Construction of a Model of Interaction of a Fiber-reinforced Plate

with an Elastic Base

А. N. Pestryakov

1

, I. G. Ovchinnikov

1,2

and A. S. Demidov

1

1

Ural State University of Railway Transport, Yekaterinburg, Russia

2

Saratov State Technical University Named After Yuri Gagarin, Saratov, Russia

Keywords: fiber-reinforced concrete, fiber concrete, elastic base plate, rigid pavement, modeling of fiber concrete,

approximation of experimental data.

Abstract: The article considers a special case of calculation of thin-walled structures, namely plates on an elastic base,

as a structure with a fairly significant scope of application in transport construction. The issues related to the

construction of a model of deformation of fiber-reinforced plates with an elastic base are considered. In the

context of solving the above-mentioned issues, an analysis of the deformation diagrams of fiber-reinforced

concrete (fiber concrete), as well as physically nonlinear relations describing the deformations of fiber-

reinforced material that variously resists tensile and compression deformations under the plane stress state

characteristic of plates, is given.

1 INTRODUCTION

After the beginning of the economic crisis in 2008,

transport builders faced a very important problem of

reducing the strength of building materials while

maintaining their strength properties. Constant

changes in prices for materials and labor costs

forced Gosstroy to abandon the basic index pricing

method (the main method in force since 1991) in

2016 and switch to the resource method. This

method has fully justified itself during the crisis

caused by sanctions and the coronavirus pandemic

(COVID-19). Designers began to regularly,

according to Customer requirements, in order to

reduce the cost, recalculate the ratio of concrete-

reinforcement in building structures (Kokodeev,

2020).

One of the important scientific directions was the

development of new materials with predetermined

properties, as well as the study of the stress-strain

state (SSS) of structures made of them (Varakin,

2020). In the manufacture of thin-walled structures

of transport structures, the use of fiber-reinforced

concrete (fiber concrete), which has significantly

greater resistance to the appearance and growth of

cracks compared to conventional concrete, proved to

be very effective. This article considers a special

case of thin-walled structures, namely plates on an

elastic base, as a structure with a fairly significant

scope of application in transport construction. This

is a scientific problem, the solution of which has

great practical potential.

Within the framework of solving this problem,

the article presents an analysis of the state of the

issue, the construction of a model of deformation of

fiber-reinforced plates on an elastic base, and also

provides a method for calculating such structures.

The solution of the problem is reduced to the

consideration of such tasks:

1. Analysis of the mechanical properties of fiber-

reinforced concrete under various stress conditions.

2. Construction of a model of deformation of

fiber-reinforced concrete as a non-linearly

deformable material sensitive to the type of stress-

strain state.

3. Development of a method for calculating

fiber-reinforced plates on an elastic base, which

allows analyzing their stress-strain states under

different boundary conditions and loading programs.

2 MATERIALS AND METHODS

A large number of researchers have been engaged in

increasing the rigidity and crack resistance of

structures. One of the promising directions is the use

Pestryakov, A., Ovchinnikov, I. and Demidov, A.

Construction of a Model of Interaction of a Fiber-reinforced Plate with an Elastic Base.

DOI: 10.5220/0011581400003527

In Proceedings of the 1st International Scientific and Practical Conference on Transport: Logistics, Construction, Maintenance, Management (TLC2M 2022), pages 187-195

ISBN: 978-989-758-606-4

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

187

of composites (materials that are heterogeneous in

their composition). Usually, researchers consider

polystructural composites, i.e. systems composed of

many structures (Selyaev, 1993; 2. Selyaev, 1986).

The mechanical characteristics of fiber

reinforcement are usually much higher than the

mechanical characteristics (Skudra, 1975).

When creating thin-walled structures of transport

structures, composite material from a concrete

matrix and reinforcing elements should be used, as

which either fibers in the form of separate rods, or

fine-mesh grids, or sections of steel fibers are used

(Kurbatov, 1980; Kurbatov, 1980). These randomly

arranged fibers lead to a significant increase in crack

resistance, and also improve the resistance of the

composite to the action of tensile stresses. Quite a

lot of works and publications have been devoted to

the study of various issues of the behavior of fiber-

reinforced concrete, and, as follows from (Nekrasov,

1925), these issues were investigated by Professor

V.P. Nekrasov at the beginning of the XX century.

Over the past three decades, extensive studies

have been conducted on the mechanical

characteristics of concrete, dispersed reinforced with

both steel and synthetic fiber. Professor Stepanova

D.S. (Stepanova, 1975), studying fiber concrete,

determines the dispersion of the fiber filler (the

degree of crushing and dispersal of reinforcement in

the structure) through the ratio between the total

surface of the fiber reinforcement and the volume of

reinforced concrete. And in the work of Tsiskreli

G.D. (Tsiskreli, 1954), dispersion refers to the ratio

between the percentage of fiber reinforcement and

the diameter of fiber reinforcement. Moreover,

despite the differences in the terminology used, it

was concluded that with an increase in the

dispersion index, the work of fiber-reinforced

concrete under tension improves, which delays the

appearance of cracks.

It is possible to note different directions of

research on the work of fiber-reinforced structures:

− study of the adhesion of the filler to concrete

depending on its saturation with fibers, (works

by Kravinskis V.K., Vylegzhanin V.P.

(Vylegzhanin, 1982; Kravinskis, 1979));

− study of structural characteristics of steel fiber

concrete, (works of Kopatsky A.V., Lobanov

I.A. (Lobanov, 1976; Kopatsky, 1979));

− study of the dependence of the parameters of

fiber reinforcement and the properties of the

concrete matrix, as well as the selection of the

optimal composition of the steel-fiber concrete

mixture according to certain parameters

(works by Polyakova L.G., Ovchinnikov I.G.,

Rabinovich F.N. (Ovchinnikov, 1990;

Rabinovich, 1985));

− study of the location of reinforcing fibers on

the properties of fiber-reinforced concrete)

works by Browns Ya.A., Nagevich Yu.M.,

Lagutina G.E., Lavrinev P.G. (Browns, 1986;

Lavrinev, 1983; Rodov, 1980)).

Obviously, this is not a complete list of modern

research directions for such materials and structures

made of them. At the moment, it has been revealed

that the presence of fiber slows down the crack

opening process from 6 to 20 times, depending on

the reinforcement parameters, the loading level

compared to traditional reinforced concrete (with the

same percentage of reinforcement) (Grigoriev, 1983;

Kadysh, 1982; Kurbatov, 1982; Pavlov, 1976;

Varakin, 2020).

This leads to the conclusion about the

effectiveness of using a composite based on a

concrete matrix and steel fiber in the manufacture of

thin-walled structures of transport structures (it is

characteristic that with thick-walled structures, the

advantages of fiber reinforcement are leveled).

In transport construction, flexible pavement has

been widely used for quite a long time, which,

unfortunately, have a short service life in severe

operating conditions. In Russia, many regions are

characterized by a sharply continental climate. It is

characterized by the freezing of soils to a

considerable depth, the presence of permafrost

zones. In this case, rigid structures of pavement

provide long service life. Building structures in the

form of thin-walled plates have become widespread

in various industries. Walls of premises, road

pavement, airfield coverings, regulatory structures

made according to the scheme of rigid plates and

slabs are widely used in modern construction.

In transport construction, plates are used as a

coating on highways with high traffic intensity, with

embankments of poor soils, on urban roads, in areas

where heavy machinery is used, as a coating of

runways at airfields, etc. Road pavement in the form

of plates of fiber-reinforced concrete has a number

of significant advantages compared to flexible

pavement:

− changes in external temperature influences

practically do not affect the stability of

mechanical properties;

−

the use of such coatings provides a longer

service life before major repairs;

− with increasing age of fiber-reinforced

concrete, its strength increases;

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

188

− the strength and rigidity of fiber-reinforced

concrete is significantly greater than that of

asphalt concrete;

− stability and its weak dependence on the

humidity of the coefficient of adhesion of

coatings made of fiber-reinforced concrete

with a car wheel.

The above data suggest that the scheme of

operation of rigid pavement can be attributed to the

operation of plates on an elastic base.

In recent years, a composite based on steel fiber

concrete has often been used for reinforced concrete

coatings. Composite (composite material) is an

artificial material obtained by a volumetric

combination of different components performing

various functions. One component (matrix) is

responsible for plasticity and elasticity, the other

(filler) for strength and rigidity. At the same time,

the final system has a pronounced emergence (that

is, the properties of the composite differ from the

properties of the constituent components). In this

case, the composite material is continuous and the

forces transmitted to it are distributed continuously

over its volume.

When constructing a model of deformation of

fiber-reinforced plate on an elastic base, we will rely

on standard hypotheses, according to which the

layers of the plate do not press on each other and the

hypothesis of direct normals is valid.

Cut out a rectangular element from the plate a

bcd with infinitesimally small dimensions dx, dy

(Fig. 1) on which a load of intensity q normal to the

surface acts from above, and an elastic base reaction

of intensity p acts from below. On the face cd act

forces

x

Q

and S

у,

, tensile force N

x

, bending and

torques М

x

and H. In turn, on the face ab, which is

separated from c d by an infinitesimal distance dx,

the above forces and moments differ by infinitesimal

quantities

dx

x

Q

x

∂

∂

,

dx

x

S

у

∂

∂

,

dx

x

N

x

∂

∂

,

dx

x

M

x

∂

∂

,

dx

x

H

∂

∂

.

Similarly, it is possible to obtain both forces and

moments on the faces a d and bc.

The equilibrium of this infinitesimal element will

be ensured when the conditions of equilibrium of the

projections of all forces on the coordinate axis and

the equilibrium of bending and torques relative to

the axes are met.

Figure 1: Forces acting on an infinitesimal element.

The projection of all efforts on the Z axis will be

recorded (1):

0

y

x

xxy

y

Q

Q

QdxdyQdyQdydx

xy

Q dx pdxdy

∂

∂

+−++−

∂∂

+=

. (1)

Giving similar terms, we get (2):

p

y

Q

x

Q

y

x

−=

∂

∂

+

∂

∂

(2)

The condition of equilibrium of bending and

torques relative to the X axis will be written (3):

2

2

2

()

()

2

()

2

() 0

2

y

yy

x

x

x

y

y

M

MdydxMdx

y

Hdy

HdxdyHdyQ

x

Q

dy

Qdx

x

Q

dy

Q dy dxdy pdx

y

∂

+−+

∂

∂

+−+−

∂

∂

−+ −

∂

∂

+−=

∂

(3)

Giving such terms and neglecting the small-order

magnitude

0

2

→

∂

∂

dy

y

Q

y

, we write (4):

y

y

Q

x

H

y

M

=

∂

∂

+

∂

∂

(4)

The condition of equilibrium of bending and

torques relative to the Y axis will be written (5):

x

x

Q

y

H

x

M

=

∂

∂

+

∂

∂

(5)

Construction of a Model of Interaction of a Fiber-reinforced Plate with an Elastic Base

189

As a result of the transformation of the above

formulas , we obtain the following equilibrium

equation (6):

2

22

22

2

y

x

M

MH

p

xxyy

∂

∂∂

++=−

∂∂∂∂

(6)

Analysis of experimental results obtained in the

study of the mechanical properties of fiber-

reinforced concrete with sufficient justification

suggests that the behavior of fiber-reinforced

concrete can be described using a model of

orthotropic nonlinear multi-resistive material.

In the case of a flat stress state in which a plate

of fiber-reinforced concrete is located, the physical

relations for an orthotropic nonlinear resistive

material take the form (7):

j

xy

xy

xi

xi

x

yj

y

y

yj

yj

y

xi

x

x

G

e

e

e

τ

ν

ψ

σ

ψ

σ

ν

ψ

σ

ψ

σ

=

−=

−=

(7)

where

e;;

τ

σ

components of the stress

tensor and strain tensor,

ν

- Poisson's ratio, x, y –

coordinates, i and j –take into account the direction

of deformation, and (i(j)=1 -stretching, i(j)=2 -

compression), G

j

- shear modulus,

ψ

- nonlinear

functions that take into account the nonlinearity of

the deformation diagram and the resistance of fiber-

reinforced concrete (8):

u

uyj

yj

u

uxi

xi

e

e

e

e

)(

;

)(

φ

ψ

φ

ψ

=

=

(8)

here

u

e

is the intensity of deformations,

yjxi

φ

φ

;

which quite correctly describe the

deformation diagrams of fiber-reinforced concrete,

taking into account the direction and type of

deformation (9):

yjyj

xixi

m

uyj

k

uyjyj

m

uxi

k

uxixi

eBeA

eBeA

−=

−=

φ

φ

;

(9)

coefficients A

xi

, In

yj

, k

xi

, m

yj

are located in such

a way as to provide the best approximation of the

deformation diagrams of fiber-reinforced concrete.

The shift modulus G

j

- is defined through these

functions

yjxi

ψ

ψ

,

and quantities

yjxi

ν

ν

,

by the

following expression (10):

−

+

−

+

= ))(

1

1

(2

1

yx

x

yj

yj

xi

xi

j

G

σσ

σ

ψ

ν

ψ

ν

( 1 0 )

Finding from the physical relations of the

voltage, we can write (11):

xyjxy

xiy

ji

j

y

yjx

ji

i

x

eG

ee

ee

=

+

−

=

+

−

=

τ

ν

νν

ψ

σ

ν

νν

ψ

σ

)(

1

)(

1

(11)

The experimental deformation diagram of fiber-

reinforced concrete is approximated by the function

(12):

3

11

3

22

0

0

AB for

AB for

εε σ

σ

εε σ

−≥

=

−<

(12)

The coefficients of which can be easily

determined from the conditions of the minimum

functional (13)

min)(

n

1j

3

→−−=

=

экс

jjj

BAI

σεε

(13)

As a result, we get the following expressions for

finding them (14):

2

1

4

1

6

1

2

1

4

1

3

1

6

1

−

−

=

===

====

n

j

j

n

j

j

n

j

j

n

j

j

n

j

jj

n

j

j

n

j

jj

A

εεε

εεσεεσ

2

1

4

1

6

1

2

1

2

1

3

1

4

1

−

−

=

===

====

n

j

j

n

j

j

n

j

j

n

j

j

n

j

jj

n

j

j

n

j

jj

B

εεε

εεσεεσ

(14)

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

190

Indexes at coefficients A and B are omitted.

Note that the values of the coefficients A

1

, B

1

are based on experimental strain curves under

tension, and the coefficients A

2

, B

2

are based on

experimental data under compression.

If we do not take into account the nonlinearity of

deformation of fiber-reinforced concrete, but take

into account only its resistance to deformation, then

the deformation diagram can be described by the

function (15):

иiии

Eс

εεσ

=),(

(15)

where i=1 corresponds to stretching, and i=2

corresponds to compression.

To assess the suitability of the above relations for

describing the deformation of fiber concrete, we use

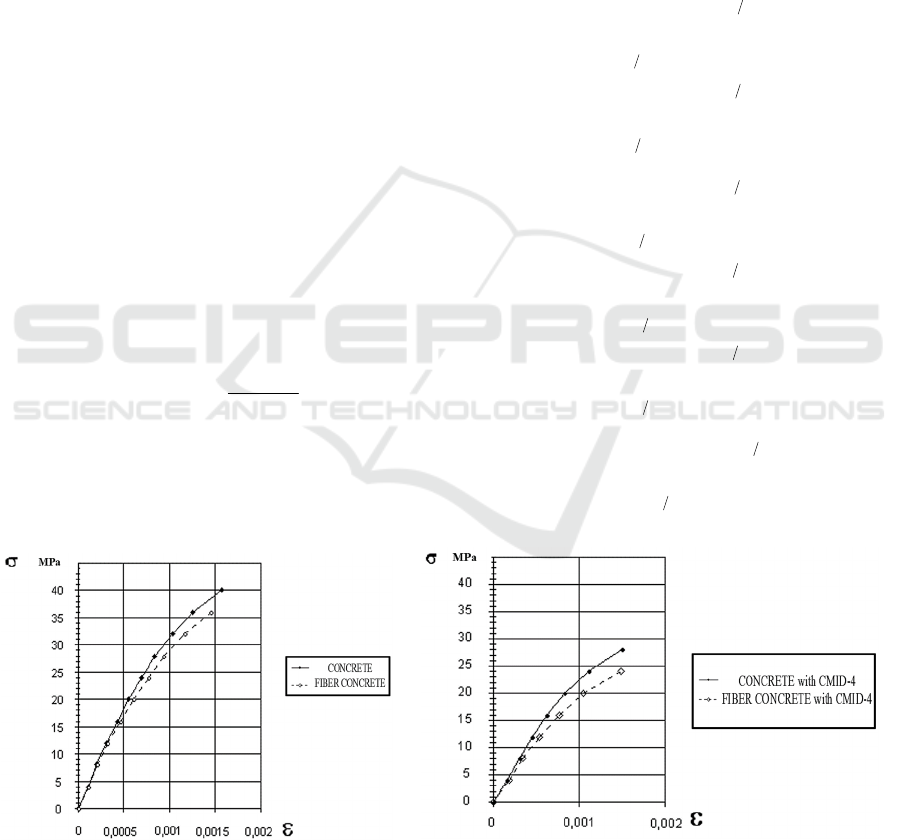

the experimental data shown in Fig. 2

In this case, to determine the elastic modulus E,

we use the minimum condition of the following

functional (16).

min)(

n

1j

2

→−=

=

i

э

i

ЕI

εσ

(16)

As a result, we get the expression (17):

1

2

1

.

n

ii

i

n

i

i

E

σε

ε

=

=

=

(17)

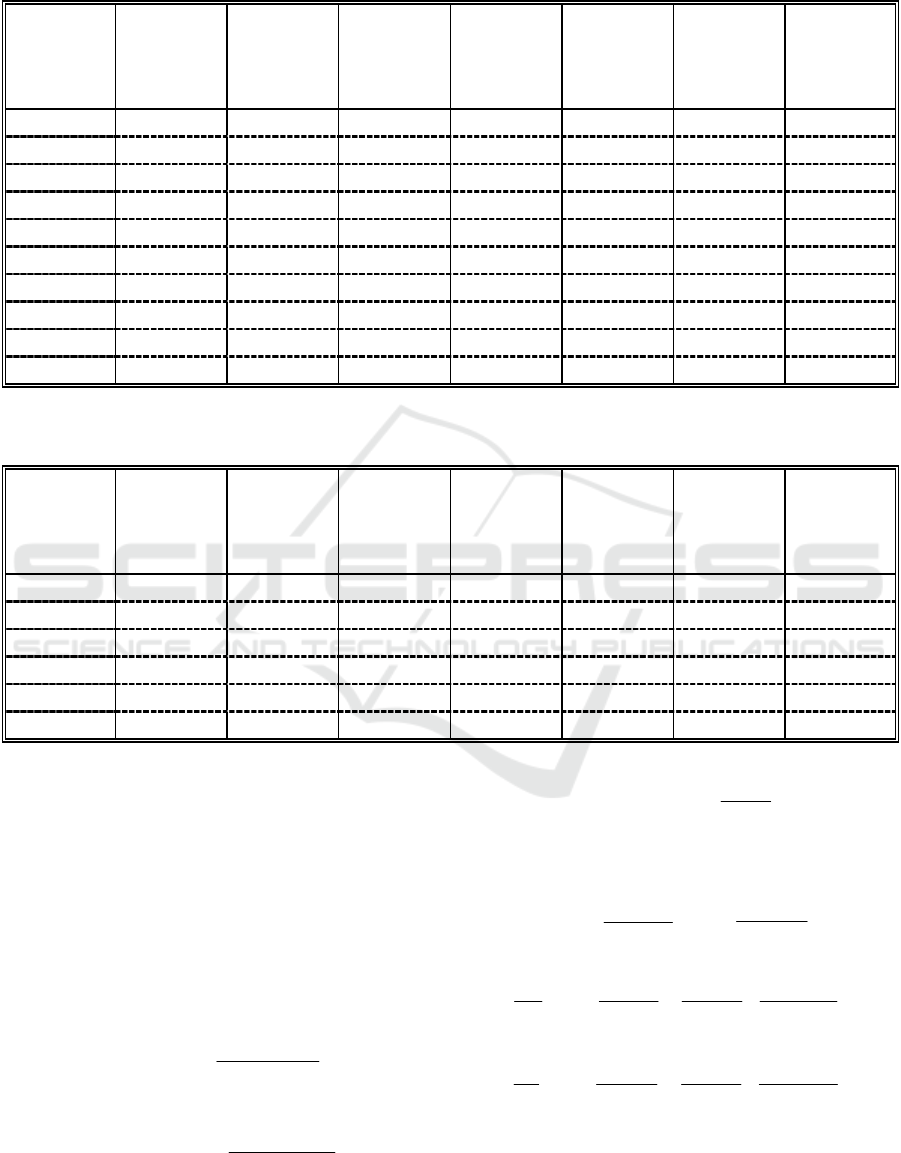

The results of the description of the deformation

curves of fiber concrete and fiber concrete with the

addition of CMID according to various models are

given in Table 1 and 2. The deviation of theoretical

data from experimental data is also shown there.

As can be seen, when using a nonlinear

deformation model to describe experimental results,

the results mostly fall into a five percent error

corridor. When using a linear model, the

approximation error reaches 15-20%.

Let's make up the resolving equation of a plate of

fiber-reinforced concrete on an elastic base.

Expressions for moments and efforts will be taken in

the following form (18):

∂+∂=

−

2

2

h

z

фб

xi

z

h

фб

xj

фб

х

x

x

zzzzМ

σσ

,

∂+∂=

−

2

2

h

z

фб

yi

z

h

фб

yj

фб

y

y

y

zzzzМ

σσ

,

∂+∂=

−

2

2

h

z

ôá

xyi

z

h

ôá

xyj

ôá

xy

xy

zzzzH

ττ

,

∂+∂=

−

2

2

h

z

фб

xi

z

h

фб

xj

фб

х

x

x

zzN

σσ

,

∂+∂=

−

2

2

h

z

фб

yi

z

h

фб

yj

фб

y

x

x

zzN

σσ

,

∂+∂=

−

2

2

h

z

фб

xyi

z

h

фб

xyj

фб

xy

xy

zzS

ττ

, (18)

Figure 2: Dependenceε from σ(under compression) for a- concrete and fiber concrete, b-for concrete and fiber concrete with

the addition of CMID-4 (Pestryakov, 2003; Polyakova, 1991).

Construction of a Model of Interaction of a Fiber-reinforced Plate with an Elastic Base

191

Table 1: The results of modeling experimental deformation curves of fiber concrete with the addition of CMID under

compression, and: A

2

=36.44* 10

3

Mpa, B

2

=46.20* 10

8

Mpa, E

2

=28.93* 10

3

Mpa.

Experimental

values of

stresses, MPa

Experimental

values of

deformations,

mm

Calculated

stresses

according to

the nonlinear

model. MPa

Calculated

stresses

according to

the linear

model. MPa

Deviations in

the nonlinear

model, MPa

Deviations in

the linear

model, MPa

Error of the

nonlinear

model %

Error of the

linear model

%

4,00 0,00011 4,16 3,30 0,16 -0,70 3,90 -17,38

8,00 0,00021 7,76 6,20 -0,24 -1,80 -3,00 -22,54

12,00 0,00032 11,55 9,30 -0,45 -2,70 -3,71 -22,54

16,00 0,00043 15,25 12,39 -0,75 -3,61 -4,70 -22,54

20,00 0,00055 19,38 16,01 -0,62 -3,99 -3,09 -19,96

24,00 0,00070 23,81 20,14 -0,19 -3,86 -0,80 -16,08

28,00 0,00085 28,03 24,48 0,03 -3,52 0,12 -12,58

32,00 0,00104 32,60 29,95 0,60 -2,05 1,87 -6,40

36,00 0,00129 37,02 37,18 1,02 1,18 2,85 3,28

40,00 0,00162 39,39 46,99 -0,61 6,99 -1,53 17,48

Table 2: The results of modeling experimental deformation curves of fiber concrete with the addition of CMID under

tension, and: A

1

=30.71* 10

3

Mpa, B

1

=11.79* 10

10

Mpa, E

1

=22.21* 10

3

Mpa.

Experimental

values of

stresses, MPa

Experimental

values of

deformations,

mm

Calculated

stresses

according to

the nonlinear

model. MPa

Calculated

stresses

according to

the linear

model. MPa

Deviations in

the nonlinear

model, MPa

Deviations in

the linear

model, MPa

Error of the

nonlinear

model %

Error of the

linear model

%

1,00 0,00003 0,98 0,71 -0,02 -0,29 -1,71 -28,65

2,00 0,00005 1,52 1,11 -0,48 -0,89 -23,99 -44,50

3,00 0,00010 3,05 2,30 0,05 -0,70 1,62 -23,36

4,00 0,00014 3,96 3,09 -0,04 -0,91 -1,06 -22,70

5,00 0,00020 5,20 4,44 0,20 -0,56 3,95 -11,21

6,00 0,00032 5,96 7,14 -0,04 1,14 -0,73 18,92

Here z

x

(x,y), z

y

(x,y), z

xy

(x,y) are functions

describing the position of neutral surfaces

determined from the conditions

σ

x

=0,

σ

y

=0,

xyj

τ

=0

and separating the stretched zones of the fiber-

reinforced plate from the compressed ones, and if

the lower zone of the bent plate is stretched, then j

=1, i=2, if the upper zone is stretched and the lower

one is compressed, then j=2, i=1. The functions z

x

(x,y), z

y

(x,y), z

xy

(x,y) are expressed in terms of

deformation parameters as follows (19):

yix

yix

x

z

χνχ

ε

ν

ε

+

+

−=y)(x,

;

xjy

xjy

y

z

χνχ

ε

ν

ε

+

+

−=y)(x,

; (19)

xy

xy

xy

z

χ

ε

2

y)(x, −=

If you use the notation (20):

ji

i

i

νν

ψ

α

−

=

1

,

ji

j

j

νν

ψ

α

−

=

1

,

−

+

−

+

= ))(

1

1

(2

1

yx

x

yj

yj

xi

xi

j

σσ

σ

ψ

ν

ψ

ν

β

−

+

−

+

= ))(

1

1

(2

1

xy

y

xi

xi

yj

yj

i

σσ

σ

ψ

ν

ψ

ν

β

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

192

∂+∂=

−

2

2

h

z

k

i

z

h

k

j

х

k

х

х

zzzzJ

αα

, for k=0,1,2

∂+∂=

−

2

2

h

z

k

i

z

h

k

j

y

k

y

y

zzzzJ

αα

, at k=0,1,2 (20)

∂+∂=

−

2

2

h

z

k

ii

z

h

k

jj

x

k

x

x

zzzzI

νανα

, at k=0,1,2

∂+∂=

−

2

2

h

z

k

ii

z

h

k

jj

y

k

y

y

zzzzI

νανα

, at k=0,1,2

∂+∂=

−

2

2

h

z

k

i

z

h

k

jk

xy

xy

zzGzzGT

, at k=0,1,2

Then the bending and torques, as well as the

forces, can be written as (21):

x

y

x

y

x

x

x

x

фб

x

IIJJM

2121

χεχε

+++=

;

y

x

y

x

y

y

y

y

фб

y

IIJJM

2121

χεχε

+++=

фб

xy

фб

xy

фб

TTH

21

2

χε

+=

;

x

y

x

y

x

x

x

x

фб

x

IIJJN

1010

χεχε

+++=

(21)

y

x

y

x

y

y

y

y

фб

y

IIJJN

1010

χεχε

+++=

;

фб

xy

фб

xy

фб

TTS

10

2

χε

+=

If there are no linear normal and horizontal shear

forces in the plate sections N

x

=0, N

y

=0, S=0, then

using additional convolution notation (22):

yxyx

xyyx

IIJJ

JJII

f

1010

1010

2

−

−

=

;

yxyx

yxyx

IIJJ

JIJI

f

1010

1010

1

−

−

=

,

yxyx

xyxy

IIJJ

JJII

f

1010

0110

4

−

−

=

yxyx

xyxy

IIJJ

JIJI

f

1010

0110

3

−

−

=

, (22)

we can find fairly simple expressions for

deformations

ε

x

,

ε

y

,

ε

xy

(23):

yxx

ff

χχε

12

+=

,

yxy

ff

χχε

43

+=

,

xyxy

T

T

χε

−=

0

1

2

(23)

Considering additional notations (24):

xxx

JIfJfD

213121

++=

;

yxx

IIfJfD

214112

++=

;

yyy

IIfJfD

212133

++=

;

yyy

JIfJfD

211144

++=

; (24)

0

2

1

25

)(

22

T

T

TD −=

,

we get (25):

yxx

DDM

χχ

21

+=

,

yxy

DDM

χχ

43

+=

,

xy

DH

χ

5

=

(25)

Using the expressions for bending and torques M

x

, M

y

, H, we transform the initial equilibrium

equation into the differential equation of bending of

a plate made of fiber-reinforced concrete interacting

with an elastic base (26):

22 2 2

12

222 2

2222

53

22

22

4

22

2

(, ) (, )

ww

DD

xxxy

ww

DD

xy xy y x

w

Dpx

y

qx

y

yy

∂∂ ∂∂

++

∂∂∂∂

∂∂∂∂

++

∂∂ ∂∂ ∂ ∂

∂∂

+=−

∂∂

(26)

3 RESULTS AND DISCUSSION

In the article, models of deformation of an

orthotropic nonlinear multi-modulus fiber-reinforced

structure under the conditions of a plane stress state

characteristic of bent plates are constructed. As a

result of the identification of models of deformation

of the material using experimental data on the

stretching and compression of fiber concrete, the

coefficients of the models were determined. Using

the proposed nonlinear orthotropic multi-resistive

model of deformation of fiber-reinforced concrete,

differential equations are obtained that are a model

of deformation of a plate of fiber-reinforced concrete

interacting with an elastic base. This model

describes the deformation of a fiber-reinforced plate

on an elastic base under various boundary conditions

on the contour. The work of the elastic base can be

taken into account according to one or another

Construction of a Model of Interaction of a Fiber-reinforced Plate with an Elastic Base

193

model by specifying an expression for the rebuff of

the elastic base p .

4 CONCLUSIONS

A fairly wide range of scientific methods were used

in the work. Experimental data were collected and

analyzed, mathematical modeling was performed,

and numerical simulation results were compared

with experimental data. It is shown that the

nonlinear multi-modulus model of fiber concrete

deformation shows a much better approximation of

experimental data than the linear, albeit multi-

modulus model. All this in general allowed us to

draw a conclusion about the reliability of the results.

The practical significance of the article consists in

constructing models of deformation of a fiber-

reinforced plate interacting with an elastic base,

taking into account the nonlinearity and diversity of

the plate material. The results of the work are used

in the educational process in the training of civil

engineers when presenting the issues of calculating

structures interacting with an elastic base, taking

into account the real conditions of the properties of

fiber-reinforced concrete from which the structures

are made. It should also be noted that the obtained

model of deformation of a fiber-reinforced concrete

plate operating on an elastic base can be effectively

used in the calculation of roadway plates on bridge

structures, in the calculation of rigid road pavement

made of fiber-reinforced concrete arranged on

highways.

REFERENCES

Selyaev, V. P., Solomatov, V. I., Erofeev, V. T., 1993.

Composite building materials of frame structure.

Saransk: Mordovian State University. p. 168.

Selyaev, V. P., Solomatov, V. I., Erofeev, V. T., 1986.

Experience in the use of composite materials in

agricultural and industrial construction.

Saransk:

Mordovian State University. p. 68.

Skudra, A. M., 1975. Structural theory of strength of

reinforced plastics under tension and compression.

Mechanics of Polymers. p. 396.

Kurbatov, L. G., 1980. To the recommendations for use in

the construction of reinforced concrete with

intermittent reinforcement.

Research of thin-walled

spatial structures and technology of their

manufacture

. LenZNIIEP. pp. 63-70.

Kurbatov, L. G., Vylegzhanin, V. P., 1974. The use of

concrete reinforced with wire segments in thin-walled

shells.

Concrete and reinforced concrete. 2. pp. 7-9.

Stepanova, D. S., 1975. Experimental study of the effect

of the thickness of the concrete coating on the crack

resistance of reinforced concrete with a high

reinforcement content. Improvement of calculation

methods and research of new types of reinforced

concrete structures

. LISI. pp. 76-81.

Tsiskreli, G. D., 1954.

Tensile resistance of non-

reinforced and reinforced concrete

. p. 149.

Nekrasov, V. P., 1925.

Method of indirect arming of

concrete

. Transport. p. 255.

Vylegzhanin, V. P., Grigoriev, V. I., 1982. The strength of

the ideformativity of fibers crossing a crack during

breakage and pulling out.

Spatial structures in civil

engineering

. LenZNIIEP. pp. 61-65.

Kravinskis, V. K., 1979. Investigation of the adhesion

strength of thin steel wire with concrete. Fiber

concrete and its application in construction

. NIIZhB.

pp. 25-27.

Lobanov, I. A., Talantova, K. V., 1976. Features of the

selection of the composition of steel fiber concrete.

Production of building materials and structures. LISI.

pp. 22-32.

Kopatsky, A. V., Gulimova, E. V., 1979. Comparative

assessment of the corrosion resistance of

reinforcement in reinforced cement and steel fiber

concrete.

Manufacture of construction products. LISI.

pp. 21-35.

Ovchinnikov, I. G., Polyakova, L. G., 1990. To the

calculation of a cylindrical shell made of composite

building material. Numerical methods for solving

problems of structural mechanics, theory of elasticity

and plasticity

. p. 169.

Rabinovich, F. N., Romanov, V. P., 1985. On the crack

resistance limit of fine-grained concrete reinforced

with steel fibers.

Mechanics of composite materials. 2.

pp. 277-283.

Browns, Ya. A., Kravinskis, V. K., Spilva, M. O., 1986.

Determination of elastic deformability characteristics

of fiber-reinforced concrete. Design and optimization

of engineering structures.

Riga Polytechnic Institute.

pp. 87-97.

Lavrinev, P. G., Rudenko, I. F., Korolev, K. M., 1983.

Roll formed steel fiber reinforced concrete.

Concrete

and reinforced concrete.

6. pp. 12-13.

Rodov, G. S., Kurbatov, L. G., Leikin, B. V., 1980. Driven

piles with the use of fiber concrete. Concrete and

reinforced concrete.

8. pp. 4-6.

Grigoriev, V. I., 1983. Dynamic strength of steel fiber

concrete under off-center loading. Improvement of

calculation methods and research of new types of

reinforced concrete structures

. LISI. p. 5-7.

Kadysh, F. S., Lagutina, G. E., 1982. On the nature of

deformations of fiber concrete during repeated

loading.

Design and optimization of engineering

structures.

Riga: Riga Polytechnic Institute. pp. 77-83.

Kurbatov, L. G., Popov, V. I., 1982. Crack resistance and

crack opening in bent steel-fiber concrete elements.

Spatial structures in civil engineering. LenZNIIEP.

pp. 33-42.

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

194

Pavlov, A. P., 1976. Development and experimental and

theoretical studies of steel fiber concrete.

Research in

the field of reinforced concrete structures.

LISI. 111.

pp. 2-7.

Pestryakov, A. N., 2003. Stress-strain state and durability

of a fiber-reinforced concrete plate on an elastic base,

taking into account the impact of an aggressive

environment.

Abstract of the dissertation of the

Candidate of Technical Sciences.

Polyakova, L. G., 1991. Stress-deformable state of a

cylindrical shell made of composite building material.

Abstract of the dissertation of the Candidate of

Technical Sciences. p. 27.

Varakin, M. Yu., Ovchinnikov, I. G., 2020. Features of the

use of modern types of concrete in transport

construction.

Transport Facilities. 2.

Kokodeev, A. V., Ovchinnikov, I. G., 2020. Improving the

methodology of resource and calendar planning – as a

way to increase the efficiency of the enterprise in the

field of transport construction. Transport Facilities. 1.

Construction of a Model of Interaction of a Fiber-reinforced Plate with an Elastic Base

195