Speed, the Double-edged Sword of the Industry 4.0

Marion Toussaint

1,2

, Sylvere Krima

3

, Allison Barnard Feeney

4

and Herve Panetto

2

1

Associate, NIST, 100 Bureau Drive, Gaithersburg, MD, 20899, U.S.A.

2

Université de Lorraine, CNRS, CRAN, 54000 Nancy, France

3

Georgetown University, Washington, DC, 20057, U.S.A.

4

NIST, 100 Bureau Drive, Gaithersburg, MD, 20899, U.S.A.

Keywords: Industry 4.0, Data Exchange, Data Interoperability, Data Traceability.

Abstract: The recent and ongoing digital transformation of the manufacturing world has led to numerous benefits, from

higher quality products to increased productivity and reduced time to market. In this digital world, data has

become a critical element in many essential decisions and processes within and across organizations. Data

exchange is now a key process for the organizations’ communication, collaboration, and efficiency. Industry

4.0/Industry of the Future adoption of modern communication technologies has made data available and

shareable at a speed faster than we can consume or track it. This speed is a double edge sword and comes with

key challenges, such as data interoperability and data traceability, which manufacturers need to understand in

order to adopt the best mitigation strategies. This paper is a summarized introduction to these challenges, their

origins, and what they mean to manufacturers.

1 INTRODUCTION

Over the centuries, technological advancement has

changed the production methods that humans use.

New techniques and production processes have

radically changed people's working conditions and

lifestyles.

The First Industrial Revolution marked the birth

of mechanization through the use of water and steam

power. The Second Industrial Revolution reflected

the emergence of mass production possible through

the discovery of electricity. The Third marked the

emergence of automation in production processes

through the introduction of electronics and

information technology. Finally, the Fourth Industrial

Revolution, also known as “Industry 4.0”, was

formed by the digital revolution that started during

the Third Industrial Revolution based on cyber-

physical systems (CPS). It is also characterized by the

interconnectivity of the systems and access to real-

time data.

The digital revolution in the world of

manufacturing is fueled by advances in information

and communication technologies. Paper-based 2D

drawings and unstructured data sources (e.g.,

spreadsheets, text documents, email, …) have been

replaced by structured digital data models containing

various types of information (e.g., product design,

manufacturing equipment, process data …). On the

same principle, automated processes to collect and

analyze data in real-time have succeeded the manual

methods formerly used.

The digitalization of manufacturing and the

adoption of IoT/CPS technology (e.g., smart sensors,

smart actuators, machine learning) and cyber-

physical systems have facilitated and resulted in the

generation and acquisition of large volumes of

heterogeneous data (Reinsel et al, 2018) (e.g., product

models or telemetry data). Organizations produce,

consume, and exchange massive volumes of data as

part of their daily operations. Data now has the power

to instantly turn into information, knowledge, and

educated decisions, in an effort to boost performances

(e.g., reducing cost or optimizing resources)

(Rüßmann et al., 2016). For instance, tooling data can

now be processed and analyzed by AI agents to

optimize machine performance and energy efficiency

in real-time. Digital data has become an essential

player in many decision-making processes and a

critical enabler to improving manufacturing

competitiveness (Tao et al., 2018).

Industry 4.0 necessitates and enables fast access

and exchange of that product data among a variety of

applications and information systems - within and

across organizations. A product creates and relies on

a large amount of data during its lifecycle in response

Toussaint, M., Krima, S., Feeney, A. and Panetto, H.

Speed, the Double-edged Sword of the Industry 4.0.

DOI: 10.5220/0011527000003329

In Proceedings of the 3rd International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2022), pages 123-128

ISBN: 978-989-758-612-5; ISSN: 2184-9285

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

123

to different processes (e.g., design, manufacturing,

inspection) and business needs (e.g., technical,

commercial, regulatory). Every organization

involved in the product lifecycle relies on this data to

perform its function. It represents the “fuel” behind

the organization's contribution, efficiency, and value:

organizations can create more value and drive faster

innovation by exchanging data across them,

facilitating collaboration.

Unfortunately, fast and reliable data exchange is

also a complex operation that comes with multiple

challenges (Panetto et al., 2019), each of which can

have drastic consequences on organizations, their

operations, their products, and their collaborators. In

this paper, we define and discuss the risks associated

with two major challenges, data interoperability and

data traceability. In the next section we introduce the

data interoperability issue and discuss why the

traditional information standard development process

is inadequate to support the Industry 4.0 fast-paced

environment. We follow by discussing cyber threats,

why manufacturing is a viable target, and how

appropriate data traceability can help mitigate these

risks in this complex environment. Finally, we

conclude and discuss future directions.

2 DATA INTEROPERABILITY

Following this digital transformation of the industry

and the modernization of the adopted communication

technologies, data is now available from all, to all,

and in a multitude of formats. Organizations can

easily connect different software and physical

systems, internally and within their network of

collaborators, as long as these systems speak a

common language.

Unfortunately, today’s manufacturing

organizations are characterized by complex

environments consisting of domain-specific

components such as systems, networks, or machines,

clustered in heterogeneous groups. While the

interaction of these components is crucial for

manufacturing as it supports production processes,

effective interoperability across all elements of the

product lifecycle is a growing challenge (Panetto,

2007). The amount of data produced and consumed

continues to increase due to this growing ecosystem

(of machines, systems, and networks), but so does the

number of data formats. These data are collected from

distributed data sources and therefore do not

necessarily share the same format. Data heterogeneity

is an important factor in data exchange. The different

components of an organization's environment must be

able to unambiguously interpret, use, integrate, and

compare the information exchanged.

These different systems need a common language

to exchange and understand information. The use of

neutral model-based data standards helps provide a

common data format, and thus facilitates

interoperability between all parties involved in an

exchange. Standards are essential for properly

integrating, exchanging, and interpreting data

manufacturers rely on (Sapp et al., 2021). Standards

define an agreed-upon language (data format,

definitions, etc.) for data exchange between the

different systems that consume, process, and produce

data. The lack of standardization results in a

multiplication of information formats that are not

necessarily compatible with each other, making it

difficult for stakeholders to communicate and

exchange data.

Information standards are an important asset for

organizations because they help facilitate business

interaction and support interoperability between

systems, people, and organizations. Information

standardization also saves time and reduces costs by

eliminating the need to have separate translators for

each pair of systems that need to exchange data. The

adoption and implementation of standards by

organizations improves performance,

competitiveness, and transparency given that

standards promote the accessibility of information by

all stakeholders. Information standards are powerful

tools for innovation and productivity and are

therefore key enablers to the evolution and

digitalization of the manufacturing sector. Nowadays,

standards support the full product lifecycle. Product

definition data is represented in ISO 10303

(informally known as STEP) (ISO, 2020).

Manufacturing planning systems can read in STEP

data and generate manufacturing instructions in G-

code (ISO, 2009) or ISO 10303-238 (STEP-NC)

(ISO, 2007). MTConnect Agents (MTConnect

Institute, n.d.) stream machine execution data that

represents an as-manufactured product. Coordinate

measurement system software can read in STEP

product definition data and generate inspection plans

and inspection results represented in the Quality

Information Framework (QIF) (DMSC, 2016).

Despite this, information standards present a

major challenge, which can impact their adoption and

implementation by organizations: the complexity and

current development process length of prominent

standards are incompatible not only with the needs

and pace of the industry but also with the lifespan of

data.

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

124

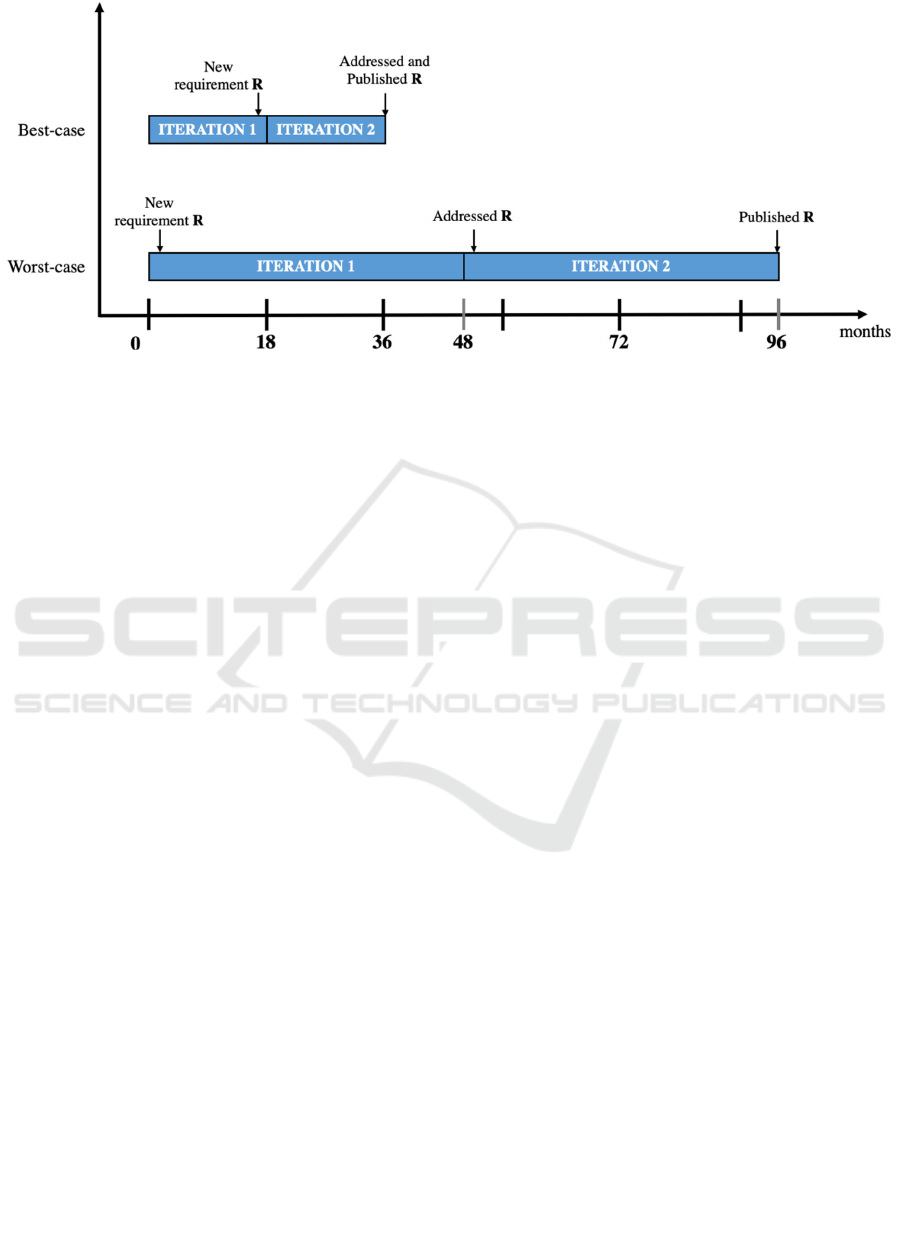

Figure 1: Requirement management in standards development process.

The information standards development process

is complex. This process is generally long, irregular,

and difficult to plan. Firstly, the waterfall

methodology for project management is prominent,

which implies that 1) the entire deliverable is only

available (for review) at the end of the development

iteration and 2) the requirements must be defined at

the beginning of the project and do not change

throughout the entire iteration. According to ISO

itself, standard development iterations can last

between 18 and 48 months (ISO, n.d.). This means

that in a worst-case scenario, if a new requirement is

identified after a new iteration just started, it will not

be addressed for another 48 months, only once the

iteration is complete, and will therefore be published

up to 96 months later. Similarly, in the best-case

scenario, a new requirement could be addressed and

published in 18 months (see Figure 1). But in both

cases, additional time must be given to software

vendors to implement, test, and deliver updated

software solutions.

Secondly, standards are developed by experts that

are working for different organizations. The

contribution and participation of these experts to the

standards development process are entirely voluntary.

The resources available depend on the experts’

schedules and their organizations’ needs, making the

development process irregular and difficult to plan.

The duration and management of the standards

development process are not aligned with the needs of

the industry. Strong market competition results in

shortened product life cycles and requirements that

change often and faster than the pace of standards

development. The standards development process is

incompatible with the data lifespan. Industry 4.0 values

speed and rapid innovation. Consequently, manu-

facturers need standards development organizations to

accelerate and simplify the standards development

process, so the resulting standards represent current

industry needs and are eagerly adopted.

3 DATA TRACEABILITY

Manufacturing has become more automated,

connected, and data-centric. Industry 4.0 is

characterized by the networking of machines,

systems, and products and the convergence of

physical, digital, and virtual environments. This

continuous networking and emergence of cyber-

physical environments allow data to be more quickly

accessible and facilitates the fast and timely exchange

of data between the systems that require the

information and the systems that have the information

(inray Industriesoftware GmbH, 2018). These data

exchanges are both intra- and inter-organizational,

and can be characterized as high-speed, high-volume,

high-frequency, and low latency exchanges. For

instance, on the manufacturing floors, complex

instructions and monitoring data are exchanged in

real-time between the different manufacturing

systems. Similarly, the integration with other

technologies, such as artificial intelligence (AI),

means that data is used to generate and share

decisions at a pace and volume significantly greater

than anything humans can manually validate or track.

This pace and volume of data exchange in the

manufacturing world comes with significant

challenges. The heavy reliance on data-driven

decisions and the integration of new technologies

have made organizations more vulnerable to cyber

threats, a major concern for companies regardless of

their size and sector. The manufacturing sector

Speed, the Double-edged Sword of the Industry 4.0

125

generates large amounts of data and relies heavily on

it, which makes this sector an ideal target for cyber-

attacks. To no surprise, the manufacturing sector was

particularly impacted by cybercrime in 2020 and 2021.

According to the IBM Security’s X-ForceThreat

Intelligence Index 2022 report, manufacturing was the

most attacked sector in 2021 (with 23,2% of all

attacks), while it was ranked second in 2020 (with

17,7% of all attacks) and eighth in 2019 (with 8,1% of

all attacks) (IBM Security 2022).

Generally, security threats are classified

according to the governing principles of the CIA triad

security model: confidentiality, integrity, and

availability (Ham, 2021; Nweke, 2017). Data

confidentiality requires that data remains secret or

private, data integrity requires that the data is

trustworthy and free from tampering, and finally, data

availability requires that data is always accessible to

authorized access when it is needed. Threats and

vulnerability are assessed based on the type of risks

1

associated with and the potential damage they can

cause to an organization's assets, such as data,

applications, and systems.

These risks cannot always be averted and are a

significant challenge to identify and contain. The

IBM’s Cost of a Data Breach Report 2022 shows that

in 2021, the mean time to identify (MTTI) a data

breach was 212 days and 75 days to be contained

(MTTC), for a total lifecycle of 287 days. This

represents a slight increase over 2020, when the

average time to identify and contain a data breach was

280 days (an average of 207 days to identify and an

average of 73 days to contain) (IBM Security, 2021a).

One threat particularly relevant is data manipulation,

an attack that focuses on subtly altering data (Wu et

al., 2018) with the objective of manipulating data-

driven decisions and relies on data exchange to

propagate tampered data and decisions across an

organization and its network. This tampering can

result in corruption, modification, and/or destruction

of the data, ultimately causing a loss of trust in the

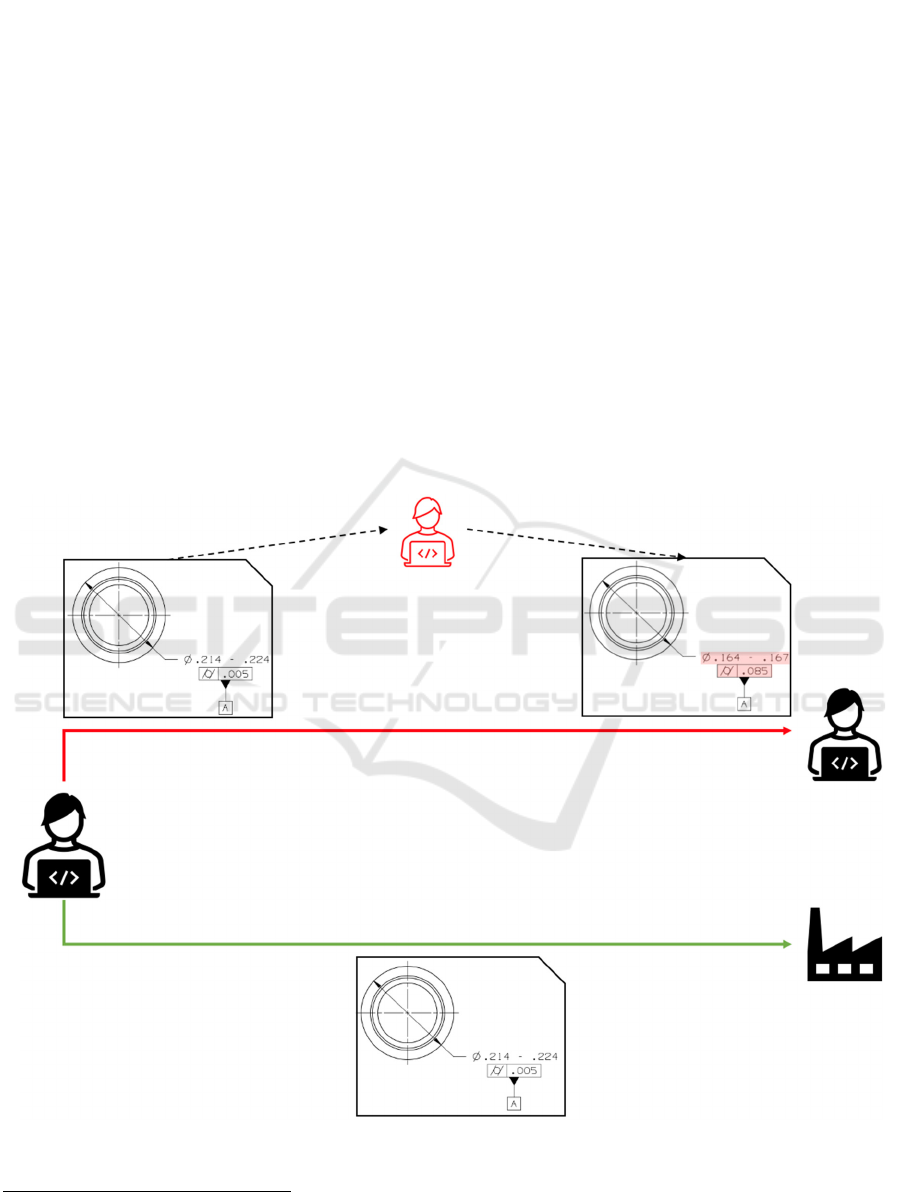

Figure 2: Example of data manipulation during a data exchange – the red flow indicates a malicious actor tampering PMI on

a 2D drawing using a Man In The Middle (MITM)

1

attack.

1

NIST Computer Security Resource Center glossary

https://csrc.nist.gov/glossary/term/man_in_the_middle_a

ttack

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

126

data (IBM Security, 2021b) and the decisions derived

from it. Data manipulation can also potentially lead to

different manufactured products.

When data is exchanged, it leaves the private and

trusted system of the data owner to be sent to other

systems. This process presents the critical risk that the

data exchanged might have been tampered with by

unauthorized parties (see Figure 2). It is therefore

important to ensure the data remains accurate,

authentic and trustworthy during the entire exchange

process. Data integrity is the CIA triad aspect the

most impacted by data exchanges, as integrity assists

both the sender, who must ensure that data attributed

to them is not tampered with, and the receiver, who

needs “the guarantee that the message that is sent is

the same as the message received and that the

message is not altered in transit” (Agarwal and

Agarwal, 2011).

Data integrity presents two main challenges: 1)

validating the accuracy of the data and 2) tracking

down inaccuracy. The former is commonly solved

using digital signatures (Hedberg et al., 2016), while

the latter is more complex and one that still needs to

be addressed. The complexity (i.e., number of actors

and steps involved), pace, and volume of data

exchange that organizations are part of makes it

impossible to manually account for and track down

every single inaccuracy. Those same benefits and

advantages that make manufacturers more

competitive and innovative also make them more

vulnerable to data integrity attacks.

4 CONCLUSION

The digital transformation of manufacturing has led

to more connected, automated, and data-driven

environments and processes. Data has become a key

enabler to processes, exchanges, and decision-

making. Manufacturing relies heavily on data and the

exchange of this data between the different

stakeholders, machines, and systems. By definition,

data exchange refers to the process of sending and

receiving data in a way in which the data content or

meaning has not been altered during communication,

in other words that the data received is an accurate

representation of the data sent.

The digitalization of manufacturing has

emphasized the importance of information

management, data exchange, and the interoperability

of the different actors in the manufacturing processes.

The emergence of new technologies and networked

data sources support new opportunities for

organizational collaboration through high-speed and

high-volume data exchange. In other words, this

digital era helped improve the speed, volume,

accuracy, and consistency of data exchange and

innovations across and within organizations. But with

great speed, came great challenges.

On one hand, faster innovation and collaboration

are being hindered by the data interoperability

challenges. Increased collaboration is associated with

an increased number of heterogeneous systems that

need to communicate with each other. While

standards are a proven solution, their long and

complex development process prevents them from

keeping up with the fast-paced environment they need

to support and provide interoperability for. Recent

efforts (Sapp et al., 2021) promote a transition from

predictive planning to adaptive project planning and

the use of Agile methods to shorten the development

iterations and increase the delivery velocity. These

recommendations should drive manufacturers to

favor standards that have adopted or are planning to

adopt such methods.

On the other hand, data-driven decisions are

exposed to the speed at which tampered data can

propagate through organizations and corrupt these

decisions. With the mean time to identify (MTTI)

such a threat already close to 215 days (IBM

Security, 2021a), the constant growth of data

produced and exchanged is likely to push the MTTI

upwards. While digital signatures have already

proven their use in identifying such corruption,

recent efforts (Krima et al., 2020; Ruland and

Sassmannshausen, 2019; Cao et al., 2020) highlight

the need for new formal data traceability methods

and the use of data standards to automate the

tracking of data exchange across large and complex

networks of organizations and systems. Without

such solutions, the mean time to contain (MTTC)

tampered data and decisions will continue to

increase with the quantity of data exchanges,

perpetuating the current trend and continuing to put

manufacturers at risk (IBM Security, 2021a). These

efforts should drive manufacturers to favor

standards over proprietary formats for their data

exchange in order to enable maximum data

traceability.

To conclude, the speed at which data exchanges

can now be set up and performed has highlighted the

need to reduce the time of 1) development and

implementation of data interoperability solutions

(Sapp et al., 2021) and 2) data traceability operations

(Krima et al., 2020; Ruland and Sassmannshausen,

2019; Cao et al., 2020) in response to cyber-attacks

that manufacturers are victims of, which are two

challenges we will focus on.

Speed, the Double-edged Sword of the Industry 4.0

127

REFERENCES

Agarwal, A., & Agarwal, A. (2011). The Security Risks

Associated with Cloud Computing. International

Journal of Computer Applications in Engineering

Sciences, 1.

Cao, Y., Jia, F., & Manogaran, G. (2020). Efficient

traceability systems of steel products using blockchain-

based industrial internet of things. IEEE Transactions

on Industrial Informatics, 16(9), 6004–6012.

https://doi.org/10.1109/tii.2019.2942211

DMSC. (2016). Digital metrology standards consortium QIF

& DMIS standards. DMSC. https://qifstandards.org/.

Ham, J. V. (2021). Toward a better understanding of

“cybersecurity.” Digital Threats: Research and

Practice, 2(3), [18], pp 1-3. https://doi.org/10.1145/

3442445

Hedberg, T. D., Jr., Krima, S., & Camelio, J. A. (2016).

Embedding X.509 Digital certificates in three-

dimensional models for authentication, authorization,

and traceability of product data. Journal of Computing

and Information Science in Engineering, 17(1).

https://doi.org/10.1115/1.4034131

IBM Security (2021a). IBM: Cost of a data breach report.

(2021). Computer Fraud & Security, 2021(8), 4–4.

https://doi.org/10.1016/s1361-3723(21)00082-8

IBM Security (2021b) IBM: 2021 X-Force Threat

Intelligence index. (2021). Network Security, 2021(3),

4–4. https://doi.org/10.1016/s1353-4858(21)00026-x

IBM Security (2022). IBM: 2022 X-Force Threat

Intelligence index. Computer Fraud & Security,

2022(3). https://doi.org/10.12968/s1361-3723(22)7056

1-1

inray Industriesoftware GmbH (2018). Industry 4.0 depends

on data transfer. timely and target-oriented. Medium.

Accessed: 2022-05-05, from https://medium.com/

@inray.industriesoftware/industry-4-0-depends-on-data

-transfer-timely-and-target-oriented-e725eeffa3e3

ISO. (n.d.). Stages and resources for standards

development. ISO. Accessed: 2022-05-10, from

https://www.iso.org/stages-and-resources-for-standard

s-development.html

ISO. (2007). ISO 10303-238:2007. ISO. Accessed: 2022-

05-10, from https://www.iso.org/standard/38036.html.

ISO. (2009). ISO 6983-1:2009. ISO. Accessed: 2022-05-

10, from https://www.iso.org/standard/34608.html

ISO. (2020). ISO 10303-242:2020. ISO. Accessed: 2022-

05-10, from https://www.iso.org/standard/66654.html

Krima, S., Toussaint, M., & Feeney, A. B. (2020). Toward

model-based integration specifications to secure the

extended enterprise. Smart and Sustainable

Manufacturing Systems, 4(1). https://doi.org/10.1520/

ssms20200022

MTConnect Institute. (n.d.). MTConnect. MTConnect.

Accessed: 2022-05-10, from https://www.mtconnect.

org/.

Nweke, Livinus. (2017). Using the CIA and AAA Models

to explain Cybersecurity Activities. PM World Journal,

VI(XII).

Panetto, H. (2007). Towards a Classification Framework

for Interoperability of Enterprise Applications.

International Journal of Computer Integrated

Manufacturing, Taylor & Francis, 2007, 20 (8), pp.727-

740. https://doi.org/10.1080/09511920600996419

Panetto, H., Iung, B., Ivanov, D., Weichhart, G., & Wang,

X. (2019). Challenges for the cyber-physical

manufacturing enterprises of the future. Annual

Reviews in Control, 47, 200–213.

https://doi.org/10.1016/j.arcontrol.2019.02.002

Reinsel, D., Gantz, J., & Rydning, J. (2018). The

digitization of the world from edge to core. IDC.

https://www.seagate.com/files/www-content/our-

story/trends/files/idc-seagate-dataage-whitepaper.pdf.

Ruland, C., & Sassmannshausen, J. (2019). System-wide

traceability of commands and data exchange in smart

grids. 2019 International Conference on Smart Energy

Systems and Technologies (SEST). http://dx.doi.org/

10.1109/sest.2019.8849108

Rüßmann, M., Lorenz, M., Gerbert, P., Waldner, M.,

Justus, J., Engel, P., & Harnisch, M. (2016). Industry

Sapp, B., Harvey, M., Toussaint, M., Krima, S., Barnard

Feeney, A., & Panetto, H. (2021). Agile for model-

based-standards development. National Institute of

Standards and Technology. http://dx.doi.org/10.6028/

nist.ams.100-40

Tao, F., Qi, Q., Liu, A., & Kusiak, A. (2018). Data-driven

smart manufacturing. Journal of Manufacturing

Systems, 48. https://doi.org/https://doi.org/10.1016/j.jm

sy.2018.01.006.

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

128