Gutenbrain: An Architecture for Equipment Technical Attributes

Extraction from Piping & Instrumentation Diagrams

Marco Vicente

1 a

, Jo

˜

ao Guarda

2 b

and Fernando Batista

3 c

1

Leonard / Vinci Group, Paris, France

2

Axians Digital Consulting, Lisbon, Portugal

3

INESC-ID, Human Language Technologies Department, Lisbon, Portugal

Keywords:

Information Retrieval, Question-answering, Piping & Instrumentation Diagrams.

Abstract:

Piping and Instrumentation Diagrams (P&ID) are detailed representations of engineering schematics with

piping, instrumentation and other related equipment and their physical process flow. They are critical in en-

gineering projects to convey the physical sequence of systems, allowing engineers to understand the process

flow, safety and regulatory requirements, and operational details. P&IDs may be provided in several formats,

including scanned paper, CAD files, PDF, images, but these documents are frequently searched manually to

identify all the equipment and their inter-connectivity. Furthermore, engineers must search the related tech-

nical specifications in separate technical documents, as P&ID usually don’t include technical specifications.

This paper presents Gutenbrain, an architecture to extract equipment technical attributes from piping & in-

strumentation diagrams and technical documentation, which relies in textual information only. It first extracts

equipment from P&IDs, using meta-data to understand the equipment type, and text coordinates to detect the

equipment even when it is represented in multiple lines of text. After detecting the equipment and storing it in

a database, it allows retrieving and inferring technical attributes from the related technical documentation us-

ing two question answering models based on BERT-like contextual embeddings, depending on the equipment

type meta-data. One question answering model works with free questions of continuous text, while the other

uses tabular data. This ensemble approach allows us to extract technical attributes from documents where

information is unstructured and scattered. The performance results for the equipment extraction stage achieve

about 97,2% precision and 71,2% recall. The stored information can be later accessed using Elasticsearch,

allowing engineers to save thousands of hours in maintenance engineering tasks.

1 INTRODUCTION

In the Oil & Gas Upstream industry, the life cycle of

any new asset (offshore or onshore) starts with the En-

gineering, Procurement & Construction phase (EPC).

The first activity of a Maintenance & Inspection En-

gineering Contract (also called a MIEC) is to create

the asset register, which is the hierarchy of all the

equipment. This is the very first mandatory mile-

stone of a MIEC to be able to move on to other activ-

ities such as criticality studies (to define the critical-

ity of each equipment), or the definition of the spare

parts to be procured and put in stock for later use.

And finally, definition of maintenance plans, proce-

a

https://orcid.org/0000-0003-1123-9917

b

https://orcid.org/0000-0002-5733-9553

c

https://orcid.org/0000-0002-1075-0177

dures, and manuals, and link them to the asset regis-

ter. The asset register is created based in the infor-

mation provided in Piping and Instrumentation Dia-

grams (P&ID). P&IDs are detailed representations of

engineering schematics with piping, instrumentation

and other related equipment and their physical pro-

cess flow. P&IDs are critical in engineering projects

to convey the physical sequence of systems, allow-

ing engineers to understand the process flow, safety

and regulatory requirements, and operational details.

P&IDs are provided in several formats: scanned pa-

per, CAD files, PDF, images. Usually, these docu-

ments are searched manually to identify all the equip-

ment and their inter connectivity. Furthermore, en-

gineers must search technical specifications in sepa-

rate technical documents, as P&ID usually don’t in-

clude technical specifications. The process consists in

gathering all documentation coming from EPC con-

204

Vicente, M., Guarda, J. and Batista, F.

Gutenbrain: An Architecture for Equipment Technical Attributes Extraction from Piping Instrumentation Diagrams.

DOI: 10.5220/0011528500003335

In Proceedings of the 14th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2022) - Volume 1: KDIR, pages 204-211

ISBN: 978-989-758-614-9; ISSN: 2184-3228

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

tractor, manufacturers, and suppliers. Each of these

thousands of documents must be searched manually

to identify all the tags of the equipment, group them

by system and sort them as per their parent/child re-

lationship. When a new revision of such a document

appears, it must be processed again to make sure there

is no impact on the asset register. So, this documenta-

tion searching activity is heavy, time consuming and

with low value for the project. The information is hard

to find, and the manual processing and the redundancy

of the activity sometimes leads to human error.

This paper presents Gutenbrain, an architecture to

extract equipment technical attributes from piping &

instrumentation diagrams and technical documenta-

tion, which relies in textual information only. It first

extracts equipment from P&IDs, using meta-data to

understand the equipment type, and text coordinates

to detect the equipment even when it is represented

in multiple lines of text. After detecting the equip-

ment and storing it in a database, it allows retriev-

ing and inferring technical attributes from the related

technical documentation using two question answer-

ing models based on BERT-like contextual embed-

dings, depending on the equipment type meta-data.

One question answering model works with free ques-

tions of continuous text, while the other uses tabu-

lar data. This ensemble approach allows us to extract

technical attributes from documents where informa-

tion is unstructured and scattered. The stored infor-

mation can be later accessed using Elasticsearch, al-

lowing engineers to save thousands of hours in main-

tenance engineering tasks.

This document is organised as follows: Section 2

presents an overview of the related literature. Section

3 describes the proposed architecture. Section 4 re-

ports the achieved evaluation results. Finally, Section

5 presents the main conclusions, and pinpoints future

working directions.

2 RELATED WORK

This section presents an overview of the existing liter-

ature. It starts by focusing on the literature concern-

ing information extraction from diagrams, and then

focuses on the retrieval and inference of technical at-

tributes from additional data.

2.1 Information Extraction from P&IDs

Literature on data extraction for piping & instrumen-

tation diagrams of for engineering drawings is scarce.

Most of the current techniques are based on Com-

puter Vision algorithms and machine learning models.

Nonetheless, there is a gap between this specific do-

main and state-of-the-art techniques and algorithms.

(Moreno-Garc

´

ıa et al., 2019) presents a comprehen-

sive study on the techniques used in the piping & in-

strumentation diagrams domain, referring that most

work that has been done in this field focus on using

computer vision models and algorithms to extract at-

tributes based on the shapes present in the documents.

The early work reported by (Yu et al., 1997) uses

a set of rules applied to the lines of a symbol to clas-

sify it on generic engineering drawings, and not only

P&IDs, and each symbol has a set of rules. (Wenyin

et al., 2007) proposes a similar method by creating

a database of symbols which were described by four

geometric constrains extracted by an algorithm. Al-

though generic and good performance, this approach

requires a pre-processing of all symbols to be de-

tected. More recently, (Fu and Kara, 2011) proposes

the use of a multi-scale sliding window and Con-

nected Component Analysis to locate the symbols and

a Convolutional Neural Network (CNN) to classify

them. This model requires labelled data to learn, and

therefore a large sample of data has to be labelled in

order to apply this method.

In the last few years, researchers applied several

Computer Vision techniques in the P&ID domain.

(Elyan et al., 2018) proposed a heuristic to locate

symbols and random forest combined with clustering

for the classification. Research also focused on ex-

tracting the relationships between the symbols. (Kang

et al., 2019) proposed not only a method to extract

symbols (with contour algorithms) but also extract-

ing the text with OCR and establishing relationships

between symbols by extracting connection lines. A

more robust and modern methodology was proposed

by (Rahul et al., 2019). They use a Fully Convolu-

tional Network (FCN) and can do all the segmenta-

tion (detection and classification) with a single model.

It also uses rules to detect connections and relation-

ships. Finally, (Gao et al., 2020) uses the ResNet-

50 (He et al., 2015), a Faster Regional Convolutional

Neural Network (Faster RCNN), backbone with data

augmentation techniques to detect and classify sym-

bols. Once again, rules are applied to infer connec-

tions and relationships.

2.2 Retrieval of Technical Attributes

Pre-trained transformer models are the state-of-the-art

for question-answering (Q&A) tasks. One of them is

DistilBERT (Sanh et al., 2019), a distilled version of

BERT (Devlin et al., 2018) that leverages the complex

architecture that BERT was trained on but is faster,

smaller and lighter. To further improve the perfor-

Gutenbrain: An Architecture for Equipment Technical Attributes Extraction from Piping Instrumentation Diagrams

205

mance of the model in a question-answering task, usu-

ally, it is fined-tuned using the (Rajpurkar et al., 2016)

dataset. It has more than 100,000 question-answers

pairs from Wikipedia.

The models described before don’t work well with

tabular data. Therefore, (Herzig et al., 2020) intro-

duces TAPAS, an extension to BERT to encode tables

as input, to do question-answering over tables without

using logical forms as previous literature suggested.

Recently, (Chen et al., 2020) proposed a method to

apply Q&A to both textual and tabular data. “Early

fusion´´ is used to fuse tabular and textual units into

a block and a cross-block reader to capture the depen-

dency between multiple evidence.

These techniques have been applied in the instruc-

tion manuals domain to extract technical attributes.

(Abinaya Govindan and Verma, ) proposed a pipeline

for dealing with image, text and tabular data using

pre-trained Q&A models. (Nandy et al., 2021) also

proposed a pipeline, for text only, using a model built

on RoBERTa (Liu et al., 2019).

3 PROPOSED ARCHITECTURE

This section describes the proposed two-steps

methodology for extracting technical attributes from

P&ID and technical documentation in detail.

3.1 P&ID Information Extraction

To be able to detect equipment in P&IDs, we first in-

gest all documentation into a database. Then, we use

this information and meta-data to detect equipment.

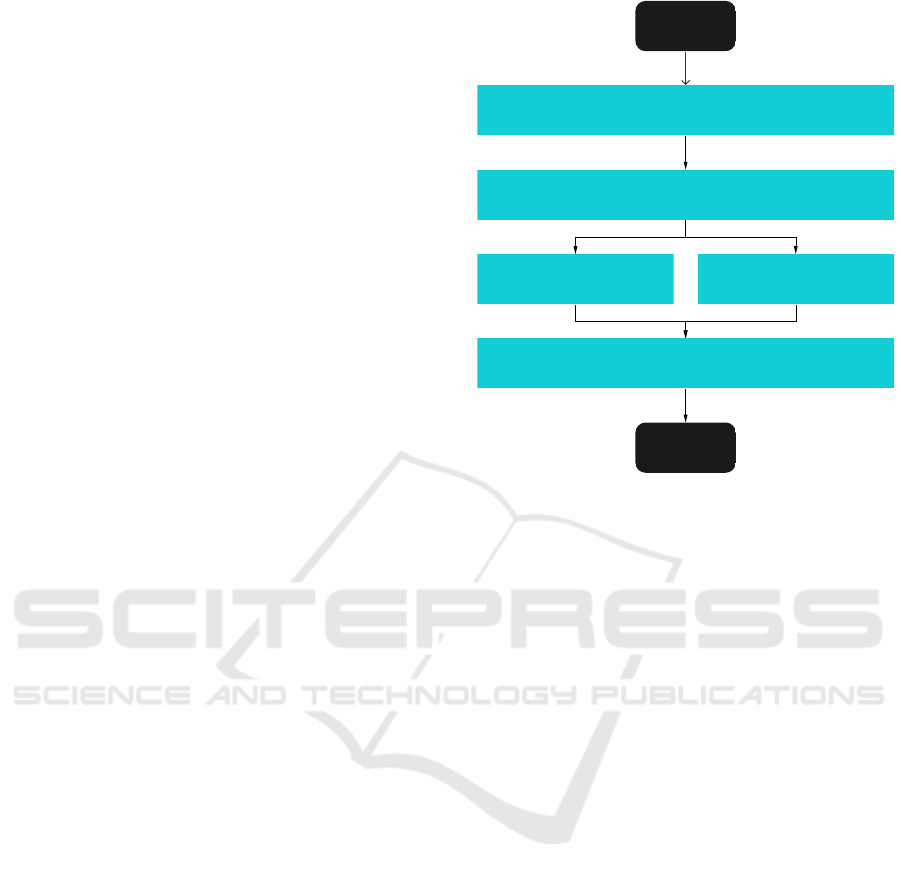

Figure 1 shows the pipeline for this initial process.

3.1.1 Extract Text and Coordinates from P&IDs

The first step consists in ingesting all P&IDs of a

project to extract the embedded data. We start by

extracting all the text and text coordinates into a

database. Documents can contain text, raster images,

vectors and text without Unicode mapping (usually

it happens in documents exported from CAD to PDF

without the font used). We start by extracting na-

tive text, and bounding boxes. The bounding boxes

are useful information, containing the coordinates of

the text. When we detect characters without Uni-

code mapping, we send the bounding box of this piece

of undetectable text to Optical Character Recognition

(OCR), using Google OCR API. After extracting all

the native text, we remove all text from the PDF and

if the pages still have information, we send the pages

stripped of native text to OCR and store the received

Extract text from piping & instrumentation diagrams

Start

Detect equipment in extracted text

Detect patterns in single line Detect patterns in multiple lines

Store detected equipment in database

End

Figure 1: P&IDs information extraction pipeline.

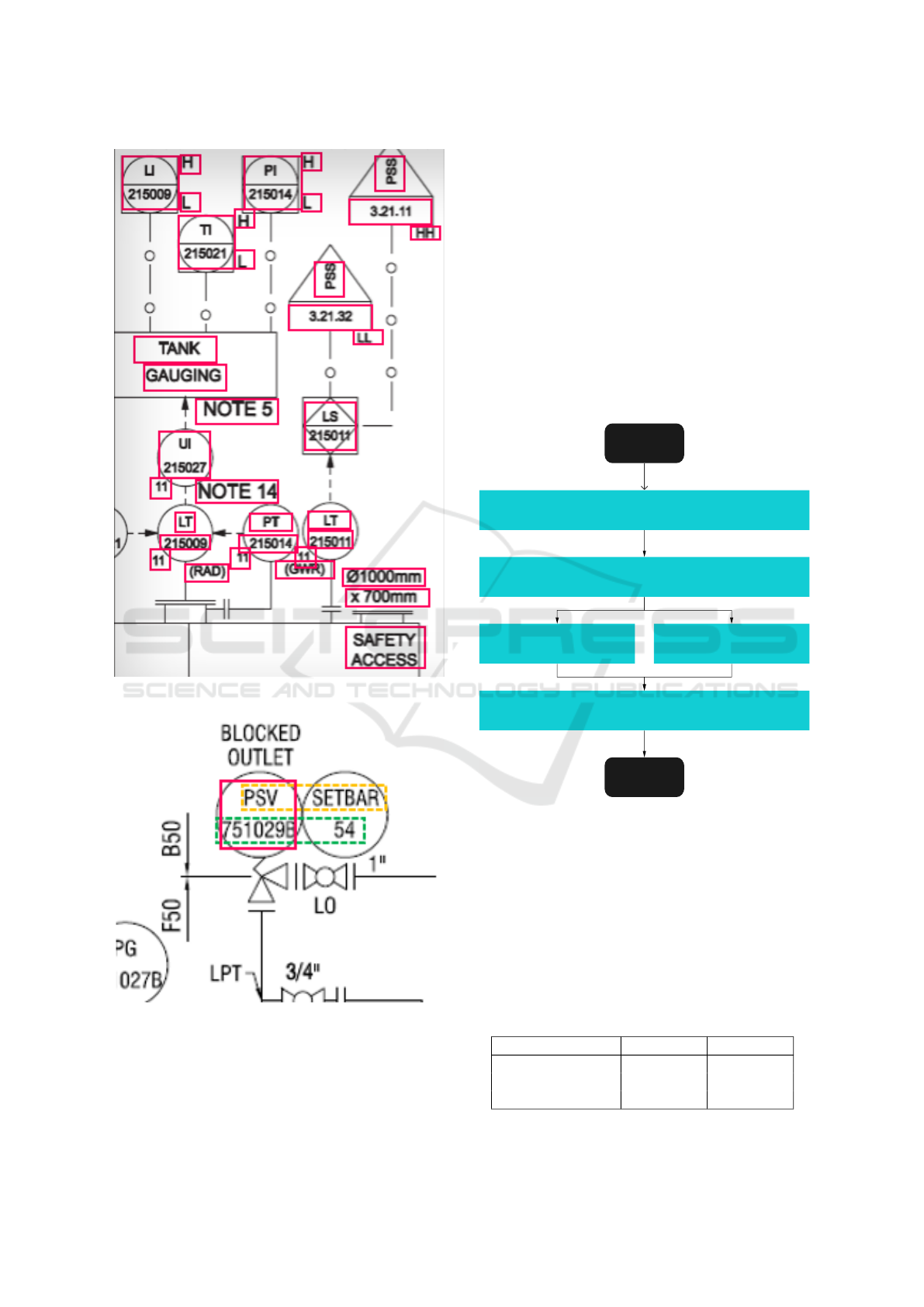

text and coordinates into our database. An example

of the extracted text and bounding boxes can be seen

in Figure 2. All information extracted is stored in the

database.

3.1.2 Detect Equipment in Extracted Text

In the industry, equipment and piping numbering are

structured according to rules with meaningful infor-

mation. The numbering of a piping or a equipment

will provide, at least, its equipment type, system, sub-

system and sequential number. Using regular expres-

sions, we detect the equipment present in each P&ID.

Having the equipment tag, we can infer its equipment

type (e.g.: water pump), system (e.g.: Water Process-

ing) and subsystem (e.g.: Filtration). The challenge

with this simple approach is that sometimes equip-

ment tags are multi-line, as we can see in Figure 3.

We developed a function to detect the nearest text

boxes of a determined text, using the coordinates of

the bounding boxes. If a text is composed of the

beginning of a pattern, we validate if the surround-

ing bounding boxes are the missing parts. After ex-

tracting all the equipment, equipment type, system

and subsystem, we store all this information in the

database.

3.2 Retrieving and Inferring the

Technical Attributes

To make informed decisions, engineers still need

technical information regarding each equipment. For

KDIR 2022 - 14th International Conference on Knowledge Discovery and Information Retrieval

206

Figure 2: Extracted text.

Figure 3: Multi-line equipment tags.

this, we developed a pipeline to extract relevant infor-

mation regarding each equipment.

3.2.1 Preprocess Technical Documentation

We ingest all technical documentation of a project

to extract the embedded data. We start by process-

ing data from thousands of unstructured files into a

database. These files are comprised by textual, tab-

ular and technical drawing data, sometimes stored in

legacy data formats. For each document we store the

type of equipment they refer to, and we store the ex-

tracted text in two formats: continuous text and tabu-

lar data. This distinction will be useful to later steps,

when deciding what model to use to extract technical

attributes. The ingestion of technical documentation

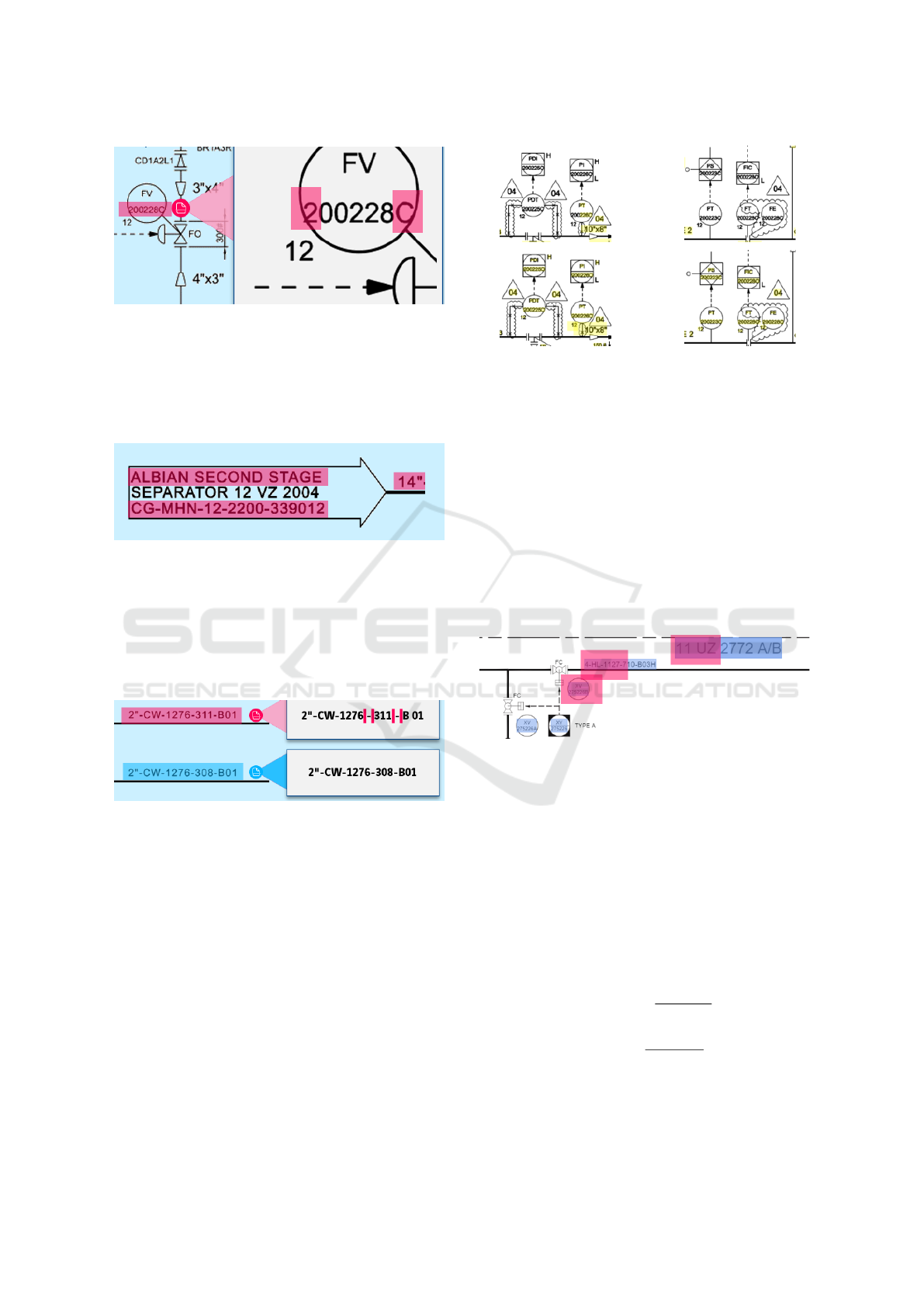

is fully automatized. Figure 4 shows the preprocess-

ing of technical documentation.

Preprocess technical information

Start

Extract equipment types referenced in documents

Extract continuous text Extract tabular data

Store technical equipment information in database

End

Figure 4: Technical documentation preprocessing pipeline.

3.2.2 Retrieval Technical Attributes

To be able to extract technical information for each

equipment type, we have created a database of 693

types of equipment, and for each equipment we filled

their attributes. Each equipment can have from 1 to

20 technical attributes, as illustrated in the examples

presented in Figure 1.

Table 1: Examples of equipment and its corresponding at-

tributes.

Equipment Attribute 1 Attribute 2

Amplifier Input Output

Air Conditioner Type Power

Centrifugal Pump Model Flow Rate

Gutenbrain: An Architecture for Equipment Technical Attributes Extraction from Piping Instrumentation Diagrams

207

Having this information loaded, we run a search

for each equipment. First, we read its equipment

type. Second, we search in the technical documen-

tation for documents classified as having information

regarding that type of equipment. Third, we divide

the information of these documents in two separate

contexts, namely: continuous text information, and

tabular information. Forth, we generate questions for

each technical attribute. For the question construc-

tion, we send a full text question. e.g.: what is the

power of the air conditioner. Finally, we send the

questions and the context information to two sepa-

rate question answering models. The continuous text

information is used as context to the question an-

swering model DistilBERT (Sanh et al., 2019). The

model used is a fine-tune checkpoint of DistilBERT-

base-uncased, fine-tuned using knowledge distillation

on SQuAD v1.1. The tabular information is sent to

the question answering model TAPAS (Herzig et al.,

2020). TAPAS is a BERT-like transformers model,

pretrained on raw tables and associated texts, allow-

ing to query tabular information. Finally, we compare

the best result of each model and save in the database

the one with higher score. Figure 5 shows the extrac-

tion of technical attributes.

Create questions for each technical attribute

Start

Prepare context for continuous text and tabular data

Get TAPAS answer using tabular

data

Get DistilBERT answer using

continouous text

Compare scores and store best answer

End

Figure 5: Retrieval of technical attributes.

3.3 Supporting Architecture

To provide Gutenbrain functionalities to users, we

rely on a cloud-based architecture. The user interface

is built in React, a JavaScript library. It allows users to

visualise and edit extracted information from P&IDs.

All the back-end functionalities are available through

REST APIs developed with fast-API and deployed in

Uvicorn, an ASGI server. Information extracted is

stored in MongoDB. MongoDB allows queries with

regular expressions, critical to equipment detection

in the P&IDs. To allow users to query semantically

in the information of all equipment, we use Elastic-

search, a search engine based on the Lucene library.

Documents are stored in a persistent storage account,

enabling the usage of containers for all other build-

ing blocks of the architecture. Finally, Google OCR

is used to extract text from images. An overview can

be seen in Figure 6.

Figure 6: Reference Architecture.

4 EXPERIMENTS AND RESULTS

This section describes the results obtained for the pro-

posed Gutenbrain architecture, also reporting on the

faced challenges. It starts by focusing on the stage

of extracting information from P&ID, and then on the

stage of retrieving technical attributes from the stored

data.

4.1 P&ID Information Extraction

4.1.1 OCR

Most of the P&IDs are scanned, have images, or are

exported from CAD files into vectors. The use of

OCR is essential to extract that text information. To

be able to extract equipment from diagrams using

OCR, three main challenges arise.

First, in the context of diagrams, text is some-

times overlapped with symbols, as shown in Figure

7. This causes two types of error: 1) only part

of the text is extracted, ignoring the characters

overlapped with symbols, or 2) overlapped shape

and characters are merged and the retrieved text is

incorrect. In both cases, the equipment tag is unre-

coverable, as we have partial or incorrect information.

KDIR 2022 - 14th International Conference on Knowledge Discovery and Information Retrieval

208

Figure 7: Text overlapped with symbol.

Second, multiple lines are hard to detect when

there is little space between, as we see in Figure 8.

This means that relevant information is lost, either by

removing full equipment or part of multi-line equip-

ment.

Figure 8: Multi-line text.

And finally, sometimes OCR adds spaces where

there are none. With these nonexistent spaces, two

things can occur: 1) the equipment pattern is not de-

tected, as it contains spaces, or 2) the OCR detects

the text as separate words or separate text blocs. An

example can be seen in Figure 9.

Figure 9: Nonexistent spaces added by OCR capture.

To tackle these challenges, we performed an OCR

benchmark between Tesseract, Azure and Google

OCR. Tesseract is convenient, as it works on-

premises, but its performance is sub-par when com-

paring with both Azure and Google. When compar-

ing Azure and Google OCR regarding how they tackle

the three above mentioned challenges, Google outper-

formed Azure in all of them. Figure 10 shows how

Google was able to detect text even with overlapped

symbols.

We are currently using Google OCR to extract text

from all diagrams and technical documentation.

Figure 10: Azure results above. Google results bellow.

4.1.2 Equipment Sanitisation

When extracting equipment, their codes can have dif-

ferent separation of components, as they are usually

not normalised. Sometimes they have hyphen sepa-

rating attributes (equipment type, system, subsystem),

other times they have space, and others they are in

multiple lines, having only the break of line to sepa-

rate them, as shown in Figure 11. To ensure the same

equipment is considered as such if it appears in sev-

eral documents, we sanitise the equipment. We add

hyphen where a space or line break is found when

storing in the database.

Figure 11: Several equipment patterns.

4.1.3 Equipment Extraction Results

To be able to validate the equipment extraction pro-

cess, we have annotated manually a dataset of P&IDs

containing 607 equipment records. These documents

are very big, but unlike the computer vision ap-

proaches where documents are split and shrinked, we

enlarged them in order to improve the OCR results.

The dataset is composed of a mix of documents with

native text, images, vectors and some text without

Unicode mapping.

Precision =

T P

T P + FP

(1)

Recall =

T P

T P + FN

(2)

The performance of the system was evaluated us-

ing Precision and Recall, two metrics commonly used

Gutenbrain: An Architecture for Equipment Technical Attributes Extraction from Piping Instrumentation Diagrams

209

in the literature and defined in equations 1 and 2,

where TP represents true positives, FP represents

false positives, and FN represents false negatives. We

also present the F1-measure, a metric that combines

precision and recall. Table 2 shows the achieved re-

sults, revealing that our system is able to achieve an

impressive performance, specially in terms of Preci-

sion. We can see that the recall is highly affected

when the document must be processed with OCR in

order to retrieve the text, since it introduces errors.

Table 2: Performance results for the equipment extraction

stage.

Results Precision Recall F1-measure

Text 0,984 0,824 0,897

OCR 0,960 0,600 0,738

Average 0,972 0,712 0,822

Current studies of P&ID information extraction

use image-based techniques, recognising symbols

through template matching. When compared with the

approach of previous works, our architecture achieves

better results. Comparison is shown in Table 3.

Table 3: Performance results comparison.

Method Authors Precision

Symbol detection (Rahul et al., 2019) 0,799

Symbol detection (Kang et al., 2019) 0,90

Text detection Gutenbrain 0,972

4.2 Retrieval and Inference of Technical

Attributes

4.2.1 Preprocessing of Technical Documentation

To be able to use technical documents’ information

in the question answering models, data was extracted

to the database in two different stacks: 1) continu-

ous text, and 2) tabular data. This will be important

when extracting technical attributes, as it is different

to search in continuous text or in tabular data. Be-

sides extracting this information, each document was

also classified with the equipment type it contained

information.

4.2.2 Retrieval of Technical Attributes

The goal of retrieving technical attributes is to find

all the characteristics for each equipment, according

to its type. e.g.: for a centrifugal pump, we want to

know its model, use, flow rate, output, pressure, in-

take temperature, viscosity and input connection.

The first step is to find the documents that have

information regarding the identified equipment type.

After finding the subset of relevant documents, we

create a set of questions to be used in both ques-

tion answering models. We use questions in full sen-

tences: ”what is the <attribute> of the <equipment

type>”. e.g.: what is the flow rate of the centrifu-

gal pump? The next step is to send the question and

all continuous text as context to our DistilBert model.

The model gives us the best answer and their score.

Afterwards, we send the same question to our TAPAS

base model, but using as context all tabular informa-

tion found in the selected documentation. Again, it

will give us the best answer and their score. To extract

answers from tabular data, our approach is similar to

the one proposed by (Chen et al., 2020). We compare

the score of each model and store the best result in

our database. Our suggestion to the technical attribute

will be the result with best confidence among both

models. As opposed to directional models, which

read the text input sequentially (left-to-right or right-

to-left), the Masked Language Model (MLM) objec-

tive enables the representation to use both the left and

the right context, which allows to pre-train a deep

bidirectional Transformer. Since maintenance engi-

neering has special jargon, BERT’s sub-word repre-

sentations and word-piece tokenization are useful for

the out-of-vocabulary words that often appear in the

corpus. This only mitigates the special jargon issue to

fully solve it the models should be fine-tuned to our

specific domain. BERT’s architecture works well for

this task-specific finetuning, since it was trained on a

large corpus

Table 4 shows some examples of questions, and

the corresponding answer with the associated score.

Table 4: Some examples of questions.

Question Answer Score

What is the wattage of

the lamp?

26W 79,30%

What are the dimensions

of the Converter?

40 x 119 x

115 mm

54,10%

What is the manufacturer

of the light?

SCHNEIDER

ELECTRIC

82,89%

We were able to find a great part of the technical

attributes from equipment, and, when the confidence

was low, we were still able to show engineers the right

documents for them to extract manually. As we are

using extractive question and answering models, we

can show the documents in the right pages for engi-

neers to validate the extracted attributes.

KDIR 2022 - 14th International Conference on Knowledge Discovery and Information Retrieval

210

5 CONCLUSIONS AND FUTURE

WORK

We have proposed an approach to extract equipment

and technical attributes from P&IDs and retrieve tech-

nical documentation from technical sheets, and de-

scribed an architecture to support this approach. We

have performed experiments on a manually labelled

dataset of P&IDs, containing 607 equipment, and

the performance results for the equipment extraction

stage achieve about 97,2% precision and 71,2% re-

call.

In the Oil & Gas Upstream industry, EPC projects

take in average 90k hours of technical engineers to

create the asset register, to do criticality studies (to

define the criticality of each equipment), the defini-

tion of the spare parts to be procured and put in stock

for later use, and the definition of maintenance plans,

procedures, and manuals. The proposed architecture,

Gutenbrain, allows the saving of 16k per project, ei-

ther by extraction automatically the equipment infor-

mation or by allowing to search in the technical in-

formation using semantic search in content otherwise

unsearchable. The experimental validation presents

an average reduction of approximately the 60% of

engineers’ effort in cumbersome tasks of extracting

equipment information allowing the saved hours to be

spent by engineers on tasks with higher value. This

approach still requires users to validate the extracted

information and extract the undetected information,

but we provide a user interface for engineers to have

the autonomy to do so.

In the future we would like to fine-tune the

question-answering models with closed-context data

from past projects to improve the results. We would

also like to complement the equipment extraction

with the computer vision approach of detecting sym-

bols within diagrams. The hypothesis being that an

ensemble method using text and symbols might out-

perform our current approach.

REFERENCES

Abinaya Govindan, G. R. and Verma, A. Intelligent ques-

tion answering module for product manuals.

Chen, W., Chang, M.-W., Schlinger, E., Wang, W., and Co-

hen, W. W. (2020). Open question answering over

tables and text. arXiv preprint arXiv:2010.10439.

Devlin, J., Chang, M.-W., Lee, K., and Toutanova, K.

(2018). Bert: Pre-training of deep bidirectional trans-

formers for language understanding. arXiv preprint

arXiv:1810.04805.

Elyan, E., Garcia, C. M., and Jayne, C. (2018). Sym-

bols classification in engineering drawings. In 2018

International Joint Conference on Neural Networks

(IJCNN), pages 1–8. IEEE.

Fu, L. and Kara, L. B. (2011). From engineering diagrams

to engineering models: Visual recognition and appli-

cations. Computer-Aided Design, 43(3):278–292.

Gao, W., Zhao, Y., and Smidts, C. (2020). Component de-

tection in piping and instrumentation diagrams of nu-

clear power plants based on neural networks. Progress

in Nuclear Energy, 128:103491.

He, K., Zhang, X., Ren, S., and Sun, J. (2015). Deep

residual learning for image recognition. CoRR,

abs/1512.03385.

Herzig, J., Nowak, P. K., M

¨

uller, T., Piccinno, F., and Eisen-

schlos, J. M. (2020). Tapas: Weakly supervised table

parsing via pre-training.

Kang, S.-O., Lee, E.-B., and Baek, H.-K. (2019). A digiti-

zation and conversion tool for imaged drawings to in-

telligent piping and instrumentation diagrams (p&id).

Energies, 12(13):2593.

Liu, Y., Ott, M., Goyal, N., Du, J., Joshi, M., Chen, D.,

Levy, O., Lewis, M., Zettlemoyer, L., and Stoyanov,

V. (2019). Roberta: A robustly optimized bert pre-

training approach. arXiv preprint arXiv:1907.11692.

Moreno-Garc

´

ıa, C. F., Elyan, E., and Jayne, C. (2019).

New trends on digitisation of complex engineer-

ing drawings. Neural computing and applications,

31(6):1695–1712.

Nandy, A., Sharma, S., Maddhashiya, S., Sachdeva, K.,

Goyal, P., and Ganguly, N. (2021). Question answer-

ing over electronic devices: A new benchmark dataset

and a multi-task learning based qa framework. arXiv

preprint arXiv:2109.05897.

Rahul, R., Paliwal, S., Sharma, M., and Vig, L.

(2019). Automatic information extraction from pip-

ing and instrumentation diagrams. arXiv preprint

arXiv:1901.11383.

Rajpurkar, P., Zhang, J., Lopyrev, K., and Liang, P. (2016).

Squad: 100,000+ questions for machine comprehen-

sion of text. arXiv preprint arXiv:1606.05250.

Sanh, V., Debut, L., Chaumond, J., and Wolf, T. (2019).

Distilbert, a distilled version of bert: smaller, faster,

cheaper and lighter. ArXiv, abs/1910.01108.

Wenyin, L., Zhang, W., and Yan, L. (2007). An interactive

example-driven approach to graphics recognition in

engineering drawings. International Journal of Docu-

ment Analysis and Recognition (IJDAR), 9(1):13–29.

Yu, Y., Samal, A., and Seth, S. C. (1997). A system for rec-

ognizing a large class of engineering drawings. IEEE

Transactions on Pattern Analysis and Machine Intel-

ligence, 19(8):868–890.

Gutenbrain: An Architecture for Equipment Technical Attributes Extraction from Piping Instrumentation Diagrams

211