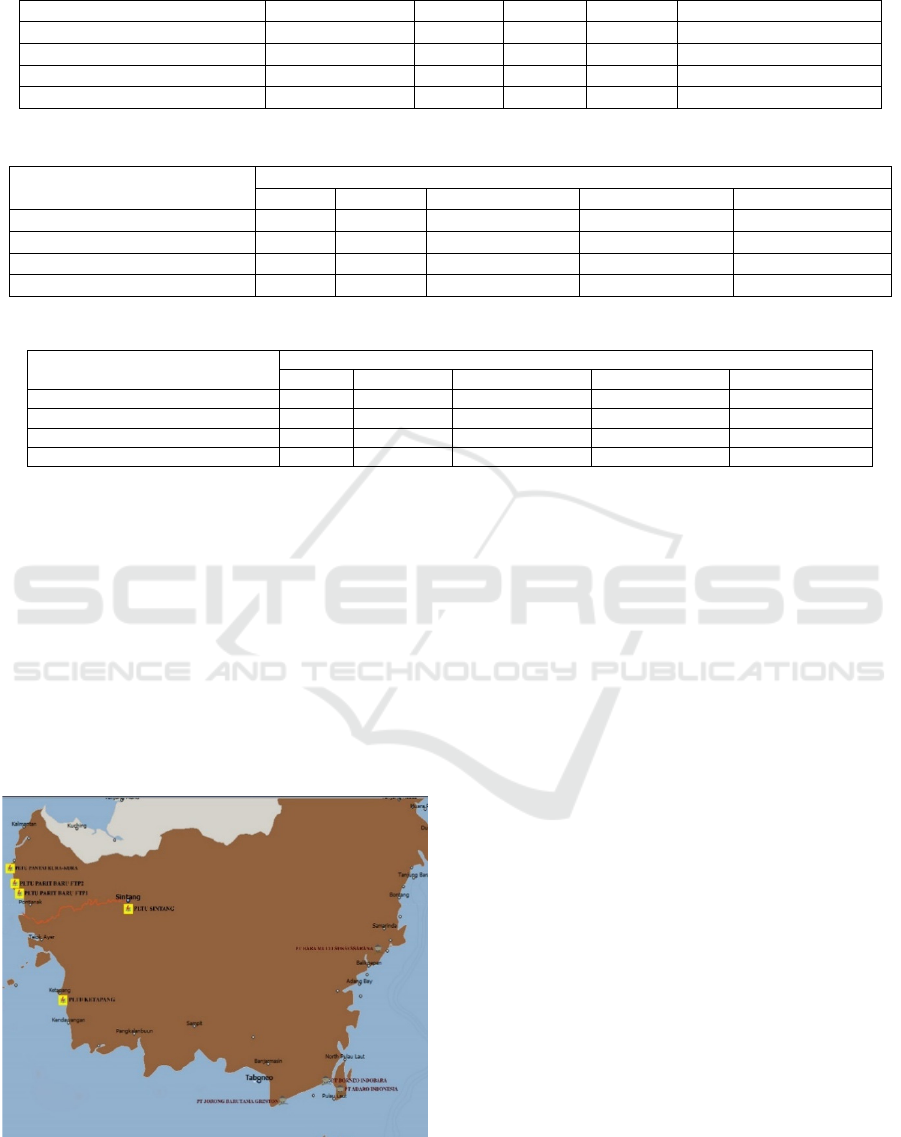

4.4 The Distance between Seaports of

Mining Company and PLTU

Sales of coal are carried out free onboard on barges

with different loading locations than loading on

vessels. It is necessary to calculate the distance from

the seaport of each mining company to each PLTU in

West Kalimantan Province. The distance is calculated

based on sea lanes that are traversed using Netpas

software. The distribution of seaports PLTU and coal

mining companies can be seen in Figure 1. It can be

seen that the location of the PLTU is spread out in

Figure 1: The Distribution of PLTU and Coal Mining

Companies.

West Kalimantan Province and the location of coal

mining companies is spread outside the West

Kalimantan Province. Then, the distance between the

seaports of the mining companies and PLTU can be

seen in the table 4.

Based on Table 4, the coal mining companies that

have the closest distance to each PLTU is PT Jorong

Barutama Greston. The furthest distance to each

PLTU is PT Bara Multi Suksessarana. The farther the

coal mining company is from the PLTU, the higher

the cost of procuring coal.

4.5 Transportation Cost

The transportation used to transport coal from the

mining company's seaport to the PLTU is a barge with

size fewer than 30 feet. Coal transportation costs are

calculated based on the distance from the coal

company's seaport to the PLTU in the Nautical Mile

(NM) unit. The calculation of these costs refers to the

Regulation of the Directorate General of Mineral and

Coal Number 644.K/30/DJB/2013 concerning the

Procedure of Determining Coal Benchmark Prices.

The cost of transporting coal using barges can be seen

in table 5.

5 OPTIMIZATION MODEL

The establishment of an optimization model that will

be achieved is minimizing the total cost of procuring

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1296

coal for the PLTU. The objective function in forming

the coal optimization model is based on the selling

price and transportation costs of coal, with the X

ij

variable as the amount of coal transported from the

coal company to the PLTU. This is the objective

function in the coal optimization model at the PLTU.

Minimum Total Cost = 52.32X

11

+

44.39X

12

+ 47.20X

13

+ 47.20X

14

+

48.15X

15

+ 57.05X

21

+ 49.11X

22

+ 51.92

X

23

+51.92X

24

+52.87X

25

+ 66.14X

31

+

58.18X

32

+ 61.01X

33

+ 61.01X

34

+

61.96X

35

+ 56.70X

41

+ 48.77X

42

+

51.57

X

43

+ 51.57

X

44

+ 52.52

X

45

(4)

Constraint function is divided into two types:

supply and demand. Demand constraints are based on

the demand for coal to generate electricity in a year

and supply constraints were limited by the company's

coal production. The ffollowing are the functions of

demand and supply constraints used.

Demand Constrains:

4,000X

11

+ 4,065X

21

+ 4,000X

31

+

4,000X

41

= 305,656,617

(5)

4,000

X

12

+ 4,065

X

22

+ 4,000

X

32

+

4,000X

42

= 145,550,769

(6)

4,000

X

13

+ 4,065

X

23

+ 4,000

X

33

+ 4,000

X

43

=1,455,507,694.2

(7)

4,000

X

14

+ 4,065

X

24

+ 4,000

X

34

+

4,000X

44

=1,455,507,694.2

(8)

4,000

X

15

+ 4,065

X

25

+ 4,000

X

35

+

4,000X

45

=800,529,231.60

(9)

Supply Constrains:

X

11

+ X

12

+ X

13

+ X

14

+ X

15

≤ 50,601,101

(10

)

X

21

+ X

22

+ X

23

+ X

24

+ X

25

≤ 1,500,000

(11

)

X

31

+ X

32

+ X

33

+ X

34

+ X

35

≤ 4,003,273.74

(12

)

X

41

+ X

42

+ X

43

+ X

44

+ X

45

≤ 203,887

(13

)

6 DISCUSSION

Based on the objective and constraint functions, the

optimization problem is solved by WINQ SB

software, so that the minimum coal procurement cost

obtained at the PLTU is USD 2,565,963,000 in a year

with the distribution of coal supply as the following

table.

Based on these results, it is found that to obtain

the most optimum coal procurement costs, coal input

is required from various companies, where this is

strongly influenced by the calorific value of coal, the

selling price of coal, and the cost of coal

transportation. Besides, the amount of coal demand

and coal production capacity of mining companies are

also the limits of the demand constrain and supply

constrain functions. The coal demand at the Sintang

PLTU can be supplied from PT Jorong Barutama

Greston with 69,467.41 tons. The Ketapang PLTU

can be supplied from 3 different mining company

including PT. Adaro Indonesia with 50,601,100 tons,

PT Bara Multi Susksessarana with 732,448.1 tons,

and PT Borneo Indobara with 4,003,374. The Parit

Baru FTP 1 PLTU can be supplied from PT Bara

Table 6: Variable Index.

Mining Company

Coal Supply from Mining Company to the PLTU (ton)

Sintang Ketapang Parit Baru FTP 1 Parit Baru FTP 2 Pantai Kura-Kura

PT Adaro Indonesia

X

11

X

12

X

13

X

14

X

15

PT Bara Multi Susksessarana

X

21

X

22

X

23

X

24

X

25

PT Borneo Indobara

X

31

X

32

X

33

X

34

X

35

PT Jorong Barutama Greston

X

41

X

42

X

43

X

44

X

45

Table 7: The Optimum Result.

Mining Company

Coal Supply from Mining Company to the PLTU (ton)

Sintang Ketapang

Parit Baru

FTP 1

Parit Baru

FTP 2

Pantai

Kura-Kura

PT Adaro Indonesia - 50,601,100.0 - - -

PT Bara Multi Susksessarana - 732,448.1 358,058.4 358,068.5 51,435.0

PT Borneo Indobara - 4,003,374.0 - - -

PT Joron

g

Barutama Greston 69,467.4 - - - 134,419.5

The Optimization of Coal Supply for Planned PLTU in West Kalimantan Province

1297

Multi Susksessarana with 358,058.4 tons and Parit

Baru FTP 2 PLTU can be supplied from PT Bara

Multi Susksessarana as much as 358,068.5 ton. Pantai

Kura-Kura PLTU can be supplied from 2 different

mining company including PT Bara Multi

Susksessarana with 51,435 tons and PT Jorong

Barutama Greston with 134,419.5 tons.

7 CONCLUSION

The minimum cost of procuring coal for PLTU

demands is USD 2,565,963,000 in a year with the

following distribution of supplies: Sintang PLTU is

supplied from PT Jorong Barutama Greston;

Ketapang PLTU is supplied from PT. Adaro

Indonesia, PT Bara Multi Susksessarana, and PT

Borneo Indobara; Parit Baru FTP 1 PLTU supplied

from PT Bara Multi Susksessarana; Parit Baru FTP 2

PLTU supplied from PT Bara Multi Susksessarana;

The Kura-Kura PLTU is supplied from PT Bara Multi

Susksessarana, and PT Jorong Barutama Greston.

ACKNOWLEDGEMENTS

The authors are thankful to the Company for

providing all the necessary data and information for

this purpose.

REFERENCES

Amrullah, M. (2019). Pemodelan Pemrograman Linier

dengan Koefisien Fungsi Objektif, Fungsi Kendala dan

Variabel Keputusan Berbentuk Bilangan Kabur Beserta

Aplikasinya. Jurnal Matematika, Statistika dan

Komputasi, 16(1), 85-96.

APBI-ICMA. (2015). Indonesian Coal book 2014/2015.

Jakarta: Petromindo.

ESDM. (2016). Handbook of Energy and Economic

Statistic of Indonesia. Jakarta: Ministry of Energy and

Mineral Resource.

ESDM. (2018). Keputusan Menteri ESDM Nomor:

1395K/30/MEM/2018 tentang Harga Jual Batubara

untuk Penyediaan Tenaga Listrik untuk Kepentingan

Umum.

Falastian, J. L. (2017). PERANCANGAN DISTRIBUSI

SEMEN DENGAN MODA TRANSPORTASI DARAT

DI PT SEMEN GRESIK. Surabaya: Institut Teknologi

Sepuluh Nopember .

Indah, D. R., & Sari, P. (2019). Penerapan Model Linear

Programming untuk Mengoptimalkan Jumlah Produksi

dalam Memperoleh Keuntungan Maksimal (Studi

Kasus pada Angga Usaha Perabot). Jurnal manajemen

Inovasi, 98-115.

Kumalasari, S. D., Rasyid, A. M., Nugroho, S., &

Mustakim, A. (2020). Perencanaan Transportasi Laut

Batubara: Studi Kasus Taboneo - Surabaya - Tuban -

Semarang . Jurnal Teknik Transportasi , 1(1), 24-39.

Mitra, S., & Avittathur, B. (2018). Application of linear

programming in optimizing the procurement and

movement of coal for an Indian coal-fired power-

generating company. Journal of the Indian Institute of

Management Calcutta, 45(3), 207-224.

Naiborhu, K. Y. (2015). Tinjauan Keekonomian

Pengembangan Bio-Coal untuk Supply Energy dalam

Negeri (PLTU) dan Komoditas Ekspor. Bandung: Tesis

Program Magister Institiut Teknologi Bandung.

PLN, P. (2015). Rencana Usaha Penyediaan tenaga Listrik

PT PLN (Persero) 2018-2027. Jakarta: PT PLN.

Putri, K. S. (2015). Kajian Pasokan Tenaga Listrik untuk

Menanggulangi Krisis Energi Listrik di Provinsi

Kalimantan Selatan. Bandung: Tesis Program Magister

Institut Teknologi Bandung.

Sartika, & Septiansyah, S. I. (2018). Estimasi Passokan

BAtubara untuk PLTU Rencana di Provinsi Kalimantan

Barat. Jurnal Inovtek Polbeng, 279-284.

Yonas, M. N. (2016). Geologi dan Potensi Batubara di

Bonggo dan Sekitarnya Kabupaten Jayapura, Provinsi

Jayapura. Promine Journal, 1-7.

Yusgiantoro, P. (2009). Ekonomi Energi Teori dan Praktek.

Jakarta: LP3ES.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1298