Edge Containerized Architecture for Manufacturing Process Time

Series Data Monitoring and Visualization

Ander Garcia

a

, Xabier Oregui

b

, Javier Franco

c

and Unai Arrieta

d

Vicomtech Foundation, Basque Research and Technology Alliance (BRTA),

Mikeletegi 57, 20009 Donostia-San Sebastián, Spain

Keywords: Cyber Physical System, Industry 4.0, Time Series, Edge Computing.

Abstract: Pushed by the Industry 4.0 paradigm, the volume of data being captured from manufacturing lines is

continuously increasing. To get a deeper insight of manufacturing processes, time series data from key

variables of the processes has to be captured, monitored and visualized. This implies that more data variables

must be monitored and data must be captured at a higher frequency: from one value of a few key variables to

values of several variables captured at frequencies of seconds. Traditional Manufacturing Execution Systems

(MES) were not designed for this scenario and cannot cope with these requirements. Thus, new architectures

and tools are required to merge Information Technology (IT) and Operation Technology (OT) fields. This

paper proposes a lightweight architecture based on micro-services and time series data requirements to

connect to manufacturing process controllers, and to capture, store, monitor and visualize relevant data about

the process. Moreover, a reference implementation based on Open Source tools is presented and validated.

1 INTRODUCTION

Pushed by the Industry 4.0 paradigm, the volume of

data being captured from manufacturing lines is

continuously increasing. To get a deeper insight of

manufacturing processes, more data variables are

being monitored and data is captured at a higher

frequency: from one value of a few key variables for

a whole batch, to time series of several variables

captured at frequencies of seconds. Traditional

Manufacturing Execution Systems (MES) were not

designed for this scenario.

Thus, new architectures are required to integrate

Information Technology (IT) and Operations

Technology (OT) fields. This implies a myriad of IT

and OT technologies, standards and specifications

related to Industry 4.0.

The complexity of this integration generates a

knowledge barrier, as these IT technologies follow a

completely different philosophy from the regular

tools used by OT engineers. Thus, Small and

Medium-sized Enterprises (SMEs), which generally

a

https://orcid.org/0000-0001-5596-2838

b

https://orcid.org/0000-0002-2443-3367

c

https://orcid.org/0000-0002-9588-6857

d

https://orcid.org/0000-0003-0710-8148

lack multidisciplinary teams with the required IT and

OT knowledge and experience, face big difficulties to

capture, monitor and visualize data from

manufacturing processes.

Standard reference architectures such as RAMI

4.0 support advanced Industry 4.0 use cases, adding

additional technological complexity, which does not

add value for most SMEs starting to monitor time

series data from their processes.

Existing market solutions rely on external cloud

servers to perform these tasks, adding a dependency

on servers out of the control of manufacturing

companies, which is not compatible with privacy and

confidentiality requirements of several

manufacturing companies.

This paper tackles this complexity by proposing a

containerized micro-service-based edge architecture

to monitor and visualize manufacturing processes.

The architecture connects to manufacturing

controllers to acquire time series data about the

processes, and then store it on a time series database

to be monitored and visualized. A reference

Garcia, A., Oregui, X., Franco, J. and Arrieta, U.

Edge Containerized Architecture for Manufacturing Process Time Series Data Monitoring and Visualization.

DOI: 10.5220/0011574500003329

In Proceedings of the 3rd International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2022), pages 145-152

ISBN: 978-989-758-612-5; ISSN: 2184-9285

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

145

implementation of the architecture based on Open-

Source tools is presented and validated with a

simulated process.

2 RELATED WORK

The German government presented the Industrie 4.0

term in 2011. The objective of the fourth industrial

revolution is to work with a higher level of

operational productivity and efficiency, connecting

the physical to the virtual world. Industry 4.0, also

known as Industrial Internet of Things (IIoT), is

related to several technologies such as Internet of

Things (IoT), Industrial Automation, Cybersecurity,

Intelligent Robotics, or Augmented Reality (Alcácer

& Cruz-Machado, 2019).

The term cyber-physical systems (CPS) was

coined in the USA in 2006 and has received several

definitions (Fei et al., 2019). CPS is the merger of

‘‘cyber” as electric and electronic systems with

‘‘physical” things. The ‘‘cyber component” allows

the ‘‘physical component” (such as mechanical

systems) to interact with the physical world by

creating a virtual copy of it. This virtual copy will

include the ‘‘physical component” of the CPS (i.e., a

cyberrepresentation) through the digitalization of

data and information (Alcácer & Cruz-Machado,

2019).

In general, a CPS consists of two main functional

components: (1) the advanced connectivity that

ensures real-time data acquisition from the physical

world and information feedback from the cyber

space; and (2) intelligent data management, analytics

and computational capability that constructs the cyber

space (Lee et al., 2015).

First attempts to integrate advances services from

Industry 4.0 on manufacturing environments were

based on cloud computing. Cloud computing

paradigm relies on remote servers with a storage and

computing power magnitudes beyond local servers.

However, cloud computing presents four main

disadvantages for manufacturing scenarios: latency,

security, privacy, and cost.

Edge computing is a paradigm where data are

analyzed and stored close to the devices generating

and consuming them, facing previous disadvantages

and making them attractive for manufacturing

scenarios (Alam et al., 2018; Qiu et al., 2020).

The main objective of edge computing is to

exploit computational resources of interconnected

devices to increase their independence and to get data

analysis and exploitation closer to where data is

generated. This paradigm optimizes cloud computing

paradigms moving data processing task (or part of

them), to the edge of the network. This philosophy is

especially relevant for manufacturing scenarios.

Edge computing devices have increasingly

powerful computation functionalities. This, combines

with advanced connectivity technologies such as 5G,

which offers a fast, robust, and massive connectivity,

is paving the way for a new type of intelligent devices

and services based on Artificial Intelligence.

Recently, various attempts have been made to

transform manufacturing systems into interoperable,

connected and digitalized elements. However, the

main challenges of the Industry 4.0, including

cybersecurity, and standardized data interchange

between devices, machines and services, are still

opened (Lu, 2017). In (Qiu et al., 2020), a review of

the application of edge computing paradigm into

manufacturing scenarios is provided, identifying

architectures, advances and open challenges.

Existing international reference architectures for

manufacturing scenarios, such as RAMI 4.0 or IIRA,

propose reference models difficult to implement

(Szántó et al., 2021). Moreover, architectures

proposed by other authors target a lot of complex

functionalities related to the Industry 4.0

(Azarmipour et al., 2020; Omar et al., 2019; Yang et

al., 2020).

Thus, their implementation is time and cost

consuming, out of the reach of small and medium

manufacturing companies.

The architecture proposed in this paper is focused

on an specific case: monitor and visualize time series

data from manufacturing processes. However, the

architecture is flexible enough to be extended with

new future services (for example to integrate

Artificial Intelligence services), increase its

performance, or integrate new communication and

security mechanisms.

3 ARCHITECTURE

The architecture is composed by the following

components: client, message queue, writer, time

series database, visualizer, and monitor (Figure 1).

The manufacturing equipment is the asset being

monitored. Data from the equipment is captured from

the manufacturing controller, which publishes it using

standard communication specifications such as OPC-

UA or MQTT.

The Open Platform Communications Unified

Architecture (OPC-UA), has become the

interoperability standard for the secure and reliable

exchange of data in the industrial domain, easing the

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

146

Figure 1: General architecture.

tasks of capturing and exporting data. In the most

common OPC UA communication paradigm, the

manufacturing equipment has an OPC UA server that

allows to read/write variables values and to invoke

custom methods. Clients connect to the server to

read/write values of the variables, to call remote

methods, and to subscribe to receive changes on their

values.

MQTT is a robust and trustworthy protocol, with

implementations with very low computation

requirements and available for most of the current

hardware and software platforms.

MQTT is based on a queue manager (broker),

where different clients send messages (publish). Each

message is sent with a certain subject (topic) and may

contain data (payload). Other clients can show their

interest in certain topics to the que manager

(subscribe). When the queue manager receives a

message with some of these topics, it sends the

message to the subscribed clients.

This communication paradigm based on

publishing messages and subscribing to topics to

receive them, has proved to be a robust, efficient, and

low latency technology. Currently, it is one of the

most used protocols for Internet of Things domain.

Although the proposed architecture does not

impose the use of a communication protocol, authors

recommend the use of OPC-UA or MQTT. Most

modern Programable Logic Controllers (PLCs)

already include OPC-UA or MQTT functionalities,

and there are several specialized gateways on the

market translating other industrial protocols to OPC-

UA or MQTT.

However, if this option is not available for some

manufacturing scenario, it would be always possible

to develop a custom communication module inside

the client to get data from the manufacturing

controller.

The first element of the architecture is the client.

Its main task is to connect to the manufacturing

equipment to obtain the values of the manufacturing

process. The client has to perform data cleaning and

validation tasks to ensure the quality of the data,

including the check of the timestamps. Moreover,

when required, data has to be transformed to a proper

format to be stored, for example to update numeric

values to labels or Booleans, or to generate synthetic

data from variables. Once data is ready, it is sent to

the writer using a message queue.

The message queue decouples the client from the

writer. It could be based on any technology, such as

MQTT, as long as it satisfies the load requirements of

each scenario.

The main task of the writer is to receive data from

the message queue and to transform it into a proper

format to be sent directly to the time series database

to be stored.

The time series database manages data storage

and retrieval operations. This database should have

advanced functionalities to ease querying time series,

and to aggregate data to optimize disk space

utilization.

The visualizer is responsible to generate

dashboards of the manufacturing processes, and to

allow final users (operators, engineers…) to visualize

and manually analyse data.

The last element, the monitor, is focused on the

generation of alarms and notifications when data of

the manufacturing process is out of its regular range

or some conditions are fulfilled.

The architecture is based on decoupled micro-

services designed to be deployed as containers. The

objective is (i) to ease the deployment at the edge, and

(ii) to allow individual changes or upgrades of each

micro-service without having to update and validate

the rest of the micro-services.

4 REFERENCE

IMPLEMENTATION

This section presents a reference implementation of

the general architecture based on Open-Source tools.

Edge Containerized Architecture for Manufacturing Process Time Series Data Monitoring and Visualization

147

Each micro-service has been designed as a Docker

container, and the architecture has been orchestrated

with the docker compose tool.

The client has been implemented as a Python

micro-service. OPC-UA and MQTT support has been

based on the FreeOpcUa library and the MQTT Paho

library from the Eclipse Foundation. The client sends

values of the variables to the message queue with a

JSON payload with and object format. Each element

of the object has three element: timestamp of the

value, identifier of the equipment, and an object of

data with variables name and value pairs. Thus, each

message can include value for one or more variables.

The message queue has been implemented with

RabbitMQ, a lightweight and widely deployed Open-

Source message broker. Although it requires more

computing resources than MQTT, RabbitMQ

supports several messaging protocols and paradigms,

and has better security and reliability features.

Moreover, RabbitMQ includes internal buffers to

avoid losing messages if the writer is temporarily

overloaded and mechanisms to easily integrate new

writer containers if several clients are sending data to

the queue.

The writer has been implemented as a Python

micro-service. It receives messages from the queue,

and transforms data into INSERT queries for the

database. This insert queries have to be formatted to

fulfil the format expected by the SQL dialect of the

database.

TimescaleDB has been selected as the time series

database engine over other alternatives such as

InfluxDB due to its advanced functionalities, SQL

language compatibility, and the rich PostgreSQL

based tooling ecosystem. TimescaleDB is an Open-

Source database designed to make SQL scalable for

time-series data. It is engineered up from PostgreSQL

and packaged as a PostgreSQL extension.

Traditional relational databases, such as MySQL

or SQL Server, are not suited for the storage of time

series data, as their performance decrease greatly as

the data volume of the time series increases. NoSQL

databases, such as MongoDB, have recently include

support for time series data, but the functionalities

they offer to work with time series data is still not

comparable to the ones offered by TimescaleDB or

InfluxDB.

Finally, both the visualizer and the monitor

components have been deployed based on Grafana.

Grafana is a popular multi-platform Open Source

analytics and interactive visualization web

application. Grafana is agnostic of the underlying

database and has an intuitive user interface both to

customize charts and dashboards, and to generate

alerts and notifications based on advanced rules and

notification channels.

All the micro-services have been deployed as

docker containers within the same docker network.

The Web access port from Grafana has been exposed

within the client host to be accessible from a Web

Client. Port 5432 from TimescaleDB has also been

exposed to allow the use of PostgreSQL desktop tools

such as pgadmin from the host machine. Information

to automatically connect micro-services and to

manage data persistence of each container has been

included inside the docker compose definition.

The main customization of the reference

implementation to be deployed in a new scenario is

related to OPC UA or MQTT, and the structure of the

data and the database. For example, different OPC

UA servers may send data either as an object, or as a

several individual variables. Regarding MQTT, each

controller may use different topic and payload

definition to send data.

The design of the database is also specific of each

scenario. In a general scenario, a table with these

columns would be enough to store data:

• Time: to store the timestamp of the value

• Id: to store the identifier of the equipment

• Variable: To store the name of the variable

• Value: To store the value of the variable. It

should be a string to allow storing different data

types

However, this design may present performance

drawbacks to retrieve data from the database, and to

visualize and monitor it, as each value has to be

parsed. Thus, it is recommended that each scenario

designs its database table to store time series data.

For OPC-UA servers, a config file with the URL,

and optionally the username and password, has to be

updated. Moreover, a list of the identifier of each

OPC UA node variable has to be filled, including the

name and type of each variable. For MQTT, server

connection data (URL, username and password) and

the topic name have to be defined. Moreover, as

MQTT payload is not standardized, code changes

may be required on the client to read variable names

and values from the MQTT messages.

5 VA L I D AT I O N

The architecture has been validated with a simulator

of a manufacturing basic boiling process. The

simulator is provided by the Open Source OPC-UA

PLC server implementation from Microsoft. The

simulated boiler has three variables (temperature,

pressure and heater state) and two methods to turn the

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

148

heater on or off. When the heater is on, the bottom

temperature increases by 1 degree per second, the top

temperature is always 5 degrees less than the bottom

one. Pressure is calculated as 100000 plus bottom

temperature.

The client has subscribed to these variables to

receive their values and sent them to the message

queue. However, instead of publishing one node for

each variable, the OPC Server publishes one node of

type BoylerDataType. This data type includes three

variables:

• HeaderState: Boolean representing whether the

boiler is on or off

• Pressure

• Temperature: IT is an object with two

variables:

o Top

o Bottom

In order to get the identifier of the boiler node, we

have used a regular OPC UA client GUI, UaExpert

from Unified Automation. The identifier is

“ns=3;i=15013”.

The client subscribes to these node, and receives

updates of the values. Each time an update is

received, the object is parsed. When the boiler is off,

there is no data about the temperatures or the

pressure. Thus, the client set their value as “-1” to

mark them as unknown.

Once data is ready, the client send it to a

RabbitMQ queue named “boiler”. The next code

shows an example payload of the message:

{

"data": {

"temperature": {

"top": 23,

"bottom": 28

},

"pressure": 100028,

"heaterState": 1

},

"time": "2022-08-12T10:15:18.784Z",

"id": "boiler01"

}

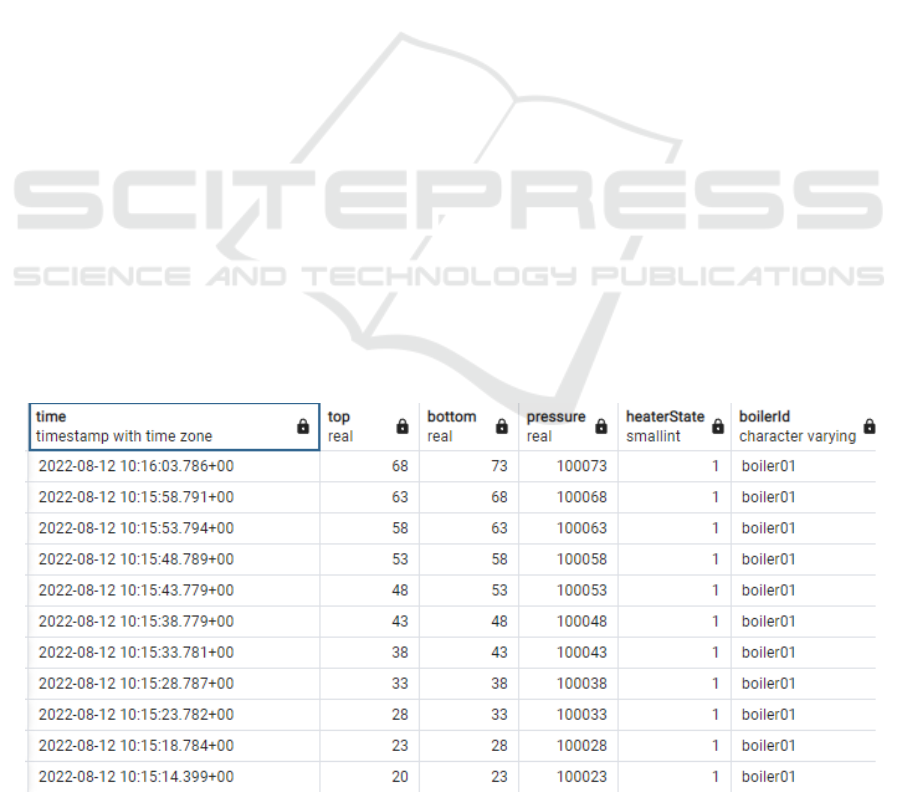

The writer receives these updates and send them to

the TimescaleDB database. A table has been created

for the boiler with the following columns:

• Time: to store the timestamp of the value

• Id: to store the identifier of the boiler and to

allow to store data from more than one boiler in

the future

• Top: To store the temperature of the top of the

boiler

• Bottom: To store the temperature of the bottom

of the boiler

• Pressure: To store the pressure

• HeaderState: To store whether the boiler is off

(0) or on (1)

The writer receives each message and generates the

following SQL query to insert data. The database

receives the query and stores data on the table (Figure

2).

INSERT INTO boiler("time", top, bottom, pressure,

"heaterState","boilerId") VALUES ('2022-08-

12T10:18:03.779Z', 30, 35, 100193, 1,'boiler01');

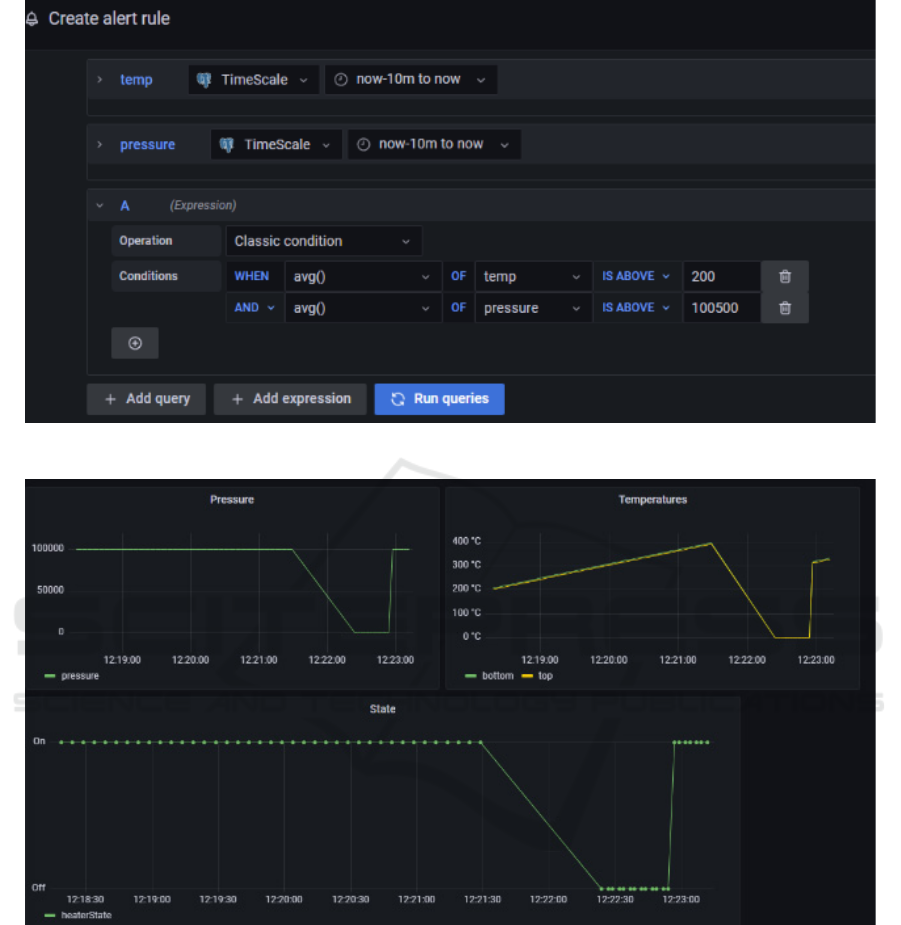

The notifier has been configured to raise alarms each

time some of these conditions are met:

• Temperature is out of the 15-300 range

• Pressure is above 101500

• Temperature is above 200 and pressure is

above 100500

Figure 2: Screenshot of a select query of the data.

Edge Containerized Architecture for Manufacturing Process Time Series Data Monitoring and Visualization

149

Figure 3: Example of a complex rule generation.

Figure 4: Example of a Grafana dashboard.

The alarms are easily configured using the

Grafana GUI (Figure 3). For each alert rule, after

selecting the datasource and the related table and

column, several conditions can be applied to decide

whether an alert should be raised.

Grafana has a powerful alert customization and

notification mechanism able to suit most of the

regular requirements to monitor manufacturing

equipment. Once rules have been defined, labels can

be attached to them to ease their management. Then,

a notification policy is applied where several filters

regarding time, labels, severities… allow to decide

whether the alert has to be redirected to any of the

available notification channels. There are several

notification channels (email, slack, PagerDuty…)

available, and custom ones can also be defined.

Finally, a dashboard showing the values of the

temperature, pressure and status of the boiler has been

generated in Grafana (Figure 4).

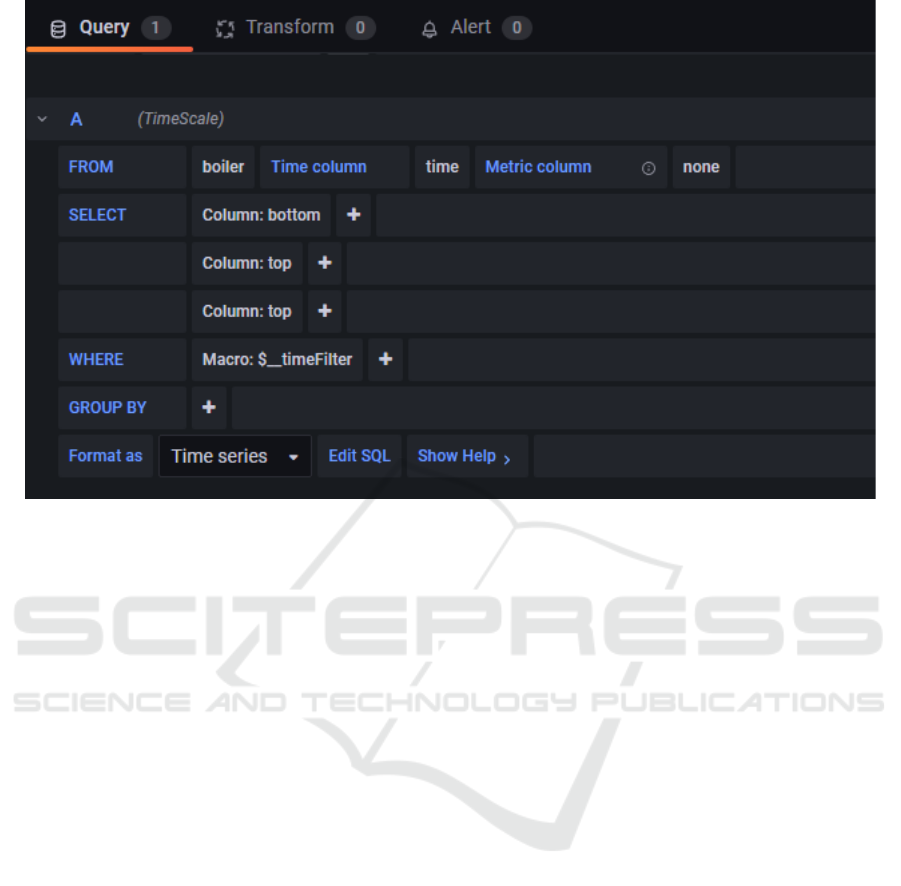

Definition of each graph is easily customized

using the available query builder (Figure 5). Using the

GUI a general SQL query is generated, and it is also

possible to insert manual SQL queries to directly

integrate advanced functions from TimescaleDB such

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

150

Figure 5: Query builder from Grafana.

as time buckets. Time buckets allow to get uniformly

distributed data points within a range, for example

one value with the average of the values from the

database each 10 minutes.

The whole system has been defined as docker

containers orchestrated within a docker compose file.

This docker compose file can be used as a template to

be deployed in new scenarios, after updating the

points mentioned in the previous section.

6 CONCLUSIONS

Industry 4.0 requires data to get insights of the

manufacturing processes. Thus, requirements to

capture more data variables and at a higher frequency

arises: from one value of a few key variables for a

whole batch, to time series of several variables

captured at frequencies of seconds. Traditional

Manufacturing Execution Systems (MES) were not

designed for this scenario composed by a high

volume of time series data of manufacturing

processes.

Thus, new architectures are required to integrate

Information Technology (IT) and Operations

Technology (OT) fields. This implies a myriad of IT

and OT technologies, standards and specifications

related to Industry 4.0, with a high complexity level.

SMEs are not ready to cope with this complexity

level.

This paper tackles this complexity by proposing a

containerized micro-service-based edge architecture

to monitor and visualize manufacturing processes.

The architecture connects to manufacturing

controllers to acquire time series data about the

processes, and then store it on a time series database

to be monitored and visualized. A reference

implementation of the architecture based on Open-

Source tools has been presented and validated with a

simulated process.

The architecture is based on decoupled containers

to be easily deployed at the edge. It has four main

elements.

The client connects to the manufacturing

equipment to obtain the values of the manufacturing

process. Once data is ready, it is sent to the writer

using a message queue.

The main task of the writer is to receive data from

the message queue and to transform it into a proper

format to be sent directly to the time series database

to be stored. The time series database manages data

storage and retrieval operations.

The visualizer is responsible to generate

dashboards of the manufacturing processes, and to

allow final users (operators, engineers…) to visualize

and manually analyse data.

The last element, the monitor, is focused on the

generation of alarms and notifications when data of

the manufacturing process is out of its regular range,

or some conditions are fulfilled.

Edge Containerized Architecture for Manufacturing Process Time Series Data Monitoring and Visualization

151

A reference implementation based on the following

Open Source has also been provided:

• Custom Python scripts for the client and the

writer

• RabbitMQ message queue to connect the client

and the writer

• TimescaleDB to store time series data

• Grafana to deploy and customize the visualizer

and the monitor

This implementation has been validated using a

simulator of a boiler from Microsoft which includes

and OPC UA Server to subscribe to its values. Data

from the boiler has been captured, adapted and stored

at the database. A Grafana dashboard has been

created to visualize data from the boiler, and three

rules have been successfully generated to create alerts

when undesirable conditions are fulfilled.

The proposed architecture greatly decreases the

technological barrier required to monitor and

visualize data from manufacturing processes.

Moreover, as data is already properly stored at the

database, it serves as a foundation for future services,

for example integrating Artificial Intelligence

algorithms to provide predictive maintenance

functionalities.

Future work starts with a validation at a real

manufacturing scenario for a relevant period of time

to test the resilience and scalability of the

implementation. Moreover, advances functionalities

from TimescaleDB to manage data retention and

aggregation policies should also be validated.

Performance of the solution in a real scenario

customized with rules and alarms related to a real

manufacturing use case should also be tackled during

the validation.

One last point to further decrease the

technological barrier consists of the integration of no-

code tools, such as node-red. Node-red is a popular

graphical tool where non-expert users interact with

simple blocks to customize the functionalities of a

system using an interactive interface.

ACKNOWLEDGEMENTS

This work has been partially founded by the Basque

Government (SPRI) through the following Elkartek

project: KK-2021/00111 ERTZEAN.

REFERENCES

Alam, M., Rufino, J., Ferreira, J., Ahmed, S. H., Shah, N.,

& Chen, Y. (2018). Orchestration of Microservices for

IoT Using Docker and Edge Computing. IEEE

Communications Magazine, 56(9), 118–123.

https://doi.org/10.1109/MCOM.2018.1701233

Alcácer, V., & Cruz-Machado, V. (2019). Scanning the

Industry 4.0: A Literature Review on Technologies for

Manufacturing Systems. Engineering Science and

Technology, an International Journal, 22(3), 899–919.

https://doi.org/10.1016/j.jestch.2019.01.006

Azarmipour, M., Elfaham, H., Gries, C., Kleinert, T., &

Epple, U. (2020). A Service-based Architecture for the

Interaction of Control and MES Systems in Industry 4.0

Environment. IEEE International Conference on

Industrial Informatics (INDIN), 2020-July, 217–222.

https://doi.org/10.1109/INDIN45582.2020.9442083

Fei, X., Shah, N., Verba, N., Chao, K. M., Sanchez-Anguix,

V., Lewandowski, J., James, A., & Usman, Z. (2019).

CPS data streams analytics based on machine learning

for Cloud and Fog Computing: A survey. Future

eneration Computer Systems, 90, 435–450.

https://doi.org/10.1016/j.future.2018.06.042

Lee, J., Bagheri, B., & Kao, H. A. (2015). A Cyber-Physical

Systems architecture for Industry 4.0-based

manufacturing systems. Manufacturing Letters, 3, 18–

23. https://doi.org/10.1016/j.mfglet.2014.12.001

Lu, Y. (2017). Industry 4.0: A survey on technologies,

applications and open research issues. Journal of

Industrial Information Integration, 6, 1–10.

https://doi.org/10.1016/j.jii.2017.04.005

Omar, A., Imen, B., M’Hammed, S., Bouziane, B., &

David, B. (2019). Deployment of Fog Computing

Platform for Cyber Physical Production System Based

on Docker Technology. Proceedings - 2019 3rd

International Conference on Applied Automation and

Industrial Diagnostics, ICAAID 2019, 1(September),

1–6. https://doi.org/10.1109/ICAAID.2019.8934949

Qiu, T., Chi, J., Zhou, X., Ning, Z., Atiquzzaman, M., &

Wu, D. O. (2020). Edge Computing in Industrial

Internet of Things: Architecture, Advances and

Challenges. IEEE Communications Surveys and

Tutorials, 22(4), 2462–2488. https://doi.org/10.1109/

COMST.2020.3009103

Szántó, N., Pedone, G., Monek, G., Háy, B., & Jósvai, J.

(2021). Transformation of traditional assembly lines

into interoperable CPPS for MES: an OPC UA enabled

scenario. Procedia Manufacturing, 54, 118–123.

https://doi.org/10.1016/j.promfg.2021.07.019

Yang, C., Lan, S., Shen, W., Wang, L., & Huang, G. Q.

(2020). Software-defined Cloud Manufacturing with

Edge Computing for Industry 4.0. 2020 International

Wireless Communications and Mobile Computing,

IWCMC 2020, 1618–1623. https://doi.org/10.1109/

IWCMC48107.2020.9148467

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

152