Research on Supply Chain Information Collaboration and

Performance based on Inter-organizational Information System

Yaqing Zhang and Syed Norris Hikmi Syed Abdullah

*

Universiti Teknologi Malaysia, Azman Hashim International Business School, Malaysia

Keywords: Inter-Organizational Information System, Supply Chain Information Coordination and Performance, Big Data

System.

Abstract: In China's market environment, more and more enterprises use inter-organizational information system to

make information flow across organizational boundaries. It can strengthen the cooperation between

organizations and win strategic competitive advantages for enterprises. Supply chain management is one of

the most important parts. Therefore, this article starts from the main functional direction of big data

technology, analyzes the impact of big data system on the information aggregation ability and information

extraction level of supply chain enterprises, adopts Likert five-point scale to measure supply chain

performance, and proves through empirical evidence. It is verified that the ability of information aggregation

and the level of information extraction have a significant positive impact on the performance of the supply

chain. Finally, the study will present a comprehensive framework to deal with the supply chain performance

of Chinese enterprises and a modest addition to the supply chain performance literature concerning strategies

for elevating supply chain performance in the Chinese enterprises. It aims to provide inspiration for Chinese

managers and organizations to cope with the escalating challenges.

1 INTRODUCTION

In the era of economic globalization, the competition

among enterprises is unprecedentedly fierce, the

demand for technology renewal and information

resource control is unprecedentedly high, and further

spread to the supply chain level. Using big data

technology to improve the core competitiveness of

the supply chain has become an inevitable choice for

relevant enterprises (Singh, 2016, Teng, 2016). In the

era of network economy, information has become one

of the most important resources in supply chain

management. It can be said that whether supply chain

partners can effectively "share information" has

become the key to the success or failure of supply

chain management (Asamoah, 2020, Agyei-Owusu,

2020, Andoh-Baidoo, 2020). With the gradual

deepening of organizational performance and quality

management research, controlling information

resources to coordinate quality management systems

among different enterprises has reached a certain

consensus in academic research and practical practice

(Yang, 2020, Chen, 2020, Hao, 2020). However, in

what way does big data system affect supply chain

quality management and ultimately improve

organizational performance, it has not formed a

generally recognized theoretical system (Tran, 2016,

Childerhouse, 2016, Deakins, 2016). Information

sharing among supply chain partners can effectively

reduce the bullwhip effect, reduce information

distortion and information risk in supply chain

management, and effectively improve the operation

performance of supply chain (Partanen, 2020,

Kohtamki, 2020, Patel, 2020). At present, the

problem of information sharing among supply chain

partners has become the focus of theoretical research,

and a large number of research results have been

obtained (Kim, 2016, Han, 2016, Yi, 2016).

However, these research results mainly focus on the

value of information sharing among supply chain

partners, and there are few research results on the pre

factors of information sharing among supply chain

partners (Wu, 2021, Ma, 2021, Li, 2021).

Profound changes have taken place in the

traditional market, and the scope of management has

been expanded to all relevant resources inside and

outside the enterprise (Basak, 2016, Guha, 2016). In

this new competitive environment, if enterprises want

to remain invincible, they must re-examine their

business models, strengthen their internal process

900

Zhang, Y. and Abdullah, S.

Research on Supply Chain Information Collaboration and Performance based on Inter-organizational Information System.

DOI: 10.5220/0011356800003440

In Proceedings of the International Conference on Big Data Economy and Digital Management (BDEDM 2022), pages 900-905

ISBN: 978-989-758-593-7

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

management and contact with partners in the supply

chain to meet the changing needs of customers, and

quickly respond to the opportunities brought by their

competitors' new business models and new

technologies (Long, 2017). Information sharing

among supply chain partners is inseparable from the

support and assistance of IT technology and

information system. The organic integration and

collaboration of information system among supply

chain partners will be a solid foundation for sharing

information (Rameshwar, 2018, Angappa, 2018,

Childe, 2018). Therefore, information system

collaboration among supply chain partners is likely to

be a very important factor affecting information

sharing, but further in-depth empirical research is

needed (Zhang, 2018, Cao, 2018). In order to make

up for the deficiency of current theoretical research,

this study will use empirical research methods to

explore the impact of supplier and manufacturer

information system collaboration and information

sharing on enterprise operation performance, and it is

expected that this study can provide practical

theoretical basis and guidance for Chinese enterprise

supply chain management (Zhang, 2018, Cao, 2018).

2 DEFINITION OF RELATED

CONCEPTS

2.1 Supply Chain Management

In order to have a deeper understanding of supply

chain and supply chain management, the definitions

of "supply chain" and "supply chain management" by

domestic and foreign scholars will be described and

combed below. Supply chain is a process of

controlling from suppliers to users through value-

added process and distribution channels. It starts at the

origin of supply and ends at the end of consumption.

Supply chain is a network cooperation between

organizations, including products and services from

upstream to downstream. Supply chain is a network

composed of a series of units. The network

successfully transforms raw materials into

intermediate work in progress, and finally into final

products and delivers them to customers and final

consumers. The process from raw materials and parts

procurement, transportation, processing,

manufacturing, distribution to final delivery to

customers is regarded as a chain, which is the supply

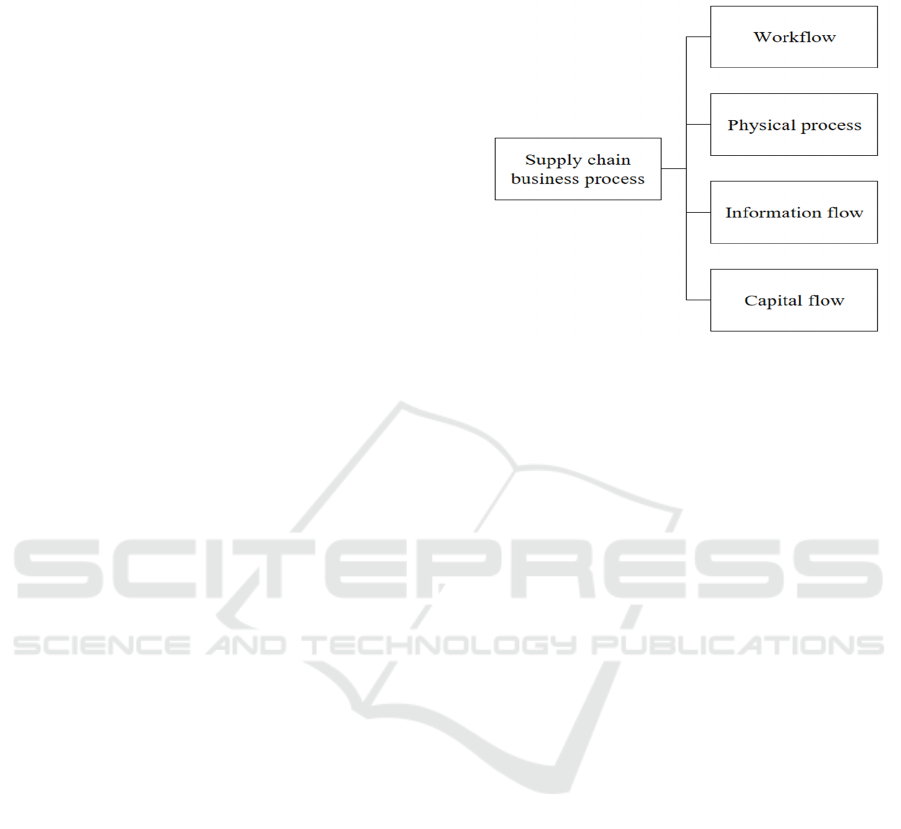

chain. The business process of the supply chain can be

divided into four aspects: work process, physical

process, information process and capital process, as

shown in Figure 1:

Figure 1: Supply chain business process.

Workflow, that is, transaction and management,

is the use of information to make decisions. The

workflow starts from the needs of consumers. The

initial work includes demand analysis, product

development and design, and the formulation of

production plan; Then there is the occurrence of

business and transactions, including the conclusion of

contracts and commitment to transactions between

enterprises, and making transaction decisions is the

most important work of all entrepreneurs; The last is

the implementation, including the whole process

from organizing production, handling import and

export documents to implementing sales. Physical

process is the delivery and transfer of physical goods,

and it is a necessary process to perform transactions.

The physical process includes the whole

transportation process, warehouse management and

packaging distribution. Compared with logistics,

capital flow is a process in which enterprises collect

customers' payment and pay off suppliers' payment

after selling products. Information is the basis of

action in all links of the supply chain. The

information process includes collecting, processing

and analyzing data and providing useful information

to assist each member of the supply chain to make

appropriate business decisions and take

corresponding actions. Supply chain management is

to optimize the supply chain and complete all

processes from procurement to meeting the final

customers at the least cost. The above workflow,

physical process, capital process and information

process are required to operate efficiently.

Research on Supply Chain Information Collaboration and Performance based on Inter-organizational Information System

901

2.2 Supply Chain Integration

Supply chain integration is a very important research

direction in the field of supply chain management in

recent years. Supply chain integration integrates the

management of various relationships, activities,

operations, processes and locations of different

members in the supply chain. However, there is no

unified standard for the definition of supply chain

integration at home and abroad. Most scholars define

it based on their research perspectives and needs.

Therefore, the following will sort out the concepts

and dimensions of supply chain integration, and

define "supply chain integration" on this basis, so as

to lay the foundation for the development of various

studies in this paper. Supply chain integration is a

kind of cooperation management between supply

chain partners in order to provide customers with

higher value and improve competitive advantage.

Supply chain integration refers to the collaboration

and cooperation within and among node enterprises

in the process of supply chain management,

including: the behavior integration of node

enterprises, the process integration of the whole chain

network, information integration, sharing risks and

rewards, collaboration and cooperation and

relationship integration. On the one hand, the main

motivation of most enterprises participating in supply

chain integration is to integrate internal and external

processes through strategic cooperation with supply

chain partners, so as to efficiently manage product

flow, service flow, information flow and capital flow,

and finally obtain excellent performance. Therefore,

how to understand "performance" is particularly

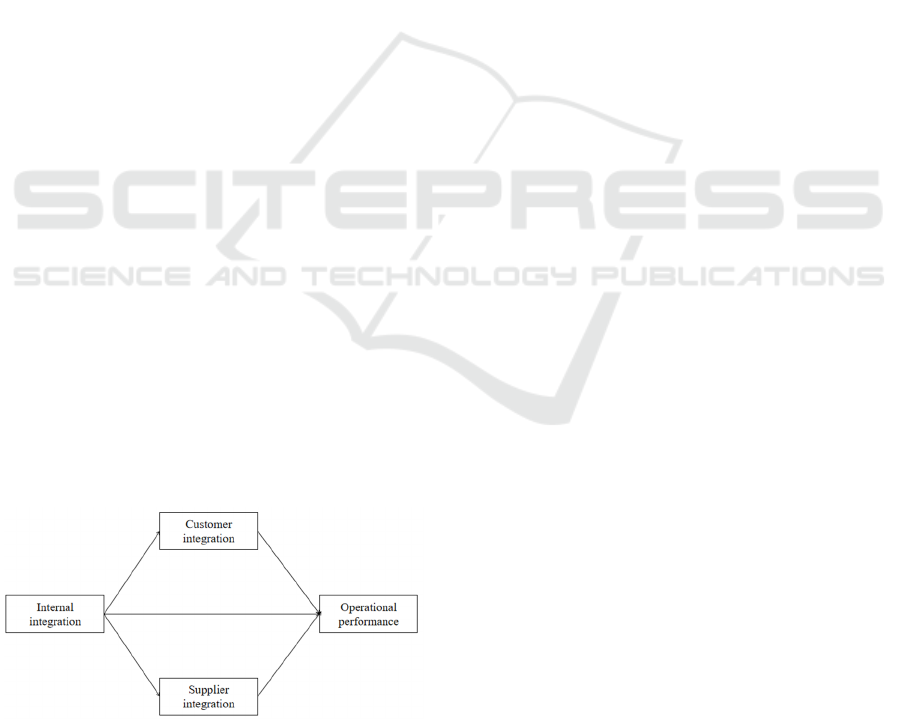

important. On the other hand, because this paper

mainly discusses the relationship between supply

chain integration and performance, it is necessary to

clearly define the concept of "performance". As

shown in Figure 2, the factors affecting operation

performance are:

Figure 2: Factors affecting operational performance.

Performance is a concept of "performance"

involved in this paper, including enterprise

performance and supply chain performance. Among

them, enterprise performance is analyzed from two

aspects: enterprise operation performance and

enterprise financial performance. Through the

analysis of the literature on the relationship between

supply chain integration and enterprise performance,

it is found that generally speaking, enterprise

performance includes operation performance,

innovation performance, customer service

performance, market performance, financial

performance, etc. these studies will define and

measure different performance according to actual

needs, and there is no unified definition. The financial

performance of enterprises mainly refers to the

performance of enterprises in terms of profitability,

operation ability and solvency. Generally, the

indicators that may be used include return on assets,

earnings per share, return on sales, return on

investment and so on. There are many different views

on the definition of supply chain performance.

Generally speaking, it can be defined from the aspects

of customer orientation, internal operation, future

development, financial value and so on. Supply chain

performance is defined and measured from the

aspects of supply chain flexibility, delivery,

inventory, efficiency and new product introduction

speed.

3 THEORETICAL BASIS OF

SUPPLY CHAIN INTEGRATION

RESEARCH

3.1 Transaction Cost Theory

The use of resources often can not rely on market

guidance. Due to the high transaction cost in the

market, enterprises can reduce the transaction cost by

allocating resources instead of the market.

Transaction cost theory mainly discusses how to

minimize production costs and transaction costs

while constructing their own boundaries, including

various necessary behaviors. Transaction cost

determines whether a transaction is carried out in the

enterprise or in the market. The factors affecting the

transaction cost are divided into six categories, and

these six categories of influencing factors do not exist

independently, but a complex relationship and will

affect each other, and finally increase the transaction

cost. Bounded rationality, the original rational

behavior of human beings trying to maximize their

interests, will limit their rational behavior because of

the limitations in spirit, physiology and language.

BDEDM 2022 - The International Conference on Big Data Economy and Digital Management

902

Therefore, the behavior in the transaction process is

not the most rational result, and the irrational

behavior of both parties will increase the difficulty of

transaction; Opportunistic behavior refers to the lack

of frankness or honesty in transactions, including

seeking self-interest by deception; Uncertainty is a

situation in which it is impossible to predict partner

behavior or future changes in the external

environment; For a few transactions, because some

transaction processes are too specialized, or because

heterogeneous information and resources cannot

flow, the trading objects are reduced or the market is

controlled by a few people. If this happens in the

transaction, it is easy to produce opportunistic

behavior; Information asymmetry is due to

uncertainty and opportunistic behavior; Atmosphere:

under the condition of harmonious atmosphere, the

negotiation process or contract signing between the

trading parties is very smooth. On the contrary, if

there is speculation and distrust between the trading

parties in the trading process, it becomes more

difficult for both parties to sign and trade, and

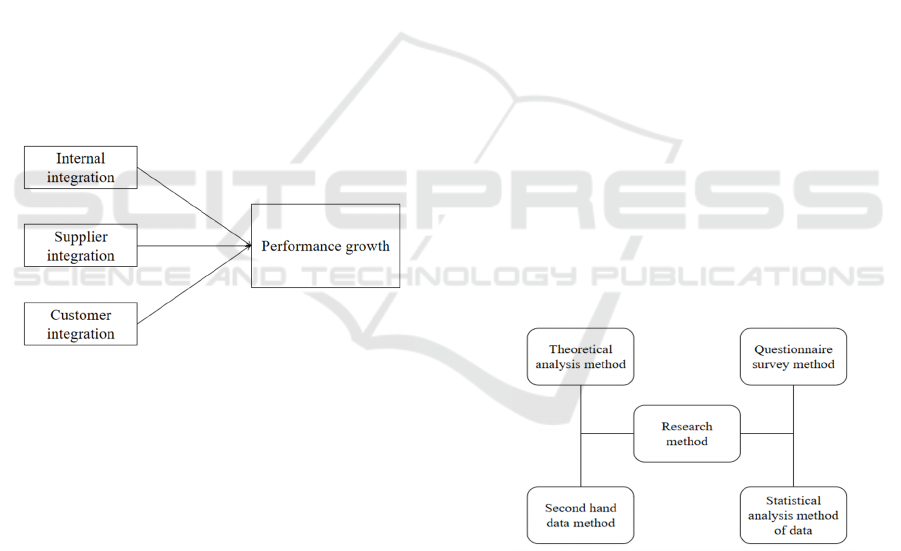

increases the transaction cost. As shown in Figure 3,

it is a longitudinal study of performance growth:

Figure 3: Longitudinal research on performance growth.

Due to the change of market environment,

information asymmetry and human bounded

rationality, people can not fully predict the future

situation in advance. In addition, the uncertainty will

also affect the investment of special assets, and then

affect the specific degree of investment protection.

Transaction uncertainty increases the market risk and

makes the signing of transaction contracts more

complex. With the increase of supervision cost and

bargaining cost, the transaction cost increases. With

the increase of transaction frequency, the collection

cost of transaction information and the signing cost

of transaction process will increase significantly.

However, at the same time, multiple transactions or

cooperation will also make each other understand

each other and increase the degree of mutual trust,

which can reduce opportunistic behavior, reduce the

risk of cooperation and improve the efficiency of

cooperation. In addition, the increase of transaction

frequency makes the enterprise internalize the

economic activities of the transaction to save the

transaction cost of the enterprise.

3.2 Methods of Researching Content

Based on the realistic background and research status,

aiming at the shortcomings of the current research,

this study focuses on "whether and how supply chain

integration affects performance". Based on cross-

sectional data, this paper mainly discusses the impact

mechanism of internal integration, customer

integration and supplier integration of supply chain

on enterprise operation performance, and then

analyzes the impact of situational variables such as

enterprise scale, industry attribute and country on the

relationship between the above variables; Based on

the longitudinal data at two time points, this paper

mainly discusses the impact mechanism of internal

integration change, customer integration change and

supplier integration change of supply chain on

enterprise operation performance change and supply

chain performance change. On this basis, this paper

discusses the mode of supply chain integration and its

relationship with enterprise operation performance

and supply chain performance. The research methods

used in this study mainly include the following four

methods: literature discussion and theoretical

analysis method, questionnaire survey method,

second-hand data method and data statistical analysis

method, as shown in Figure 4:

Figure 4: Research methods of supply chain information.

The study, sorting and analysis of relevant

literature is the basic work of academic research,

which lays a solid foundation for learning from

relevant theories and understanding the latest

research trends. In order to explore the impact

mechanism of supply chain integration on operational

performance, supply chain performance and financial

performance, analyze the key influencing factors of

supply chain integration and how different forms of

Research on Supply Chain Information Collaboration and Performance based on Inter-organizational Information System

903

supply chain integration affect performance, this

study will collect a large number of relevant literature

at home and abroad, analyze and sort out relevant

literature from the aspects of theoretical basis and

research status, It is concluded and compared to

clarify the concept and its relationship, so as to lay

the foundation for the research hypothesis and

conceptual model; Questionnaire survey is one of the

main research methods of this study. The number and

scope of enterprises and the variables involved in the

questionnaire mainly include supply chain

integration, operation performance and supply chain

performance; The second-hand data method is

organized, implemented and submitted on time

according to the contents of the statement system of

industrial enterprises formulated by the National

Bureau of statistics. Industrial statistical indicators

include main technical and economic indicators such

as industrial added value, total industrial output value

and industrial sales output value, as well as main

financial cost indicators, employees and total wages;

Data statistics and analysis methods. In order to

process the data and verify the research hypothesis,

the data analysis methods used in this study mainly

include: descriptive statistical analysis, analysis of

variance, correlation analysis, exploratory factor

analysis, confirmatory factor analysis, structural

equation model analysis and hierarchical linear

model analysis.

4 CONCLUSIONS

Using structural equation model and difference

analysis method, supply chain information discusses

the relationship between information system

collaboration, information sharing and operation

performance between manufacturers and suppliers,

and obtains some meaningful conclusions: firstly, we

believe that information system collaboration among

supply chain partners is a unique, scarce and non

imitatable competitive resource of enterprises, It can

bring sustainable competitive advantage to

enterprises; Secondly, our empirical results show that

information system collaboration among supply

chain partners plays a very important role in

improving the content and quality of information

sharing; Thirdly, our empirical results also find that

the direct effect of information system collaboration

among supply chain partners on enterprise operation

performance is not significant; Fourth, our empirical

results also show that the information sharing content

and information sharing quality among supply chain

partners have a significant positive impact on all

dimensions of enterprise operation performance,

which means that the information system

collaboration among supply chain partners has a

significant indirect effect on enterprise operation

performance. Senior management should not only

pay attention to the construction of information

infrastructure of investment enterprises, but also pay

attention to the seamless connection with the

information systems of upstream and downstream

enterprises of supply chain partners, so as to improve

the coordination level of information systems among

supply chain partners, so as to cultivate them into the

company's core resources, which will bring

sustainable competitive advantages and benefits to

the company. Only when the mutual trust relationship

reaches a certain level, the information systems of

both sides can realize seamless connection.

REFERENCES

Asamoah D, Agyei-Owusu B, Andoh-Baidoo F K, et al.

Inter-organizational systems use and supply chain

performance: Mediating role of supply chain

management capabilities. International Journal of

Information Management: vol.10, no.21, pp.95, 2020.

Basak M, Guha I. E-Procurement Utilisation in the

Maintenance Repair and Overhaul (MRO) Supply

Chain by SMEs in India. Journal of Cases on

Information Technology, vol.18, no.2, pp.51-61, 2016.

Kim Y W, Han S H, Yi J S, et al. Supply chain cost model

for prefabricated building material based on time-

driven activity-based costing. Canadian Journal of

Civil Engineering, vol.25, no.10, pp.22, 2016.

Long, Qingqi. A framework for data-driven computational

experiments of inter-organizational collaborations in

supply chain networks. INFORMATION SCIENCES,

no.39, pp.43-63, 2017.

Partanen J, Kohtamki M, Patel P C, et al. Supply chain

ambidexterity and manufacturing SME performance:

The moderating roles of network capability and

strategic information flow. International Journal of

Production Economics, no.21, pp.70, 2020.

Rameshwar D, Angappa G, Childe S J, et al. Examining the

role of big data and predictive analytics on

collaborative performance in context to sustainable

consumption and production behaviour. Journal of

Cleaner Production, vol.196, no.4, pp.15-21, 2018.

Singh A, Teng J. Enhancing supply chain outcomes through

Information Technology and Trust. Computers in

Human Behavior, vol.54, no.12, pp.290-300, 2016.

Tran T, Childerhouse P, Deakins E. Supply chain

information sharing: Challenges and risk mitigation

strategies. Journal of Manufacturing Technology

Management, vol.27, no.8, pp.11-16, 2016.

Wu F, Ma J, Li Y. Complex Fluctuation of Power Price in

Dual-Channel and Multienergy Supply Chain Based on

BDEDM 2022 - The International Conference on Big Data Economy and Digital Management

904

Sticky Expectation. International Journal of Bifurcation

and Chaos, vol.31, no.14, 2021.

Wu I L, Chiu M L. Examining supply chain collaboration

with determinants and performance impact: Social

capital, justice, and technology use perspectives.

International Journal of Information Management,

no.39, pp.5-19, 2018.

Yang H, Chen W, Hao Y F. Supply chain partnership, inter-

organizational knowledge trading and enterprise

innovation performance: the theoretical and empirical

research in project-based supply chain. Soft

Computing, vol.24, no.9, 2020.

Zhang Q, Cao M. Exploring antecedents of supply chain

collaboration: Effects of culture and interorganizational

system appropriation. International Journal of

Production Economics, vol.195, no.11, pp.146-157,

2018.

Research on Supply Chain Information Collaboration and Performance based on Inter-organizational Information System

905