New Benchmarks and Optimization Model for the Storage Location

Assignment Problem

Johan Oxenstierna

1,2 a

, Jacek Malec

1b

and Volker Krueger

1c

1

Dept. of Computer Science, Lund University, Lund, Sweden

2

Kairos Logic AB, Lund, Sweden

Keywords: Storage Location Assignment Problem, Order Batching Problem, Quadratic Assignment Problem,

Warehousing, Computational Efficiency.

Abstract: The Storage Location Assignment Problem (SLAP) is of primary significance to warehouse operations since

the cost of order-picking is strongly related to where and how far vehicles have to travel. Unfortunately, a

generalized model of the SLAP, including various warehouse layouts, order-picking methodologies and

constraints, poses a highly intractable problem. Proposed optimization methods for the SLAP tend to be

designed for specific scenarios and there exists no standard benchmark dataset format. We propose new SLAP

benchmark instances on a TSPLIB format and show how they can be efficiently optimized using an Order

Batching Problem (OBP) optimizer, Single Batch Iterated (SBI), with a Quadratic Assignment Problem

(QAP) surrogate model (QAP-SBI). In experiments we find that the QAP surrogate model demonstrates a

sufficiently strong predictive power while being 50-122 times faster than SBI. We conclude that a QAP

surrogate model can be successfully utilized to increase computational efficiency. Further work is needed to

tune hyperparameters in QAP-SBI and to incorporate capability to handle more SLAP scenarios.

1 INTRODUCTION

The Storage Location Assignment Problem (SLAP)

concerns the “allocation of products into a storage

space and optimization of the material handling (…)

or storage space utilization [costs]” (Charris et al.,

2018). Material handling involves all processes

relating to the movement of products in a warehouse.

The location assignment of products thus has an

impact on the quality of material handling (Mantel et

al., 2007). For example, if a vehicle needs to pick a

set of products, the travel cost clearly depends on

where the products are located. At the same time, the

opposite is true in that material handling has an

impact on location assignment: Vehicle constraints,

traffic rules and picking methodologies can all have

an impact on how a strong location assignment is

formulated in the first place.

Kübler et al. (2020) describe a “joint storage

location assignment, order batching and picker

routing problem” where the SLAP includes two

a

https://orcid.org/0000−0002−6608−9621

b

https://orcid.org/0000−0002−2121−1937

c

https://orcid.org/0000−0002−8836−8816

interlinked optimization problems in the warehouse:

In the Order Batching Problem (OBP) vehicles are

assigned to carry sets of orders (each order contains a

set of products) (Koster et al., 2007). In the Picker

Routing Problem the picking path of a vehicle is

decided and it is equivalent to a Traveling Salesman

Problem (TSP) (Ratliff & Rosenthal, 1983). This

paper builds on Kübler et al.’s joint formulation and

we treat the Key Performance Indicator (KPI) in both

OBP and SLAP optimization as an estimate of

aggregate travel in the warehouse. The key difference

between the OBP and SLAP in this regard is that all

products are assumed to have fixed locations in the

former, whereas a subset of products are assumed to

be available for location assignment or reassignment

in the latter.

The main focus of this paper is two areas where

the SLAP has not seen much previous work. The first

area is that of benchmarking. Currently there is a

scarcity of benchmark data on any version of the

SLAP, and existing datasets are on various formats,

26

Oxenstierna, J., Malec, J. and Krueger, V.

New Benchmarks and Optimization Model for the Storage Location Assignment Problem.

DOI: 10.5220/0011378400003329

In Proceedings of the 3rd International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2022), pages 26-35

ISBN: 978-989-758-612-5; ISSN: 2184-9285

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

making them difficult to reproduce (Section 2). We

propose new benchmark instances using

modifications to the wide-spread TSPLIB format

(Reinelt, 1991) (Section 5). A key discussion

regarding benchmark instances is how they can be

kept as simple and standardized as possible, to enable

easy reproducibility, while not losing applicability

within the industry. One benchmarking area which is

particularly difficult to standardize is the “relocation

efforts” for different types of SLAP assignment

scenarios (Section 2). We have delimited our SLAP

model to assignment scenarios where products are

hitherto not located in the warehouse.

The second focus area is the maximization of

computational efficiency in OBP optimization. As

mentioned above, a feature in the proposed model is

that an OBP is used to estimate the quality of SLAP

location assignments. Since the OBP is NP-hard it

must be optimized in a way which trades off solution

quality with CPU-time. We use the computationally

efficient OBP optimizer Single Batch Iterated (SBI)

(Oxenstierna, Malec, et al., 2021; Oxenstierna et al.,

2022). Within the proposed SLAP optimizer, SBI still

requires a lot of CPU-time and we investigate

whether it can be assisted by a Quadratic Assignment

Problem (QAP) surrogate model to make

optimization more efficient. The contributions are as

follows:

1. Introduction of SLAP benchmark data on the

TSPLIB format.

2. Feasibility analysis of a QAP surrogate model

within a SLAP optimizer.

2 LITERATURE REVIEW

This section goes through general strategies for

conducting storage location assignment and ways in

which their quality can be evaluated. Various SLAP

formulations and proposed optimization algorithms

are covered. We mainly concern ourselves with a

standard picker-to-parts set up and we particularly

refer to Kubler et al. (2020), since their proposed

model shares similarities with ours.

There exist numerous general strategies for

conducting storage location assignment (Charris et

al., 2018). Three key strategies are Dedicated, Class-

based and Random storage:

• Dedicated: Each product is assigned to a specific

location which never changes. This strategy is

suitable if the product collection changes rarely and

simplicity is desired. Human pickers can furthermore

benefit from this strategy since they can learn to

associate specific products with locations, which

might speed up their picking (Zhang et al., 2019).

• Random: Each product can be assigned any

available location in the warehouse. This is suitable

whenever the product collection changes frequently.

• Class-based (zoning): The warehouse is divided

into zones and the products into classes (usually

based on demand of products). Each class is assigned

a zone. The outline of the zone can be regarded as

dedicated in that it does not change, whereas the

placement of each product in a zone is assumed to be

random (Mantel et al., 2007). Class-based storage

assignment can therefore be regarded as a middle

ground between dedicated and random.

The quality of a location assignment is commonly

evaluated based on some model of aggregate travel

cost. For this purpose, a simplified simulation of

order-picking in the warehouse can be used (Charris

et al., 2018; Mantel et al., 2007). Some proposals

include the simulation of order-picking by the so

called Cube per Order Index (COI) (Kallina & Lynn,

1976). COI includes the volume of a product and the

frequency with which it is picked (historically or

forecasted). The general idea is then to assign

products with high pick frequency and relatively low

volume to locations close to the depot. Since orders

may contain products which are not located close to

each other, COI is only capable of simulating an

order-picking scenario adequately where orders

contain one product and vehicles carry one product at

a time. This may be sufficient when trucks pick a

couple of pallets or when certain types of robots are

used (Azadeh et al., 2019). Mantel et al. (2007),

introduced Order Oriented Slotting (OOS) where

vehicles are assumed to pick one order at a time, but

where the number of products in an order may be

greater than 1. They also introduce a Quadratic

Assignment Problem (QAP) model to estimate the

quality of a product location assignment, which

includes the distance between the product locations in

the order and a single depot location. A similar model

to OOS is used by Fontana & Nepomuceno (2017),

Lee et al. (2020) and Žulj et al. (2018).

There is not much prior research on SLAP’s

where vehicles are assumed to pick more than one

order at a time, i.e., where OBP optimization in some

form is included in SLAP optimization. We are only

aware of two papers within this category. The first is

Kübler et al. (2020), whose work we discuss further

below. The second is Xiang et al. (2018), but their

work concerns a robotic warehouse where the

vehicles are pods (moving racks) and is not easily

comparable to a picker-to-parts system.

New Benchmarks and Optimization Model for the Storage Location Assignment Problem

27

Travel cost is not the only way in which a SLAP

solution quality can be evaluated. Lee et al. (2020),

for example, study the effect of location assignment

and traffic congestion in the warehouse. If too many

products are assigned locations close to the depot (the

goal in common COI), there may be a traffic

congestion problem and it should ideally be included

in an industrially adopted model. They call their

version Correlated and Traffic Balanced Storage

Assignment (C&TBSA) and they formulate it as a

multi-objective problem with travel cost on the one

hand, and traffic congestion avoidance on the other.

Larco et al. (2017) study the relationship between

worker welfare and storage location assignment. If

picking is conducted by humans who move products

from shelves onto a vehicle, the weight and volume,

as well as the height of the shelf the product is placed

on, can have an impact on worker welfare. Worker

welfare can be quantified with parameters such as

“ergonomic loading”, “expenditure of human energy”

or “worker discomfort” (Charris et al., 2018).

The SLAP can be divided into two broad

categories depending on the number of location

assignments sought. Either the assignment is a “re-

warehousing” operation, which means that a large

portion of the warehouse’s products are (re)assigned

locations (Kofler et al., 2014). Most often, and more

realistically, however, only a small number of

products are (re)assigned a location and this is called

“healing” (Kofler et al., 2014). Solution proposals

involving healing often look closely at different types

of scenarios for carrying out initial assignments or

reassignments. Below are four scenarios presented by

Kübler et al. (2020):

I. Empty storage location: A product is

assigned to a previously unoccupied

location.

II. Direct exchange: A product changes

location with another product.

III. Indirect exchange 1: A product is moved to

another location which is occupied by

another product. The latter product is moved

to a third, empty location.

IV. Indirect exchange 2: A product is moved to

another location which is occupied by

another product. The latter product is moved

to a third location which is occupied by a

third product. The third product is moved to

the original location of the first product.

The above relocation scenarios are all associated

with different efforts, ranging from the lightest in

scenario I, to the heaviest in scenario IV. Kübler et al.

quantify efforts by considering both physical and

administrative times, which are transformed to effort

terms by proposed proportionalities. Total effort is

computed based on distances between old and new

locations for products and the total physical and

administrative efforts.

Concerning SLAP optimizers, proposals include

exact models such as Mixed Integer Linear

Programming (MILP), dynamic programming and

branch and bound algorithms (Charris et al., 2018).

The warehouse environment modeled in these studies

are simplified to a large extent (Charris et al., 2018;

Garfinkel, 2005; Kofler et al., 2014; Larco et al.,

2017). The main simplification concerns the above-

mentioned modeling of order-picking using COI or

OOS. Other simplifications involve limiting the

number of products (Garfinkel, 2005), number of

locations (Wu et al., 2014), or by requiring the

conventional warehouse rack layout (Kübler et al.,

2020). The conventional layout assumes Manhattan

style blocks of aisles and cross-aisles and it is used

almost exclusively in existing SLAP literature (we are

only aware of two exception cases using the

“fishbone” and “cascade” layouts (Cardona et al.,

2012; Charris et al., 2018).

Most proposed SLAP optimizers provide non-

exact solutions using heuristics or meta-heuristics.

These include multi-phase optimization where the

first phase evaluates possible locations for products

and the second phase carries out and evaluates the

possible assignments (Wutthisirisart et al., 2015). In

the meta-heuristic domain there are proposals

involving Genetic and Evolutionary Algorithms (Ene

& Öztürk, 2011; Lee et al., 2020), Simulated

Annealing (Zhang et al., 2019) and Particle Swarm

Optimization (PSO) (Kübler et al., 2020). In Kübler

et al. (2020), a heuristic zoning optimizer is used to

generate location assignments and a Discrete

Evolutionary Particle Swarm Optimizer (DEPSO) is

used to optimize the OBP (used as order-picking

model). DEPSO is a modification of a standard PSO

algorithm where the evolutionary part mitigates risk

of convergence on local minima. The discrete part

breaks the requirement of a continuous search space,

which is a requirement in standard PSO. If TSP

optimization is desired within a SLAP, S-shape or

Largest Gap algorithms (Roodbergen & Koster,

2001) are often used. For unconventional layouts with

a pre-computed distance matrix

Google OR-tools or

Concorde have been proposed for TSP optimization

(Oxenstierna et al., 2022; Rensburg, 2019).

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

28

3 PROBLEM FORMULATION

3.1 SLAP Model

The objective function of the SLAP model is similar

to the ones formulated in Henn & Wäscher (2012) and

Oxenstierna, van Rensburg, et al. (2021): Minimize

the distance needed to pick a given set of orders, using

order-batching:

𝑚𝑖𝑛 𝐷

(

𝑏

)

𝑎

,

∈ℬ

𝑚∈

ℳ

,ℬ⊂2

𝒪

(1)

where 𝒪 denotes orders, where ℬ denotes generated

batches, where 𝐷

(

𝑏

)

denotes the distance to pick

batch 𝑏 (the distance of a TSP solution) and where 𝑚

denotes a vehicle. 𝑎

denotes a binary variable that

is 1 if vehicle 𝑚 is assigned to pick 𝑏 and 0

otherwise. Products 𝒫 belong to orders 𝒪∈2

𝒫

and

the locations of all products in any order 𝑜∈𝒪 are

retrievable with function 𝑙𝑜𝑐

:𝒪→2

ℒ

𝒫

. ℒ

𝒫

denotes

all product locations in the warehouse. Similarly, all

locations in a batch of orders are retrievable using

function 𝑙𝑜𝑐

:ℬ→2

ℒ

𝒫

. The formulation is built on a

digitization pipeline for warehouses on any 2D rack-

layout, mapping of products to location coordinates,

precomputation of all shortest distances between

locations using the Floyd-Warshall graph algorithm,

constraints for order-integrity and vehicle capacities,

depot configurations and number of vertex visits.

Comprehensive details for warehouse digitization

and preprocessing for the OBP are beyond the scope

of this paper, so for details we refer to Oxenstierna,

van Rensburg, et al., (2021) and Rensburg (2019). As

mentioned in Section 1, the main difference between

the OBP and SLAP formulations concerns the

definition of product locations. In Oxenstierna, van

Rensburg, et al. (2021) each product 𝑝 ∈ 𝒫 “has a

[fixed] location”. We change this for the SLAP such

that a subset of products 𝒫

⊂𝒫 have their locations

removed in the warehouse. The SLAP then consists

of minimizing the OBP objective in Equation (1)

while trying various location assignments for 𝒫

.

The above SLAP scenario is represented by the

“empty storage location” scenario I in Kübler et al.

(2020) (Section 2). The relocation effort needed to

place the products at their assigned locations can be

assumed insignificant in this scenario, since finding

empty locations for new products in a warehouse is

not optional, but a requirement. The other of Kübler

et al.’s scenarios are “reassignments”, which means

that that the potential gains in travel cost due to

location reassignment must be weighed against the

cost of reassigning them. Including reassignments

makes a SLAP optimization model more complete,

but arguably also more complex. One of the aims of

this paper is to propose a model which allows for a

relatively simple and standardized SLAP benchmark

instance format. Contrary to Kübler et al., we chose

not to include various assignment scenarios in our

model, but on the other, we do not require a specific

warehouse layout. We invite further discussions on

how to rank and choose SLAP modeling features for

a standardized format.

3.2 QAP Model

Since Equation 1 poses an NP-hard problem, it would

require an infeasible amount of CPU-time to re-run

the minimization for a large number of candidate

solutions (location assignments). We therefore

propose to filter out promising candidates based on a

surrogate model. For this purpose we use a Quadratic

Assignment Problem (QAP) model with the

following objective:

𝑚𝑖𝑛 𝑤

∈ℒ

𝒫

∈ℒ

𝒫

∈𝒫

𝑑

×

∈𝒫

×𝑎

(

𝑝

,𝑙

)

𝑎

(

𝑝

,𝑙

)

(2)

where 𝑤 denotes weight, where 𝑑 denotes distance

and 𝑎

(

𝑝,𝑙

)

a function which returns 1 if product 𝑝 is

located at location 𝑙 and 0 otherwise. Cost is the

element-wise summation of a weight matrix and a

distance matrix. The cell values in the weight matrix

represent the number of times two products, 𝑝

,𝑝

,

appear in the same order 𝑜∈𝒪. The distances

between all product locations is assumed pre-

computed according to (Rensburg, 2019). If the

matrix indices for products in 𝒫

are permuted in such

a way that the aggregate distance and weights

between them is decreased, the QAP cost should also

decrease.

The intention with the QAP surrogate is then to

apply it in an accept/reject Markov Chain Monte

Carlo (MCMC) method (Cai et al., 2008). A sample

(solution candidate) 𝑥 should only be accepted if its

QAP cost estimate 𝑓

(

𝑥

)

(Equation 2) is low and close

to a corresponding OBP ground truth value 𝑓

∗

(

𝑥

)

(Equation 1). Assuming 𝑓

(

𝑥

)

and 𝑓

∗

(

𝑥

)

are

proportional, the accept probability can be upper

bounded by the following quotient (Christen & Fox,

2005):

𝑔

𝑓

(

𝑥

)

,

𝑓

∗

(

𝑥

)

≤

1

1+ 𝑒

|

(

)

∗

(

)|

(3)

New Benchmarks and Optimization Model for the Storage Location Assignment Problem

29

where 𝑔𝑓

(

𝑥

)

,𝑓

∗

(

𝑥

)

denotes the accept probability

and 𝐶 and 𝑃 positive constants. Unfortunately,

Equation 3 cannot be directly utilized in our case.

Since sample 𝑥 in the SLAP is a permutation of

arbitrary length (henceforth 𝒙), it would require an

infeasible amount of CPU-time to establish

proportionality between 𝑓 and 𝑓

∗

so that norm

|

𝑓

(

𝑥

)

−𝑓

∗

(

𝑥

)|

generalizes. Below we describe two

proposals for how this problem can be resolved.

If we have a dataset of finite samples with

available ground truth costs Ψ=𝒙,

𝑓

∗

(

𝒙

)

∈𝑿

×

ℝ

,𝑛∈ℤ, and a task where a single sample (e.g. the

best) should be found, a basic model of

proportionality between 𝑓 and 𝑓

∗

is provided by

softmax cross-entropy (Bruch et al., 2019; Cao et al.,

2007):

ℙ

𝑓

(

𝒙

)

=

𝑒

(𝒙

)

∑

𝑒

𝒙

(4)

ℙ

𝑓

∗

(

𝒙

)

=

𝑓

∗

(𝒙

)

∑

𝑓

∗

𝒙

(5)

𝐿

(

𝑓

)

=−

1

|

Ψ

|

ℙ

𝑓

∗

(

𝒙

𝑖

)

𝑙𝑜𝑔ℙ

𝑓

(

𝒙

𝑖

)

𝒙

𝒊

,

∗

(

𝒙

𝒊

)

∈

(6)

where ℙ𝑓

(

𝒙

)

and ℙ𝑓

∗

(

𝒙

)

denote the estimated

and ground truth probabilities of producing a sample,

respectively. 𝐿

(

𝑓

)

is the loss of 𝑓 (i.e., its distance to

𝑓

∗

). This model can be extended into Normalized

Discounted Cumulative Gain (NDCG) (Bruch et al.,

2019):

𝑁𝐷𝐶𝐺 =

𝐷𝐶𝐺

𝐼𝐷𝐶𝐺

(7)

𝐷𝐶𝐺 =

𝑓

(

𝒙

)

𝑙𝑜𝑔

𝜋

(

𝒙

)

(

𝑖

)

+1

(8)

𝐼𝐷𝐶𝐺 =

𝑓

∗

(

𝒙

)

𝑙𝑜𝑔

𝜋

𝑓

∗

(

𝒙

)

(

𝑖

)

+1

(9)

where 𝑓

(

𝒙

)

and 𝑓

∗

(

𝒙

)

denote relevance values

proportional to the approximated and ground truth

values in 𝑓

(

𝒙

)

and 𝑓

∗

(

𝒙

)

, respectively.𝜋 denotes a

ranking (a list of integers between 1 to 𝑛). 𝐼𝐷𝐶𝐺

denotes an ideal value where 𝑓

∗

(

𝒙

)

>𝑓

∗

(

𝒙

)

>

⋯>𝑓

∗

(

𝒙

)

. Bruch et al. (2019) argue that NDCG is

a stronger choice than softmax cross-entropy

whenever 𝑓

∗

is of non-binary type, which is the case

in Equation 1. We thus use NDCG to provide a

distance estimate between Equation 1 ( 𝑓

∗

) and

Equation 2

(

𝑓

)

. Choices for datatype for 𝑓

are

further discussed in the experiments in Section 5. In

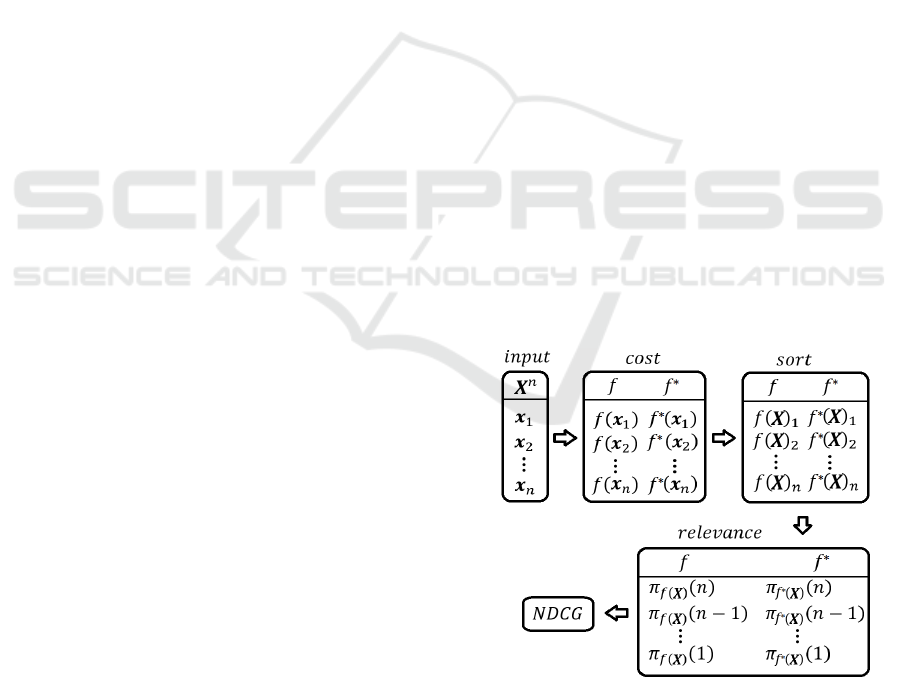

Figure 4 (Appendix) an example is shown where

NDCG is computed from an input vector with range

1,𝑛

where 𝑛 denotes the number of solution

candidates (samples).

4 OPTIMIZATION ALGORITHM

The proposed optimization algorithm (QAP-SBI)

includes a module for SLAP candidate solution

generation and two estimators of solution quality: A

fast but noisy estimator using a Quadratic Assignment

Problem (QAP) model, and a slow but accurate Order

Batching Problem (OBP) optimizer (SBI):

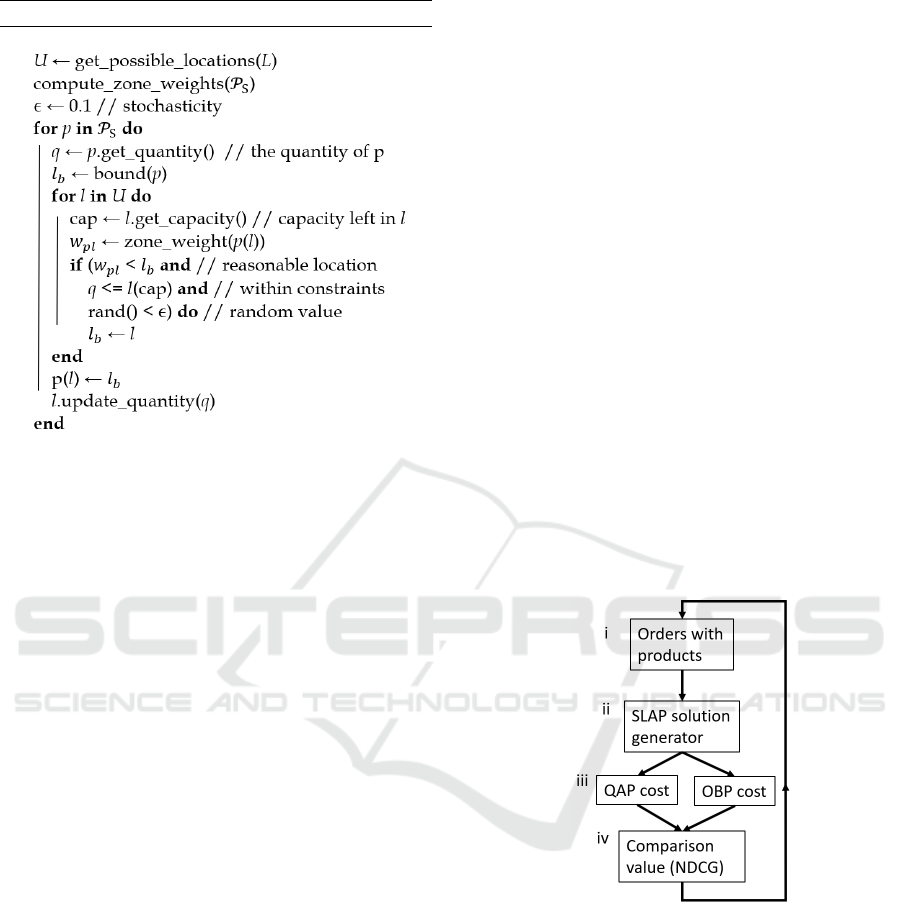

Figure 1: Optimization model.

The input in step i is a future-predicted set of orders

𝒪 with products 𝒫 and 𝒫

⊂𝒫 (Section 3).

Predicting future orders is beyond the scope of this

paper and we assume this set already exists. See

Kübler et al. (2020) for an example of how prediction

of future orders can be carried out. In step ii 𝑛 SLAP

candidate solutions (for 𝒫

) are generated using basic

zoning (Section 2), stochasticity and a volume

capacity parameter. The pseudocode below describes

this procedure:

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

30

Algorithm 1: Assignment generation.

U is a set of locations which are not filled to capacity

in the warehouse and product 𝑝∈𝒫 must fit within

the location capacity constraint. A “zone weight” is

calculated to provide a probability that the product

should be assigned to a certain zone, depending on the

weight to other products in the same zone (using the

same weights matrix as described in Section 3). In the

rest of the procedure possible locations for the

products are iterated and a suitable SLAP candidate

is finally selected.

The solution costs of the candidate assignments

are estimated using the QAP model (step iii in Figure

1). In step iv the candidate solutions with the

strongest QAP estimates are selected and submitted

to OBP optimization in step v. We use the OBP

optimizer Single Batch Iterated (SBI) and its main

features are its high computational efficiency and its

ability to handle warehouses with unconventional

rack layouts (Oxenstierna et al., 2022). SBI only has

optimality bounds for small instances, so the quality

of its results for larger instances can be debated (as

far as we are aware there exists no proposal for how

to obtain optimal results for such instances within

feasible CPU-time). OBP optimization is beyond the

scope of this paper and we here treat SBI primarily as

a black-box which outputs ground-truth costs for

Equation 1. Steps ii, iii, iv and v are repeated until a

final timeout in step vi, when the candidate with

minimal OBP cost is selected as the best solution.

The algorithm in Figure 1 is an adaptation of the

MCMC sampling algorithm proposed by Christen &

Fox (2005), with two major differences: 1. CPU-time

parameters are used to dictate total number of

produced samples instead of convergence. 2. Step iv

selects multiple candidate solutions rather than one.

The latter step provides a convenient method with

which to validate the performance of the QAP model:

If all samples are accepted in iv and submitted to SBI

estimation, the predictive strength of the QAP model

can be easily evaluated.

In Figure 1 we note that steps iii and iv will be

useless for the overall optimizer if iv outputs random

candidate solutions. Steps iii and iv should therefore

perform better than a random baseline to be of use

(Freund et al., 2003; Freund & Schapire, 1996). In

Section 5 we follow this track and propose an

experimental set up where the QAP model is

benchmarked against a random baseline.

5 EXPERIMENTS

5.1 Experimental Set up

The main aim of the experiment is to empirically

validate the predictive strength of the QAP model

against ground truth values obtained through OBP

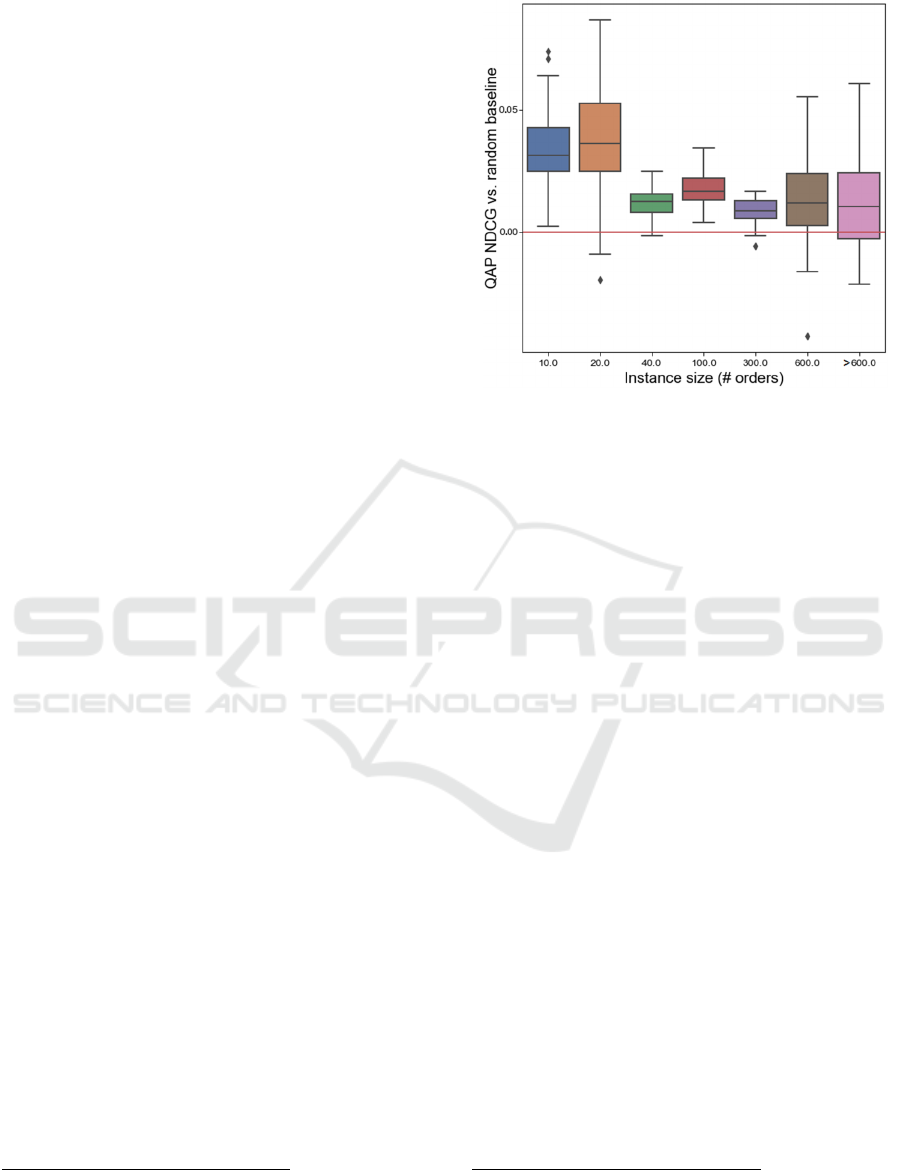

optimization. The diagram below shows the

experimental set up:

Figure 2: The modules in the experimental set up.

A test-instance is loaded in step i (orders with

products). In step ii, 𝑛 SLAP solution candidates are

generated semi-stochastically according to Algorithm

1. In step iii the cost of the generated solutions is

estimated using the QAP model and the OBP

optimizer SBI. The predictive strength of the QAP

model is defined as its ability to rank the solution

candidates according to NDCG (Section 3); 𝐼𝐷𝐶𝐺 is

computed from the ranking of costs according to the

OBP optimizer and 𝐷𝐶𝐺 is computed from the

ranking of costs according to the QAP model.

Relevance values 𝑓

(

𝒙

)

and 𝑓

∗

(

𝒙

)

are chosen to be

New Benchmarks and Optimization Model for the Storage Location Assignment Problem

31

the ranking of samples 𝒙 according to respective cost

functions. For 𝑛 candidate solutions the values are

defined as 𝑓

∗

(

𝒙

)

=(𝜋

∗

(

𝒙

)

(

𝑛

)

,𝜋

∗

(

𝒙

)

(

𝑛−

1

)

,…,𝜋

∗

(

𝒙

)

(

1

)

) and 𝑓

(

𝒙

)

=(𝜋

(

𝒙

)

(

𝑛

)

,𝜋

(

𝒙

)

(

𝑛−

1

)

,…,𝜋

(

𝒙

)

(

1

)

) (this corresponds to the set up shown

in Figure 4).

5.2 Benchmark Datasets

The TSPLIB format datasets (Reinelt, 1991) in

L6_203

1

and L09_251

2

are modified for the SLAP

and publicly shared in L17_533

3

. L17_533 includes

instances with one conventional and 5

unconventional warehouse obstacle layouts, various

depot configurations and vehicle capacities. The

number of orders range from 4 to 1000 and number

of products range between 10 to 3000. The SLAP

modification of the instances includes the tagging of

a number of products for storage assignment (𝒫

in

Section 3 and “SKUsToSlot” in the instance set). The

tag “assignmentOptions” is also added and includes

tagging of locations for assignment and how cost is to

be computed (it is always set to the “empty storage

location” scenario, Section 2). For analysis, instances

are divided into classes according to vehicle

capacities, number of orders and products and

number of candidate solutions. The global best OBP

result is tracked and then uploaded as the current

benchmark result for the corresponding instance. We

refer to the documentation in L17_533 for further

details. All instances are optimized using Intel Core

i7-4710MQ 2.5 GZ 4 cores, 16 GB RAM.

5.3 Experiment Result

Figure 3 and Table 1 summarize the results of the

QAP NDCG estimates versus the random value

baseline. On average, the QAP NDCG values are in

the range 0.83-0.90 (average over six 𝑛 values). They

are generally better than the random value baseline by

1-3%, with standard deviations ranging between 0.5-

2% (Figure 3). Most QAP estimates beat the random

baseline, but there are numerous exceptions,

especially for larger instances. The fraction of CPU-

time required by the QAP model versus the OBP

optimizer is between 0.008-0.019, meaning that it is

50-122 times faster. Table 1 also shows that this ratio

grows with instance size.

1

https://github.com/johanoxenstierna/OBP_instances,

collected 23-01-2022.

2

https://github.com/johanoxenstierna/L09_251,

collected 23-01-2022.

Figure 3: The predictive strength of the QAP surrogate

model, in terms of NDCG ranking, versus a random

baseline (red line). The middle lines are the means and the

outer edges are 95% and 99% confidence intervals,

respectively.

Overall, the result provides evidence that the QAP

model may be of use within the larger algorithm

proposed in Section 4. On the one hand, experiments

suggest that the quality of the QAP model worsens

with instance size (Figure 3), but on the other, it

becomes relatively faster compared to the OBP

optimizer (Table 1). This means that more samples

can be chosen from when selecting candidates for the

ground truth OBP valuation. As mentioned in Section

4, we should also note that the quality of the “ground

truth” estimates provided by the OBP optimizer

decreases with instance size, making analysis of

results for larger instance classes more difficult in

general.

Translating the result into a generally suitable

sample size 𝑛 for the optimizer shown in step iv in

Figure 1 is challenging due to the many various

possible SLAP input parameters. One alternative is to

estimate 𝑛 by using a normal distribution: 𝑛=

𝑧

/

𝜎/𝐸

, with critical value 𝑧

/

(1.96 for 95%

confidence interval), sample size standard deviation

σ and desired margin of error 𝐸, but choices for σ and

𝐸 can of course be debated. Another alternative is to

use convergence-based conditions as in the MCMC

algorithm proposed by Christen & Fox (2005). One

implementational weakness with this alternative is

3

https://github.com/johanoxenstierna/L17_533,

collected 18-05-2022.

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

32

that it is fully sequential, meaning that it would be

harder to parallelize (steps iii and iv in Figure 1). In

summary, the proposed ranking-based NDCG model

requires a parameter 𝑛 which is difficult to tune, but

at the same time it brings some implementational

advantages over a standard MCMC method.

6 CONCLUSION

In this paper new benchmark instances and a new

optimization model for the Storage Location

Assignment Problem (SLAP) are proposed. The

overall optimization model includes a module and a

sub-module: The sub-module consists of a Quadratic

Assignment Problem (QAP) surrogate model, and it

is used within a module where an Order Batching

Problem (OBP) is optimized using Single Batch

Iterated (QAP-SBI). QAP-SBI is loosely based on a

Markov Chain Monte Carlo (MCMC) accept/reject

sampling method. Both modules are used to estimate

the aggregate travel cost of SLAP candidate solutions

(samples). The intent is to increase computational

efficiency by producing fast but noisy cost estimates

using the QAP model, and then submitting the

samples with the lowest cost to ground-truth

evaluation using OBP optimization (SBI).

In order to validate QAP-SBI, experiments were

conducted to test the predictive strength of the QAP

surrogate model. If its predictive strength is not high

enough, its utility within the proposed MCMC

method cannot be justified. Overall, results show that

the QAP model meets this requirement: Its

predictions are generally stronger than a random

value baseline, while being 50-122 times faster than

SBI. Establishing the number of solution candidates

that should be estimated by the QAP model for every

SBI estimate in the proposed MCMC model is left for

future work. For future work we also invite further

discussions into how to best represent SLAP features

in public benchmark data. The many versions of the

SLAP threaten generalizability, but the community

needs to discuss suitable benchmark formats for the

problem.

ACKNOWLEDGEMENTS

This work was partially supported by the Wallenberg

AI, Autonomous Systems and Software Program

(WASP) funded by the Knut and Alice Wallenberg

Foundation. We also convey thanks to Kairos Logic

AB for software.

REFERENCES

Azadeh, K., De Koster, R., & Roy, D. (2019). Robotized

and Automated Warehouse Systems: Review and

Recent Developments. Transportation Science, 53.

Bruch, S., Wang, X., Bendersky, M., & Najork, M. (2019).

An Analysis of the Softmax Cross Entropy Loss for

Learning-to-Rank with Binary Relevance. Proceedings

of the 2019 ACM SIGIR International Conference on

the Theory of Information Retrieval (ICTIR 2019), 75–

78.

Cai, B., Meyer, R., & Perron, F. (2008). Metropolis–

Hastings algorithms with adaptive proposals.

Statistics and Computing, 18(4), 421–433.

https://doi.org/10.1007/s11222-008-9051-5

Cao, Z., Qin, T., Liu, T.-Y., Tsai, M.-F., & Li, H. (2007).

Learning to Rank: From Pairwise Approach to Listwise

Approach. Proceedings of the 24th International

Conference on Machine Learning, 227, 129–136.

https://doi.org/10.1145/1273496.1273513

Cardona, L. F., Rivera, L., & Martínez, H. J. (2012).

Analytical study of the Fishbone Warehouse layout.

International Journal of Logistics Research and

Applications, 15(6), 365–388.

Charris, E., Rojas-Reyes, J., & Montoya-Torres, J. (2018).

The storage location assignment problem: A literature

review. International Journal of Industrial Engineering

Computations, 10.

Christen, J. A., & Fox, C. (2005). Markov Chain Monte

Carlo Using an Approximation. Journal of

Computational and Graphical Statistics, 14(4), 795–

810.

Ene, S., & Öztürk, N. (2011). Storage location assignment

and order picking optimization in the automotive

industry. The International Journal of Advanced

Manufacturing Technology, 60, 1–11.

https://doi.org/10.1007/s00170-011-3593-y

Fontana, M. E., & Nepomuceno, V. S. (2017). Multi-

criteria approach for products classification and their

storage location assignment. The International Journal

of Advanced Manufacturing Technology, 88(9), 3205–

3216.

Freund, Y., Iyer, R., Schapire, R. E., & Singer, Y. (2003).

An efficient boosting algorithm for combining

preferences. Journal of Machine Learning Research,

4(Nov), 933–969.

Freund, Y., & Schapire, R. E. (1996). Experiments with a

New Boosting Algorithm.

Garfinkel, M. (2005). Minimizing multi-zone orders in the

correlated storage assingment problem. School of

Industrial and Systems Engineering, Georgia Institute

of Technology.

Henn, S., & Wäscher, G. (2012). Tabu search heuristics for

the order batching problem in manual order picking

systems. European Journal of Operational Research,

222(3), 484–494.

Kallina, C., & Lynn, J. (1976). Application of the Cube-per-

Order Index Rule for Stock Location in a Distribution

Warehouse. Interfaces, 7(1), 37–46.

New Benchmarks and Optimization Model for the Storage Location Assignment Problem

33

Kofler, M., Beham, A., Wagner, S., & Affenzeller, M.

(2014). Affinity Based Slotting in Warehouses with

Dynamic Order Patterns. Advanced Methods and

Applications in Computational Intelligence, 123–143.

Koster, R. de, Le-Duc, T., & Roodbergen, K. J. (2007).

Design and control of warehouse order picking: A

literature review. European Journal of Operational

Research, 182(2), 481–501.

Kübler, P., Glock, C. H., & Bauernhansl, T. (2020). A new

iterative method for solving the joint dynamic storage

location assignment, order batching and picker routing

problem in manual picker-to-parts warehouses.

Computers & Industrial Engineering, 147, 106645.

Larco, J. A., Koster, R. de, Roodbergen, K. J., & Dul, J.

(2017). Managing warehouse efficiency and worker

discomfort through enhanced storage assignment

decisions. International Journal of Production

Research, 55(21), 6407–6422. https://doi.org/10.1080/

00207543.2016.1165880

Lee, I. G., Chung, S. H., & Yoon, S. W. (2020). Two-stage

storage assignment to minimize travel time and

congestion for warehouse order picking operations.

Computers & Industrial Engineering, 139, 106129.

https://doi.org/10.1016/j.cie.2019.106129

Mantel, R., Schuur, P., & Heragu, S. (2007). Order oriented

slotting: A new assignment strategy for warehouses.

European Journal of Industrial Engineering, 1, 301–

316.

Oxenstierna, J., Malec, J., & Krueger, V. (2021). Layout-

Agnostic Order-Batching Optimization. International

Conference on Computational Logistics, 115–129.

Oxenstierna, J., Malec, J., & Krueger, V. (2022). Analysis

of Computational Efficiency in Iterative Order

Batching Optimization. Proceedings of the 11th

International Conference on Operations Research and

Enterprise Systems - ICORES, 345–353.

https://doi.org/10.5220/0010837700003117

Oxenstierna, J., van Rensburg, L. J., Malec, J., & Krueger,

V. (2021). Formulation of a Layout-Agnostic Order

Batching Problem. In B. Dorronsoro, L. Amodeo, M.

Pavone, & P. Ruiz (Eds.), Optimization and Learning

(pp. 216–226). Springer International Publishing.

Ratliff, H., & Rosenthal, A. (1983). Order-Picking in a

Rectangular Warehouse: A Solvable Case of the

Traveling Salesman Problem. Operations Research, 31,

507–521.

Reinelt, G. (1991). TSPLIB - A Traveling Salesman

Problem Library. INFORMS J. Comput., 3, 376–384.

Rensburg, L. J. van. (2019). Artificial intelligence for

warehouse picking optimization—An NP-hard problem

[Master’s Thesis]. Uppsala University.

Roodbergen, K. J., & Koster, R. (2001). Routing methods

for warehouses with multiple cross aisles. International

Journal of Production Research

, 39(9), 1865–1883.

Wu, J., Qin, T., Chen, J., Si, H., & Lin, K. (2014). Slotting

Optimization Algorithm of the Stereo Warehouse.

Proceedings of the 2012 2nd International Conference

on Computer and Information Application (ICCIA

2012), 128–132. https://doi.org/10.2991/iccia.2012.31

Wutthisirisart, P., Noble, J. S., & Chang, C. A. (2015). A

two-phased heuristic for relation-based item location.

Computers & Industrial Engineering, 82, 94–102.

https://doi.org/10.1016/j.cie.2015.01.020

Xiang, X., Liu, C., & Miao, L. (2018). Storage assignment

and order batching problem in Kiva mobile fulfilment

system. Engineering Optimization, 50(11), 1941–1962.

https://doi.org/10.1080/0305215X.2017.1419346

Zhang, R.-Q., Wang, M., & Pan, X. (2019). New model of

the storage location assignment problem considering

demand correlation pattern. Computers & Industrial

Engineering, 129, 210–219.

https://doi.org/10.1016/j.cie.2019.01.027

Žulj, I., Glock, C. H., Grosse, E. H., & Schneider, M.

(2018). Picker routing and storage-assignment

strategies for precedence-constrained order picking.

Computers & Industrial Engineering, 123, 338–347.

https://doi.org/10.1016/j.cie.2018.06.015

APPENDIX

NDCG flowchart: The below example shows how

Normalized Discounted Cumulative Gain (NDCG)

can be computed from input permutations (products

to locations), approximated (𝑓) and ground truth (𝑓

∗

)

values. Note that 𝑓

(

𝑿

)

denotes a sorting of 𝑿

according to the cost valuation of elements in the cost

step. Also note that relevance values can be

formulated in several ways.

Figure 4: NDCG flowchart.

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

34

Table 1: Summary of instances and results for the CPU-times of the OBP model (SBI) and the QAP model, as well as an

aggregate of the results concerning the predictive strength of the QAP model.

New Benchmarks and Optimization Model for the Storage Location Assignment Problem

35